A kind of PE pipe material and its processing system and processing method

A processing system and pipe technology, applied in the field of pipe processing, can solve the problems of uneven and rough cutting surface, affecting installation, economic loss, etc., and achieve the effect of scientific and reasonable processing method, convenient post-installation, efficient and stable cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

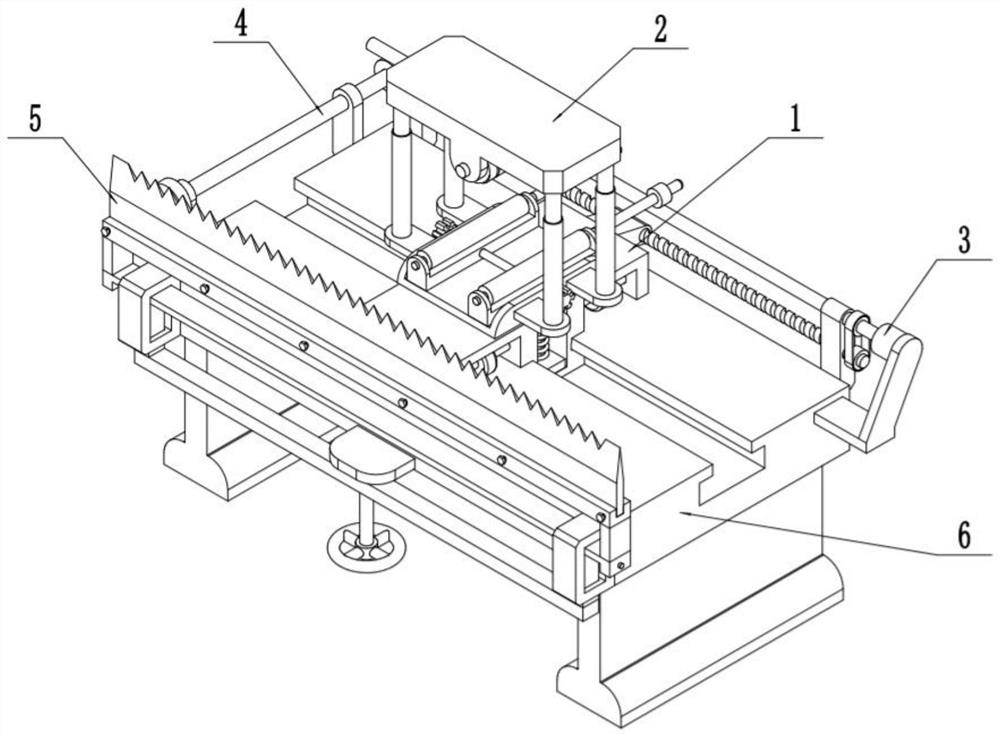

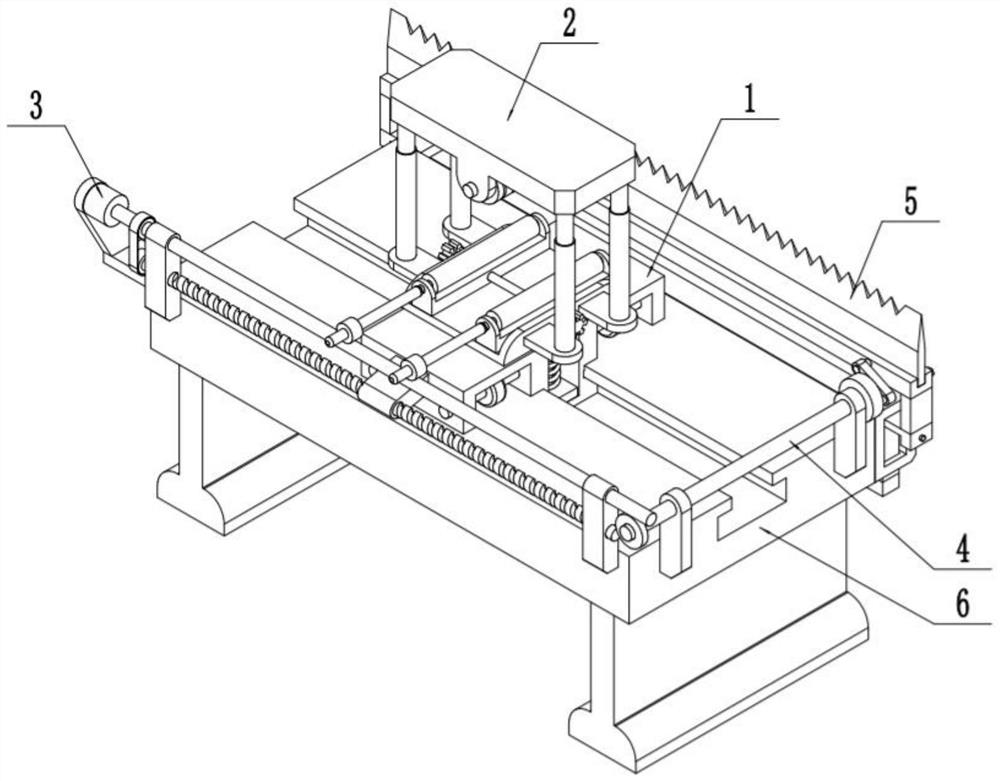

[0038] Such as Figure 1-11As shown, a PE pipe processing system includes a movable seat 1, a clamping device 2, a driving device 3, a linkage device 4, a pipe cutting device 5 and a processing frame 6, and the movable seat 1 is slidably connected to the processing frame 6 Above; the clamping device 2 is slidably connected to the movable seat 1; the driving device 3 is fixedly connected to the processing frame 6; the driving device 3 is transmission-connected to the movable seat 1, the clamping device 2 and the linkage device 4; The linkage device 4 is fixed on the processing frame 6 ; the linkage device 4 is connected to the pipe cutting device 5 through transmission; When the PE pipe processing system described above processes PE pipes, the PE pipes are installed on the clamping device 2; the position of the pipe cutting device 5 is adjusted to make it contact with the pipe surface of the PE pipes, and to generate upward pressure on the PE pipes. The pressure; connect the d...

Embodiment 2

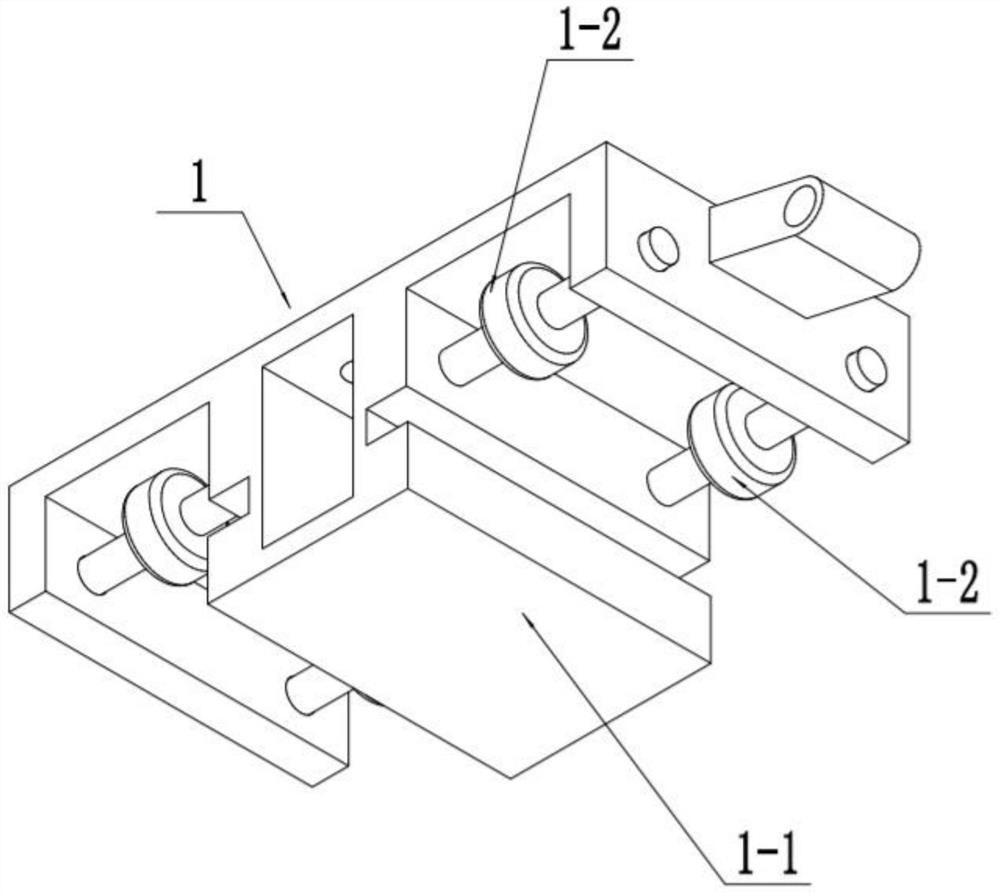

[0040] Such as Figure 1-11 As shown, the movable seat 1 includes a sliding seat body 1-1 and auxiliary wheels 1-2; the middle part of the lower end of the sliding seat body 1-1 is slidingly fitted in the T-shaped chute of the processing frame 6; the sliding The front and rear sides of the lower end of the seat body 1-1 are respectively rotated and connected to two auxiliary wheels 1-2; the wheel surfaces of the two auxiliary wheels 1-2 are rolled and fitted on the processing frame 6; the driving device 3 is connected by transmission and sliding Seat body 1-1. After the driving device 3 starts, it can drive the lower end of the sliding seat body 1-1 to slide in the T-shaped chute of the processing frame 6, and the auxiliary wheel 1-2 rolls on the top surface of the processing frame 6, driven by the sliding seat body 1-1. The clamping device 2 and the PE pipe on the clamping device 2 move horizontally.

Embodiment 3

[0042] Such as Figure 1-11 As shown, the clamping device 2 includes an upper seat 2-1, a lower seat 2-2, an electric push rod 2-3, an upper clamping tube 2-4, a lower clamping tube 2-5, a rotating shaft 2-6, a first worm gear 2-7, sliding frame 2-8, two-way screw rod 2-9, turntable 2-10, sliding column 2-11, compression spring 2-12 and horizontal plate 2-13; the lower end of the lower seat 2-2 is fixedly connected Two sliding columns 2-11, the two sliding columns 2-11 are slidingly fitted on the processing frame 6, the lower ends of the two sliding columns 2-11 are fixedly connected with a horizontal plate 2-13, and the horizontal plate 2-13 is slidingly fitted on the In the central groove of the processing frame 6; the sliding column 2-11 is covered with a compression spring 2-12, and the compression spring 2-12 is located between the horizontal plate 2-13 and the top surface of the central groove; the lower seat Two electric push rods 2-3 are respectively fixedly connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com