Drying device for U-shaped quartz tubes

A drying device and quartz tube technology, applied in drying, dryer, drying gas arrangement, etc., can solve the problem of insufficient drying of quartz tubes, and achieve guaranteed drying time, strong pertinence, and efficient drying process. Efficient and full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

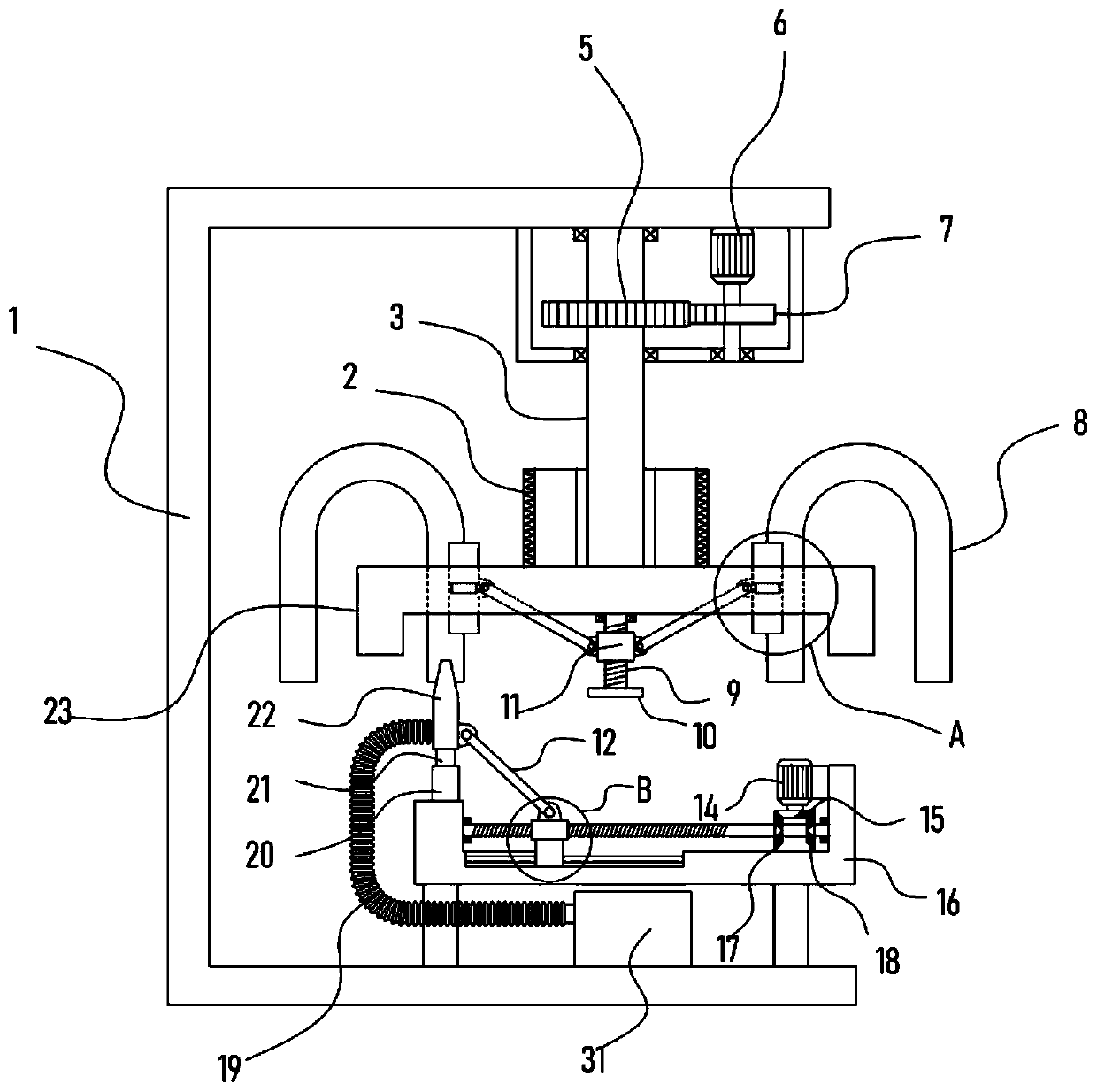

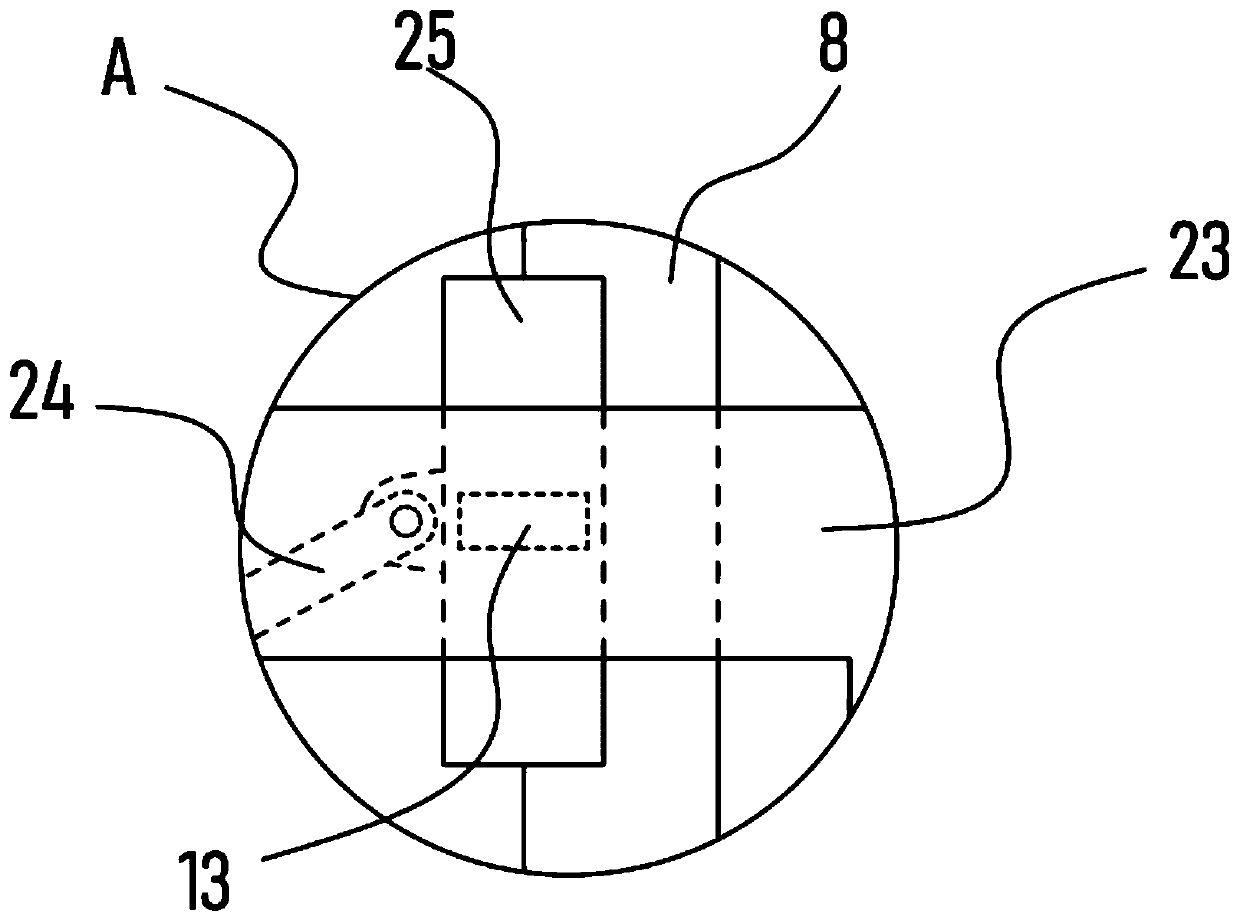

[0022] see Figure 1-4 , a U-shaped quartz tube drying device, comprising a fixed frame 1, a bracket 16 is fixed on the fixed frame 1, a turntable 23 is mounted on the fixed frame 1, and a rotating disk 23 is vertically fixed and pivotally connected to the fixed frame. The rotating shaft 3 on the frame 1, the fixed frame 1 is provided with a driving mechanism for driving the rotating shaft 3 step-by-step rotation, and the rotating disk 23 is provided with a locking mechanism for fixing the U-shaped quartz tube 8, so An annular heater 2 is sleeved on the rotating shaft 3, a blower 31 is fixed on the fixed frame 1, and the outlet end of the blower 31 is connected with a nozzle 22 vertically corresponding to the mouth of the U-shaped quartz tube 8 through a bellows 19. , the bracket 16 is fixed with a servo motor II14, and the servo motor II14 is drivingly connected with a lifting mechanism for driving the lifting mechanism of the spray head 22.

[0023] The turntable 23 provide...

Embodiment 2

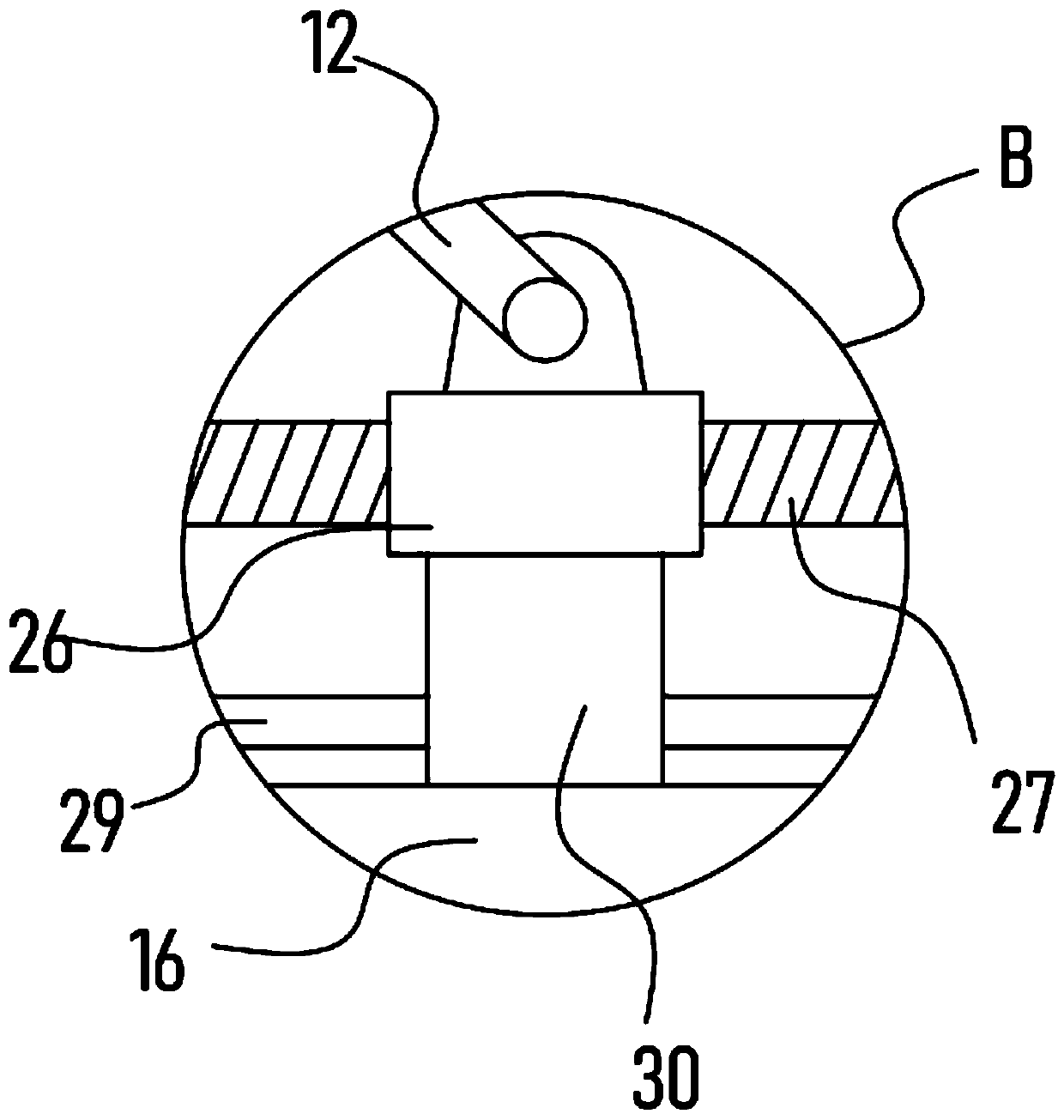

[0029] On the basis of Embodiment 1, in addition, this device is also provided with a lifting mechanism including a screw rod 27 that is rotatably installed on the bracket 16. The screw rod 27 is threaded with a screw rod sleeve block 26, and the bottom of the nozzle 22 is vertical. A guide rod 21 is directly fixed, and the sliding sleeve on the guide rod 21 is provided with a guide sleeve 20 fixed on the bracket 16. A pull rod 12 is hinged between the guide sleeve 20 and the screw cover block 26. The lifting mechanism also includes a servo motor II14 The incomplete bevel gear 15 is driven to rotate, and the incomplete bevel gear 15 is alternately meshed with a bevel gear I17 and a bevel gear II18 sleeved and fixed on the screw rod 27 .

[0030] Through the above settings, the servo motor II14 drives the incomplete bevel gear 15 to rotate, and the incomplete bevel gear 15 is alternately meshed with the bevel gear I17 and the bevel gear II18. At this time, the screw 27 rotates a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com