a grooving knife

A grooving knife and chip breaker technology, which is applied in the direction of milling cutting blades, milling cutters, manufacturing tools, etc., can solve the problems that the grooving knife is easy to shake and the processing is not stable enough, so as to improve the surface finish, good positioning effect, Effect of reducing chip removal strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

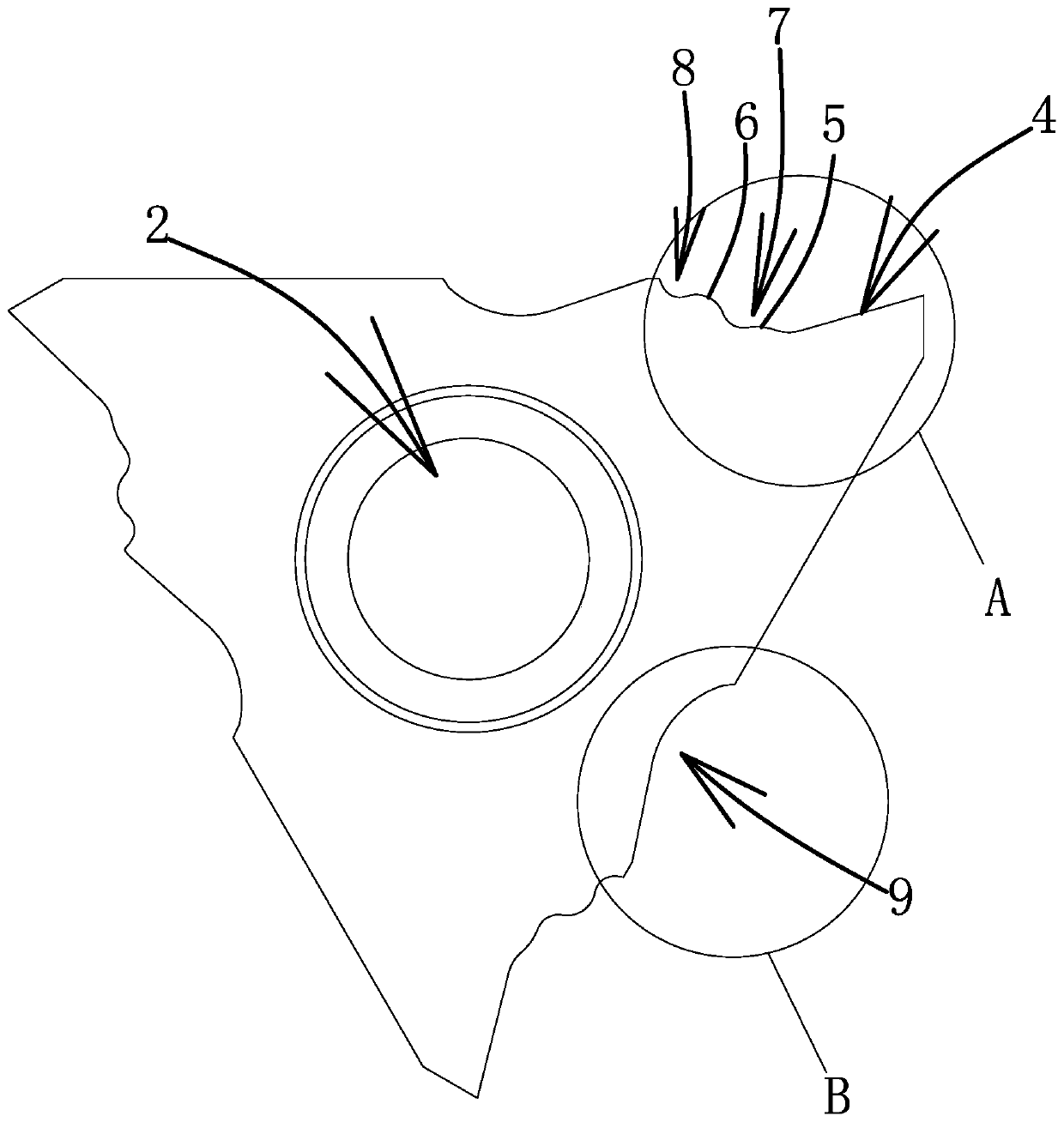

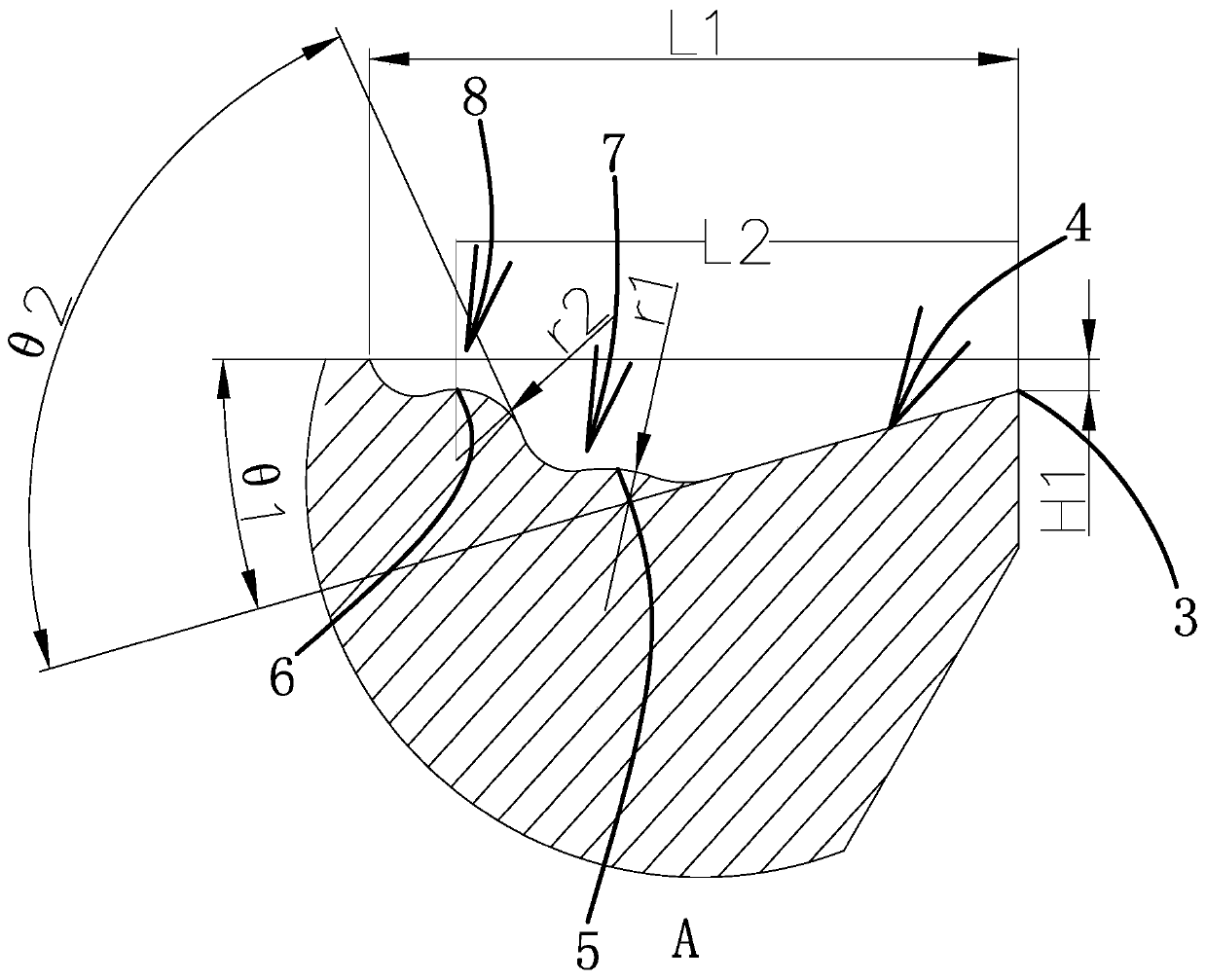

[0032] Such as Figures 1 to 5 As shown, a grooving knife includes a triangular body 1, the middle of the body 1 is provided with a mounting hole 2 for screws to pass through, and the three end corners of the body 1 are provided with cutting edges 3, and the cutting edges 3 are all Located on the side of the main body 1, a chip breaker is provided on the rake face 4 of the cutting edge 3, and a chip breaker is provided in the chip breaker. The chip breaker includes a protruding front chip breaker 5 and a rear chip breaker 6 set in the chip breaker. The front chip breaker 5 is arc-shaped and transitions smoothly with the rake face 4. The front chip breaker 5 is located Between the cutting edge 3 and the rear chip breaker 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com