Complicated groove type milling cutter and method for machining chip breaker grooves of complicated groove type milling cutter

A chip breaker and milling cutter technology, which is applied in the direction of milling cutters, milling cutting inserts, metal processing equipment, etc., can solve the problems that the advantages of milling cutters have not been fully utilized, and it is not easy to take into account, so as to achieve good chip breaking effect and suppress chatter The effect of low capacity and edge wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

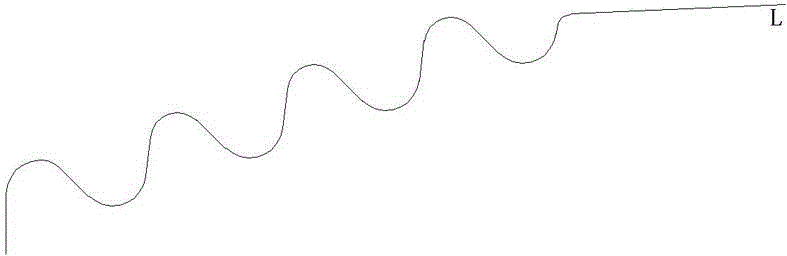

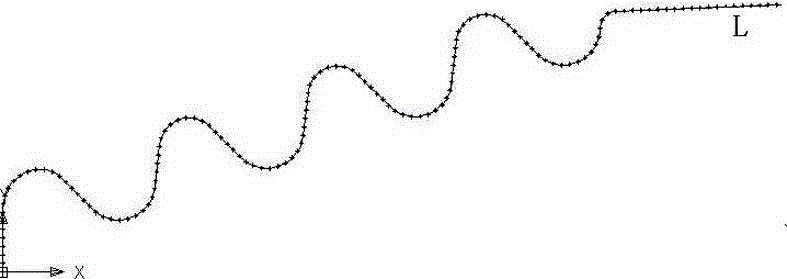

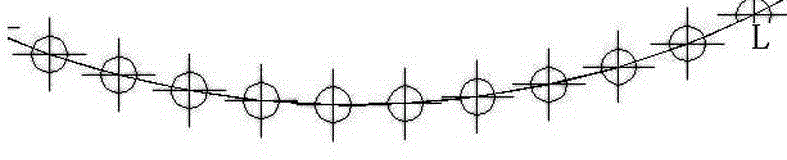

[0034] This milling cutter is specially used to process the Christmas tree (i.e. fir tree) shaped wheel groove on the assembly wheel of the moving blade of the steam turbine rotor. The cutting edge profile of the milling cutter is Christmas tree shape with 3 or 4 teeth. 10°, the helix angle is 3 to 10°, there is a chip breaker on the back of each tooth of the milling cutter that is consistent with the track of the cutting edge line, the line of these chip breakers is corrugated, and the chip breaker of each tooth The grooves are staggered in wavelength / tooth order in the helical direction of the milling cutter; see Figure 11 , the chipbreaker profile satisfies the following relationship:

[0035] R>r; and R = X 2 / (8Z)+Z / 2-r

[0036] The parameter definition in the formula:

[0037] X-wavelength, the distance between two adjacent peaks or troughs;

[0038] Z-wave depth, the sum of the upper half-wave amplitude and the lower half-wave amplitude;

[0039] R - the arc radiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com