Disc-shaped cutting tool

A disc-shaped, tool technology, applied in milling cutters, manufacturing tools, metal processing equipment, etc., can solve problems such as ineffective chip breaking, and achieve the effect of improving chip breaking performance, improving grades, and making products more beautiful

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

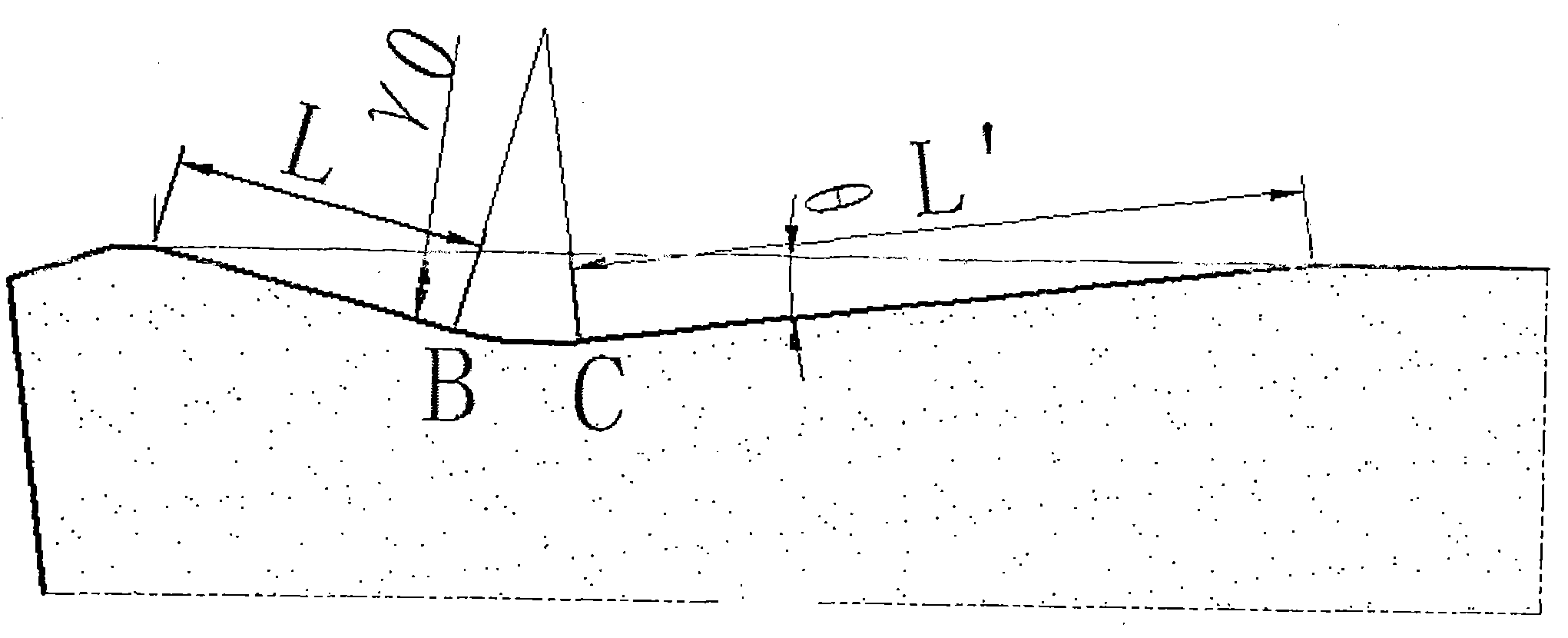

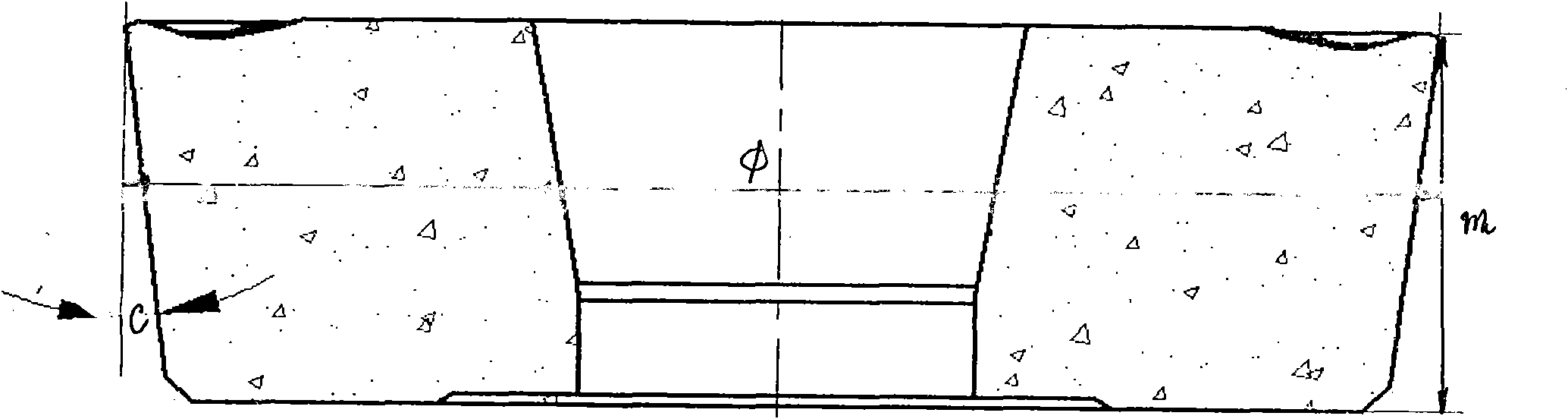

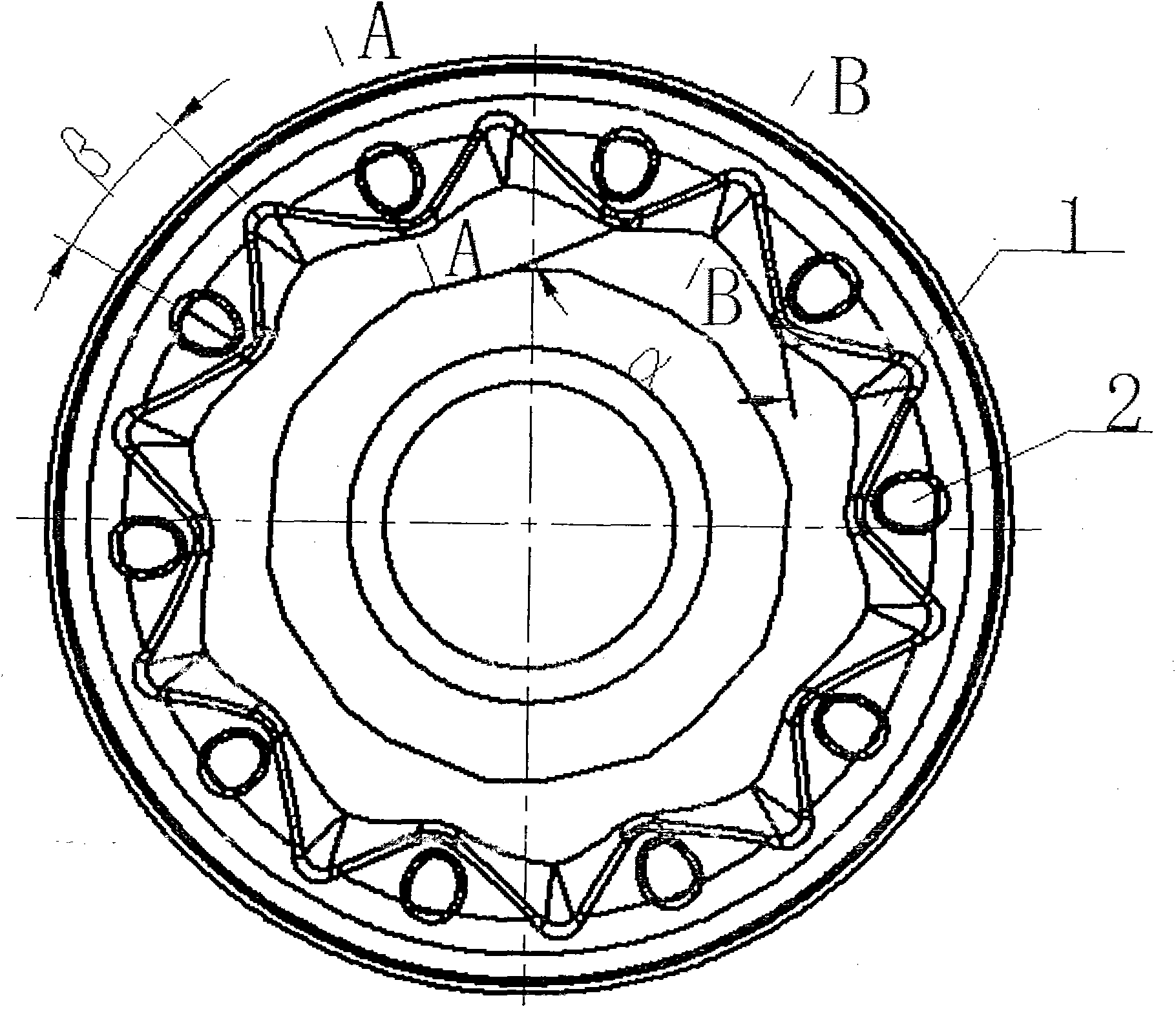

[0022] The outer circle of the tool of the present invention is φ32mm, the tool tip height m is 9.52mm, and the relief angle c is 7°. The angle γ0 between the rake face and the front face is 17°, the angle θ between the anti-chip face and the rear face is 10°, the distance between the front and rear faces is 0.15mm, and 10 bosses 1 are evenly distributed on the anti-chip face. The stages are connected to form a ring-shaped 10-point star block. The cone angle of the boss is α=78, 3°. There is a spherical crown-shaped bump 2 on the anti-chip surface of the triangle area between two adjacent cone angles. The projection of the bump 2 on the triangular area occupies one third of the area of the triangular area. The distance between the apex of the bump 2 and the anti-chip surface is 0.2 mm, and the distance between the apex of the boss 1 and the anti-chip surface is 0.3 mm. The angle β between the vertex of the taper angle of the bump 1 and the vertex of the bump 2 and the tool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com