Wave-shaped helical-edge reamer

A helical blade and reamer technology, applied in reamers, metal processing equipment, reaming devices, etc., can solve the problems of increasing the replacement frequency and cost of reamers, failing to meet the requirements of hole surface quality, and reducing processing efficiency, etc., to achieve Low friction coefficient, small vibration, and improved processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

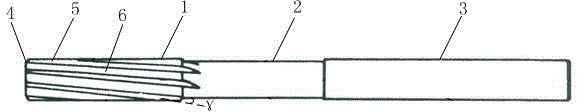

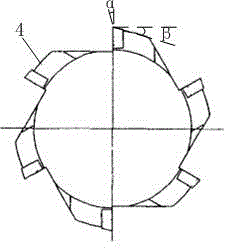

[0016] like Figure 1-2 As shown, a wave-shaped spiral edge reamer includes a cutter head 1, a neck 2 and a handle 3 connected in sequence; it is characterized in that the cutter head 1 includes a knife tooth 4 at the top of the knife head, and a knife tooth 4 The connected side cutting edges 5 and the chip flutes 6 between the side cutting edges; the side cutting edges 5 are helical sinusoidal wave edges; the cutter head 1 is provided with a soft coating; the cutter of the cutter teeth 4 The rake angle α is 2°, and the back angle β is 6°.

[0017] The corrugated spiral blade reamer is made of high-speed steel as a whole.

[0018] The soft coating material on the cutter head 1 is tungsten dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com