High-efficiency chip-breaking wear-reducing double-sided diamond turning tool blade under high-pressure cooling

A blade and chip breaking technology, which is applied in the field of high-efficiency chip breaking and wear-reducing double-sided diamond turning blades, can solve the problems of high cutting temperature, tool wear, and large cutting force, so as to reduce cutting temperature, prolong service life, and reduce cutting resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

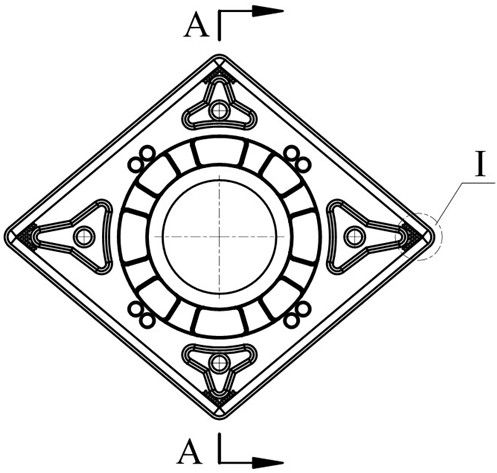

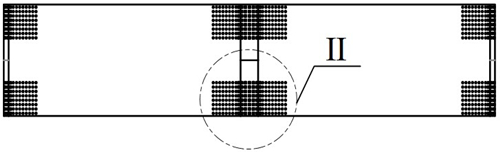

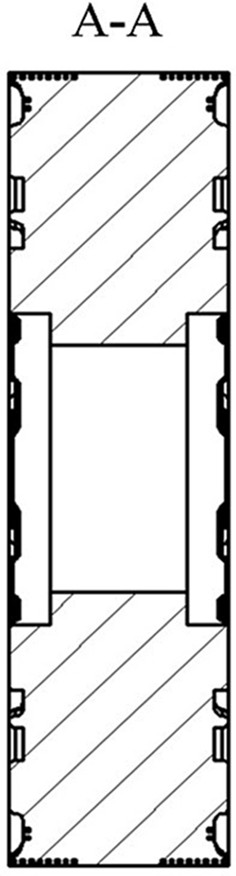

[0020] Specific implementation mode one: combine Figure 1-Figure 6 Describe this embodiment. The high-efficiency chip-breaking and wear-reducing double-sided diamond-shaped turning insert described in this embodiment has an 80° diamond-shaped cutter body, and the horizontal section is center-symmetrical. The double-sided usable design is adopted. The pressing threaded hole (8) at the position fixes the insert on the tool holder, and there is a straight cutting edge (6) on the edge of the rake face (5) of the insert, and the intersection of every two straight cutting edges (6) is a circular arc Tool tip (7), circular groove micro-texture (2) is distributed at each circular-arc tool tip (7), and a triangular chip-breaking boss ( 3), each triangular-shaped chip-breaking boss (3) is provided with a circular chip-breaking groove (4), and a combined disc-shaped boss is provided near the pressing threaded hole (8) in the middle area of the blade. There are 8 trapezoidal protrusio...

specific Embodiment approach 2

[0021] Specific implementation mode two: combination figure 1 with Figure 4 To illustrate this embodiment, the blade described in this embodiment is placed near the circular arc tool tip (7) into a circular groove micro-texture (2) distributed in a linear array with a radius of 25 μm and a depth of 35 μm, effectively reducing the The friction coefficient of the tool-chip interface during the cutting process improves the stress distribution and heat dissipation conditions of the tool, inhibits the chips from sticking on the rake face (5), slows down the wear of the arc tool tip (7), and improves the tool durability; The circular groove micro-texture (2) distributed linearly, its direction is perpendicular to the chip flow direction, so that the tool has the effect of reducing wear and anti-wear; when cutting under conventional and high-pressure cooling conditions, the circular groove micro-texture The texture (2) can store a small amount of coolant or lubricant to lubricate t...

specific Embodiment approach 3

[0022] Specific implementation mode three: combination figure 1 with Image 6 Describe this embodiment, the quasi-triangular chip breaking boss (3) in this embodiment can reduce the cutting force, improve the strength of the arc tip (7), and enhance the chipping resistance of the arc tip (7); Under the action of the anti-chip angle of the triangular chip-breaking boss (3), the curling radius of the chip becomes smaller, which increases the curling strain generated inside the chip, thereby intensifying the internal plastic deformation of the chip, which is conducive to the rapid breaking of the chip and makes the cutting process smooth and stable proceed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com