Drill bit for processing deep hole with large length-diameter ratio

A large length-to-diameter ratio, drill bit technology, applied in boring/drilling, metal processing equipment, drilling/drilling equipment, etc., can solve the problems of high production cost, inconvenient grinding of drill tips, and difficult production. Achieve the effect of solving the problem of not easy chip breaking, improving the strength of the tool tip and improving the cutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

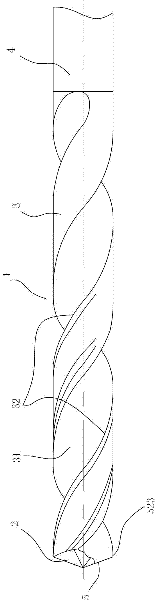

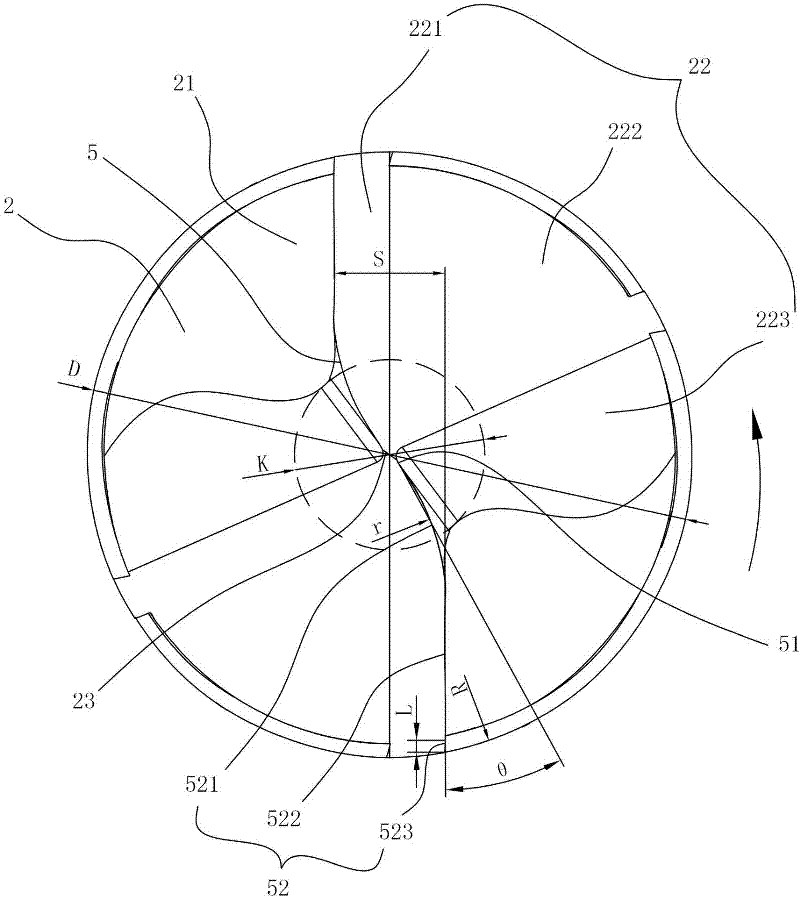

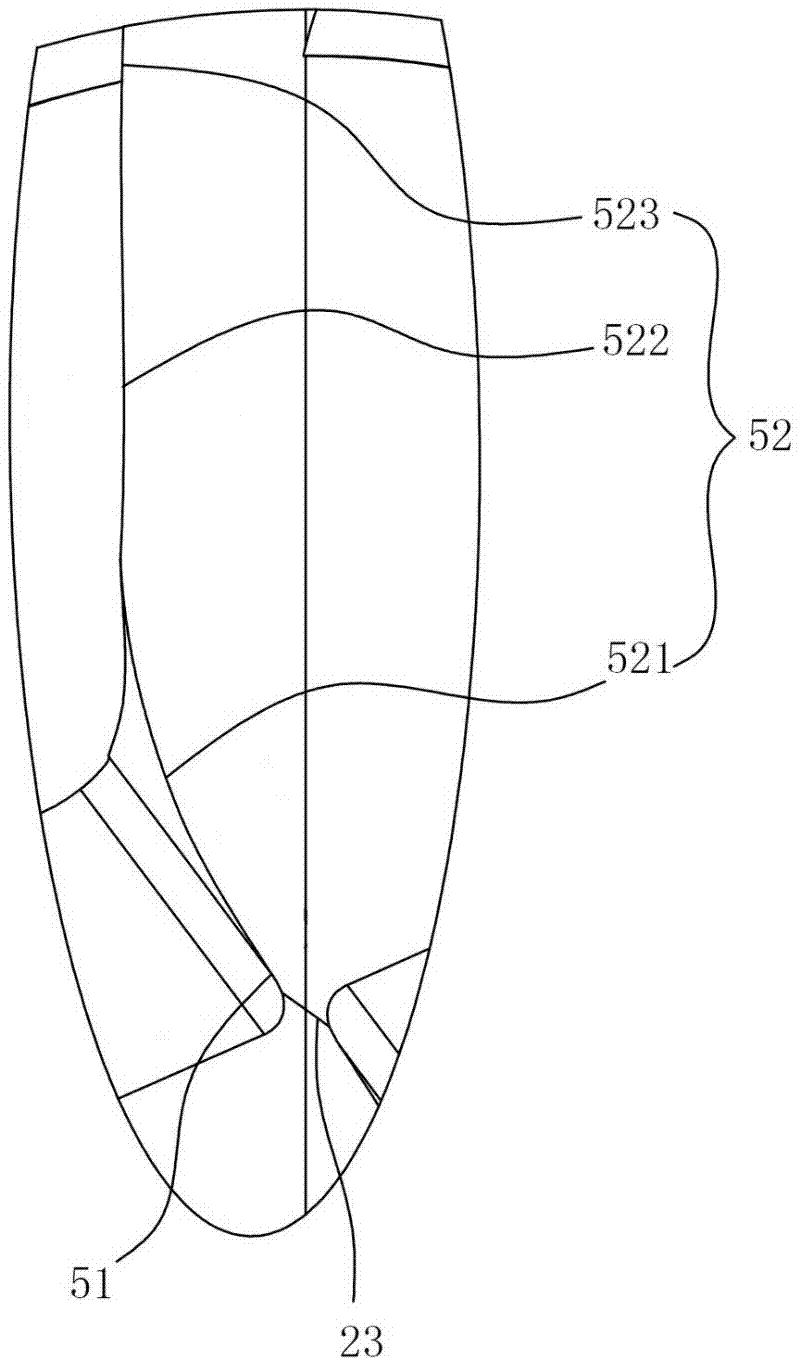

[0025] Figure 1 to Figure 8 It shows a drill bit embodiment of the present invention for deep hole machining with large length-to-diameter ratio. The drill bit includes a drill bit body 1. The drill bit body 1 includes a drill tip part 2, a chip removal part 3 and a shank part 4. The chip removal part 3. There are chip flutes 31 and minor cutting edges 32 extending from the drill tip 2 to the shank 4. The drill tip 2 is provided with a rake face 21, a relief face 22 and a chisel edge 23. The relief face 22 is defined by the angle The first rear face 221 , the second rear face 222 and the third rear face 223 which increase in sequence are formed. The rake face 21 intersects with the first rear face 221 to form a main cutting edge 5 . The main cutting edge 5 consists of a straight inner edge 51 and a curved outer edge 52 The linear inner edge 51 is connected with the chisel edge 23, and the curved outer edge 52 includes an arc cutting edge 523, a straight cutting edge 522, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com