Double-faced woolen fabric cutting device

A technology of double-faced woolen and fabrics, which is applied in the cutting of textile materials, processing of thin materials, transportation and packaging, etc. Cutting problems such as low degree of automation in processing to achieve the effect of avoiding looseness and disorder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

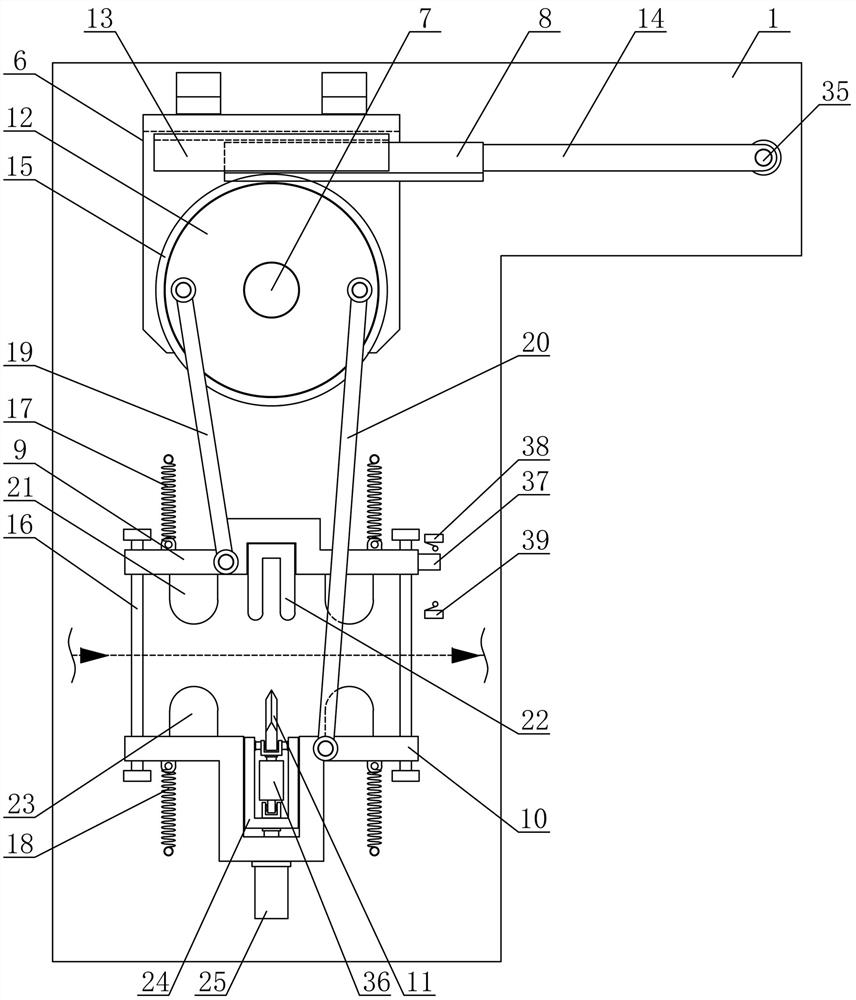

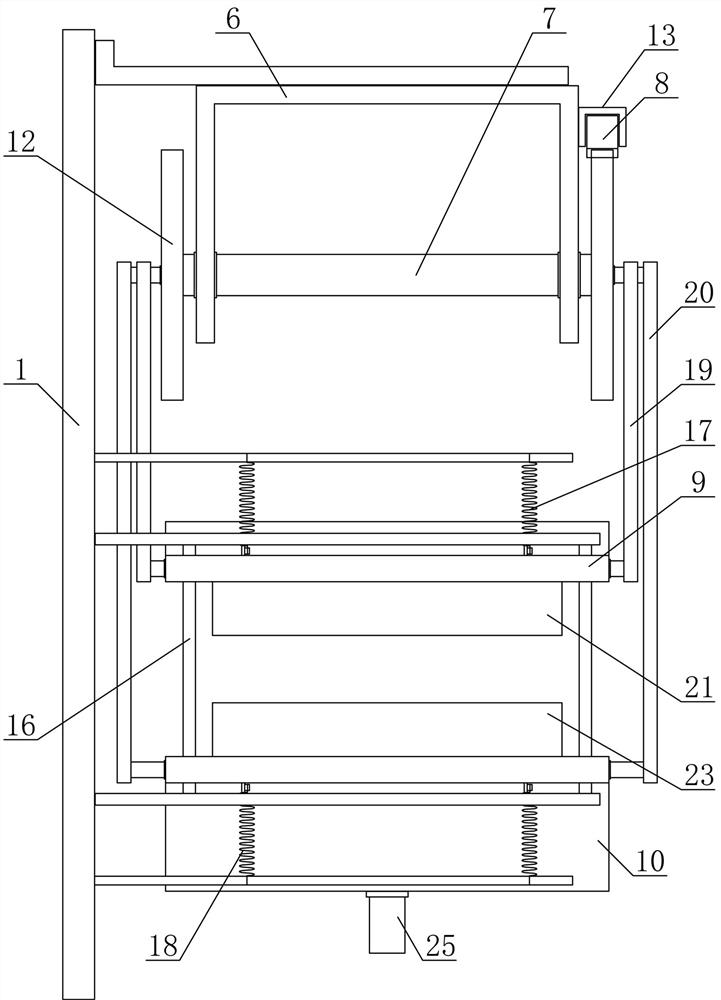

[0027] In order to further describe the present invention, a specific implementation of a double-faced wool fabric cutting device will be further described below in conjunction with the accompanying drawings. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

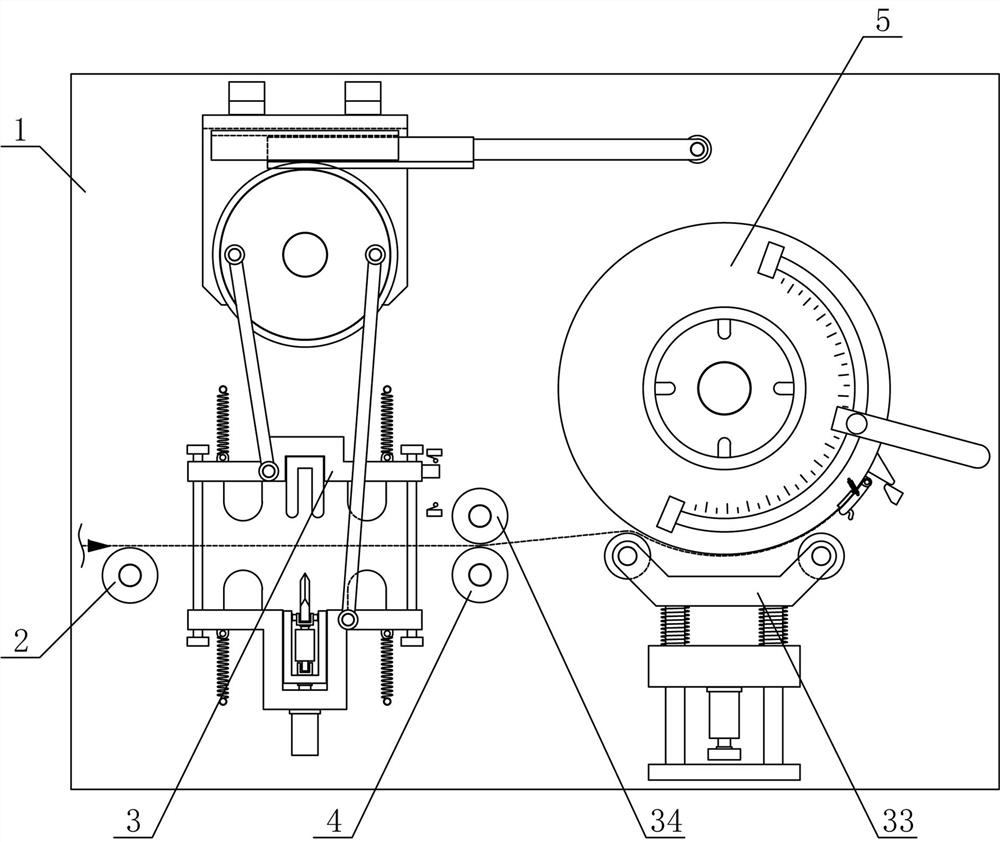

[0028] Such as figure 1 Shown, a kind of double-faced cloth fabric cutting device of the present invention comprises fabric processing support 1, feed conveying roller 2, fabric press-cutting mechanism 3, guide material conveying roller 4 and fabric roll pulling and turning roller 5, fabric pressing The cutting mechanism 3 and the fabric roll pulling roller 5 are sequentially arranged on both sides of the fabric processing support 1 along the fabric conveying direction, and the feeding conveying roller 2 and the material guiding conveying roller 4 are horizontally rotated sequentially along the fabric conveying direction and connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com