PCBN blade with tree-shaped chip breaker groove

A chip breaker and blade technology, which is applied to tools used in lathes, accessories of toolholders, turning equipment, etc., can solve the problems of machining surface quality, poor chip breaking effect, and easy chip entanglement that affect machining efficiency. Achieving good chip breaking effect, overcoming chip breaking difficulties and reducing cutting resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

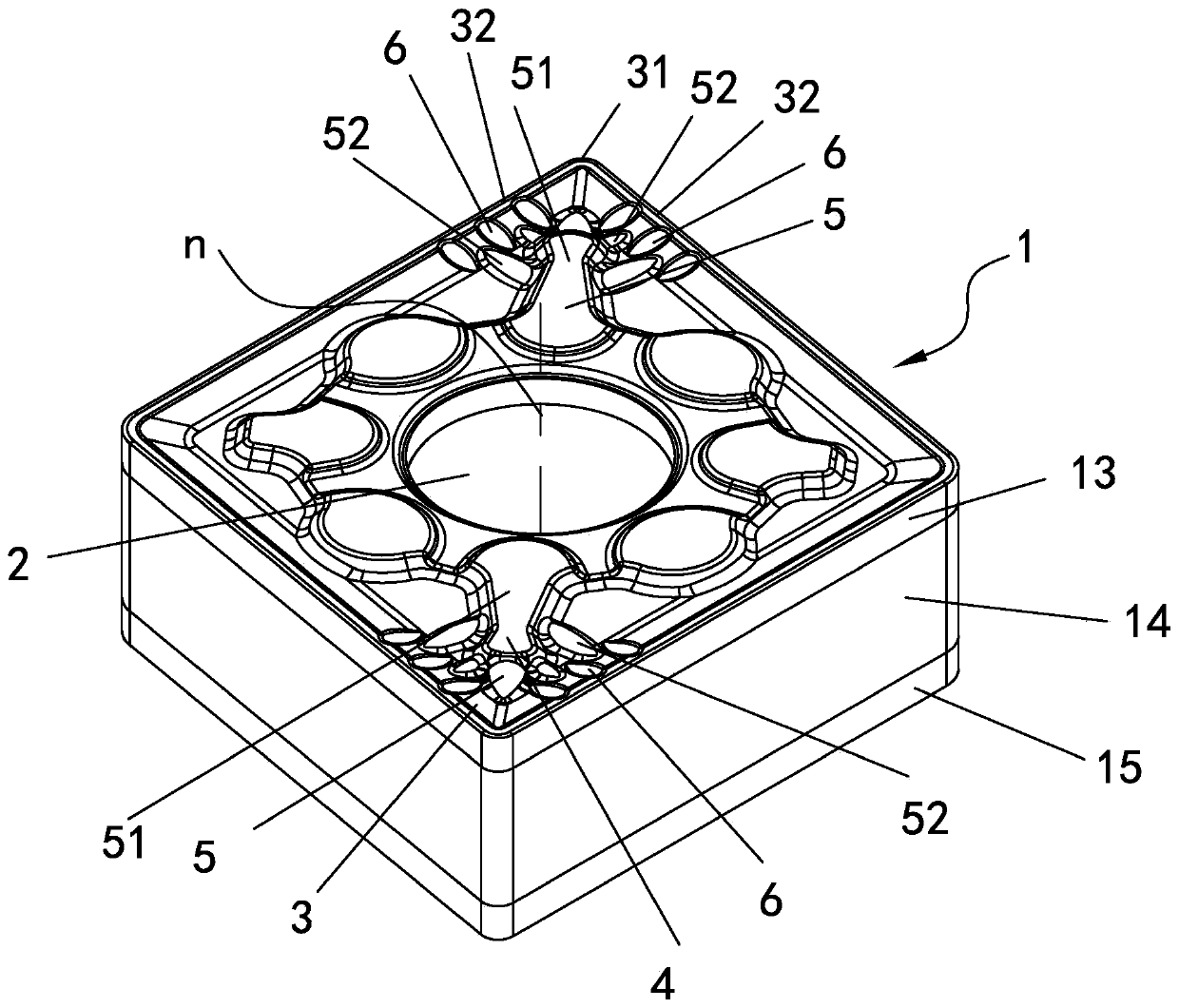

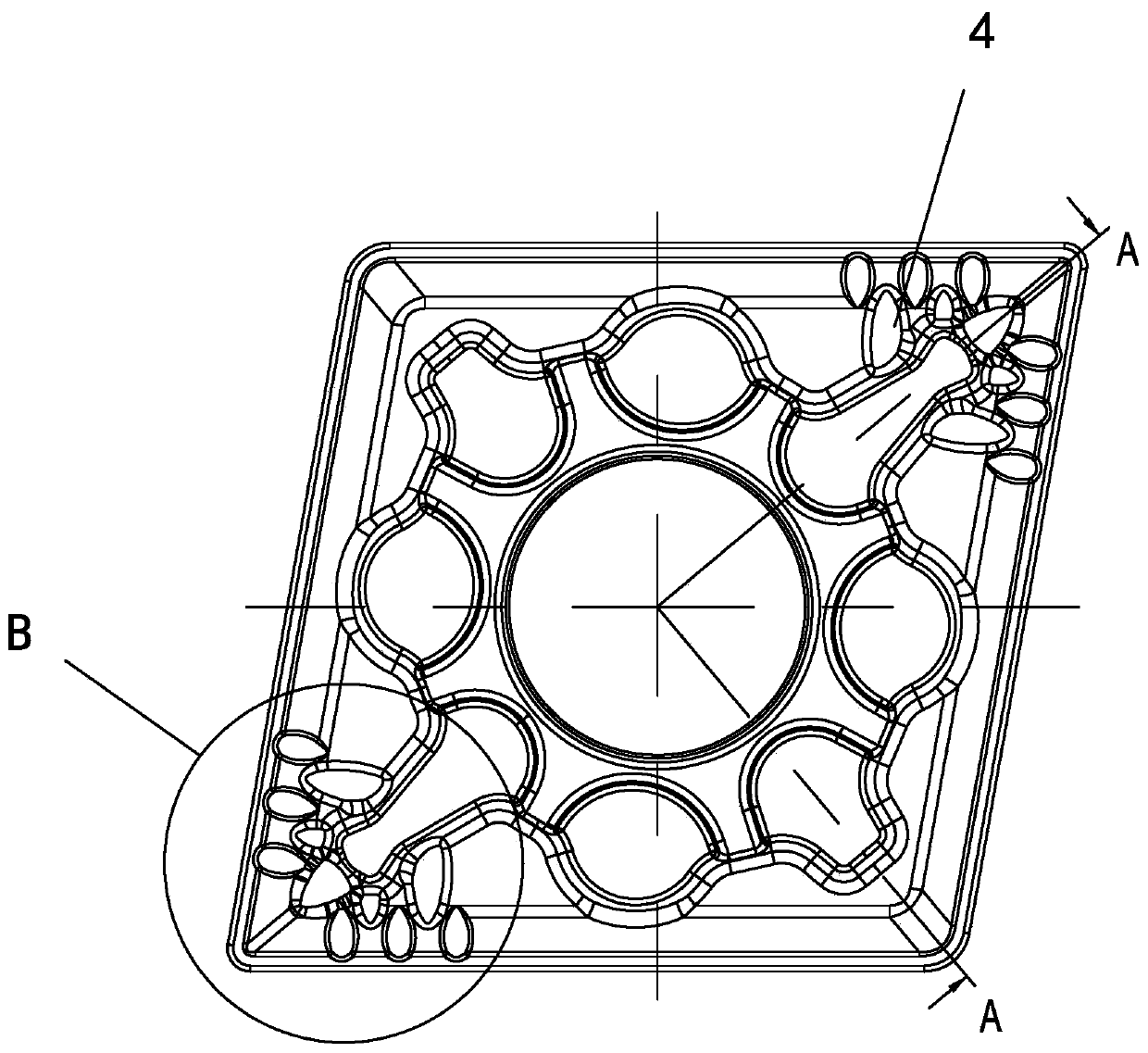

[0030] see Figure 1 to Figure 4 As shown, a PCBN insert with a tree-like chip breaker of the present invention includes a insert body 1, and the contour projection of the insert body 1 is roughly polygonal in shape; The screw fastening hole 2 on the lower surface 12, and the screw fastening hole 2 is in the roughly middle position; at least one corner position corresponding to the roughly polygonal shape of the blade body 1 is provided with a cutting portion 3 made of PCBN material; The cutting part 3 includes a cutting edge 31 corresponding to the top corner and side cutting edges 32 on both sides of the cutting edge, and a tree-shaped chip breaker formed by laser processing extending from the cutting edge to the screw fastening hole. Slot 4. The tree-shaped chip breaker 4 of the present invention is formed by laser processing, and compared with the traditional press-formed carbide structure groove, it has better physical and mechanical properties, longer tool life, and bet...

Embodiment 2

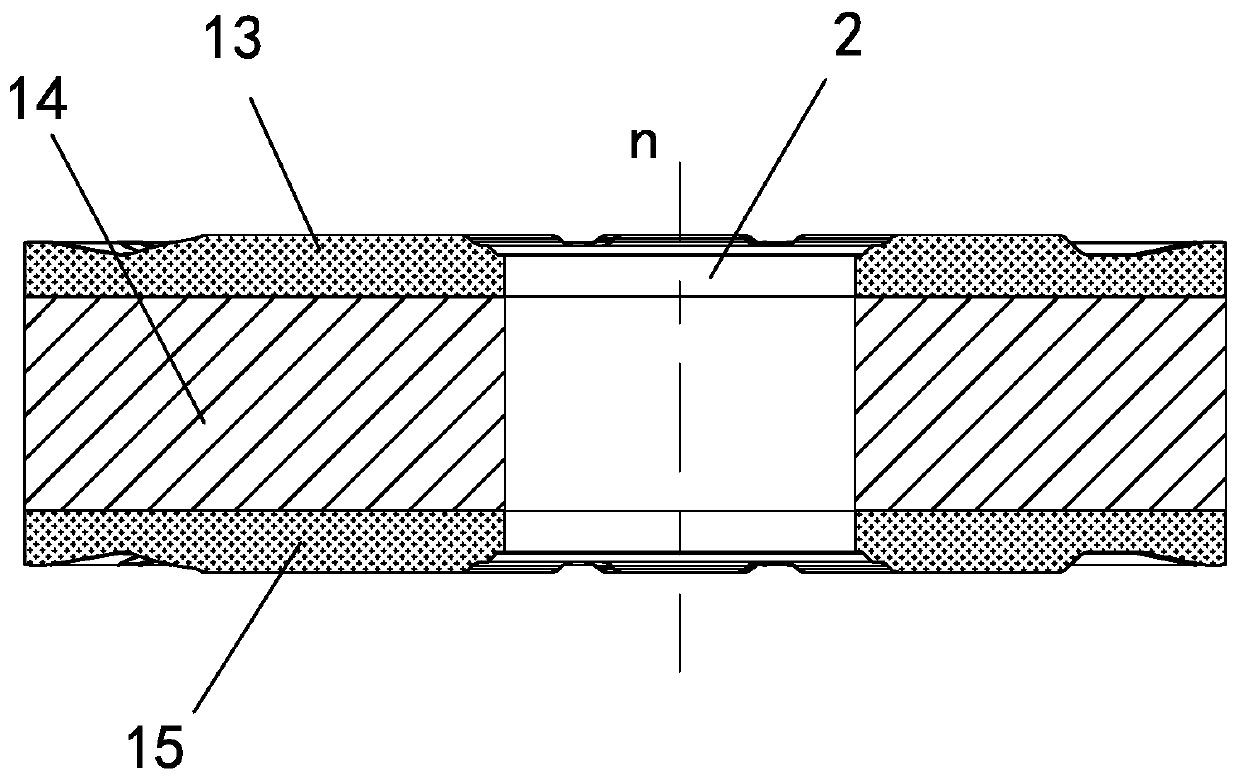

[0042] see Figure 5 As shown, a PCBN insert with a tree-shaped chip breaker of the present invention is different from Embodiment 1 in that the insert body 1 is composed of an upper layer of PCBN material layer 13 and a lower layer of cemented carbide material layer 14 As a result, there are only two layers of structure; the cutting part 3 is arranged at the corresponding corner position of the upper layer 13 of the blade body. The invention belongs to a single-sided blade, which has only two processing positions and is generally economical, but it can bear relatively large cutting and load, the blade has good installation stability, and is suitable for rough machining.

Embodiment 3

[0044] see Image 6 As shown, a PCBN insert with a tree-shaped chip breaker of the present invention is different from Embodiment 1 in that the insert body 1 is made of integral PCBN material, and the cutting part 3 is arranged on the insert body The corresponding corner positions of the upper surface and\or lower surface of . The present invention can be a single-sided blade or a double-sided blade. The present invention does not need high-temperature and high-pressure sintering process, and the PCBN wool material is directly made into a PCBN blade with a tree-shaped chip breaker through grinding and laser processing. The chip breaker can be placed on one of the surfaces of the wool material or With upper and lower surfaces, the PCBN insert can realize rough, fine and semi-finish processing in different working conditions, with a wide range of processing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com