Preparation mold mechanism of forward curved vane of shot blasting machine and preparation method

A technology of forward curved blade and mold mechanism, which is applied in the field of preparation mold mechanism and preparation of forward curved blade of shot blasting machine, which can solve the problems of shortened service life, friction and wear, and blade prone to wear, so as to improve the preparation efficiency and eliminate air holes , Avoid the effect of melt cooling and solidification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

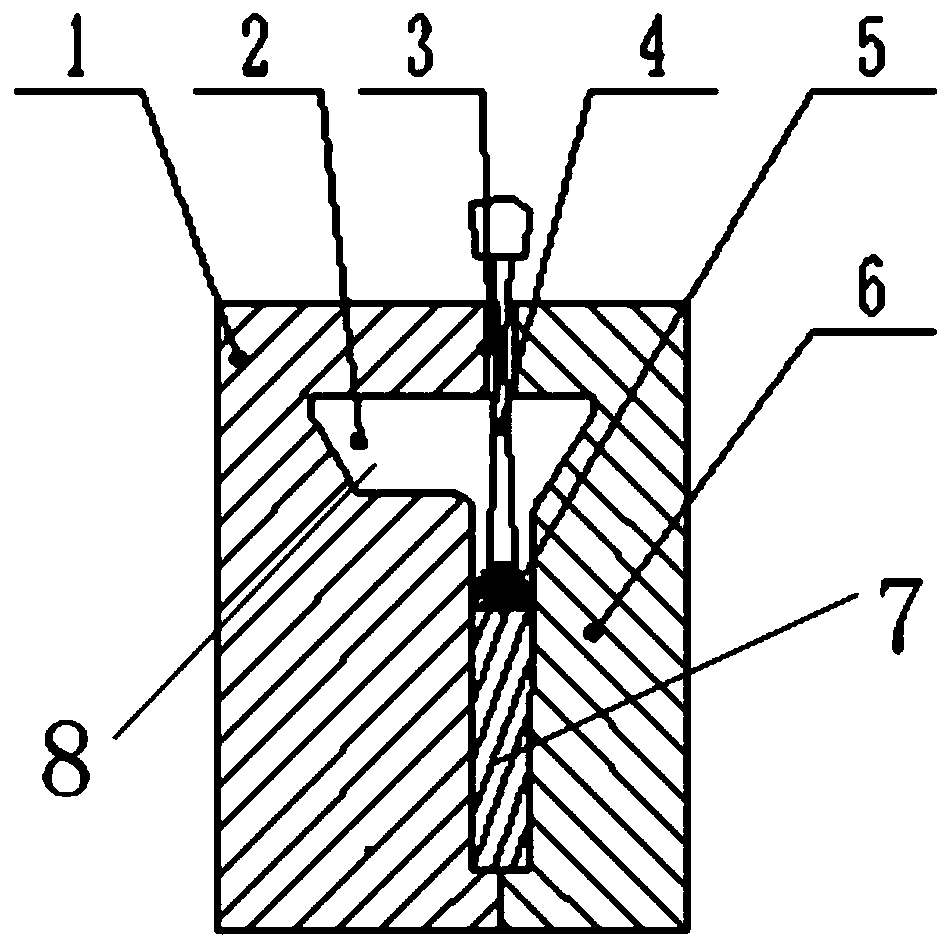

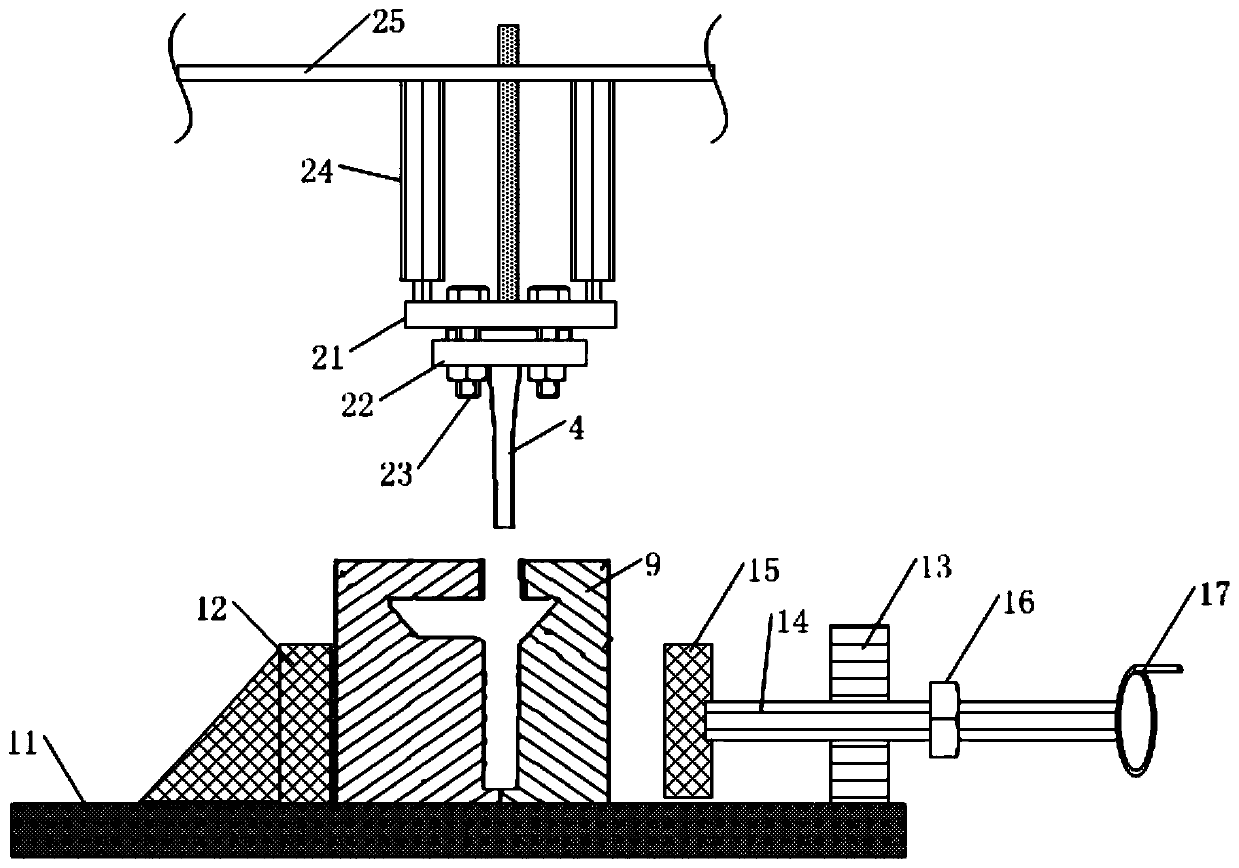

[0033] The invention provides a mold mechanism for preparing a front curved blade of a shot blasting machine, such as figure 1 As shown, it includes: mold body 9; mold body 9 includes: left mold 1, Laval nozzle 4 and right mold 6;

[0034] The left mold 1 is attached to the right mold 6;

[0035] A cavity 2 is provided at the bonding connection between the left mold 1 and the right mold 6, and the cavity wall of the cavity 2 is provided with an injection hole 3 communicating with the outside of the cavity; the Laval nozzle 4 is inserted from the injection hole 3 into the cavity The interior of the body 2; the material particles 5 are injected into the interior of the cavity 2 through the Laval nozzle 4 and the injection hole 3.

[0036] Spatially relative terms for convenience of description, such as "under", "under", "lower", "above", "above", etc. may be used herein to describe the relationship between one element or feature and another as shown in the figures. A relations...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com