PCD forming sleeve milling cutter

A technology of forming sleeves and milling cutters, which is applied in the direction of milling cutters, milling machine equipment, manufacturing tools, etc., can solve the problems of inconvenient cutting, reducing the overall rigidity of the cutting tool, and scratches on the workpiece surface, so as to reduce the possibility of cutter vibration and solve the problem of Insufficient cutting space, good rigidity and structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following is attached Figure 1-2 The application is described in further detail.

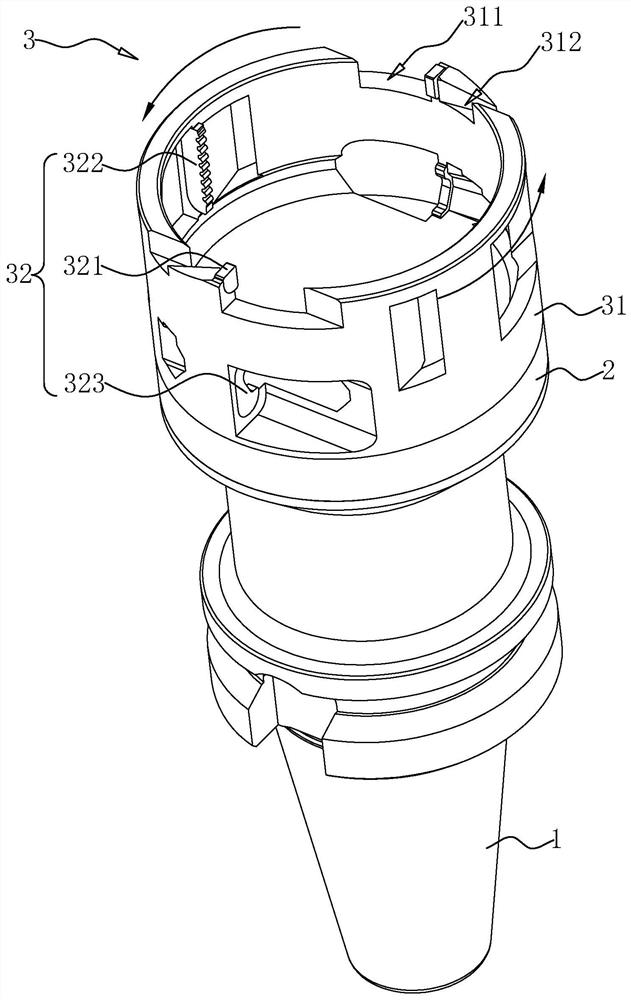

[0029] The embodiment of the present application discloses a PCD forming sleeve milling cutter, refer to figure 1 , including a knife handle 1, a knife neck platform 2 and a knife head 3, and the three are arranged in sequence. More specifically, the knife handle 1 can be a BT30 knife handle, the knife neck platform 2 is integrally formed at one end of the knife handle 1 , and the knife head 3 is fixed on the side of the knife neck platform 2 away from the knife handle 1 .

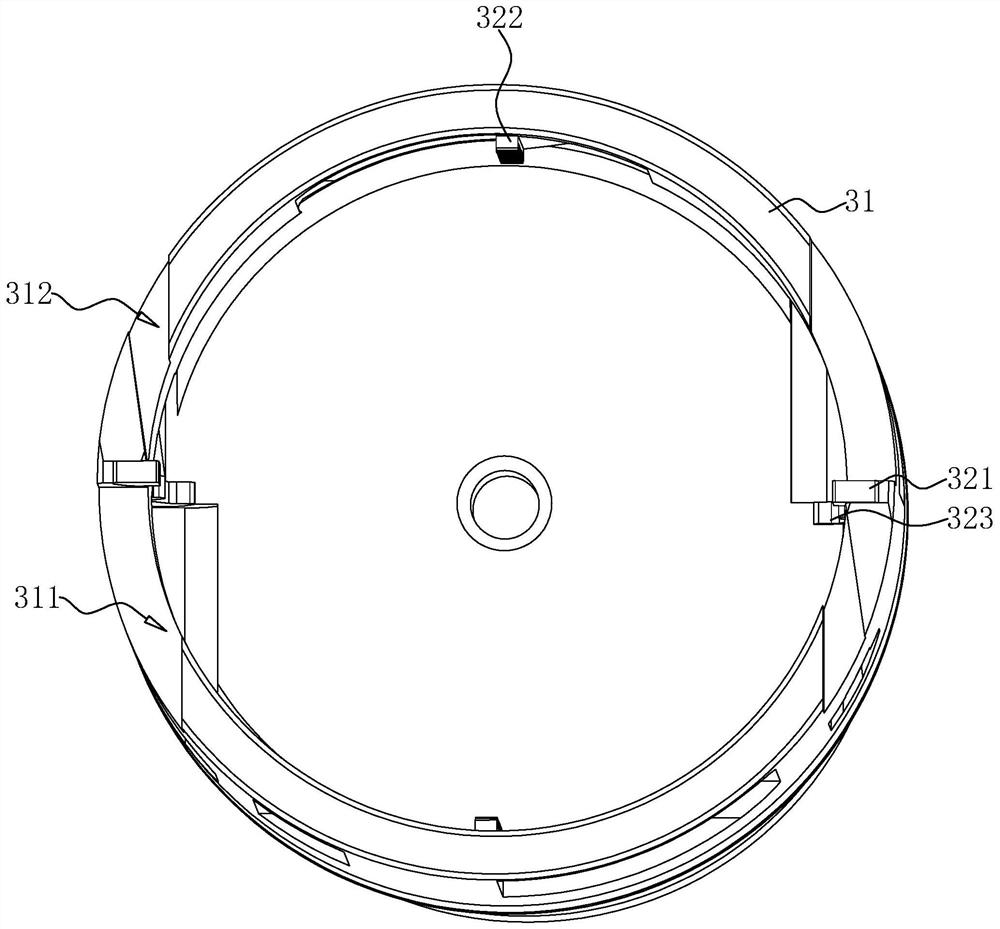

[0030] The cutter head 3 includes an annular tool rest 31 fixed on the knife neck platform 2 and a cutter body 32 installed on the inner wall of the annular tool rest 31. The diameter of the annular tool rest 31 is greater than the diameter of the workpiece to be processed. Specifically, the annular tool rest 31 The size of the rotating ring can enter the limited space of the workpiece to be processed without ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com