Longitudinal ultrasonic vibration turning device based on engine lathe

A technology of ultrasonic vibration and ordinary lathes, which is applied in the direction of turning equipment, auxiliary devices, toolholder accessories, etc., can solve the problems of high manufacturing cost, small application range, unfavorable popularization, etc., and achieve the reduction of surface roughness and cutting force. Processing effect, effect of reducing economic cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in combination with the accompanying drawings, and specific implementation methods will be given.

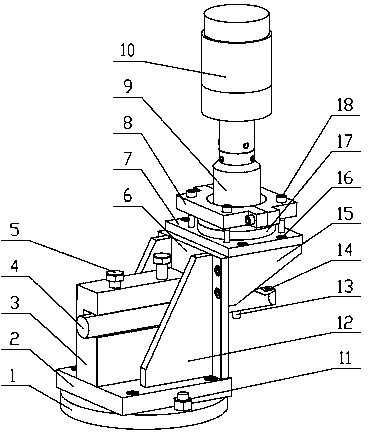

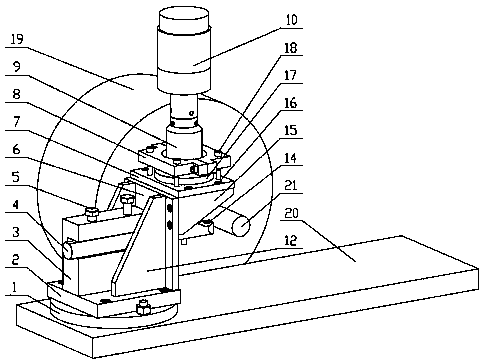

[0024] Such as Figure 1-5 As shown, the present invention is a longitudinal ultrasonic vibration turning device based on an ordinary lathe, including an ultrasonic vibration system, a special fixture, and an ordinary lathe, and the ultrasonic vibration system and the ordinary lathe are connected together through a special fixture.

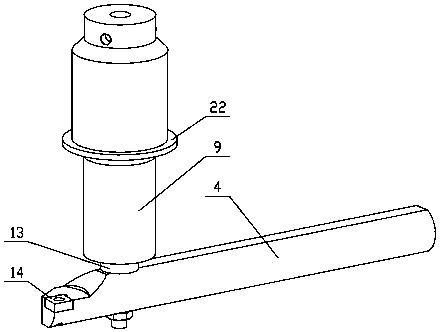

[0025] The ultrasonic vibration system is the core and key of ultrasonic machining. It can make the blade obtain a certain amplitude of ultrasonic vibration to act on the workpiece, thereby realizing ultrasonic vibration turning processing. The ultrasonic vibration system includes the cutter bar 4, the ultrasonic horn 9, and the ultrasonic transducer 10, special screw rod 13, blade 14, outer flange 17, inner flange 22, flange screw 23.

[0026] The connection between the cutter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com