Atomizer capable of preventing high-melting-point substances from blocking and application of atomizer

A nebulizer, high melting point technology, applied in the direction of spraying device, spraying device, etc., can solve the problems of few atomizers blocking high melting point compounds, affecting the production efficiency and product quality, and blocking the atomization process of the guide tube, etc. Achieve the effects of maintaining temperature, improving safety performance, and improving thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

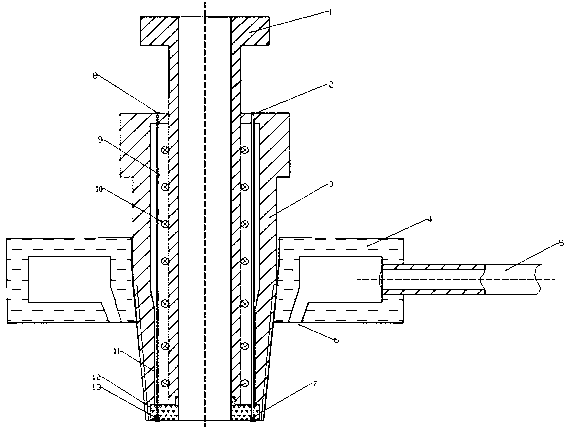

[0043] An atomizer that prevents clogging of high melting point substances, its structure schematic diagram is as follows figure 1 As shown, it includes a guide tube 1, a nozzle 4, and also includes a metal jacket 3, a gap 9 between the guide tube and the metal jacket, a heating element 10, a reflective coating 11, a ceramic ring 12 and the realization of the metal jacket upper end and the metal jacket. Metal screw rod 2, ceramic seal ring 13 that ceramic ring 12 is connected;

[0044] The nozzle 4 is provided with a nozzle inlet pipe 5 and a nozzle air outlet 6;

[0045] The metal jacket 3 is cylindrical and is made of carbon steel or stainless steel. The center part of the upper end of the metal jacket 3 has a hole suitable for the outer diameter of the draft tube 1 for installing the draft tube 1 and the metal jacket 3. The lower end of the metal jacket is open, and the metal jacket 3 is tapered from top to bottom at one end near the 1 / 3~1 / 2 of the lower end outlet to 80 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com