Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55results about How to "Good chip breaking effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

CrNiMo series easily cut pinion steel and manufacturing method thereof

The invention relates to a CrNiMo series easily cut pinion steel and a manufacturing method thereof. The steel comprises the following chemical compositions by weight percent: 0.17-0.23% of C, 0.15-0.37% of Si, 0.60-0.95% of Mn, 0.35-0.65% of Cr, 0.35-0.75% of Ni, 0.15-0.25% of Mo, less than or equal to 0.030% of P, 0.010-0.040% of S, 0.005-0.050% of Al, 0.3-0.6% of Ca / S, and the balance of Fe and micro-impurities. The manufacturing method comprises the following steps: smelting in a primary refining furnace (electric furnace or converter); and carrying out LF+VD (ladle refining + vacuum degassing) or RH external refining, continuous casting and rolling, wherein through the external refining and vacuum degassing treatment, the content of the oxygen in the steel is not more than 15*16<-6>,the content of microelement S is controlled, the cutting property of the CrNiMo series pinion steel is improved, and the steel is suitable for speedily cutting and processing important precision parts.

Owner:SHANDONG IRON & STEEL CO LTD

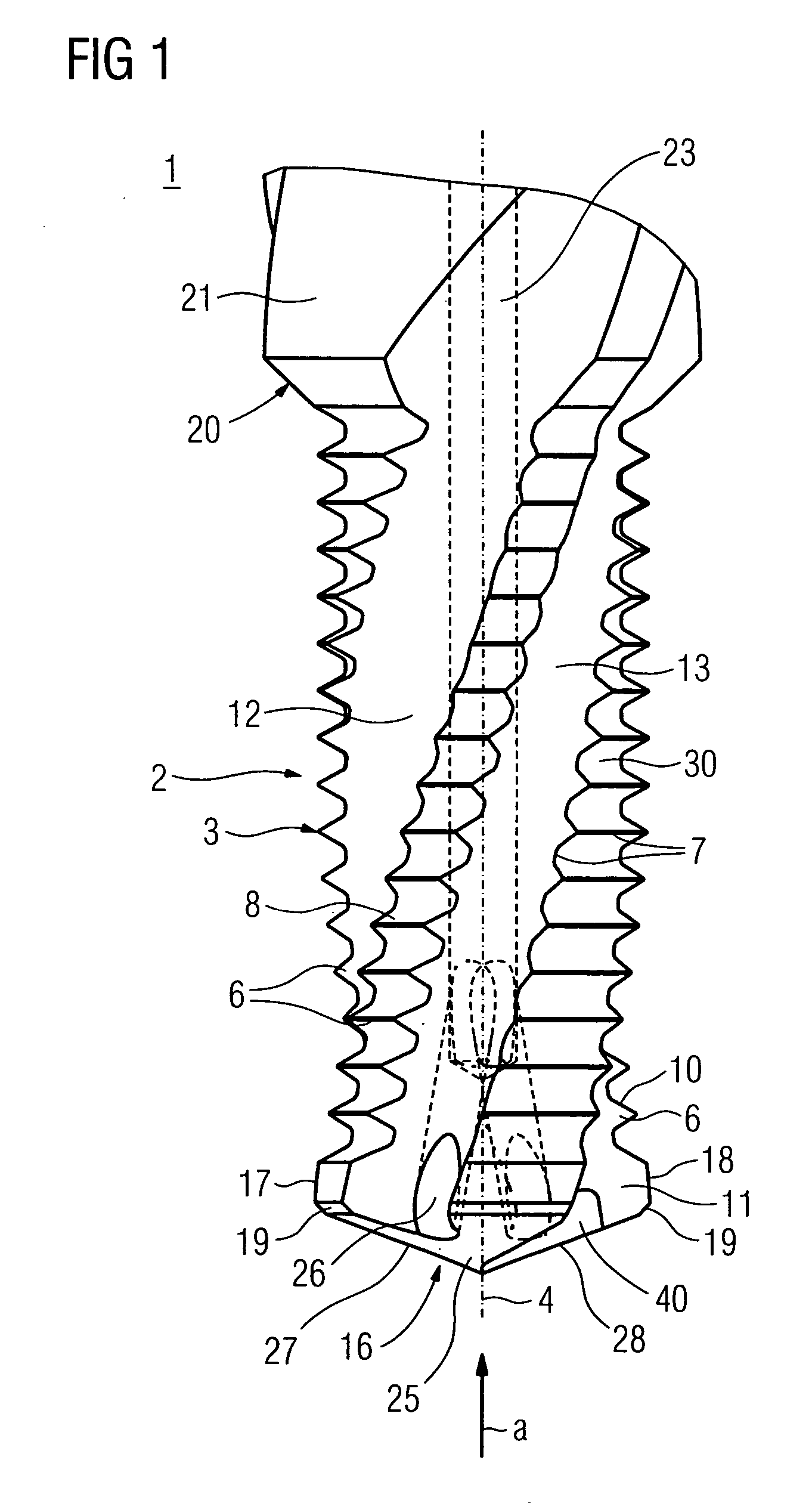

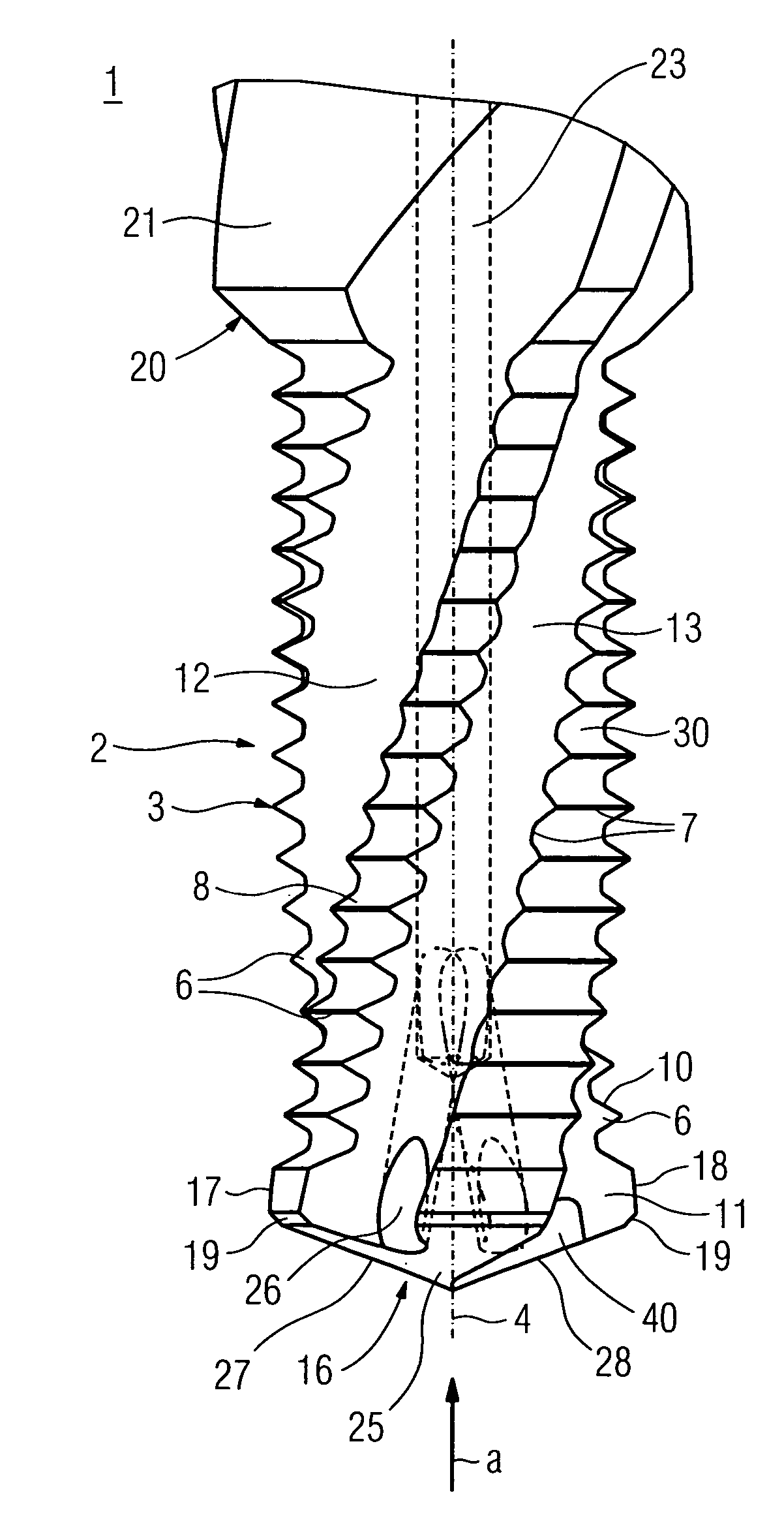

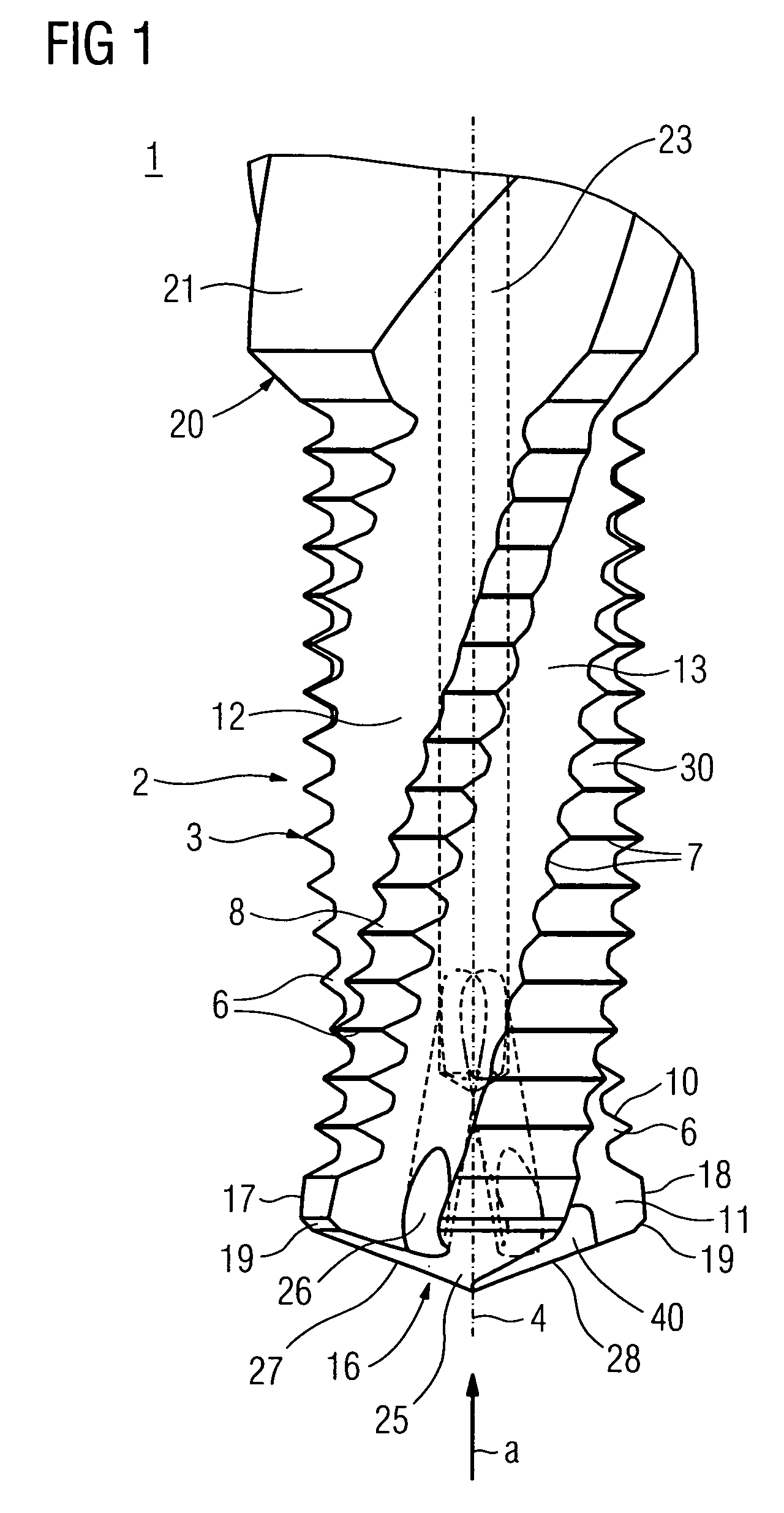

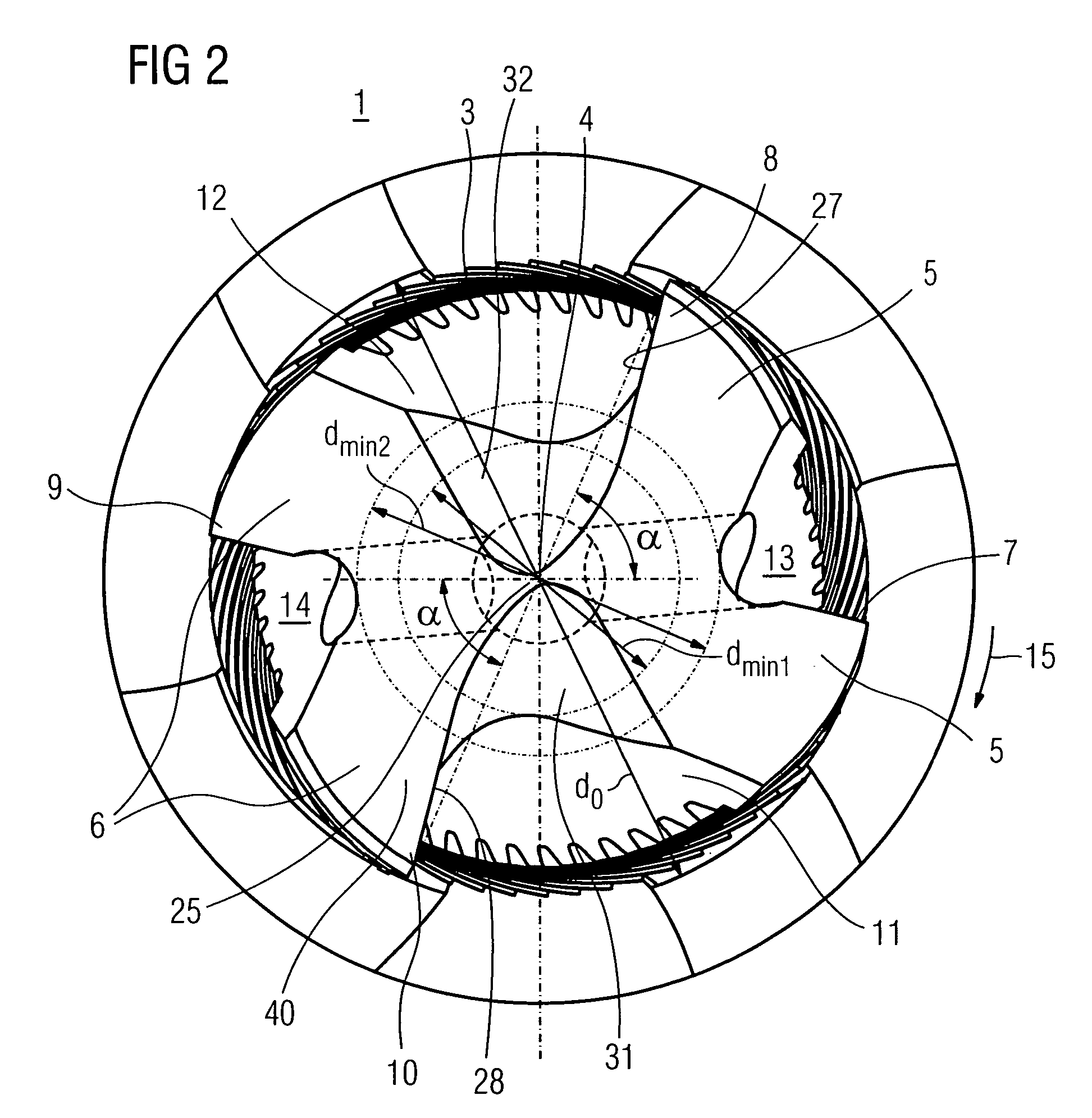

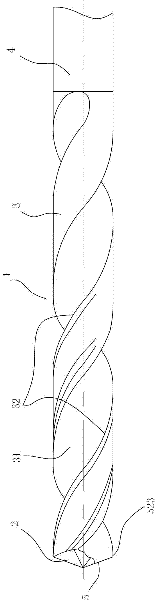

Drill thread milling cutter

InactiveUS20060216125A1Improve cutting effectGood chip breaking effectThread cutting toolsWood turning toolsMilling cutterEngineering

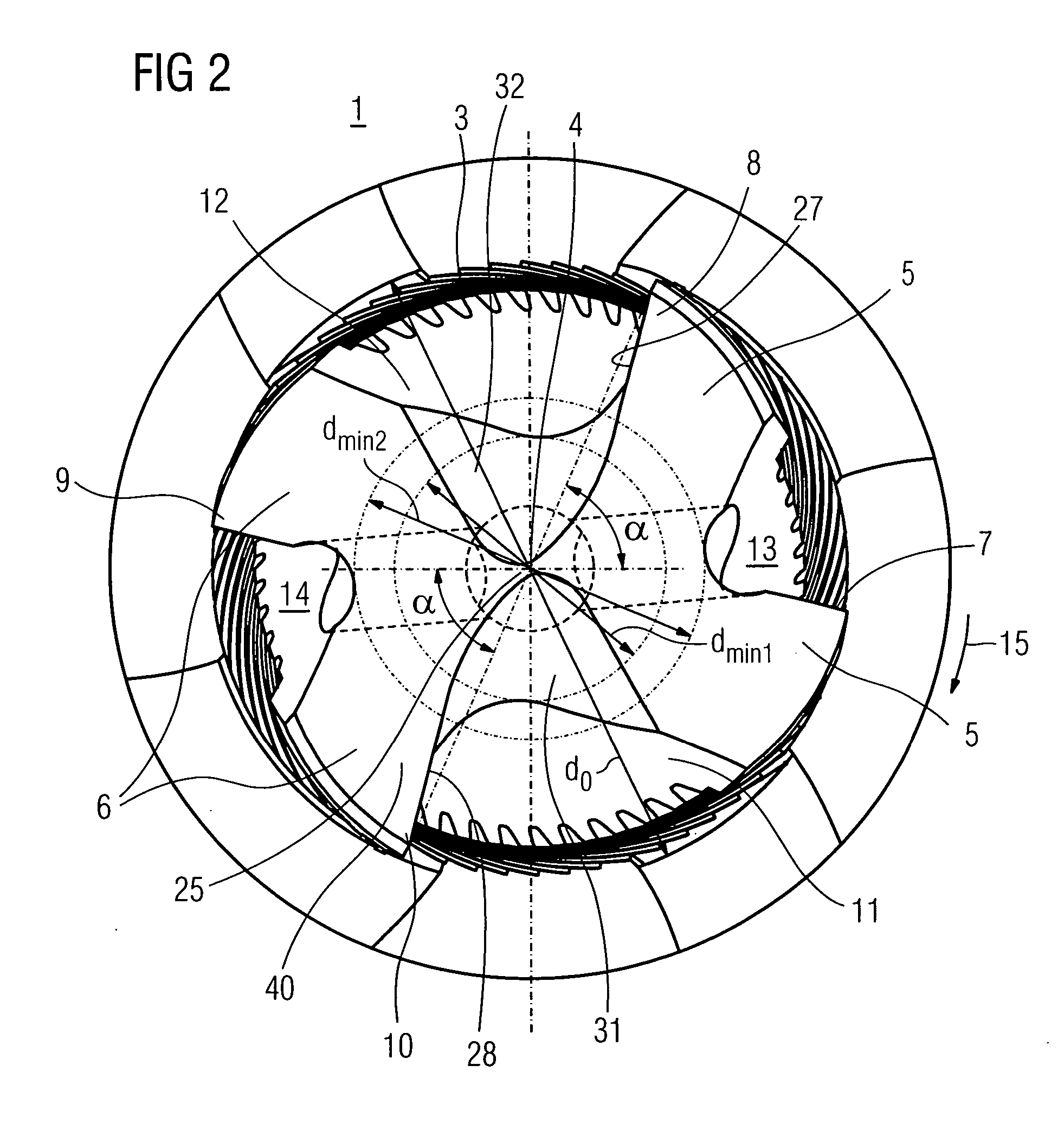

The invention relates to a drill thread milling cutter (1) for producing a bore and for the subsequent milling of a thread in the bore, said drill thread milling cutter (1) having a working region (2), on the circumference (3) of which a number of drilling and milling cutting edges are arranged. A number of milling cutting edges (7, 8, 9, 10) greater than the number of drilling cutting edges (17) by a factor greater than 2 are arranged or are effective in the direction of rotation.

Owner:EMUGE WERK RICHARD GLIMPEL & FAB FUR PRAZISIONSWERKZEUGE

Totally-synthesized water-based stainless steel cutting liquid, and preparation method and using method thereof

ActiveCN103865622AGood instant solubilityEasy to cleanLubricant compositionWater basedPolyethylene glycol

The invention discloses a totally-synthesized water-based stainless steel cutting liquid. The cutting liquid contains the following components: a stainless steel water-based extreme-pressure agent, caprylic-capric acid, boric acid triethanolamine ester, polyethylene glycol, a cation quaternary ammonium salt metal filings settling agent, a dicarboxylic compound antirusting agent, a monobutyl ether coupling agent, a hard-water-resisting agent, a defoamer and distilled water. By virtue of an environmental-friendly total-synthesis formula, the cleaning and settling properties of the cutting liquid are enhanced; an environmental-friendly special water-based extreme-pressure lubricant is used to substitute for the traditional synthetic ester, thereby ensuring the long-time stability of the cleaning and settling properties of the cutting liquid. The cutting liquid plays a very good role in protecting non-ferrous metal and ferrous metal; by virtue of the cation quaternary ammonium salt settling agent, the problem of iron filings settling during the processing of stainless steel is eliminated, and the transparency and stability of the cutting liquid in long-time use are guaranteed.

Owner:苏州安美润滑科技有限公司

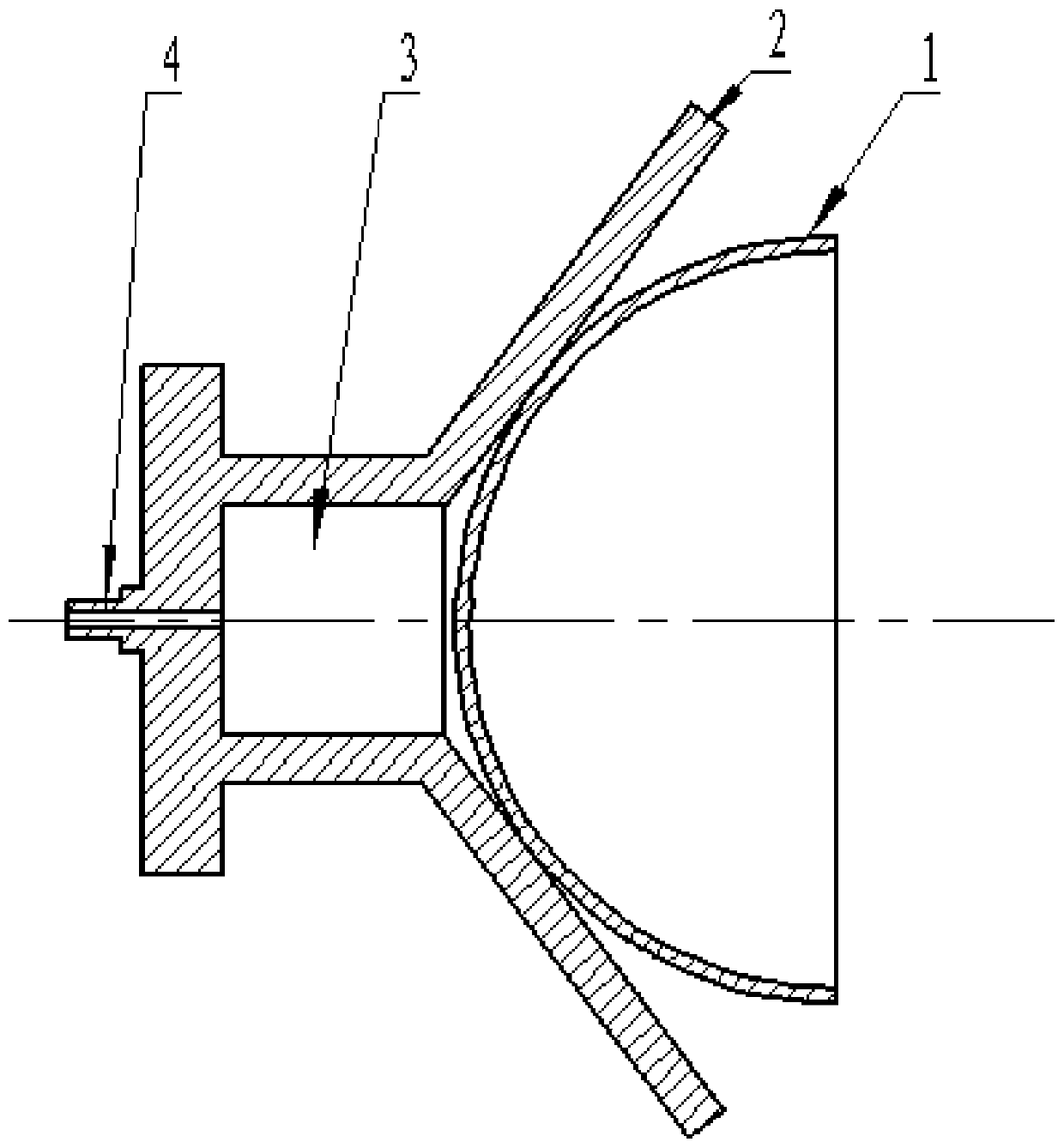

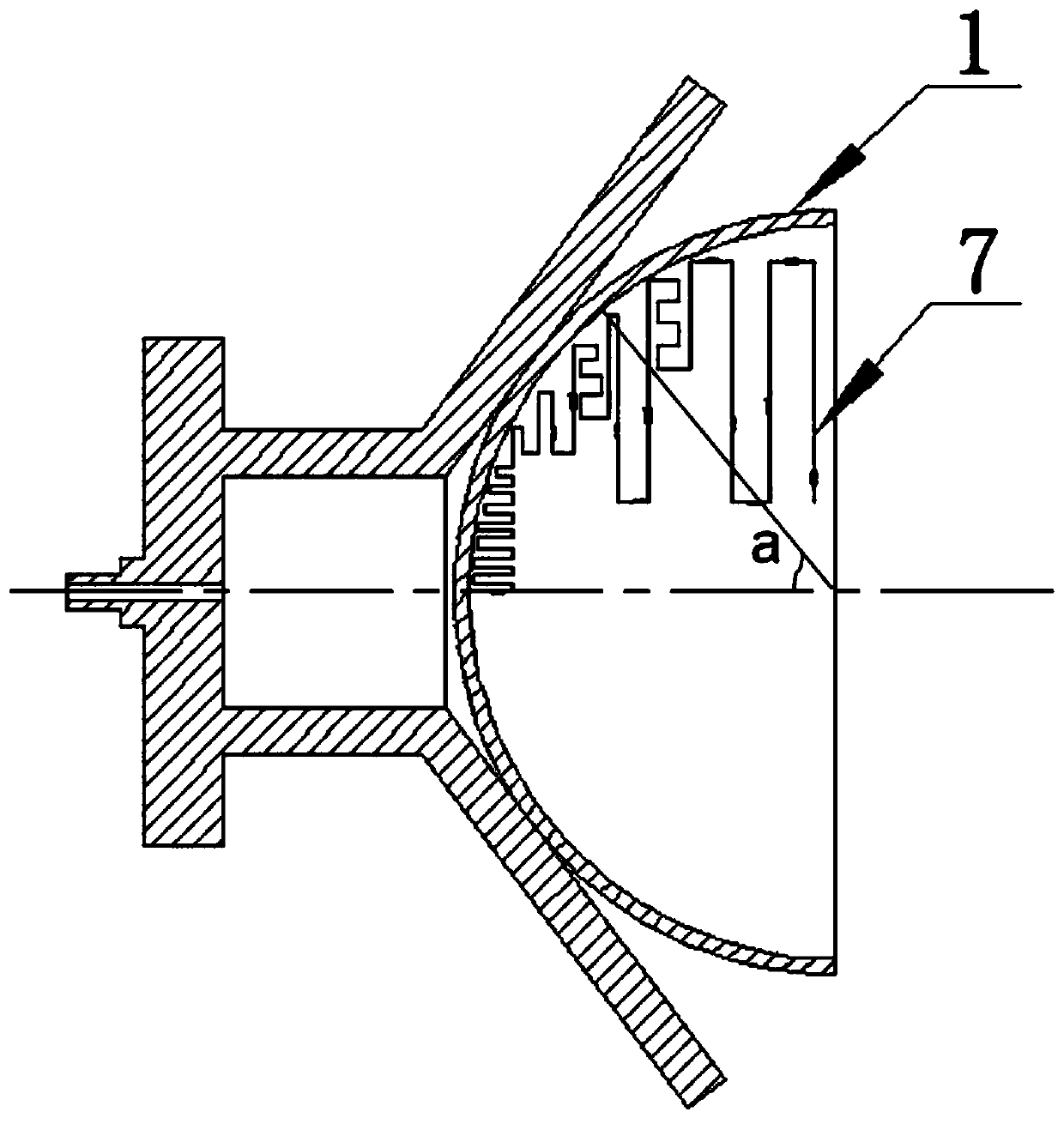

Automatic machining method of thin-wall hemispherical shell

ActiveCN110293233AGood chip breaking effectChip breaking stabilityWork clamping meansPositioning apparatusProduction lineVacuum extractor

The invention discloses an automatic machining method of a thin-wall hemispherical shell, and belongs to the technical field of automatic mechanical machining. The method specially comprises the stepsthat (1) a vacuum suction tool is taken and is assembled and connected to a vacuum air pump, and a vacuum cavity of the vacuum suction tool is made to form negative pressure; (2) a workpiece to be machined is adsorbed on the vacuum suction tool; (3) radial feed and axial feed is intermittently carried out on the workpiece to be machined in the machining process; and (4) machining of the workpieceto be machined is completed. By ingeniously designing the feed mode, the chip breaking problem in the plastic material machining process is effectively improved, the chip winding condition of a cutter is improved, manual intervention during machining is avoided, effective guarantee is provided for automatic machining, the method is reasonable in design and easy to implement, machining precision and quality of the thin-wall hemispherical shell can be greatly improved by using the method, and the method is suitable for an automatic production line.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Drill thread milling cutter

InactiveUS7419339B2Improve cutting effectGood chip breaking effectThread cutting toolsWood turning toolsMilling cutterDrill bit

The invention relates to a drill thread milling cutter (1) for producing a bore and for the subsequent milling of a thread in the bore, said drill thread milling cutter (1) having a working region (2), on the circumference (3) of which a number of drilling and milling cutting edges are arranged. A number of milling cutting edges (7, 8, 9, 10) greater than the number of drilling cutting edges (17) by a factor greater than 2 are arranged or are effective in the direction of rotation.

Owner:EMUGE WERK RICHARD GLIMPEL & FAB FUR PRAZISIONSWERKZEUGE

Precise composite reamer

InactiveCN102672277AEffective protectionImprove roundnessReaming toolsPolycrystalline diamondEngineering

The invention discloses a precise composite reamer. The precise composite reamer comprises a reamer handle, a reamer head and two blades, wherein the reamer handle is welded with the tail part of the reamer head; the reamer head comprises a cylindrical section and a working section; the working section of the reamer head is provided with two diagonal V-shaped chip discharging grooves; the two blades are respectively arranged at the front ends of the two V-shaped chip discharging grooves and are composite blades made of polycrystalline diamond (PCD); the reamer head is made of YG8; the reamer handle is made of GCr15; the reamer handle and the tail part of the reamer head are in V-shaped welding, and the direction of V-shaped welding and the diagonal direction of the two V-shaped chip discharging grooves are vertical. The part of the reamer head participating in cutting is made of YG8, so that (1) the rigidity of the reamer is increased; and (2) the part of the reamer participates in machining of chamfering and arc transition and also participates in cutting similarly to the PCD blades, so that the process requirements are met, and the cost is saved. The handle part is made of GCr15, so that the production cost of the reamer is reduced, simultaneously the machining difficulty of a thread hole in the tail part of the reamer handle is reduced, the production efficiency is increased and the production cost of the reamer is reduced.

Owner:ZHENGZHOU DIAMOND PRECISION MFG

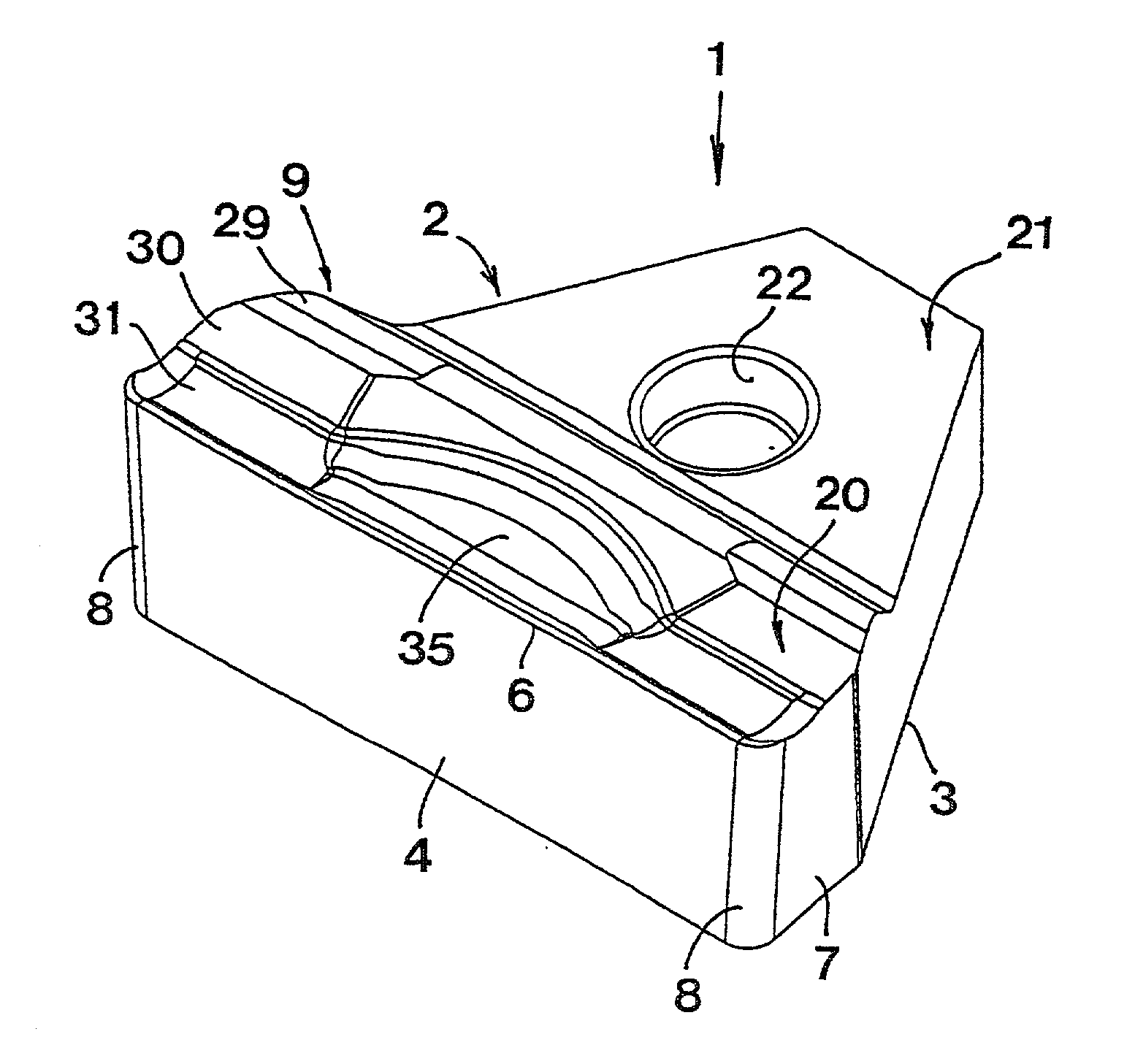

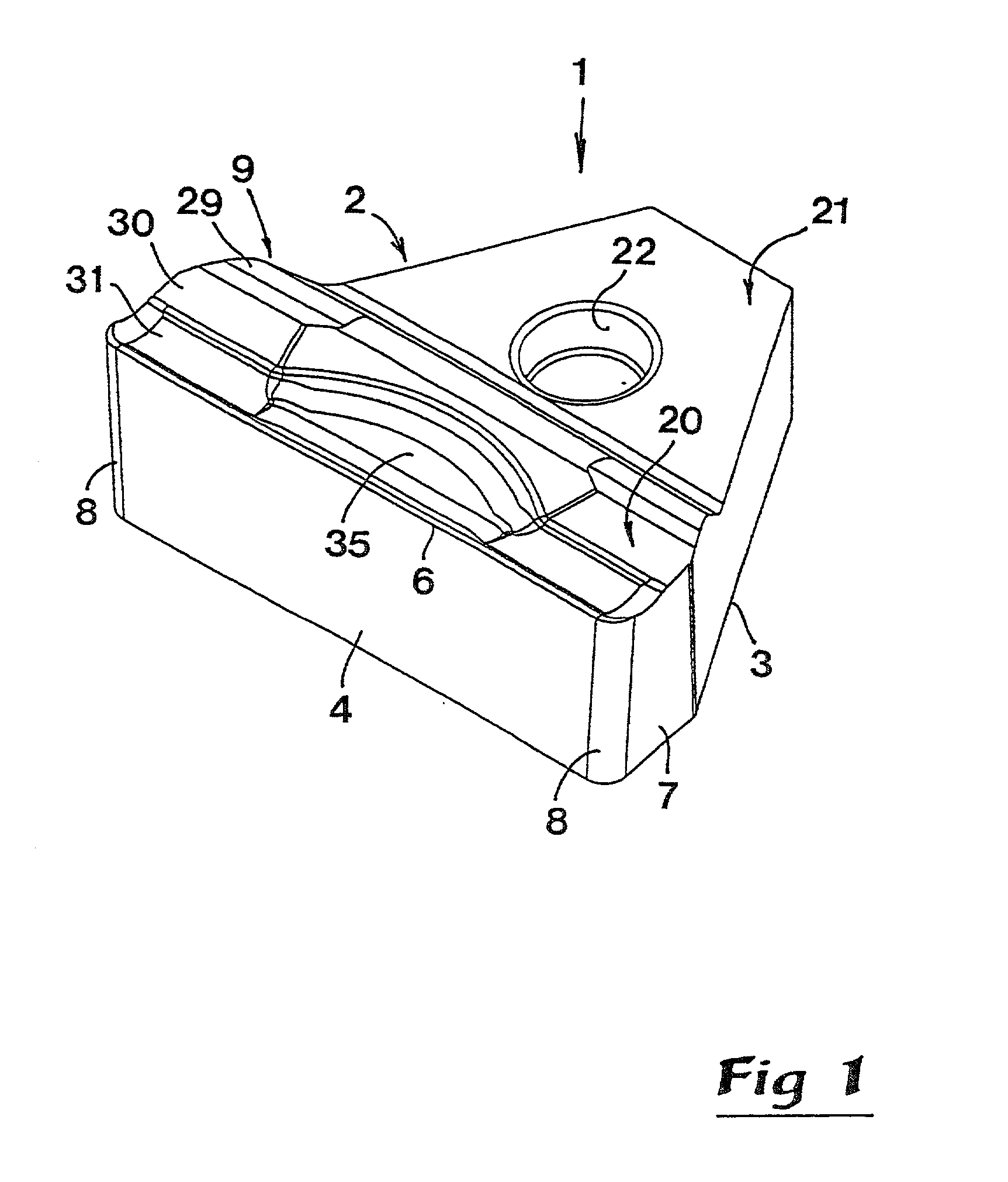

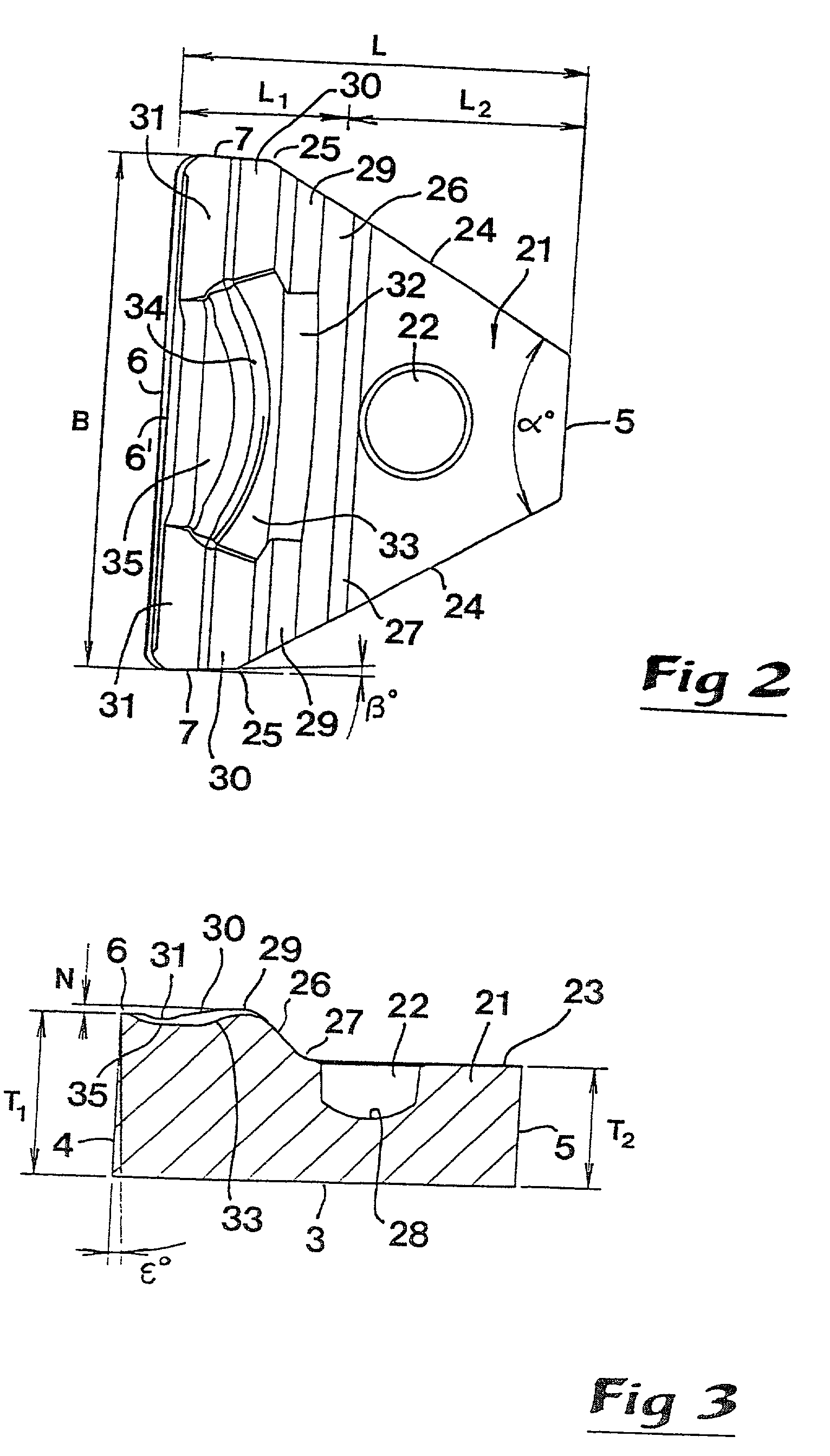

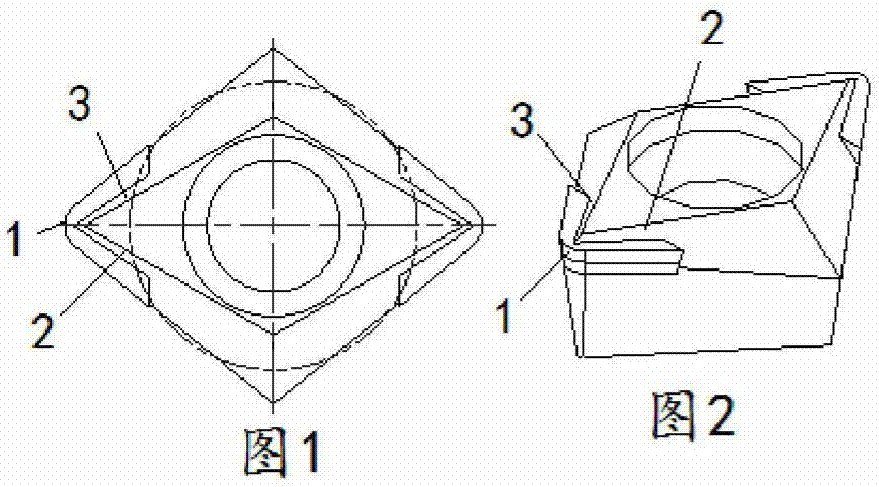

Cutting insert for heavy turning operations

InactiveUS20020031410A1Minimize the numberGood chip breaking effectCutting insertsTurning toolsEngineeringMechanical engineering

A cutting insert intended for heavy turning operations has a top side, a bottom side, a front surface disposed between the top and bottom sides, and a cutting edge disposed in the area between the top side and the front surface. The cutting insert includes a comparatively thick front part having a chip breaker positioned behind the edge and a rear part, which is thinner than the front part and tapers rearwardly therefrom. Disposed in the top side of the rear part is a recess for receiving a clamping unit to fix the cutting insert in a co-operating sear of a holder.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

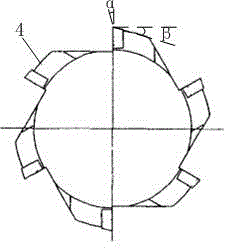

Stainless steel flange turning blade

PendingCN109332736AGuaranteed StrengthTake into account the sharpnessCutting insertsTurning toolsEngineeringUltimate tensile strength

The invention relates to the technical field of metal cutting machining, in particular to a stainless steel flange turning blade. The stainless steel flange turning blade comprises a blade body with apolygon body. The blade body is provided with a plurality of first protruding parts along the periphery of a positioning center hole, and second protruding parts are located on the outer sides of every two adjacent first protruding parts. Cutting units are arranged on the vertex corners of the blade body. Each cutting unit comprises a main cutting edge, an arc cutting edge and a scrap breaking unit. Each scrap breaking unit is composed of a first scrap breaking table, a first front blade face, a second front blade face, a scrap breaking groove bottom plane, a scrap containing groove and a half-moon-shaped protruding part. The edge width at the position of each arc cutting edge and the angle of a first front corner at the position of each arc cutting edge are larger than the edge width atthe position of the corresponding main cutting edge and the angle of a first front corner at the position of the corresponding main cutting edge. According to the turning blade, the strength of the cutting edges is combined while the sharpness of the cutting edges is guaranteed. Through the design of the double scrap cutting tables and the design of the half-moon-shaped protruding parts, the cutting blade has a good scrap breaking effect during stainless steel flange rough machining and finish machining.

Owner:OKE PRECISION CUTTING TOOLS CO LTD

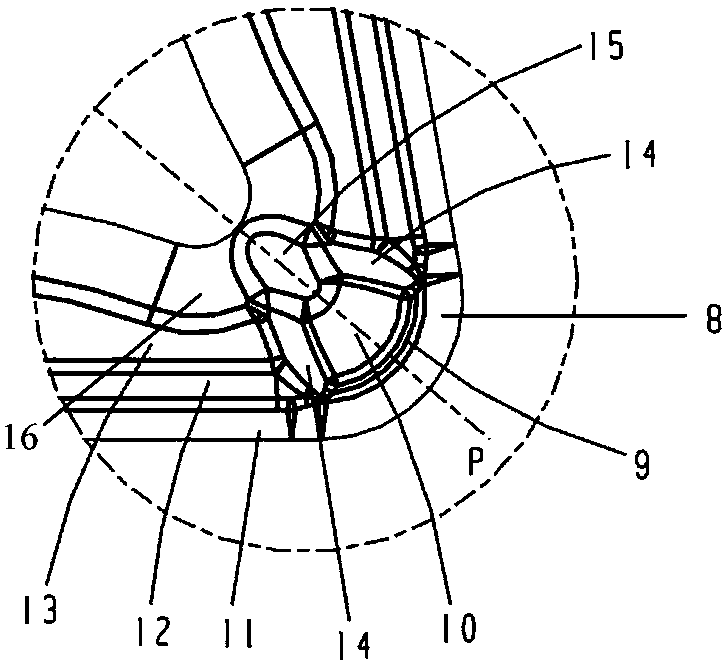

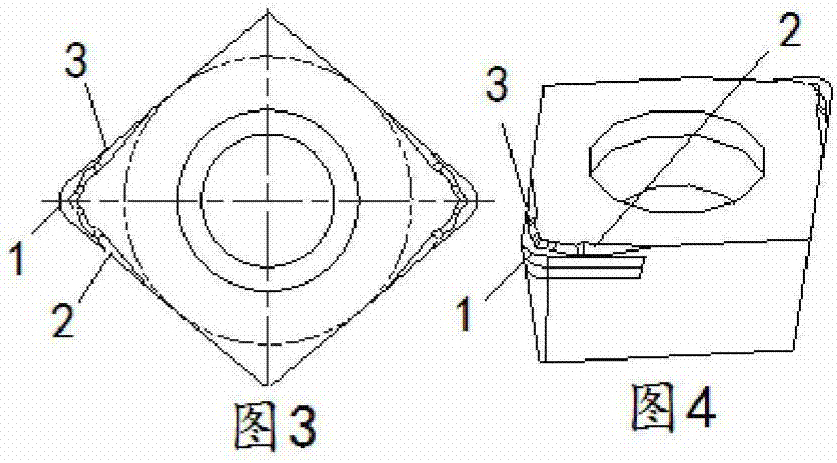

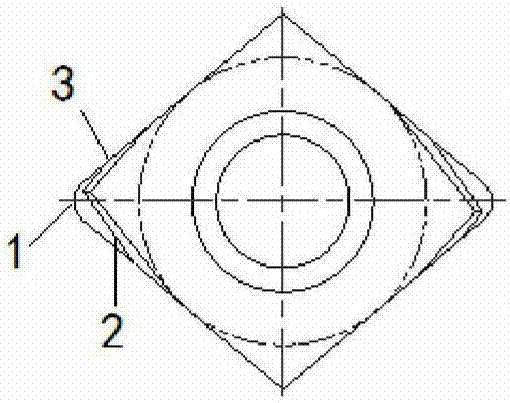

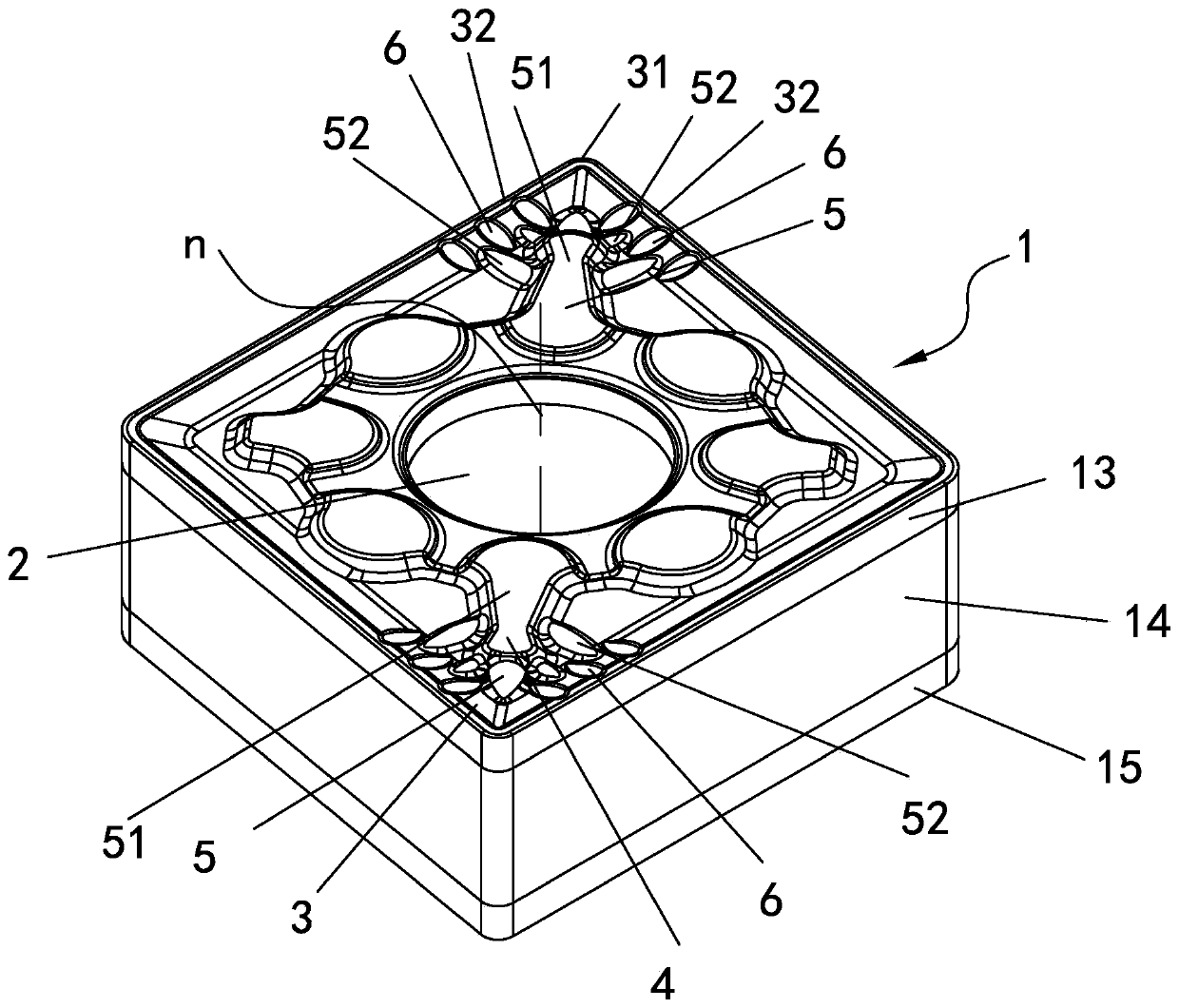

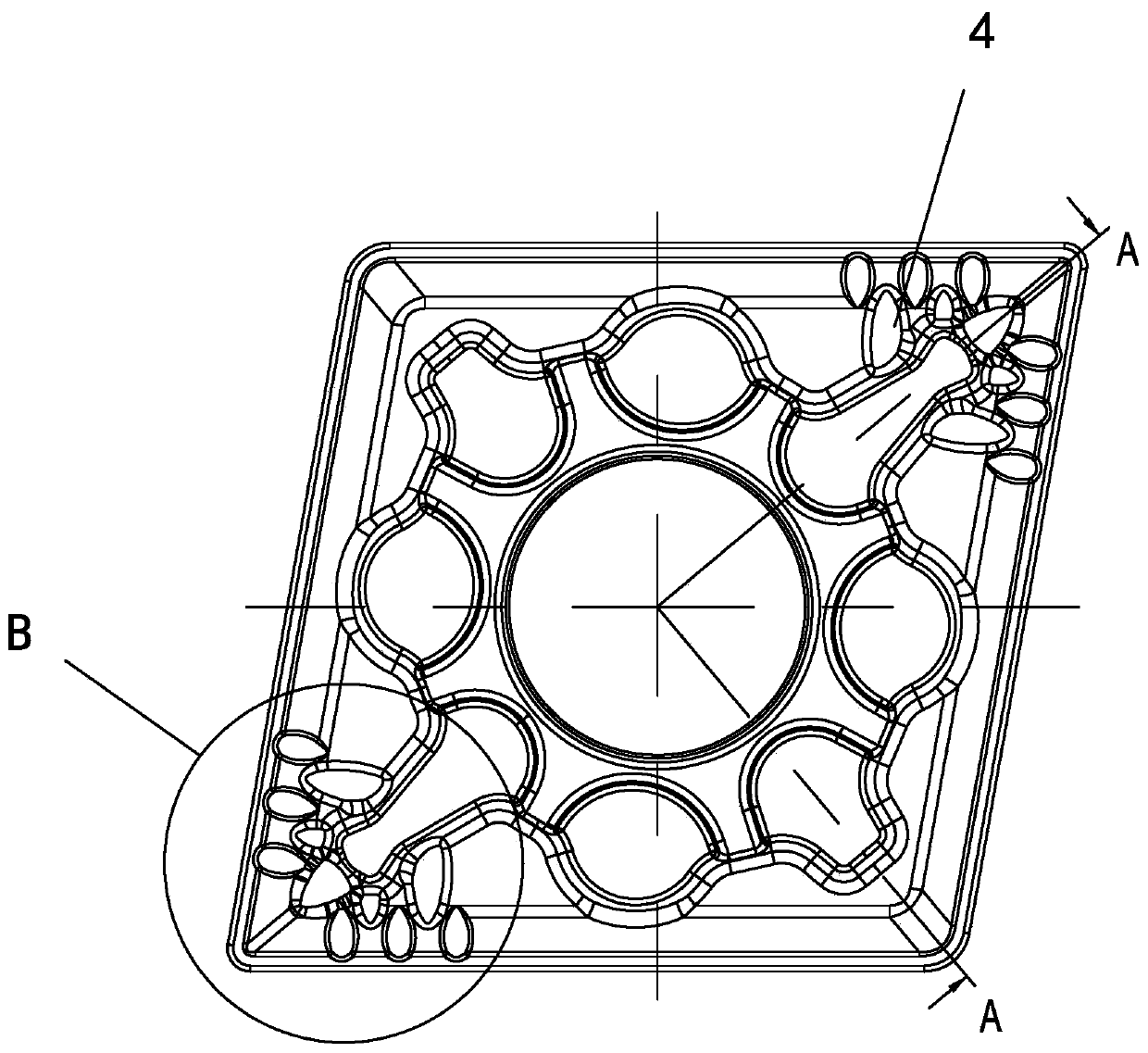

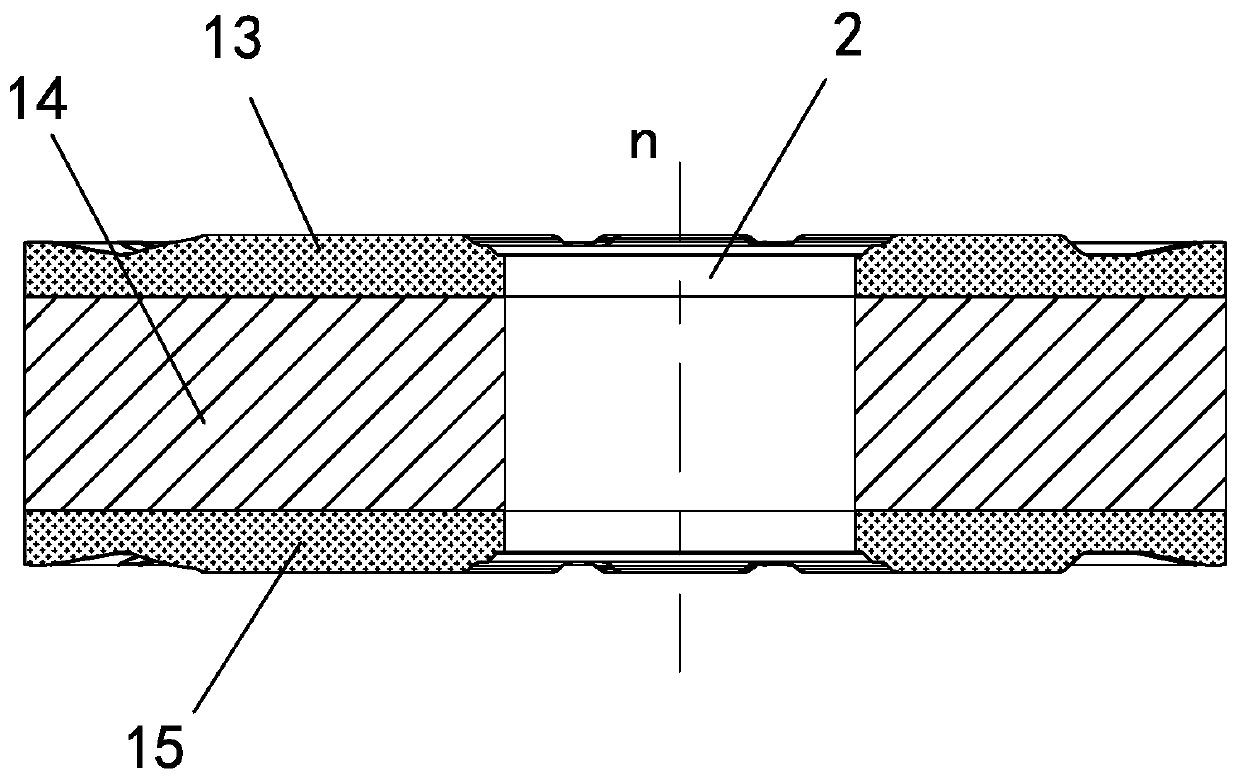

Disc-shaped cutting tool

InactiveCN101890528AGood chip breaking effectImprove product qualityMilling cuttersCircular surfaceBiomedical engineering

The invention provides a disc-shaped cutting tool, which solves the problem of poor chip breaking performance of conventional cutting tools. A chip breaker groove consists of a front tool face, a circular surface and a reverse chip surface, wherein the front tool face and the reverse chip surface are coaxial conical surfaces and are in tangential connection with the circular surface; an included angle gamma0 between the front tool face and a front end face is 15 to 17 DEG; an included angle theta between the reverse chip surface and the rear end face is 15 to 17 DEG; a rear end face is 0.1 to 0.2mm higher than the front end face, namely the height h of a cutting edge is 0.1 to 0.2mm; a plurality of bosses (1) are uniformly distributed on the coaxial periphery of the reverse chip surface; and bumps (2) are arranged between every two adjacent bosses.

Owner:CHENGDU TOOL RES INST

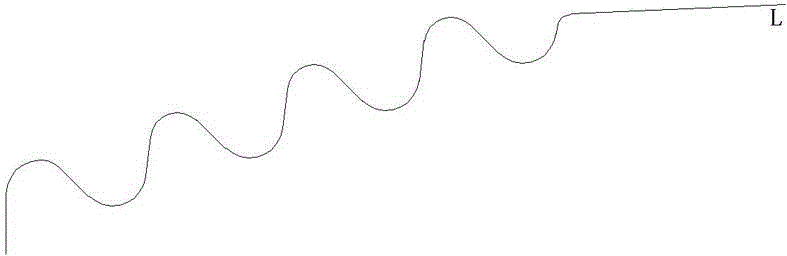

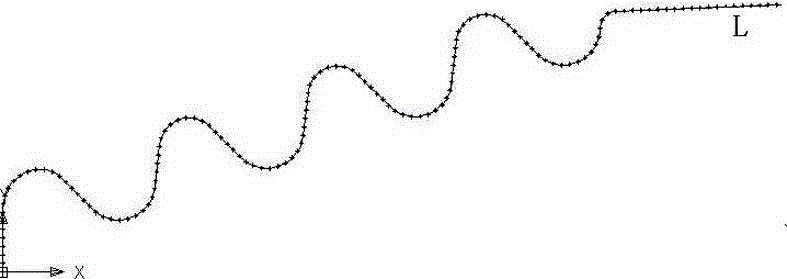

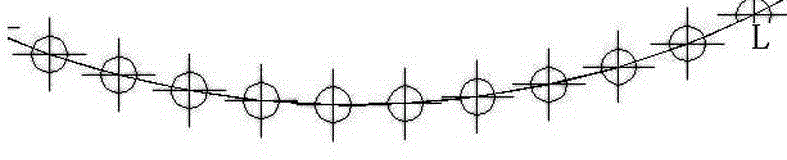

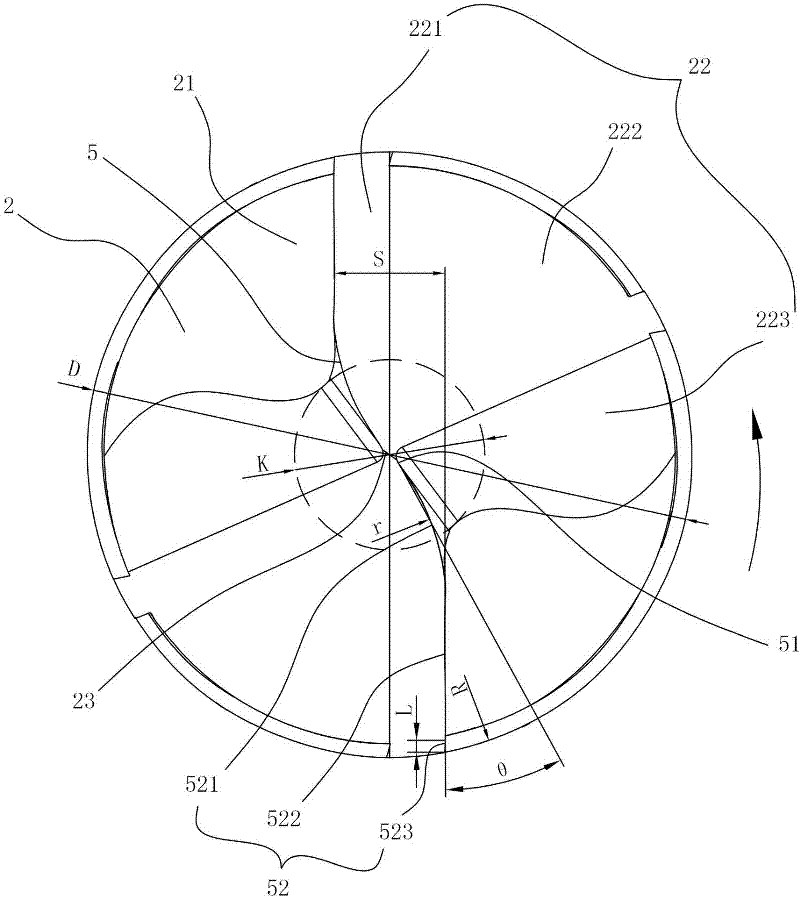

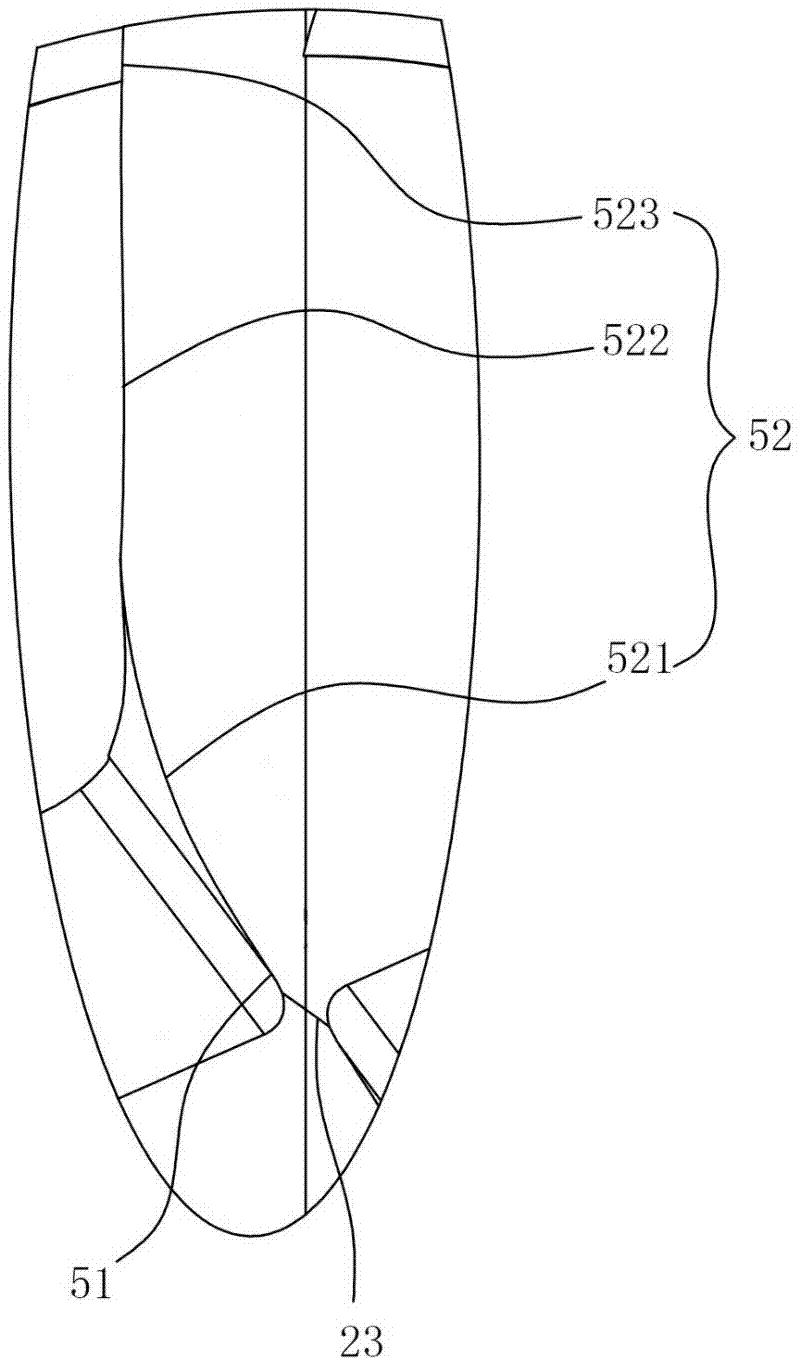

Complicated groove type milling cutter and method for machining chip breaker grooves of complicated groove type milling cutter

ActiveCN104439472AReduce wearStrong vibration suppression abilityMilling cuttersMilling cutting insertsNumerical controlMilling cutter

The invention discloses a complicated groove type milling cutter and a method for machining chip breaker grooves of the complicated groove type milling cutter. The molded line of an cutting edge of the milling cutter is in the shape of a Christmas tree, the milling cutter is provided with three or four teeth, the front angle of the milling cutter is 10 degrees, the helical angle of the milling cutter ranges from 3 degrees to 10 degrees, a chip breaker groove is formed in the back of the blade of the cutter and located on each tooth, the shape of each chip breaker groove is the same as the shape of the molded line of the cutting edge, the molded lines of the chip breaker grooves are corrugated, the chip breaker grooves of the teeth are sequentially staggered by certain wavelengths / teeth in the spiral direction of the milling cutter, the molded lines of the chip breaker grooves meet the relation R>r and the relation R=X2 / (8Z)+Z / 2-r, X refers to the wavelength, Z refers to the wave depth, R refers to the circular arc radius of upper half waves, and r refers to the circular arc radius of lower half waves. The method for machining the chip breaker grooves comprises the steps that the molded lines of the chip breaker grooves of the milling cutter are drawn by means of autocad drawing tool software and are guided into the num software of a numerically-controlled machine tool control system, a chip breaker groove machining program is generated automatically, and the chip breaker grooves of the milling cutter are machined automatically through a machine tool.

Owner:DONGFANG TURBINE CO LTD

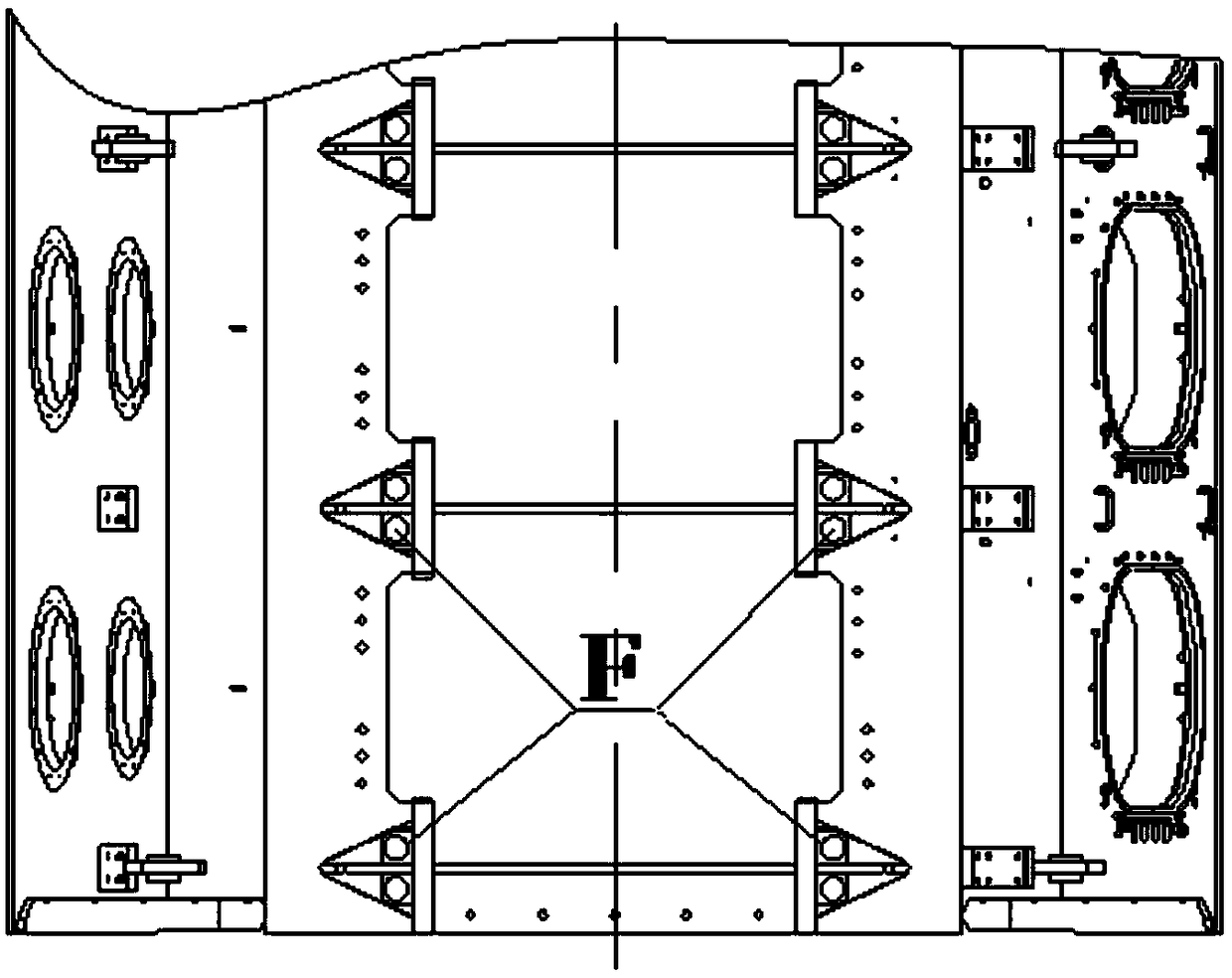

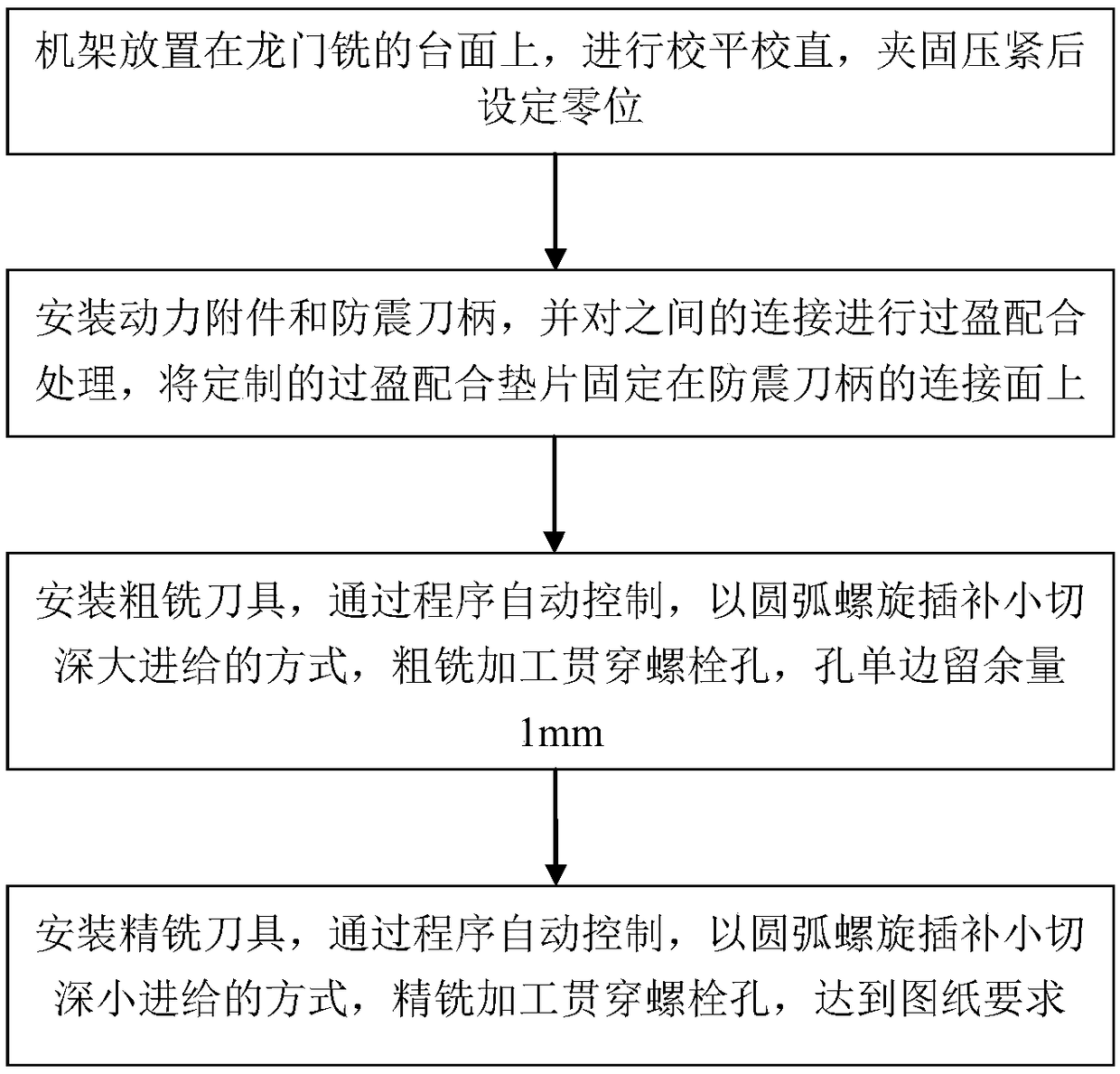

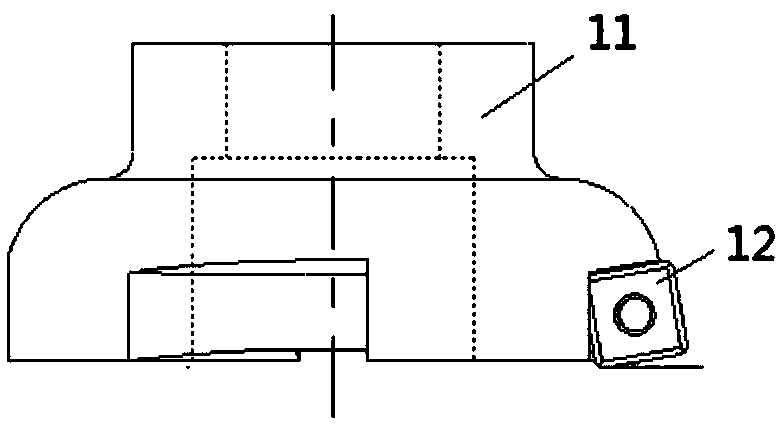

Method for machining diesel engine frame through bolt holes and tools thereof

InactiveCN109262033AImprove rigidityReduce cutting vibrationMilling cuttersMilling equipment detailsNumerical controlInterference fit

A method for machining diesel engine frame through bolt holes and tools thereof are provided. On a numerical control gantry milling machine, a rough milling tool and a finishing milling tool mounted on a shockproof shank connected to a power accessory are successively adopted to automatically complete rough milling and finishing milling of all the through bolt holes in a frame in a circular arc interpolation method according to a numerical control program command; the connection between the shockproof shank and the power accessory is subjected to interference fit processing, that is, the gap size of the connection surface of the shockproof shank and the power accessory is measured when the shockproof shank is first installed, and an interference fit gasket is customized according to the gap size and fixed on the connection surface of the shockproof shank. According to the method, the tool angle is optimized, the high-efficiency continuous full program control automatic machining is achieved, and the effects of small machining tremor, cutting temperature reduction and smooth chip discharge are achieved. Not only the hole wall machining quality is ensured, but also the machining efficiency is improved. The method is suitable for machining of the diesel engine frame through bolt holes and deep holes.

Owner:CSSC MES DIESEL

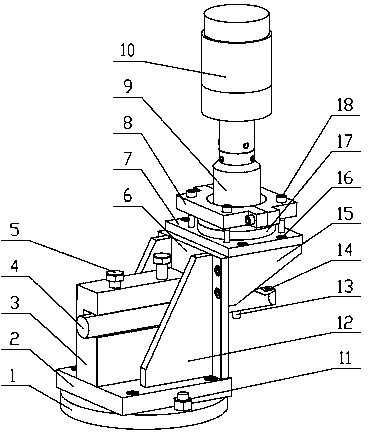

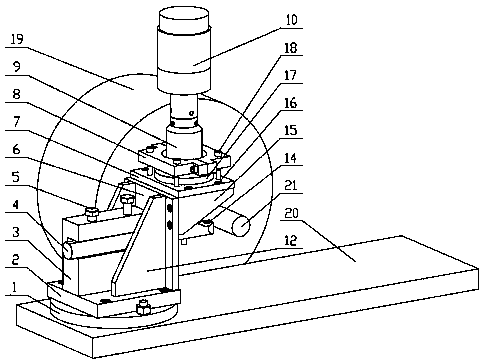

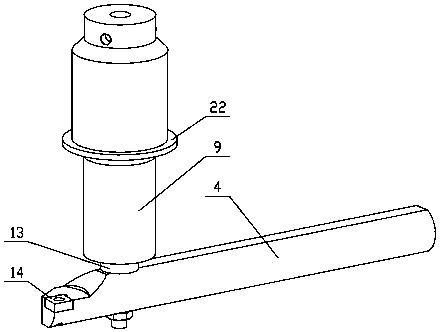

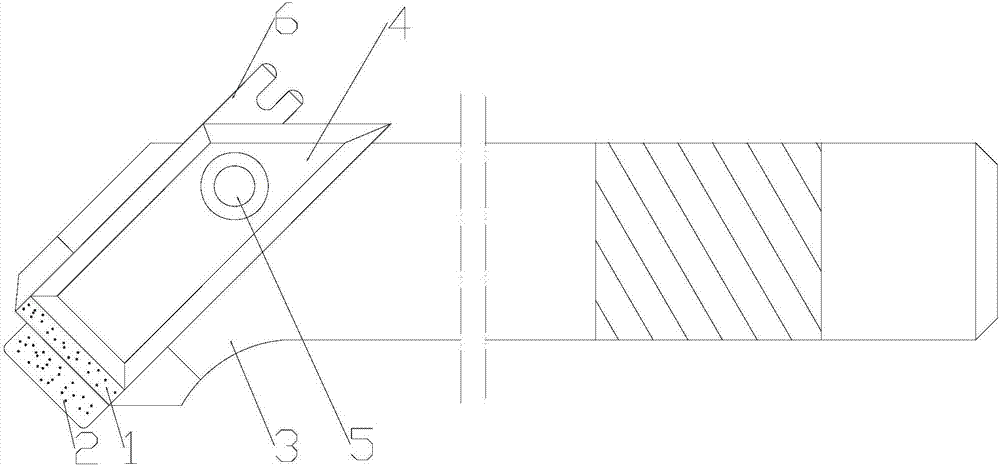

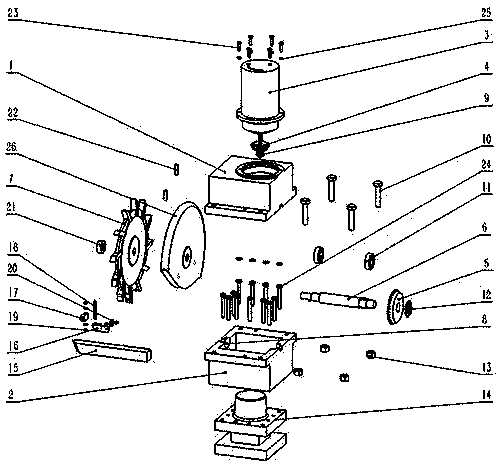

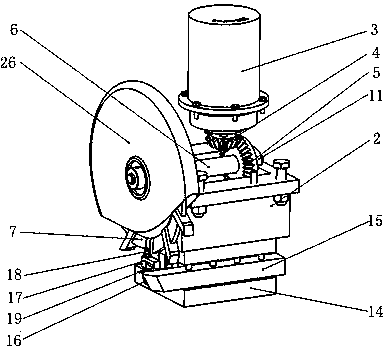

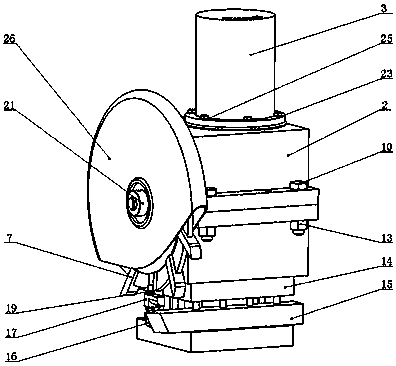

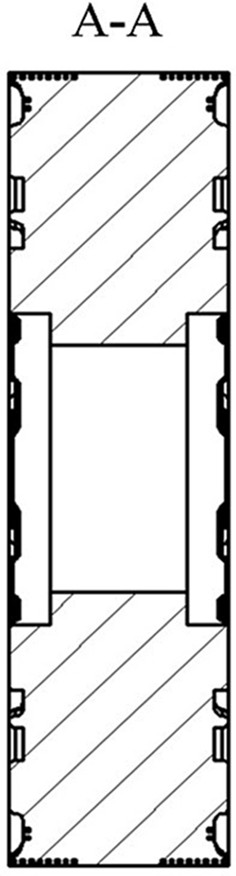

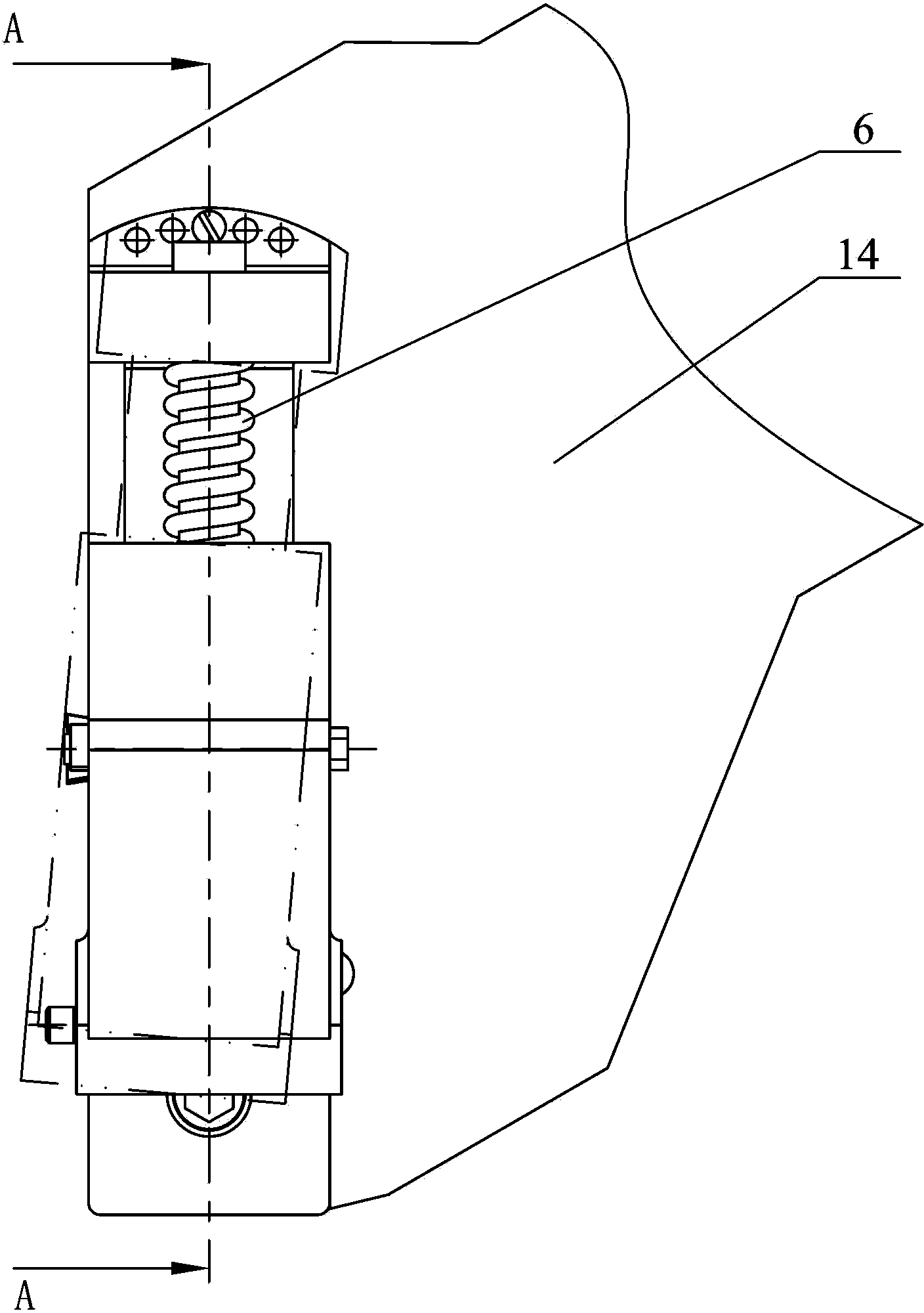

Longitudinal ultrasonic vibration turning device based on engine lathe

PendingCN109158622AWide adaptabilityImprove stabilityAuxillary equipmentTool holdersUltrasonic vibrationEngineering

The invention discloses a longitudinal ultrasonic vibration turning device based on an engine lathe. The longitudinal ultrasonic vibration turning device comprises an ultrasonic vibration system, a special fixture and the engine lathe, wherein the engine lathe is connected to the ultrasonic vibration system through the special fixture; the special fixture comprises a base, a connecting plate fixedly arranged on the base, a cutter frame arranged on the connecting plate and a support frame; the ultrasonic vibration system comprises a cutter bar arranged on the cutter frame, a cutter blade arranged at one end of the cutter bar and used for cutting a workpiece, and an ultrasonic vibration mechanism causing the cutter blade to obtain certain amplitude; the ultrasonic vibration mechanism is connected to the support frame through an inner flange plate and an outer flange plate; and the base is connected to a slide carriage of the engine lather through a fastening bolt. The longitudinal ultrasonic vibration turning device based on the engine lathe overcomes the shortcomings of a traditional turning technology, improves the processing quality and the processing efficiency and has the characteristics of convenient structure installation, simple and easy disassembly, low economic cost and the like.

Owner:EAST CHINA UNIV OF TECH

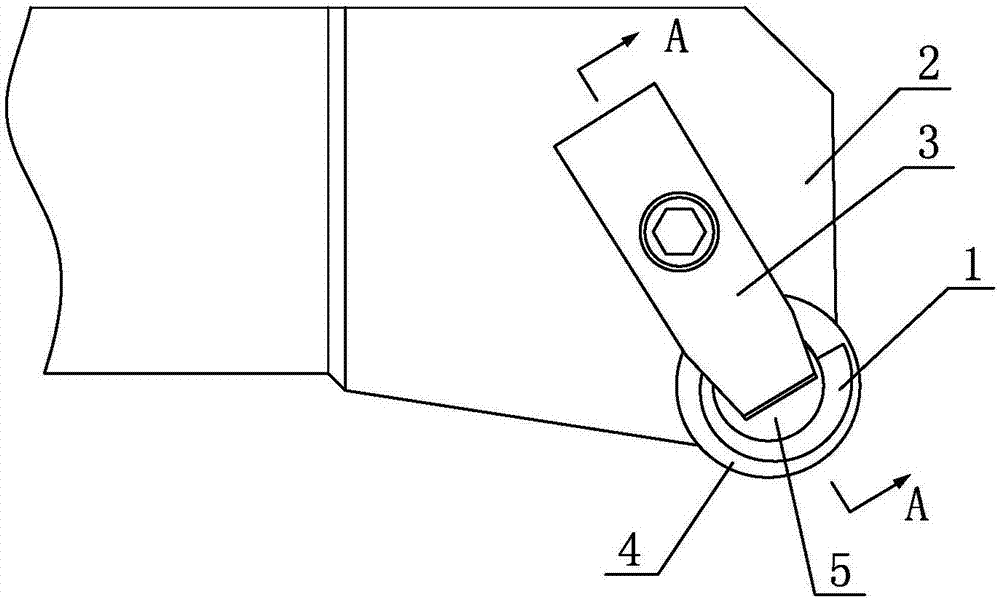

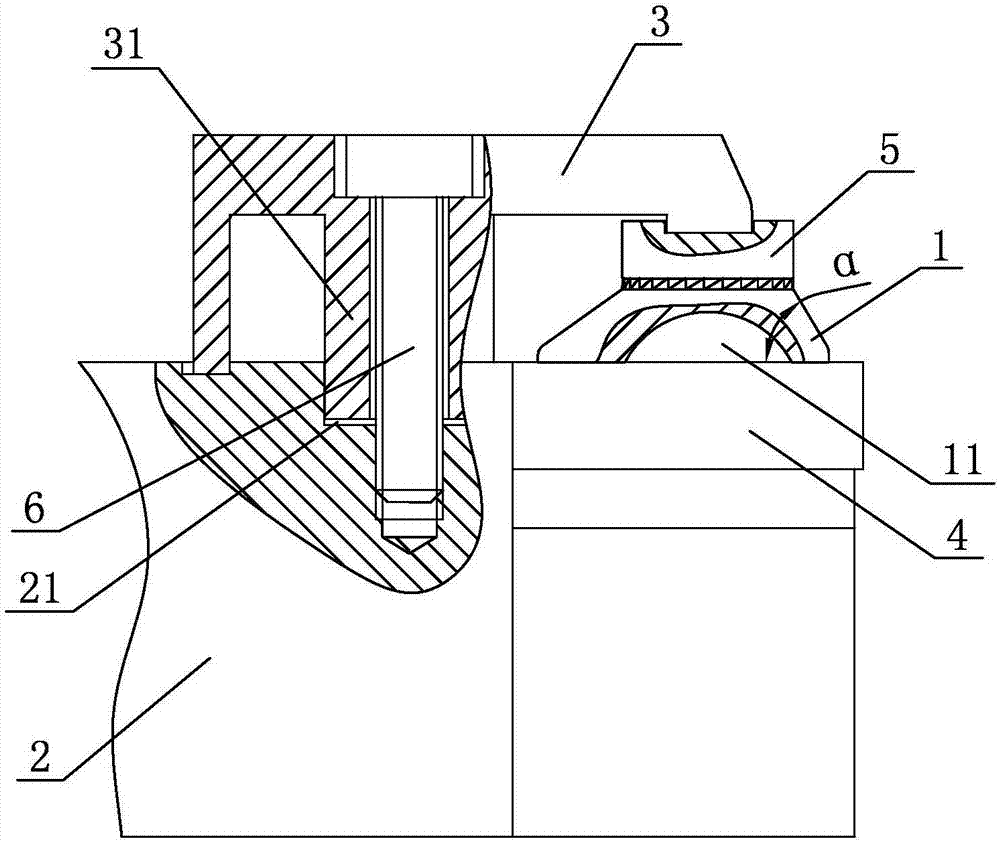

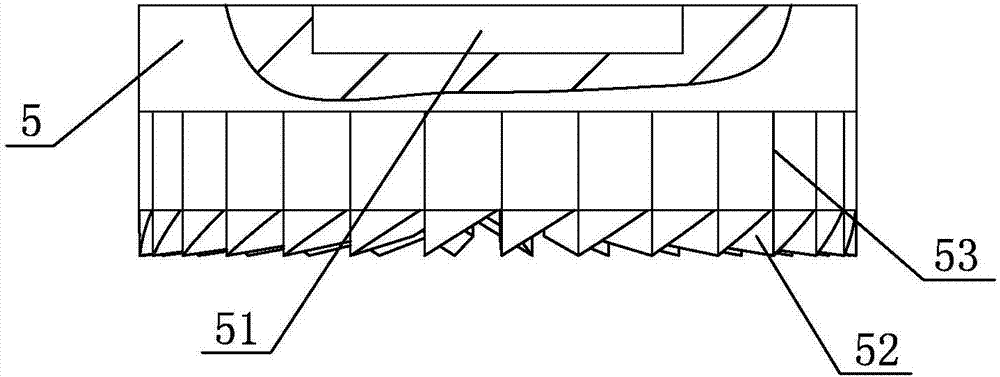

Strong turning tool with adjustable chip breaking block and use method thereof

PendingCN107096932ABreaking down the non-adjustable disadvantagesSave man hoursTurning toolsEngineeringSharpening

The invention relates to a strong turning tool with an adjustable chip breaking block and a use method thereof. The strong turning tool comprises the chip breaking block, a blade, a tool bar, a pressing piece, a clamping and fixing screw and an adjusting screw. A blade installation groove which is each in a parallelogram shape and an adjusting screw hole are formed in the upper end surface of the end of the tool bar, openings are formed in the front end surface and the upper side surface of the blade installation groove, and the blade is installed in the blade installation groove; the adjusting screw hole communicate with the rear side surface of the blade installation groove, the pressing piece is arranged at the end of the tool bar, and a chip breaking block installation groove is formed in the lower end surface of the end of the pressing piece; the chip breaking block is installed in the chip breaking block installation groove, and the bottom surface of the chip breaking block abuts against the top surface of the blade; and the clamping and fixing screw penetrates through the pressing piece and is connected with the tool bar, and the adjusting screw penetrates through the adjusting screw hole and then abuts against the blade. Compared with the prior art, the strong turning tool with the adjustable chip breaking block and the use method thereof overcome the defect that a chip breaking block of an ordinary tool cannot be adjusted, so that adjusting of the chip breaking block is achieved, and after being sharpened, the blade can also be adjusted; and the tool bar can also be repeatedly used, tool bar materials are saved, and the working time for sharpening and tool bar forging is greatly saved.

Owner:FUZHOU UNIV

Wave-edge rough milling cutter for machining cast iron scroll plate

PendingCN112157303AReduce loadSmall elastic deformationTransportation and packagingMilling cuttersMilling cutterStructural engineering

The invention provides a wave-edge rough milling cutter for machining a cast iron scroll plate. The wave-edge rough milling cutter improves the cutting efficiency and the durability of a cutter and prolongs the service life of the cutter. A transition neck part is used for connecting a cutter clamping handle part with a cutting edge part. The wave-edge rough milling cutter is characterized in thatthe cutter clamping handle part is a cylindrical straight handle; the cutting edge part comprises a plurality of cutting edges and chip grooves, the cutting edges and the chip grooves are spirally arranged, the N cutting edges are annularly distributed on the outer circumference of the cutting tool part in the cross section state, N is a natural number larger than or equal to 3, the chip groovesare located in corresponding interval areas of the circumferential face formed after the adjacent cutting edges are combined, chip breaker grooves and chip containing grooves are formed in the chip grooves, the chip containing grooves are provided with groove bottom faces and cutter outlet faces, each cutting edge is composed of an end edge, a peripheral edge and a cutter point R angle used for connecting the end edge and the peripheral edge, the front end of each end edge and the front end of each peripheral edge are respectively provided with a front cutter face and a straight rear cutter face, and sine-wave-shaped arc teeth are arranged on each peripheral edge.

Owner:SUZHOU AHNO PRECISION CUTTING TECH CO LTD

Cutting chip breaking device with active power

InactiveCN108115155AGood chip breaking effectFine-tune the positionAuxillary equipmentMilling cutterEngineering

Owner:TAIYUAN UNIV OF TECH

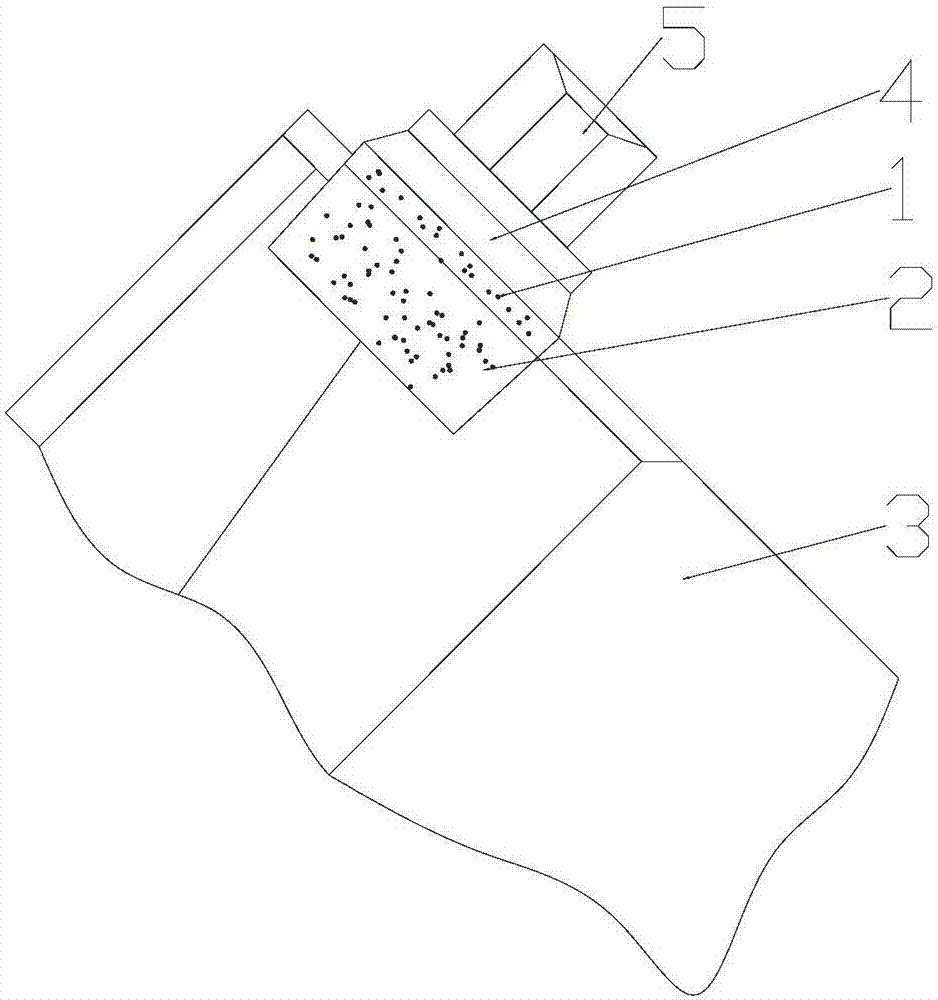

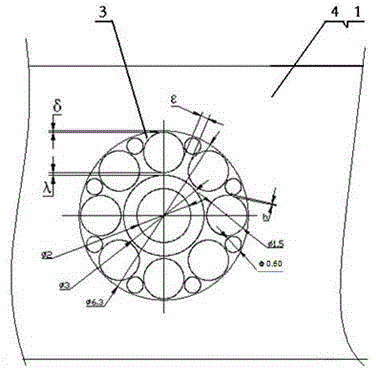

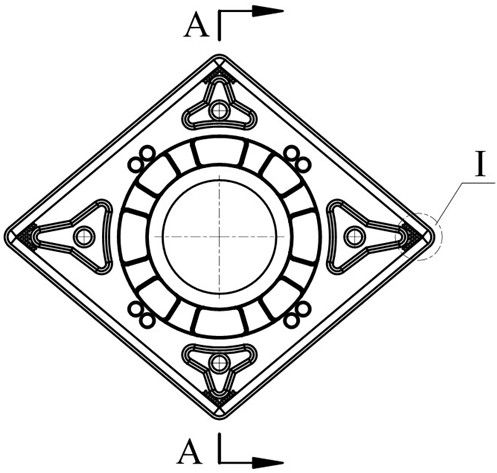

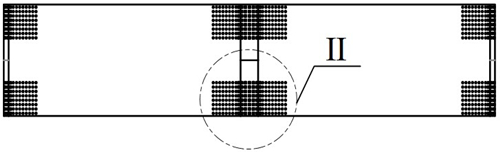

Processing method of finished holes of circuit board with inner-layer copper thickness of more than 420 micrometers

ActiveCN104690769ASolve sheddingNo tool wrapping phenomenonMetal working apparatusCopper wireMicrometer

The invention belongs to a processing method of finished holes of a circuit board with the inner-layer copper thickness of more than 420 micrometers. The processing method comprises the following steps: adopting a drilling head with phi 0.60 mm to uniformly drill a plurality of holes with phi of 0.60 mm around the finished holes (3) on the circuit board (4) of which the inner-layer copper thickness is more than 420 micrometers; adopting a drilling head with phi of 1.50 mm to drill a plurality of holes with phi of 1.50 mm; adopting a drilling head with phi of 2.00 mm to drill holes with phi of 2.00 mm at the centers of the finished holes (3); adopting a drilling head of 3.00 mm to drill holes with phi of 3.00 mm. The processing method disclosed by the invention has the advantages that the cutting force is effectively reduced, the drilling heat is lowered, and the problem that bonding pads on inner layers drop off is solved; the chip breaking effect is better; the phenomenon that copper wires wind cutters is avoided; the edges of the holes are smooth and tidy and do not have obvious burrs; the feeding rate of drilling is high.

Owner:DALIAN CHONGDA CIRCUIT

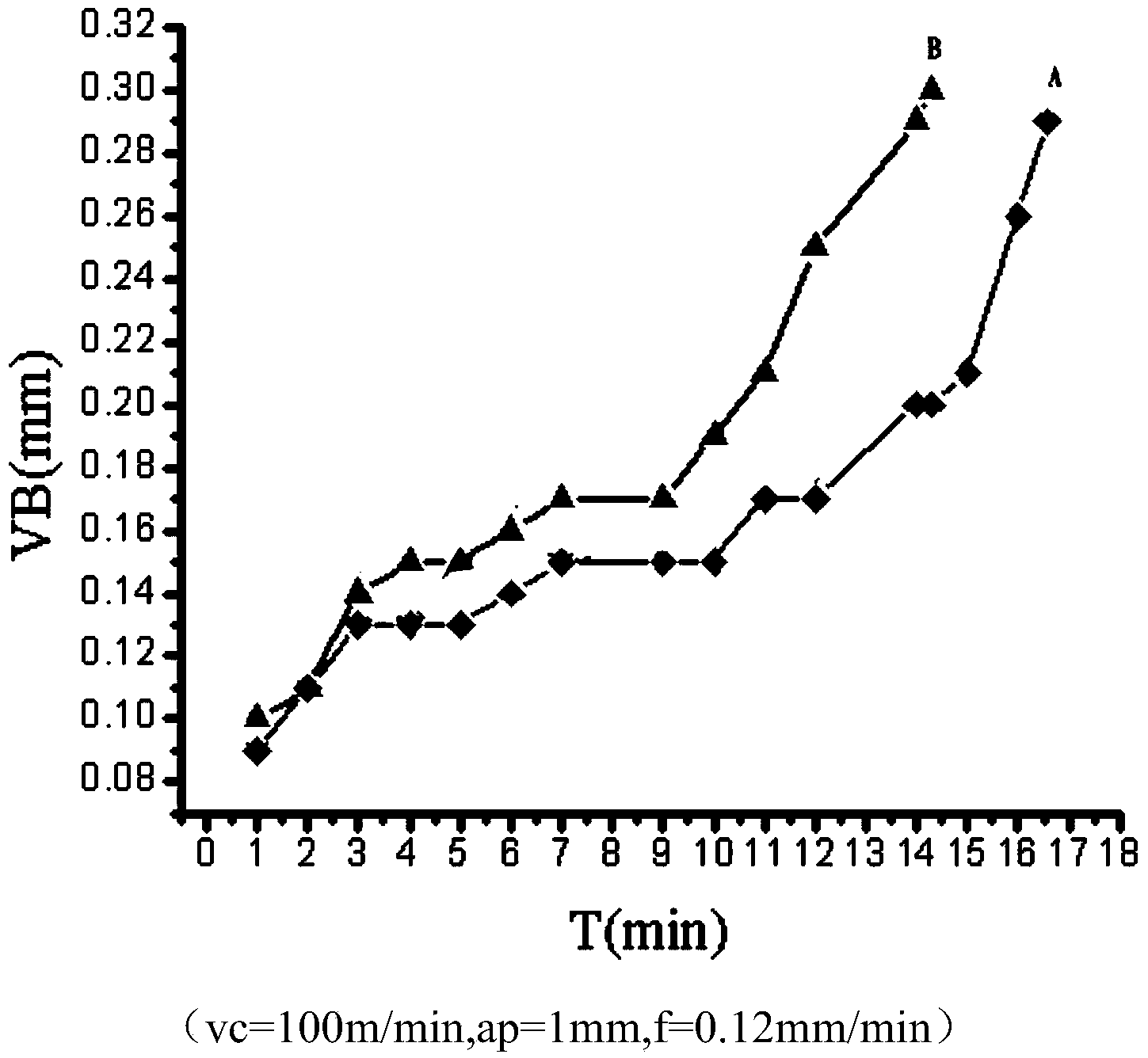

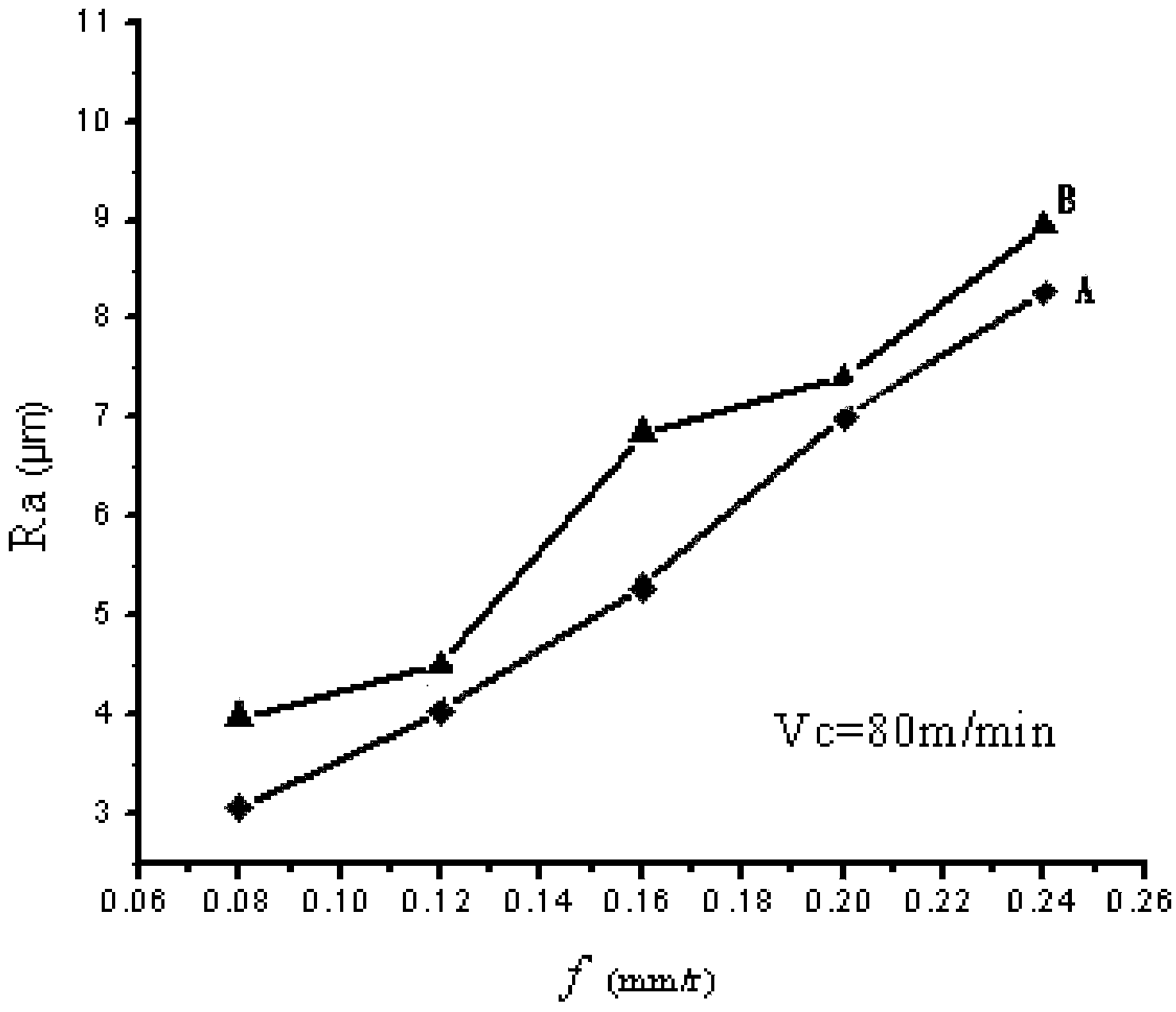

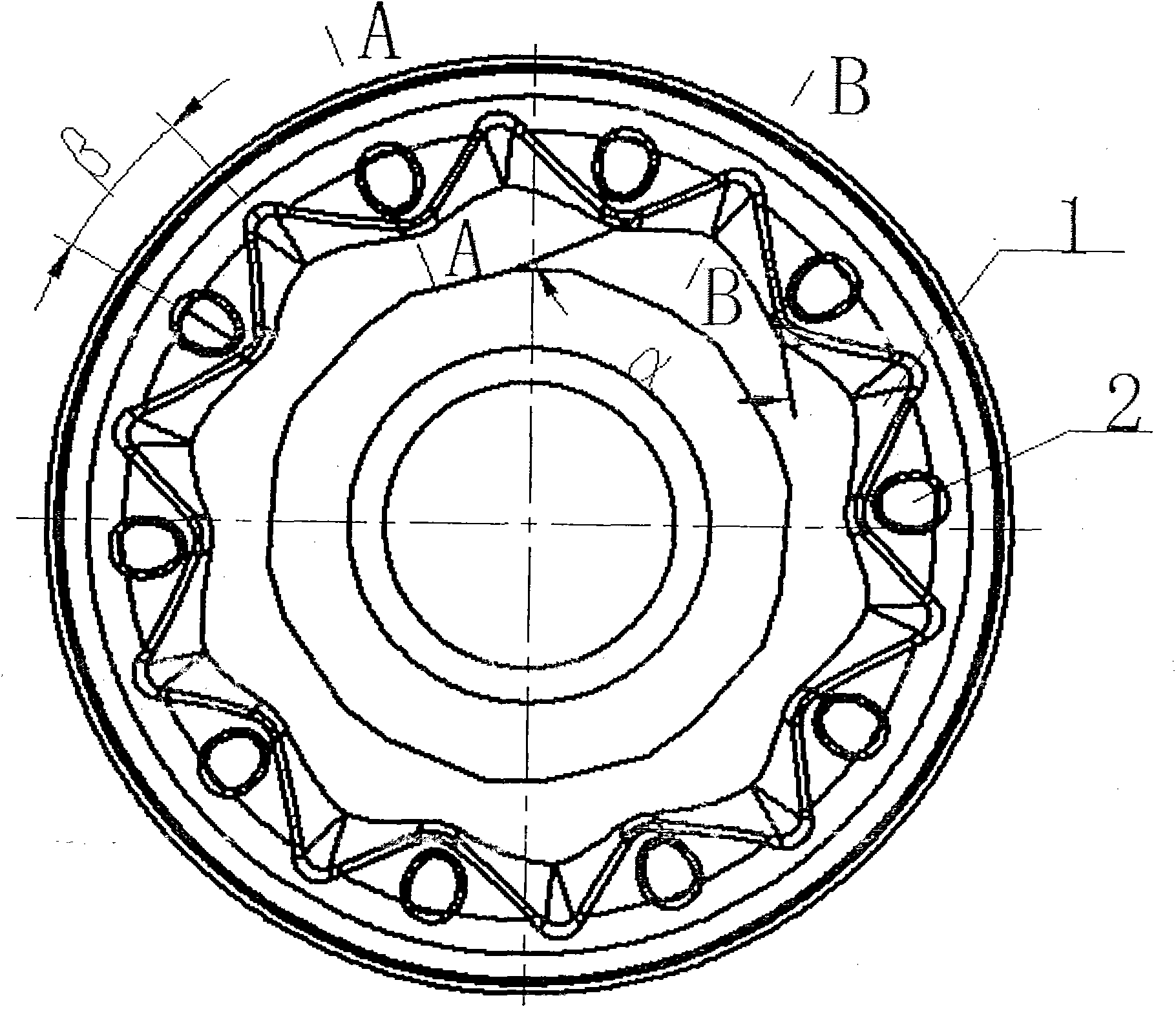

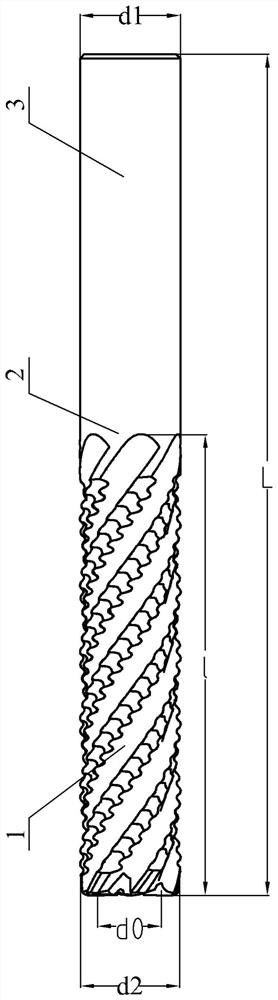

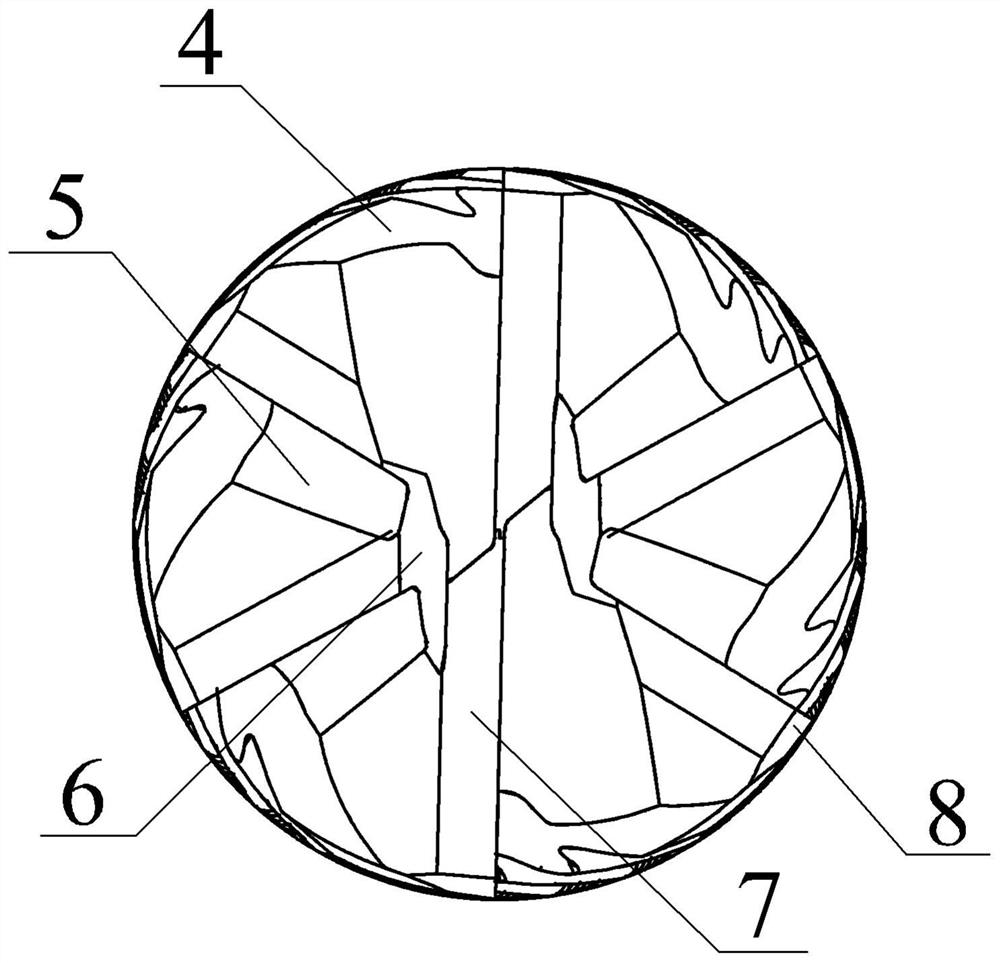

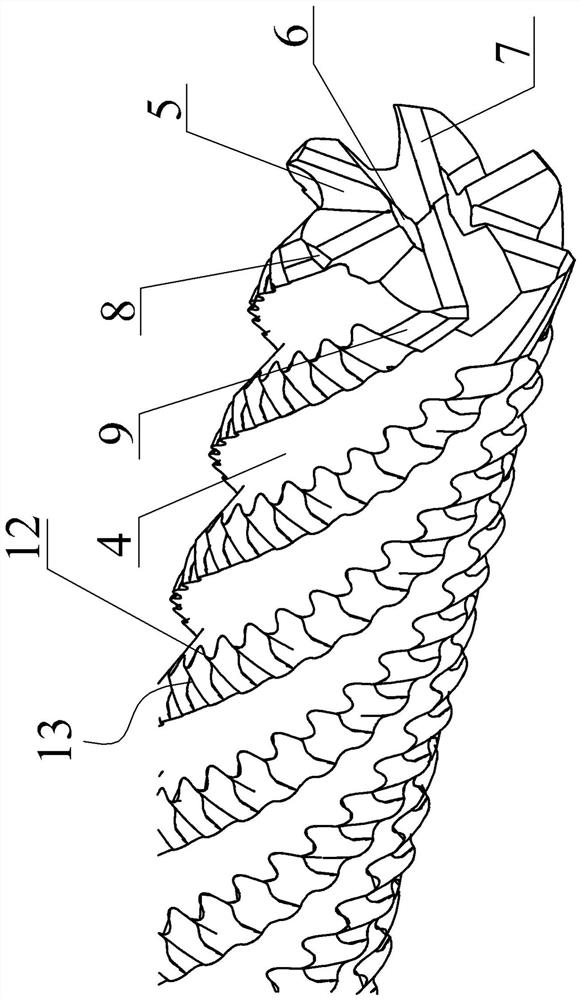

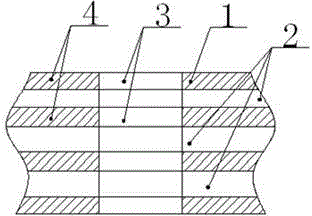

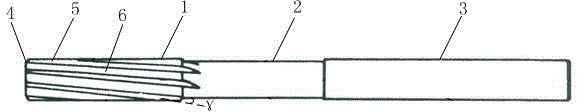

Wave-shaped helical-edge reamer

The invention discloses a wave-shaped helical-edge reamer comprising a bit (1), a neck portion (2) and a handle (3). The wave-shaped helical-edge reamer is characterized in that the bit (1) comprises teeth (4) at the top of the bit, side-cutting edges (5) connected with the teeth (4) and chip spaces (6) formed between the side-cutting edges; the side-cutting edges (5) are helical sine shaped edges; the bit (1) is provided with a flexible coating; anterior angle Alpha of the teeth (4) is 2 degrees, and posterior angle Beta of the teeth (4) is 6 degrees. The wave-shaped helical-edge reamer has the advantages that due to the wave-shaped helical edge structure, cutting is quick, chip breaking performance is excellent, chip removing is smooth, vibration is small, no damages occur to the edge, service life is long, change frequency and cost are low, production efficiency is improved, and the surface roughness of the workpieces to be processed is improved.

Owner:滁州用朴合金工具有限公司

PCD forming sleeve milling cutter

PendingCN112024961AStable supportSolve the problem of insufficient cutting spaceMilling cuttersTool bitMilling cutter

The invention relates to the technical field of milling cutters, in particular to a PCD forming sleeve milling cutter. The cutter comprises a cutter handle, a cutter neck platform formed at one end ofthe cutter handle and a cutter head fixedly connected to the side, away from the cutter handle, of the cutter neck platform. The cutter head comprises an annular cutter rest fixedly connected to thecutter neck platform and used for being arranged outside a to-be-machined workpiece in a sleeving manner, and a cutter body installed on the inner wall of the annular cutter rest. The milling cutter has the effects that the outer contour of the workpiece of a narrow space structure can be conveniently machined, and meanwhile, the possibility of cutter vibration is reduced to reduce scratches on the surface of the workpiece.

Owner:BEIJING WORLDIA DIAMOND TOOLS

High-efficiency chip-breaking wear-reducing double-sided diamond turning tool blade under high-pressure cooling

PendingCN112475340AReduce coefficient of frictionIncrease stressCutting insertsTurning toolsDiamond turningEngineering

The invention discloses a high-efficiency chip-breaking wear-reducing double-sided diamond turning tool blade under high-pressure cooling, and belongs to the technical field of cutting tools. The double-sided diamond turning tool blade aims to solve the problems that an existing blade is high in cutting temperature, large in cutting force, difficult in chip breaking, serious in tool wear, low in cutting efficiency and the like in the cutting machining process. The double-sided diamond turning tool blade comprises a double-sided available diamond blade with an included angle of 80 degrees, wherein linear cutting edges are arranged at the edges of a front blade face of the blade; circular protrusions are arranged on the front blade face along the directions of the linear cutting edges, a circular arc-shaped tool nose is arranged at the intersection of every two cutting edges, and a circular groove microstructure is distributed at each circular arc-shaped tool nose; triangular-like chip breaking bosses are arranged at the positions close to the circular groove microstructures, and a circular chip breaking groove is formed in each triangular-like chip breaking boss; and combined microstructures are arranged on a rear blade face of the blade, eight trapezoidal protrusions are distributed in the middle area of the blade, and a flow guide groove is formed between every two adjacent trapezoidal protrusions. The high-efficiency chip-breaking wear-reducing double-sided diamond turning tool blade under high-pressure cooling is used for semi-finish machining and finish machining of a high-temperature alloy material under a high-pressure cooling condition.

Owner:HARBIN UNIV OF SCI & TECH

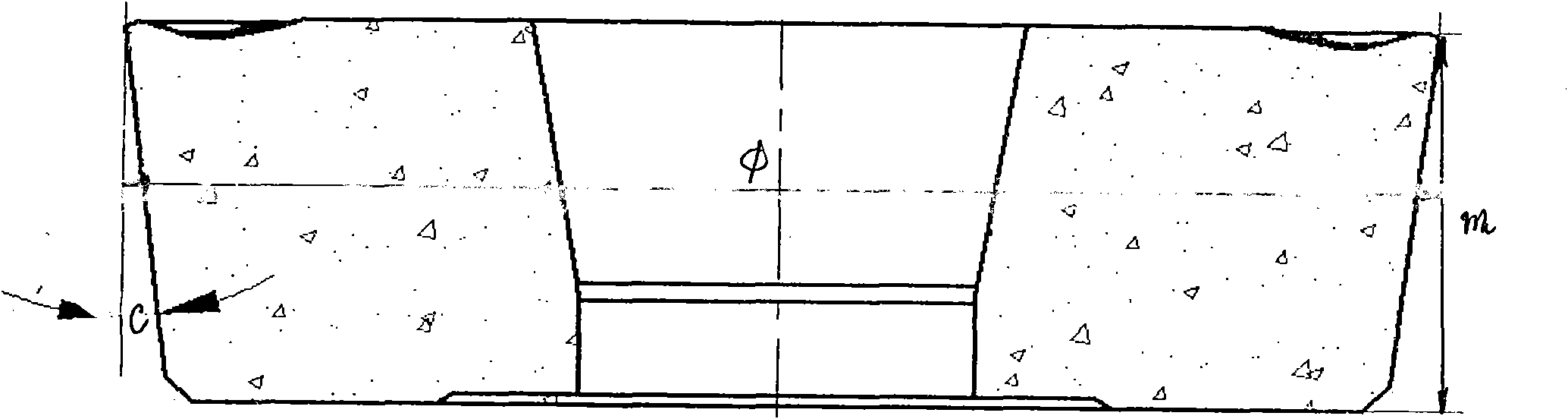

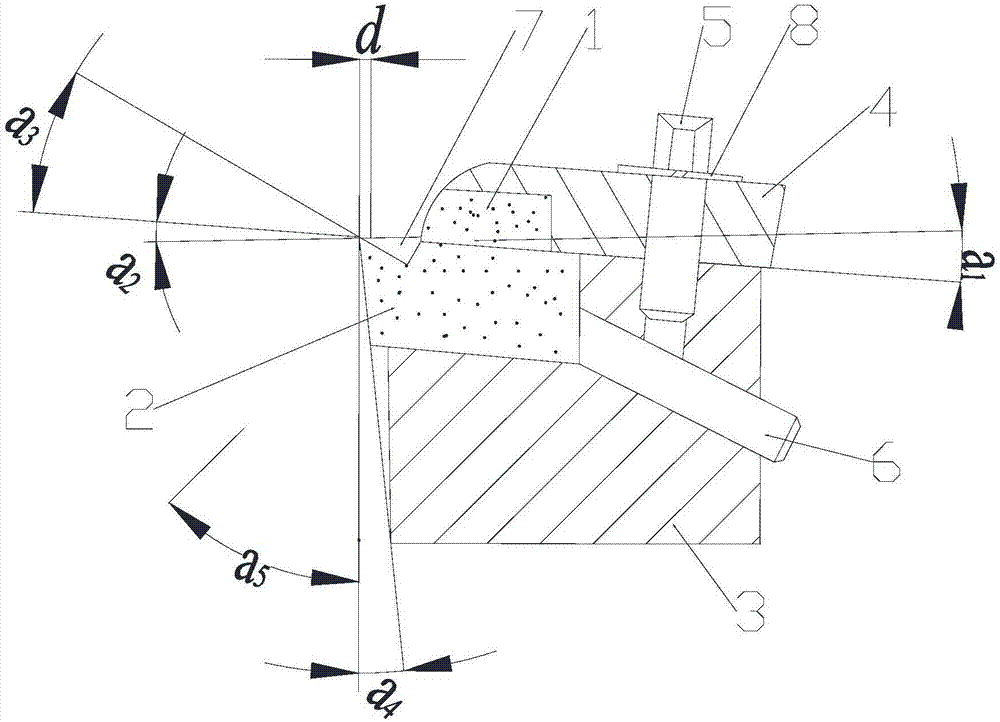

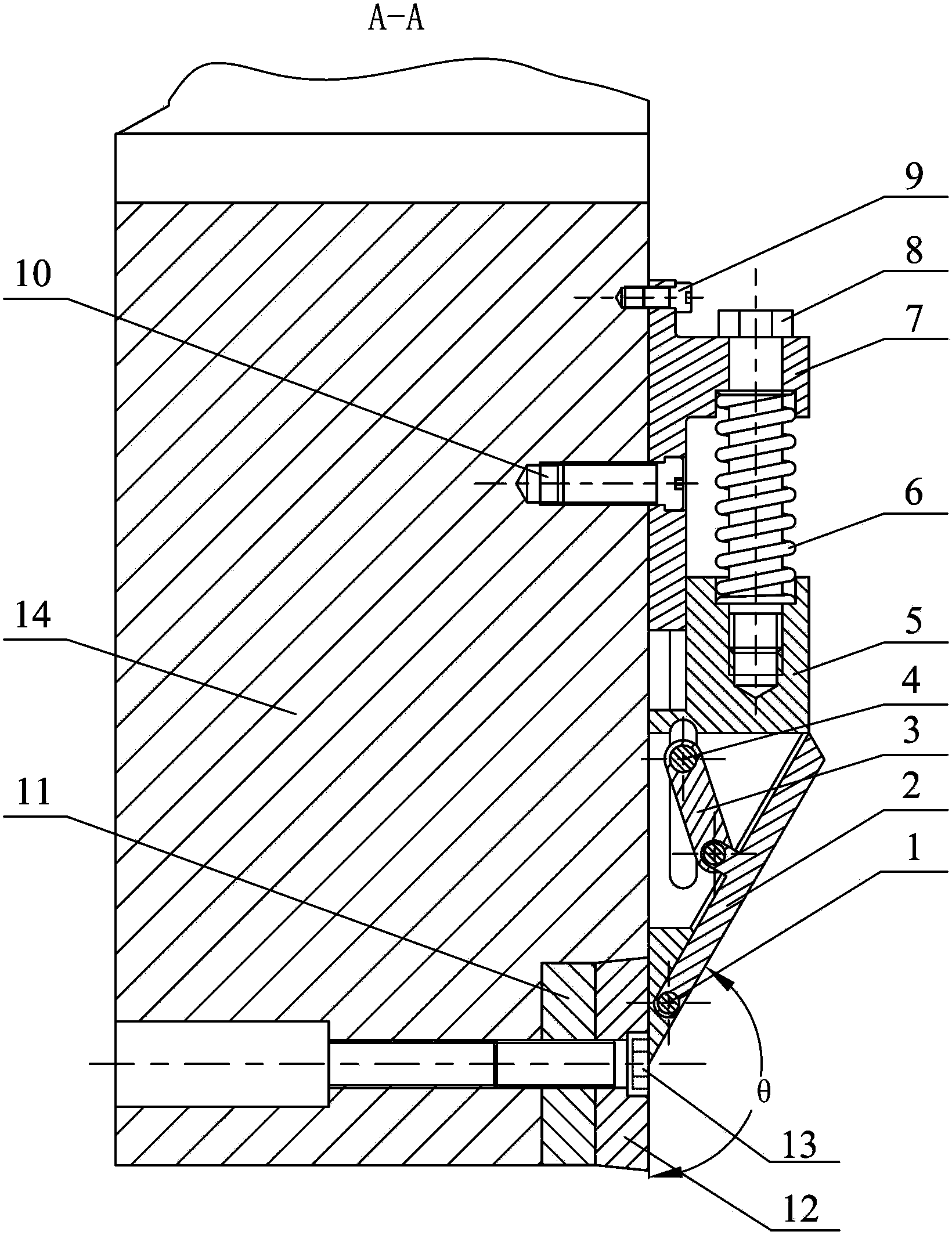

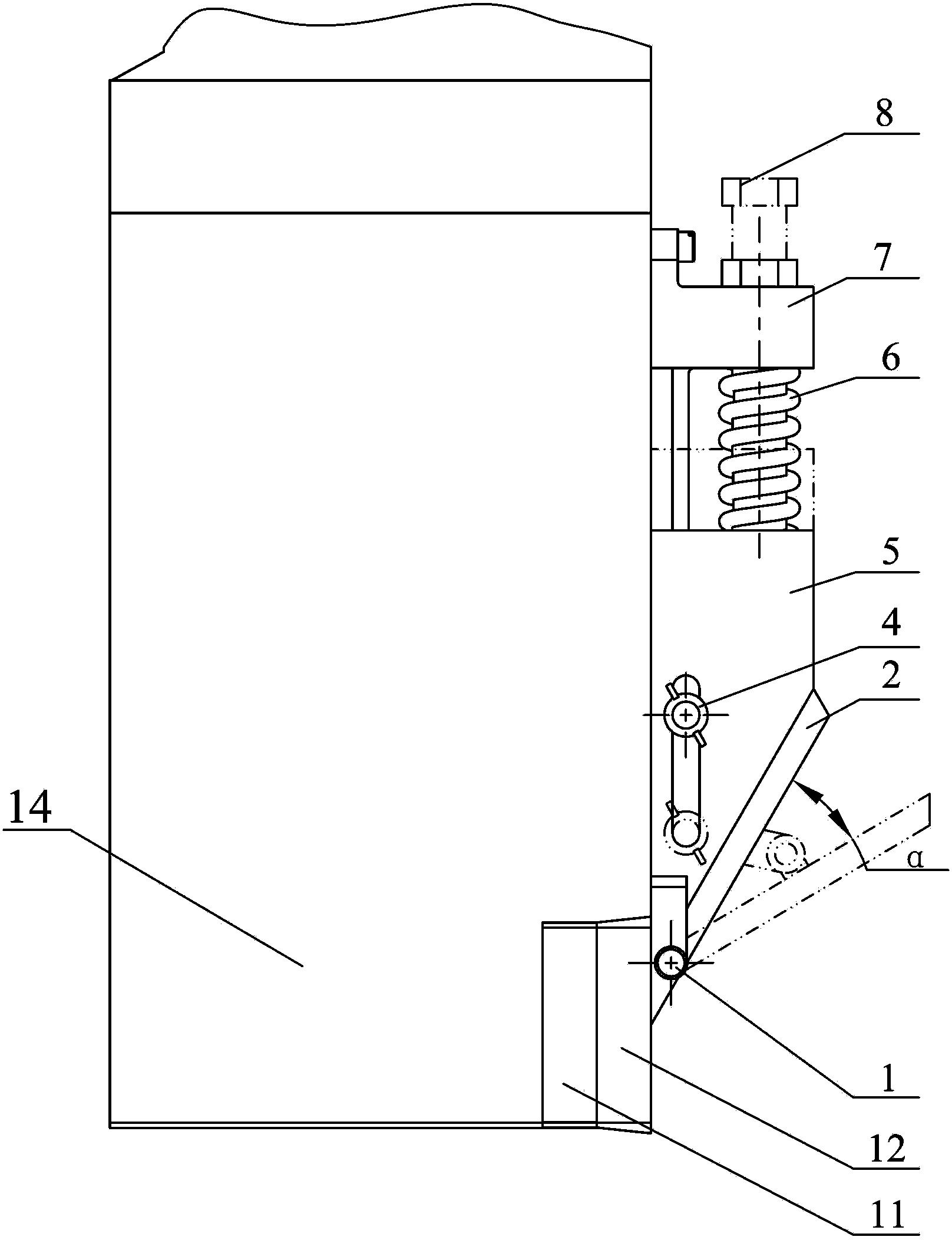

Adaptive chip breaker for heavy turning

InactiveCN103357923AImprove general performanceExtended service lifeBoring/drilling componentsComputer engineering

The invention discloses an adaptive chip breaker for heavy turning, belongs to the technical field of turning tools, and solves the problems of high possibility of generating C-shaped chips and sigma-shaped chips in a heavy turning process and long development cycle, high research and development expense and narrow application range of an indexable cutting tool of a chip breaking groove in the prior art. An angle adjusting hole of a horizontal plate is in threaded connection with a second threaded hole of a turning tool rod through an angle limiting bolt; the horizontal plate is in threaded connection with the turning tool rod through a central rotary bolt; a sliding block is glidingly arranged on the horizontal plate; a damping adjusting bolt penetrates through a vertical plate to be in threaded connection with the sliding block; a compression spring is arranged on the damping adjusting bolt in a sleeving manner; a baffle block is connected with the sliding block through a baffle block positioning bolt; the baffle block can rotate around the baffle block positioning bolt; one end of a push rod is glidingly connected with the sliding block; the other end of the push rod is hinged to the side surface of the baffle block; a gasket, a blade and the turning tool rod are fixedly connected through blade fastening bolts. The adaptive chip breaker is used for turning a workpiece.

Owner:HARBIN UNIV OF SCI & TECH

Drill bit for processing deep hole with large length-diameter ratio

ActiveCN101912987BHigh strengthIncreased durabilityTwist drillsBoring/drilling machinesDiameter ratioTransition edge

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Embedded ultrahard cutter and manufacturing method

PendingCN107470660AAchieve replacementAchieve secondary grindingCutting insertsTurning toolsTool bitFlagellar basal body

The invention discloses an embedded ultrahard cutter and a manufacturing method, and belongs to the technical field of cutters. A tool bit is welded at the angle part of a blade, and is provided with a tool point; a first chip cutting table and a second chip cutting table are respectively arranged on the surface of the tool bit, namely two sides of the tool point; and the first chip cutting table and the second chip cutting table are respectively matched with an inclined surface on the upper surface of the blade. The first chip cutting table and the second chip cutting table are variable side surfaces. The first chip cutting table and the second chip cutting table are asymmetrically positioned on the back surface of the tool point; and the side surfaces of the first chip cutting table and the second chip cutting table are planes. Compared with a chip cutting groove blade for laser carving of a chip cutting table in the parent of 201521037249.6, the embedded ultrahard cutter has the following advantages: the difficulty and the time of machining complicated appearances and grooves on hard alloy basal bodies by using such processes as laser carving, cutting and grinding are far lower than the difficulty of machining on diamond cutter surfaces; the tool bit replacement and the secondary grinding can be realized; the basal bodies have no need to be replaced; and the use efficiency is improved.

Owner:BEIJING WORLDIA DIAMOND TOOLS

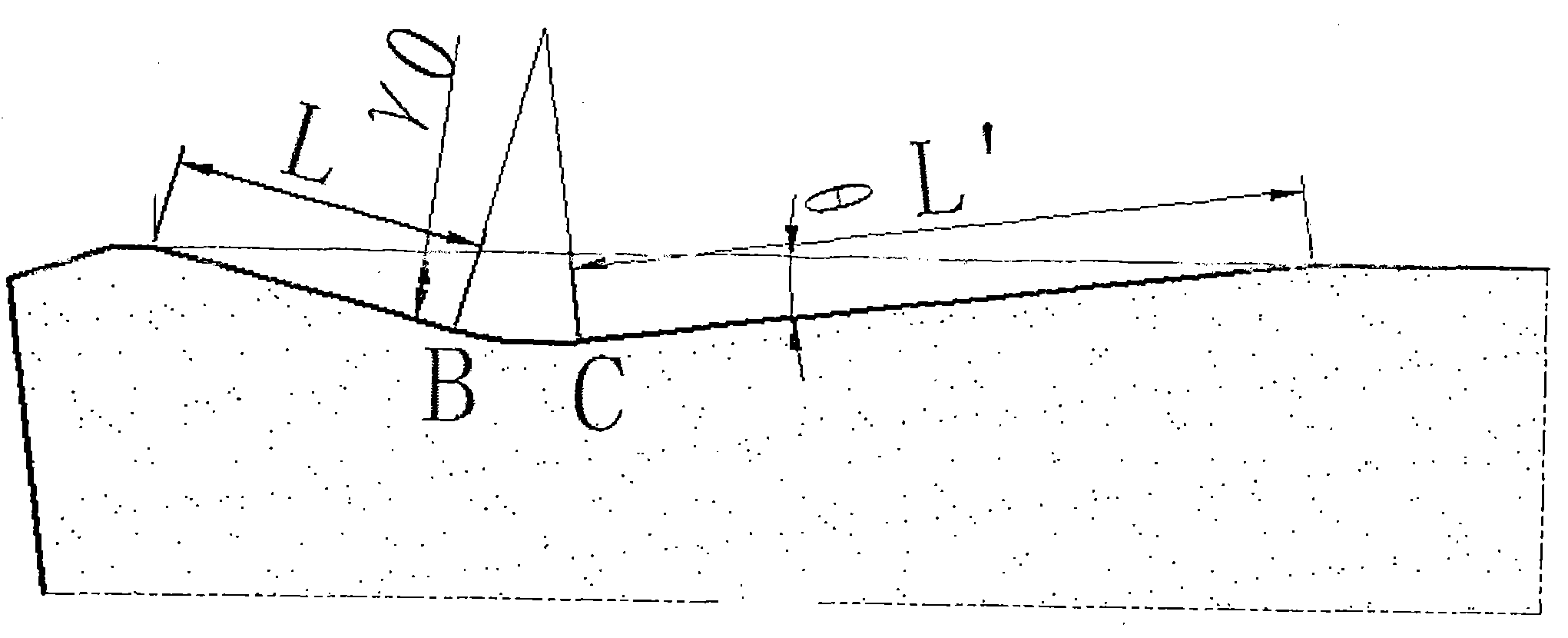

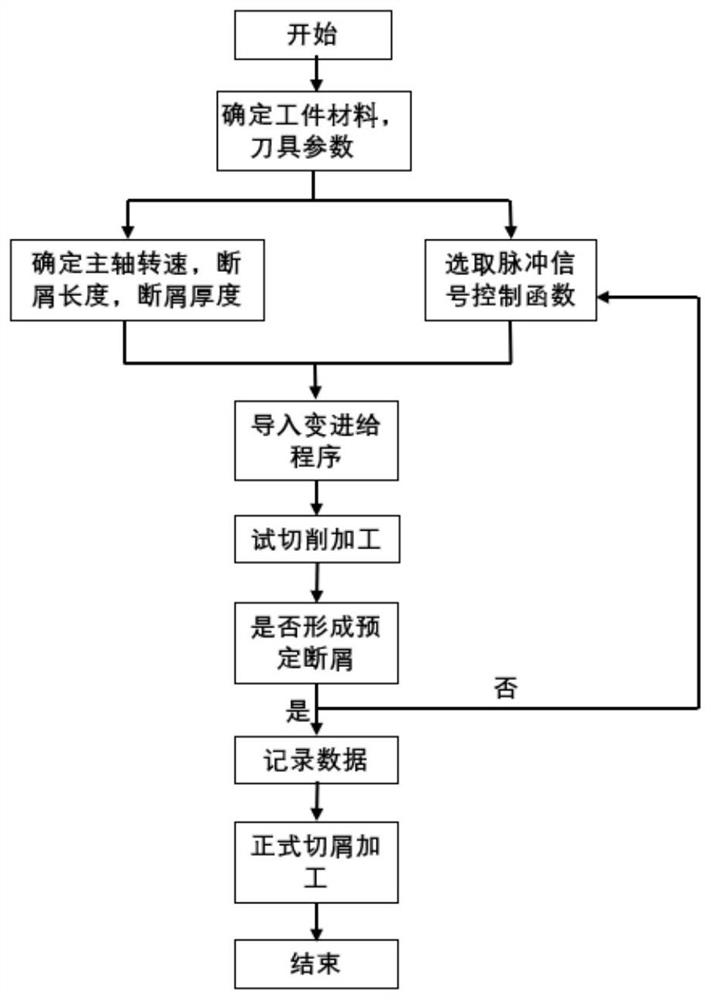

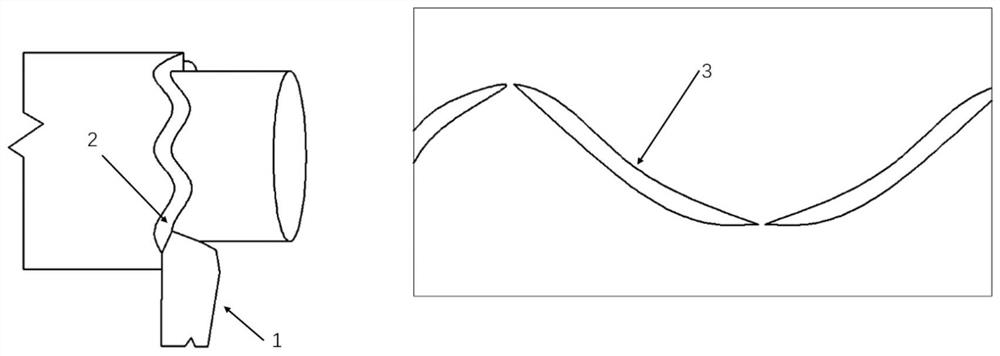

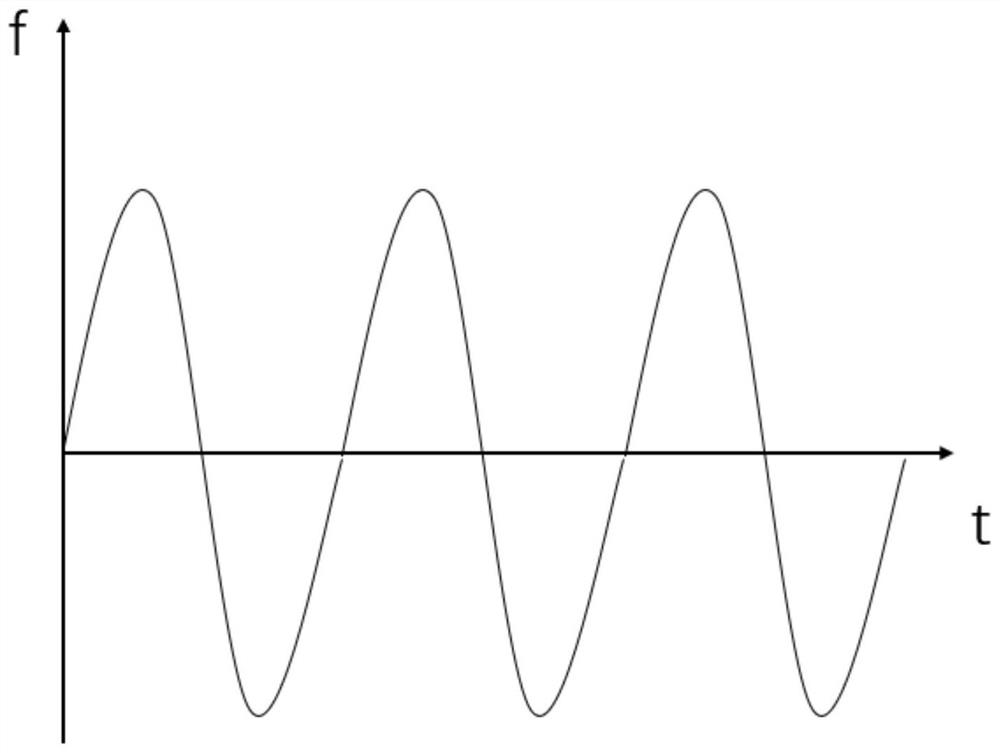

Variable-feed turning chip breaking method capable of achieving real-time monitoring

PendingCN113369989AHigh strengthImprove toughnessMeasurement/indication equipmentsPulse controlNumerical control

The invention discloses a variable-feed turning chip breaking method capable of achieving real-time monitoring. The variable-feed turning chip breaking method is characterized in that when a numerical control machine tool carries out turning, the chip breaking thickness W and the chip breaking length L are taken as control targets, and a pulse control function is selected, so that the thicknesses of chips obtained after the cutting are inconsistent, the purpose of chip breaking is achieved, meanwhile, the cutting state is monitored in real time through an acoustic emission sensing module, if a certain section does not reach the predicted chip breaking state in the cutting process, the pulse control function is modified, it is ensured that chip breaking is completed, data of the whole process is recorded, an acoustic emission sensing technology and a variable feeding chip breaking method are utilized on a numerical control machine tool, no complex auxiliary device is needed, operation is easy and convenient, economical efficiency is good, and the automation degree is high.

Owner:XIANGTAN UNIV

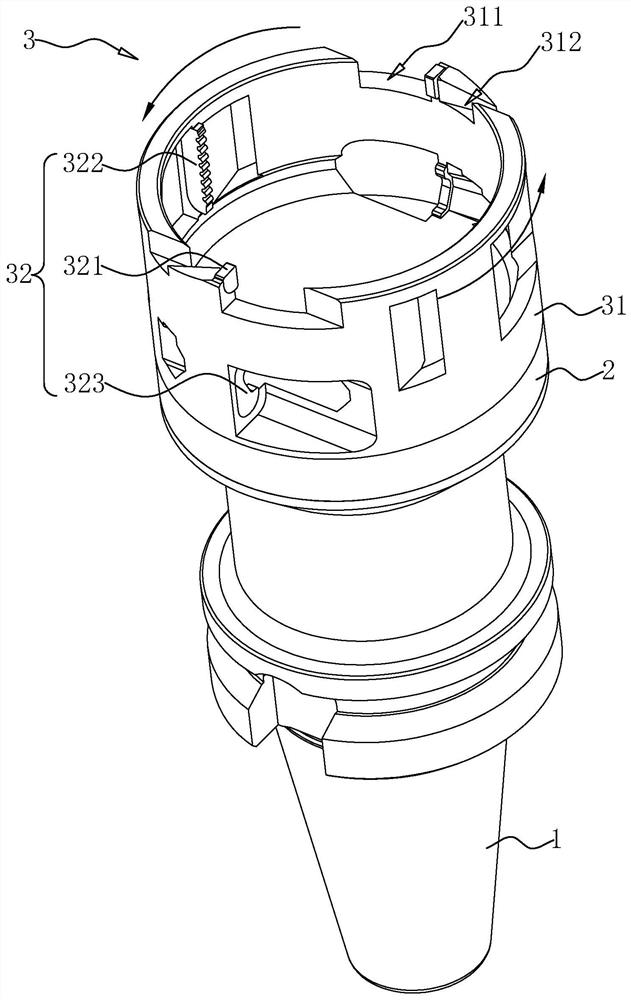

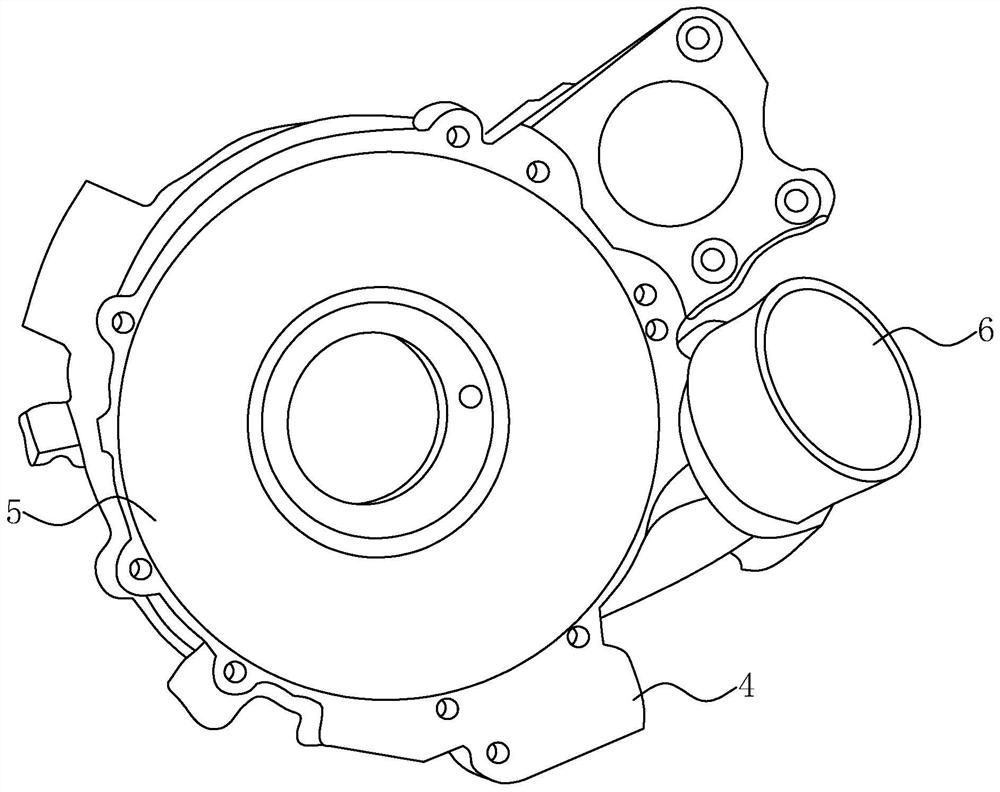

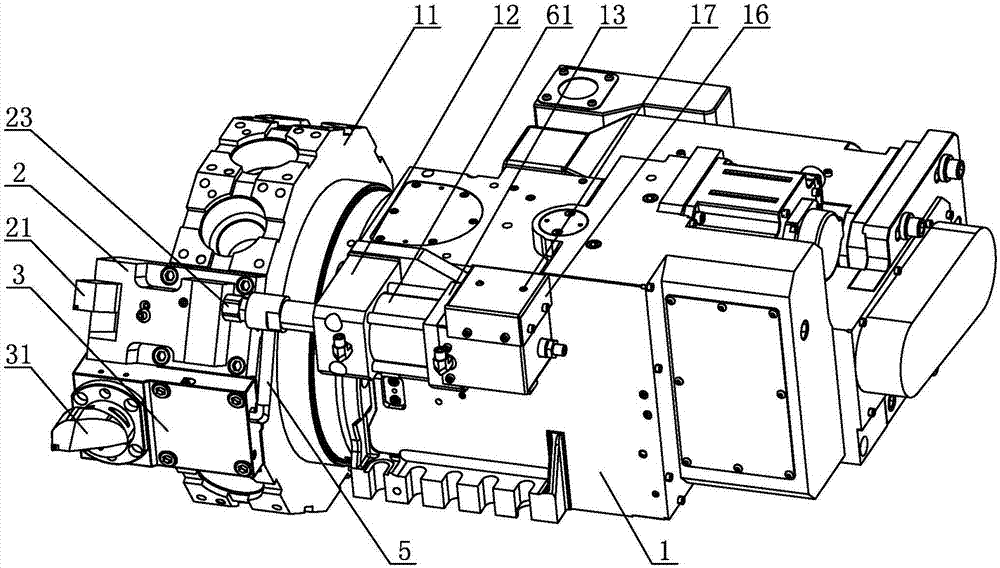

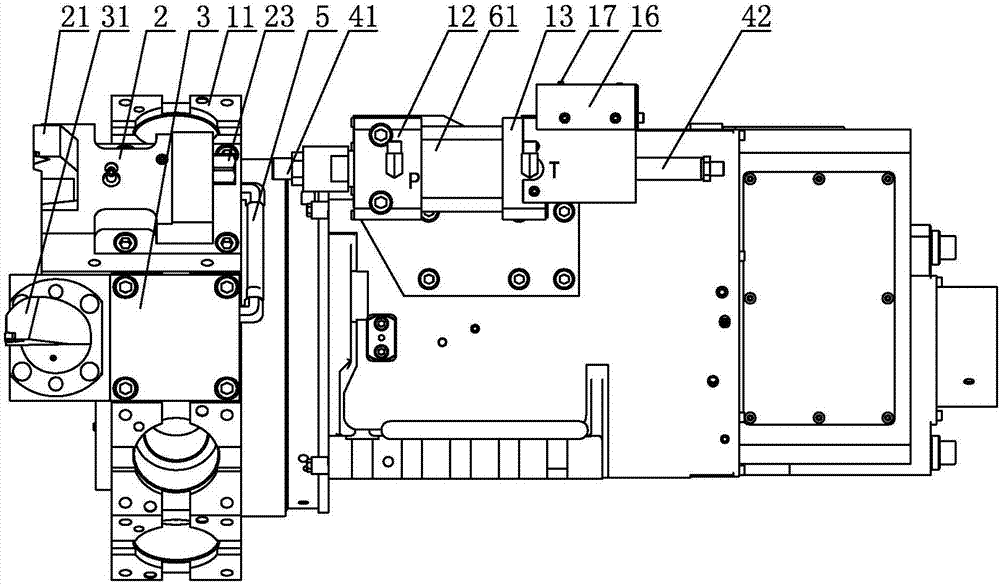

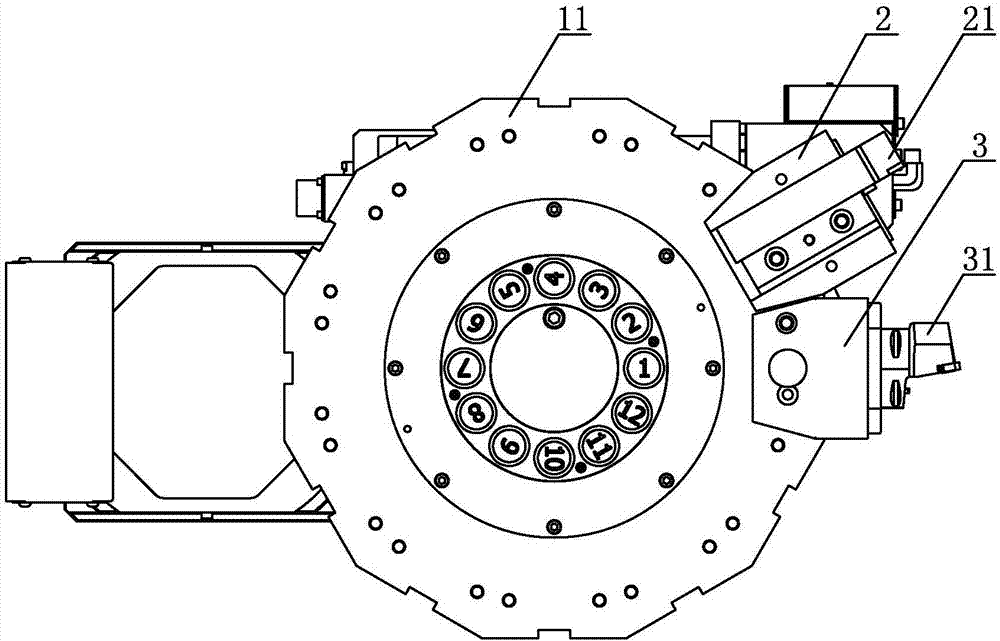

High-pressure water discharging cutter tower assembly of numerically-controlled lathe

ActiveCN107243653AMaximize utilizationGood chip breaking effectAuxillary equipmentTurning toolsWater dischargeWater channel

The invention discloses a high-pressure water discharging cutter tower assembly of a numerically-controlled lathe. The cutter tower assembly comprises a cutter tower, a first cutter holder, a second cutter holder and a water conveying pipe, wherein an excircle cutter is mounted on the first cutter holder; a threaded cutter is mounted on the second cutter holder; a first channel is formed in the first cutter holder; a second water channel is formed in the second cutter holder; the first water channel is connected with the second water channel through a steel pipe; a water outlet of the second water channel is connected with a central water discharging hole of the threaded cutter; a rapidly replaceable connector socket is mounted at a water inlet of the first water channel; a rapidly replaceable connector plug is mounted at a water outlet of the water conveying pipe; a water inlet of the water conveying pipe is connected with a high-pressure water pump with water discharging pressure of 20-30MPa; a driving mechanism is mounted on the cutter tower; the water conveying pipe is connected with the output end of the driving mechanism. The cutter tower assembly is capable of rapidly switching a threaded machining mode and an excircle machining mode, achieving threaded machining and excircle machining of the workpieces and spraying high-pressure water with pressure being higher than 20MPa from the threaded cutter in the threaded machining process; the problem of chip breaking in the threaded machining process can be effectively solved.

Owner:NINGBO HAITIAN PRECISION MASCH CO LTD

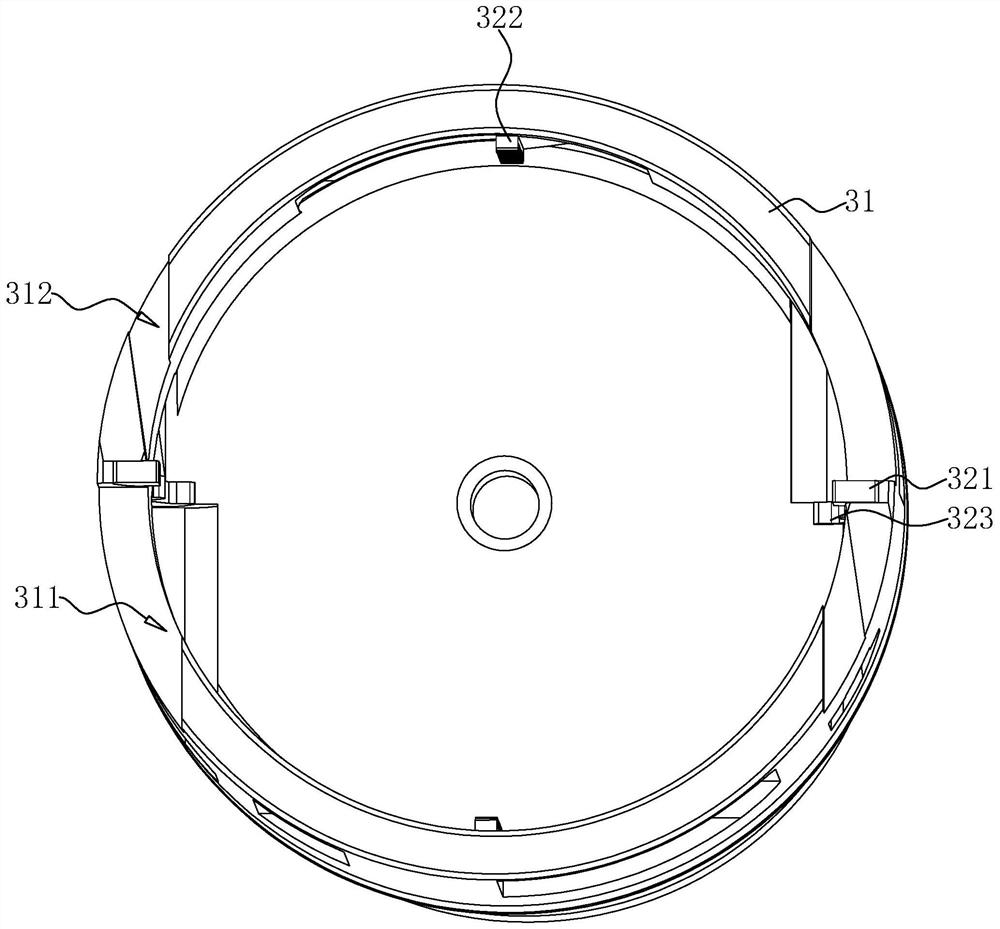

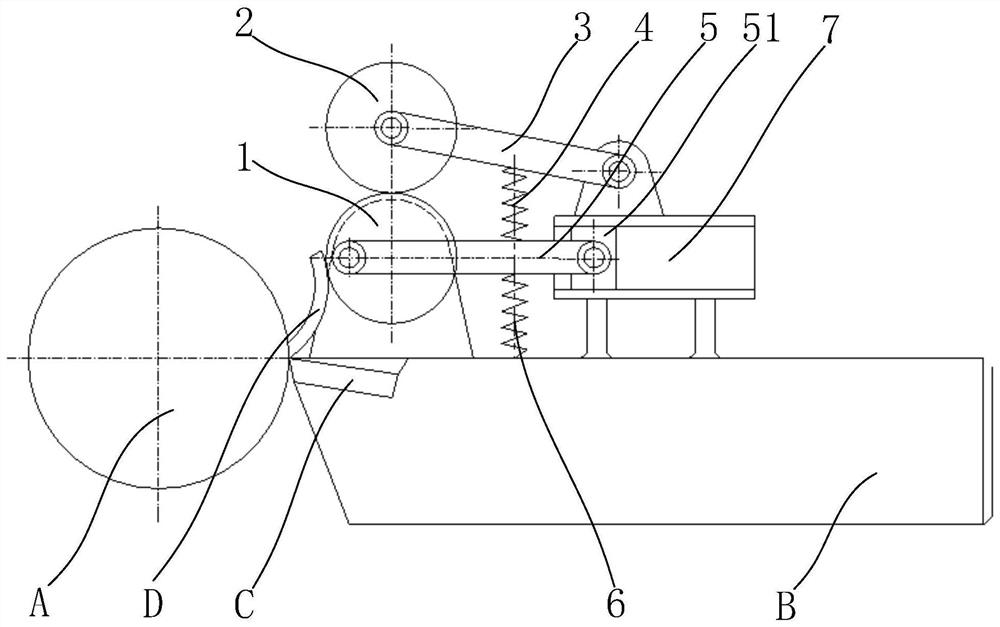

Chip breaking device of adjustable circular ultra-hard turning tool

Disclosed is a chip breaking device of an adjustable circular ultra-hard turning tool. The chip breaking device of the adjustable circular ultra-hard turning tool comprises a chip breaking block and a blade press plate, wherein the blade press plate is fixedly installed on a tool handle. The chip breaking block is located on the upper end face of a circular ultra-hard blade, and is characterized in that the circumferential surface of the chip breaking block is spiral, the spiral line is an archimedes spiral line or a hyperbolic spiral line or a fibonacci spiral line, and a chip breaking block angle adjusting mechanism is arranged between the blade press plate and the chip breaking block. The chip breaking device of the adjustable circular ultra-hard turning tool has the advantages that due to the facts that the circumferential surface of the chip breaking block is spiral, and the chip breaking block angle adjusting mechanism is arranged between the blade press plate and the chip breaking block, the chip breaking device can rotate the chip breaking block according to different cutting working conditions of the circular ultra-hard turning tool, the chip breaking effect of the chip breaking block can be optimal, and the adaptability is good; and due to the facts that fixation of the chip breaking device can be achieved by the use of the existing blade press plate of the ultra-hard turning tool, and the original structure of the circular ultra-hard turning tool does not need to be changed, the chip breaking device is easy to process, convenient to assemble and disassemble, and low in cost, and positioning and clamping of the chip breaking device are reliable and stable.

Owner:NINGBO UNIV

Vibration chip breaking device and lathe

ActiveCN110539009BConducive to intensifying plastic deformationIntensified plastic deformationTurning toolsStructural engineeringElectrical and Electronics engineering

The invention discloses a vibrating chip breaking device. The frictional force of chips generated from a workpiece drives the friction roller to rotate; the vibration wheel is arranged above the friction roller, and the distances between the outer periphery of the friction roller and the rotating shaft are different, and the friction roller drives the vibration wheel up and down. Ups and downs; one end of the swing rod is connected to the vibration wheel, so that the vibration wheel swings around the hinge shaft at the other end; one end of the vibration spring is connected to the swing rod, and the other end is supported by the handle, and the vibration spring provides upward elastic force to the vibration rod to maintain the movement of the vibration wheel ;Because the distance between the circumference of the friction roller and the rotating shaft is not equal, the distance between the friction roller and the workpiece changes periodically during the rotation of the friction roller, which changes the angle of the chip, which is beneficial to aggravate the plastic deformation of the chip, and the vibration wheel periodically The eccentric roller is vibrated to increase the deformation and breaking probability of chips, improve the effect of chip breaking, and make chips easier to break. The lathe of the present invention can achieve the same technical effect.

Owner:AKEMET (JIANGSU) FLUID CONTROL SYST CO LTD

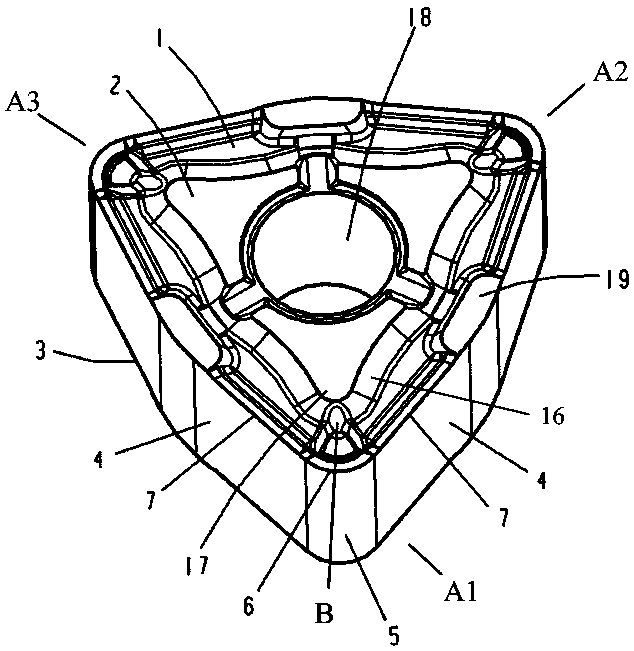

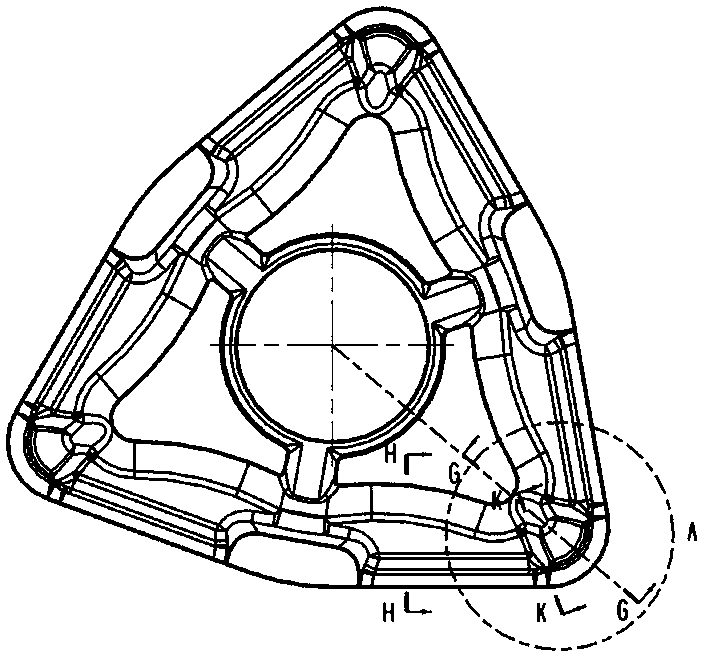

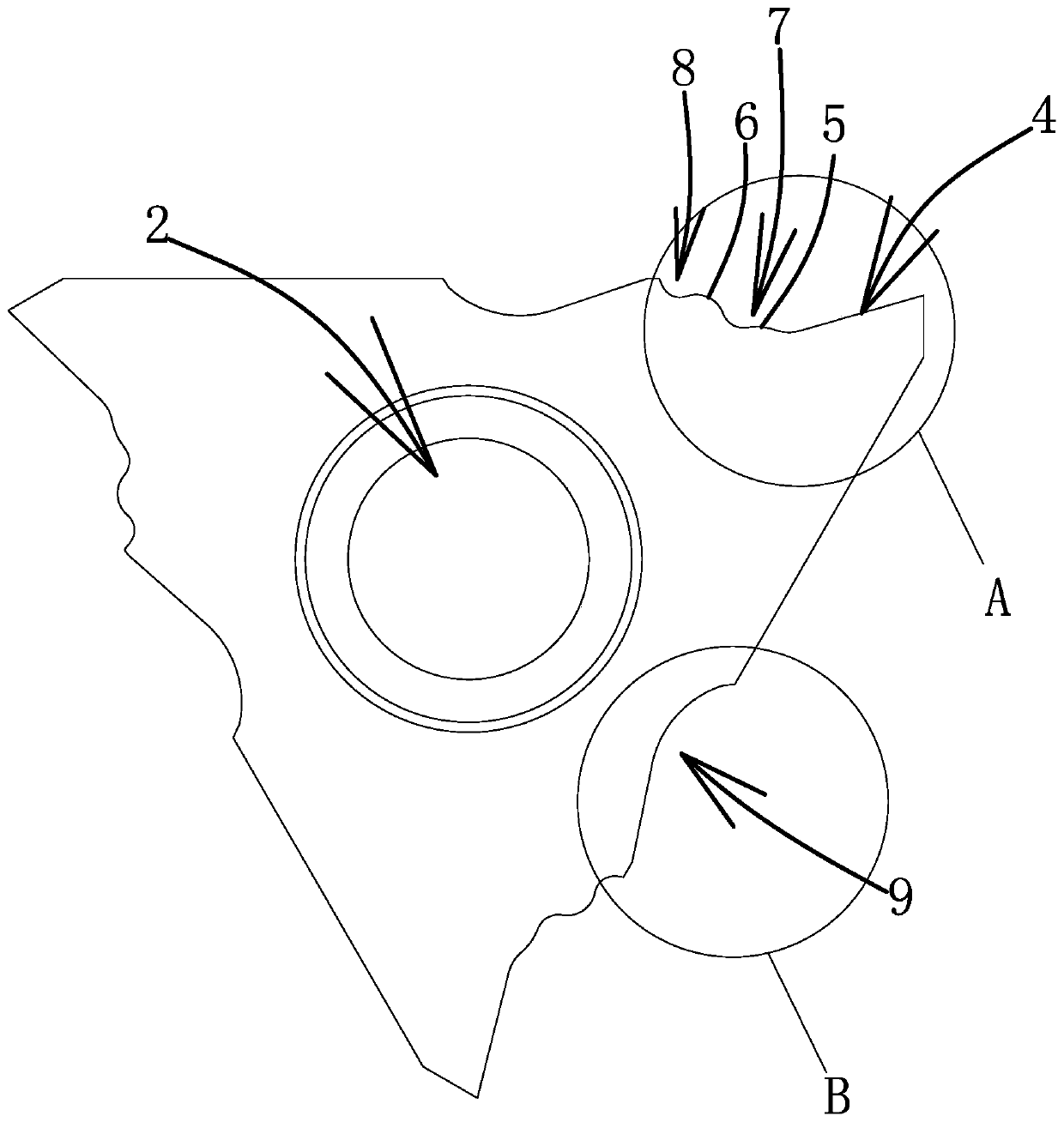

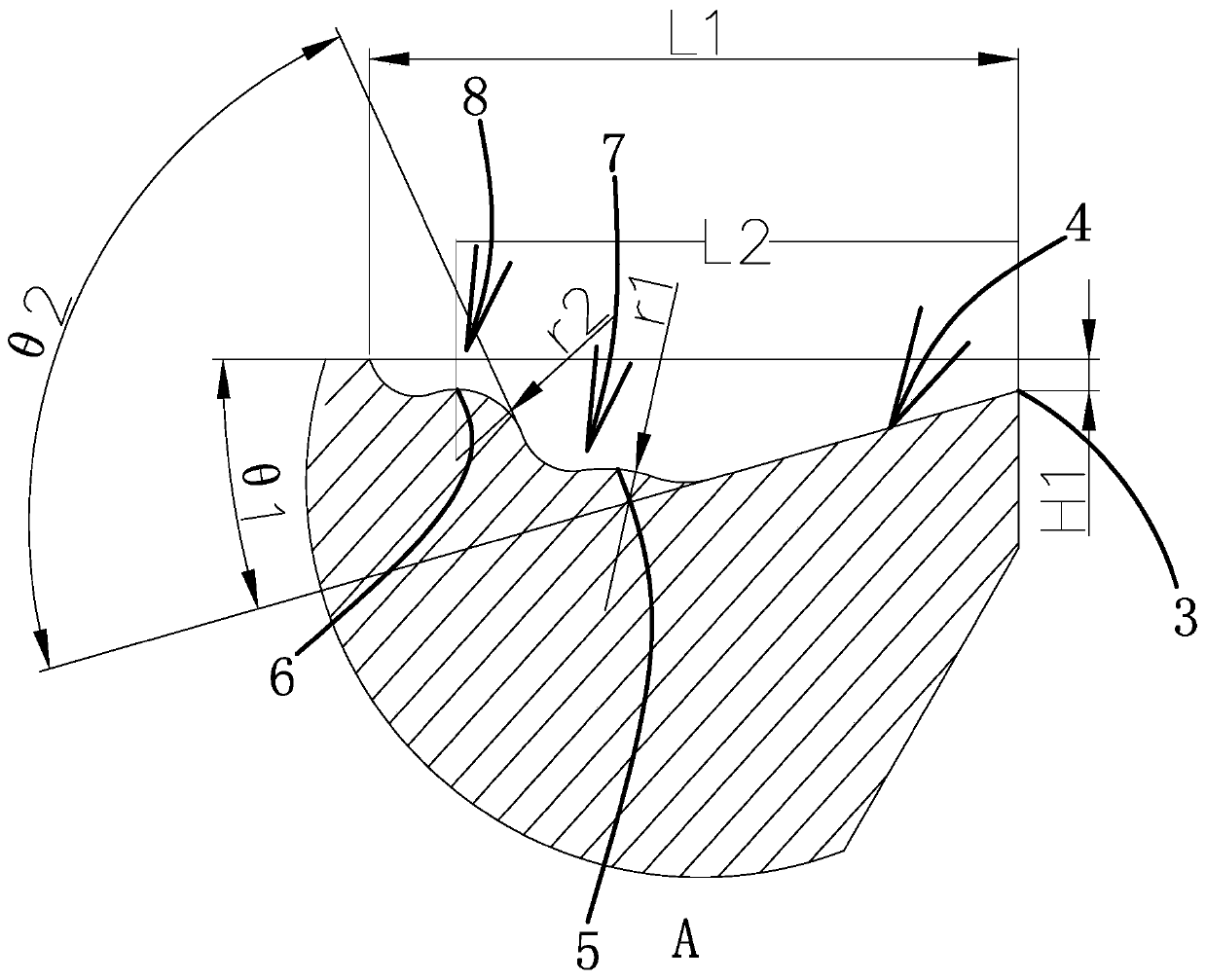

a grooving knife

ActiveCN109365891BPrecise positioningNot easy to shakeTransportation and packagingMilling cuttersStructural engineeringMachining

The invention provides a grooving knife, which belongs to the technical field of cutting tools. It solves the problem that the existing grooving knife is easy to shake after being used for a long time and the processing is not stable enough. The grooving knife comprises a triangular body, the middle part of the body is provided with mounting holes for screws to pass through, and cutting edges are provided at the three end corners of the body, and the cutting edges are all located on the side of the body. A chip breaker is provided on the rake face, a chip breaker is provided in the chip breaker, a limit groove is provided on the inner end of the body close to the chip breaker, and the sides of the limit groove are vertically arranged with the upper and lower end surfaces of the body. The grooving knife of the invention has the advantages of better positioning effect and higher processing precision.

Owner:台州市锐安硬质合金工具有限公司

PCBN blade with tree-shaped chip breaker groove

PendingCN111001832AEfficient and stable cuttingReduce cutting resistanceTurning toolsStructural engineeringBoron nitride

The invention discloses a PCBN blade with a tree-shaped chip breaker groove. The blade comprises a blade body, wherein the outline projection of the blade body is approximately polygonal, a screw fastening hole penetrating through an upper surface and a lower surface is formed in the thickness direction of the blade body, the screw fastening hole is approximately located in the middle, a cutting part made of the PCBN (Polycrystalline Cubic Boron Nitride) material is arranged at at least one corner position corresponding to the approximately polygonal shape of the blade body, the cutting part comprises a tool nose cutting edge corresponding to a vertex angle, side cutting edges on two sides of the tool nose cutting edge, and the tree-shaped chip breaker groove which extends from the cuttingedges to the screw fastening hole and is formed through laser machining. The blade is advantaged in that the blade is provided with the chip breaker groove for breaking scrap iron, so the blade is ensured to have the good chip breaking effect in the machining process, and further has good wear resistance and machining stability.

Owner:XIAMEN GOLDEN EGRET SPECIAL ALLOY

Chip breaking dragging wheel device for numerical-control machine tools

InactiveCN108723443AExquisite structureEasy to useBoring/drilling componentsMaintainance and safety accessoriesNumerical controlEngineering

The invention discloses a chip breaking dragging wheel device for numerical-control machine tools. The chip breaking dragging wheel device comprises a dragging wheel body. The dragging wheel body is of a cylindrical structure with an opening upper end, the upper end of the dragging wheel body is obliquely arranged, at least two arc-shaped grooves are formed in a side of the upper edge which are positioned between a highest point and a lowest point of the upper end of the dragging wheel body, the lowest points of the arc-shaped grooves are lower than the lowest point of the dragging wheel body,and a connecting hole is formed in the lower end of the dragging wheel body. The chip breaking dragging wheel device has the advantages that the chip breaking dragging wheel device is exquisite in structure and convenient to use; drill bits can be lifted to the surfaces of workpieces in each procedure, accordingly, good chip removing and breaking effects can be realized, and the drill bits are long in service life.

Owner:天长市永鑫制冷设备有限公司

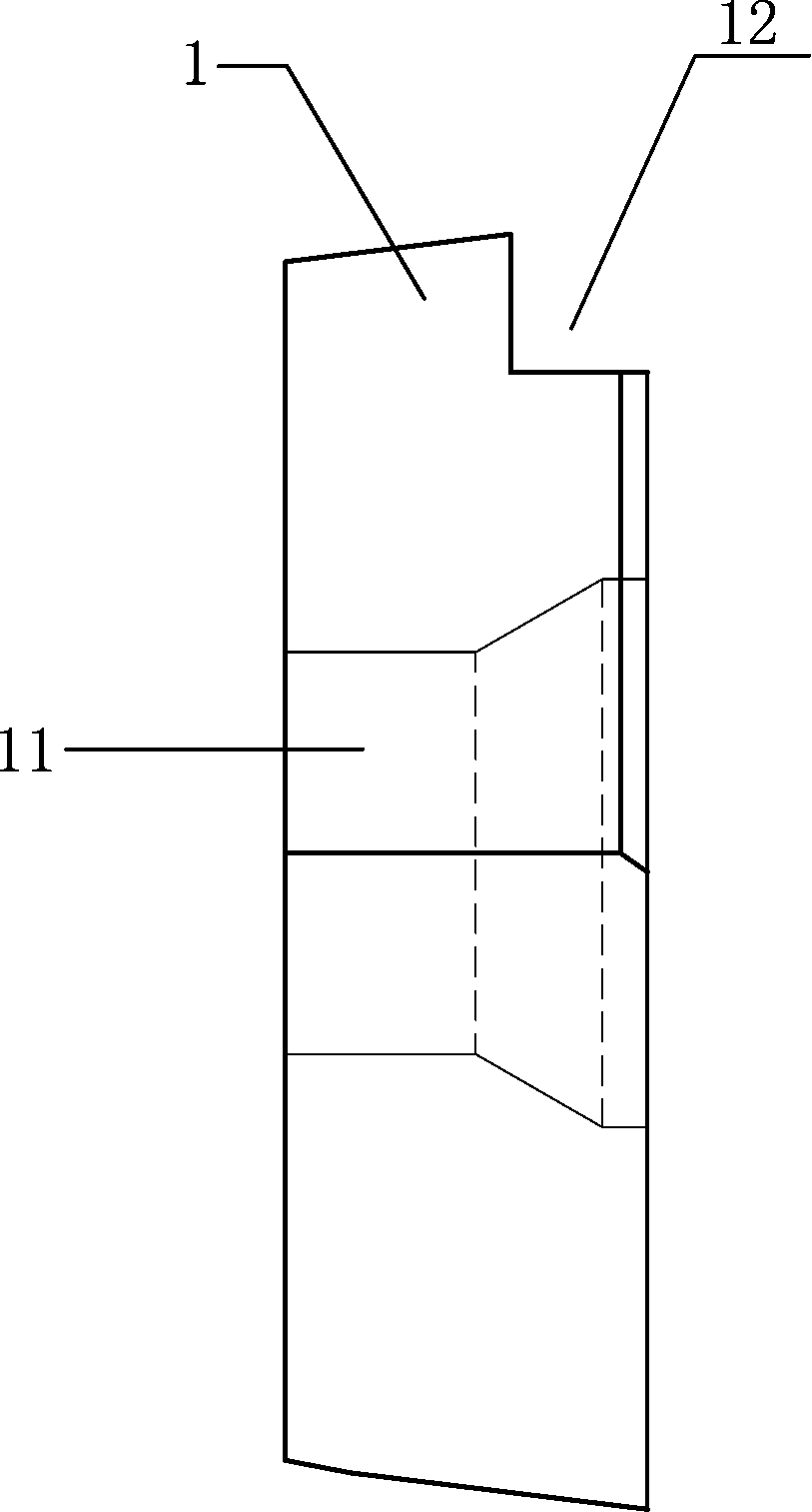

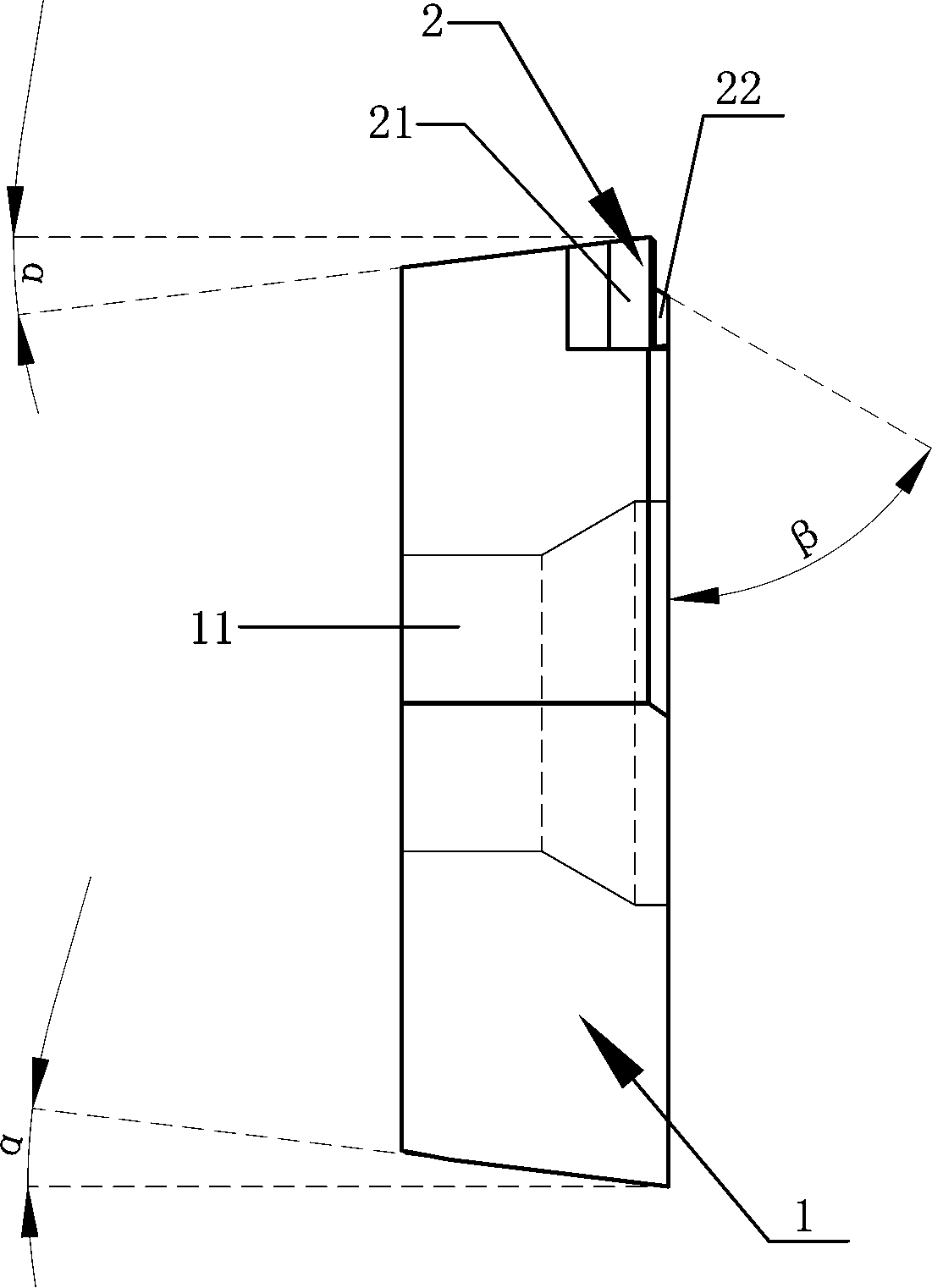

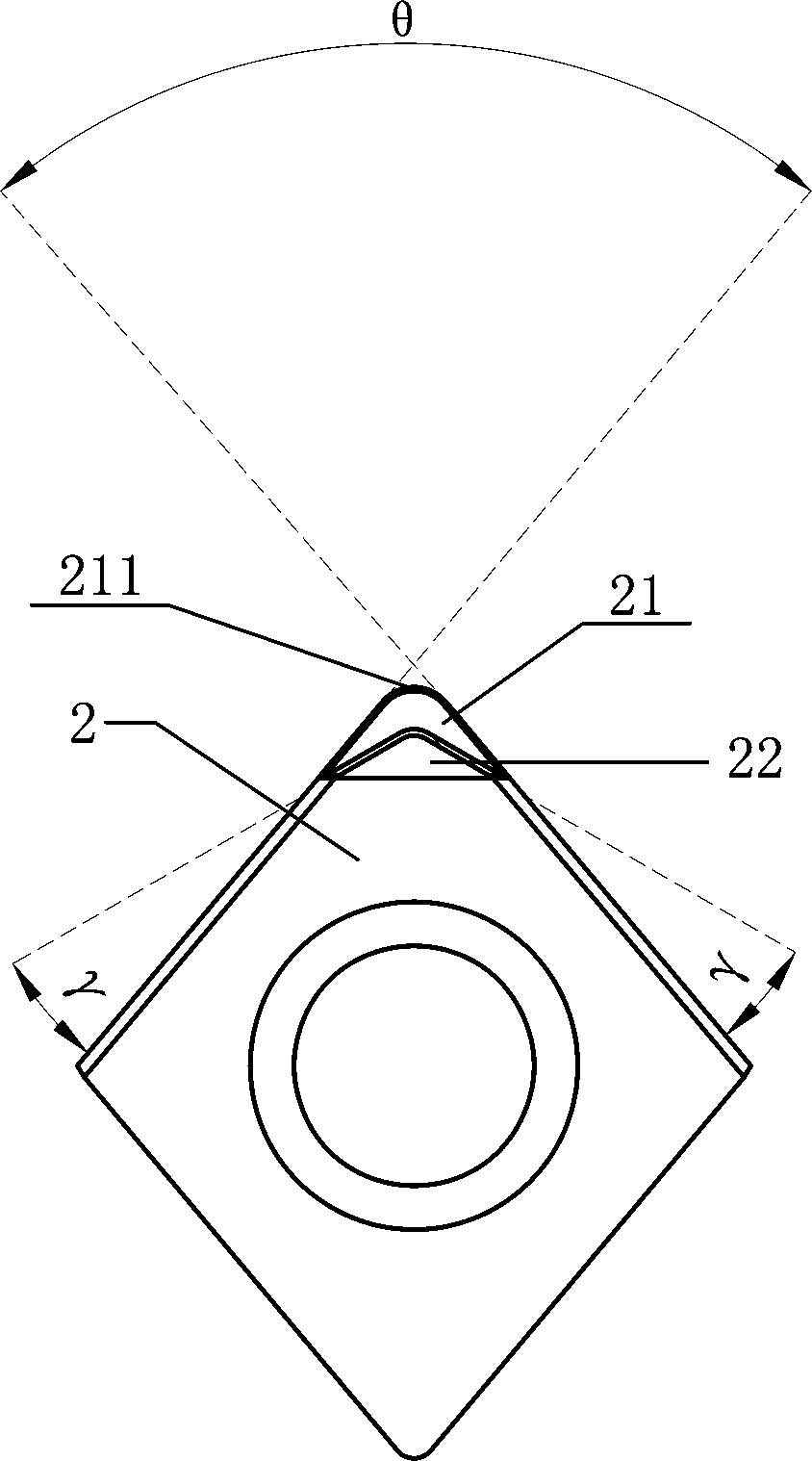

Turning tool capable of realizing chip breaking

The invention relates to the field of tools used for lathes or boring mills, in particular to a turning tool capable of realizing chip breaking. The turning tool capable of realizing chip breaking comprises a tool frame (1), and is characterized in that the turning tool further comprises a blade (2), wherein the tool frame (1) is a convex polygon, the number of sides of the convex polygon is not less than three, all the sides are equal, and at least one vertex angle of the tool frame (1) is cut inwards to form a blade groove (12); and the blade (2) comprises a cutting portion (21) and a chip breaking portion (22), the front portions of the top surfaces of the cutting portion (21) and the chip breaking portion (22) are separately formed by smoothly connecting the two ends of a section of inferior arc with a straight section, the front portion of the cutting portion (21) is a cutting edge (211), and the front end of the chip breaking portion (22) is an oblique plane. The turning tool capable of realizing chip breaking is simple in structure, convenient to use, good in chip breaking effect and high in adaptability.

Owner:上海新山田精密刀具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com