Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Fewer stages of extraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for non-saponification extraction and separation of light rare earth elements

ActiveCN104120258ALow viscosityImprove liquidityProcess efficiency improvementRare-earth elementPhosphate

The invention discloses a method for non-saponification extraction and separation of light rare earth elements. After a compound extraction agent consisting of acid phosphorus type extraction agent, alkaline amine type extraction agent and solvent oil is mixed with phosphate solvent or organic alcohol solvent at 30-70 DEG C, chlorinated light rare earth liquid is extracted and separated; and the water washing and the hydrochloric acid reverse extraction are performed to finally realize the separation of La, Ce, Pr and Nd; and a mixed organic phase after the reverse extraction is returned to an extraction tank for recycling. The method pretreats the mixed organic phase consisting of the compound extraction agent and the solvent, so that such defects as high viscosity, weak mobility, easy emulsification and long phase splitting time are overcome; the method has no need to saponify the acid phosphorus type extraction agent, so that no alkali liquor consumption and no waste water emission in the extraction process are realized, but the separation capacity of a saponification extracting agent system is achieved, and the extraction grade is reduced compared with that needed by the saponification extracting agent system; and the method is a rare earth element separation process with economy and high efficiency.

Owner:GUANGXI NORMAL UNIV

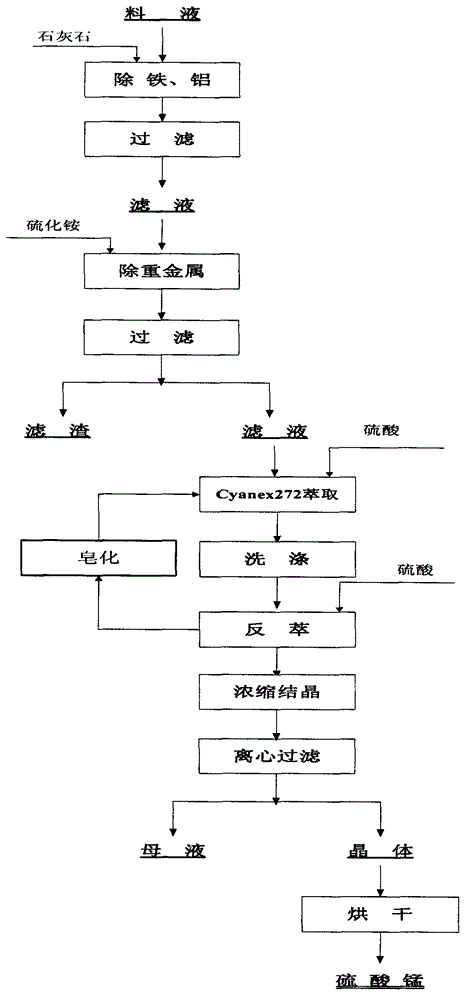

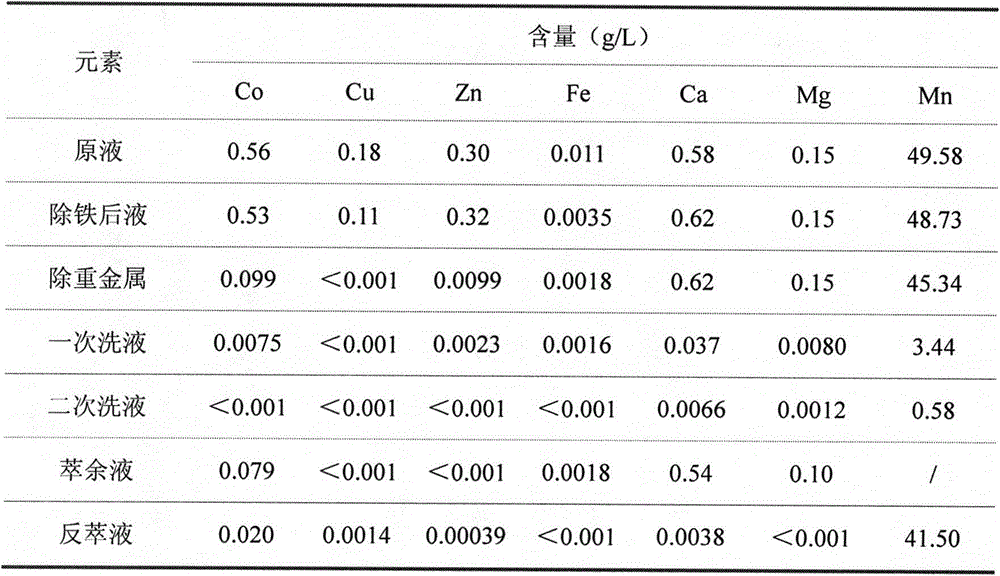

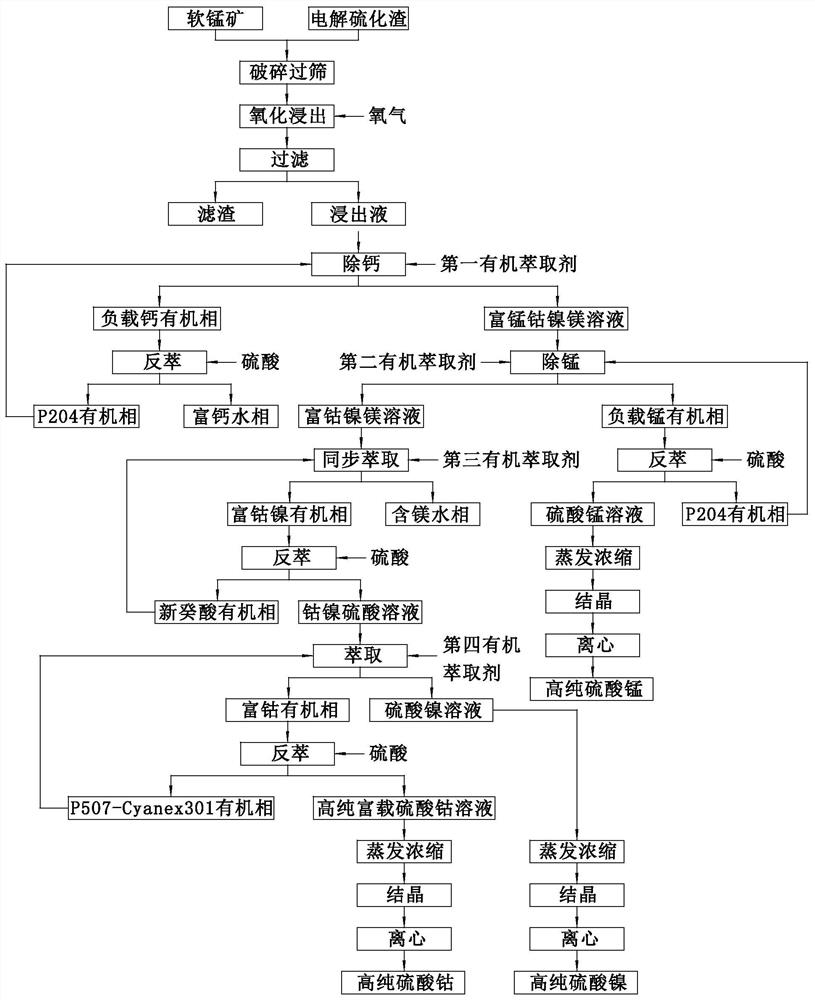

Method for preparing high-purity manganese sulfate from manganese-containing waste liquid

The invention relates to a method for preparing high-purity manganese sulfate from a manganese-containing waste liquid. The existing method for treating the high-manganese-containing waste liquid generated in the wet production of cobalt salts mainly comprises a lime precipitation method and a method for preparing manganese sulfate by removing calcium and magnesium via fluoride and adopting a P204 or P507 extracting agent and has the respective problems that the utilization value of prepared manganese hydroxide is low, the fluoride-containing wastewater is polluted and the like. According to the method, heavy metals are removed by virtue of sulfide, manganese is extracted through a Cyanex272 extracting agent, calcium and magnesium are thrown and the reverse extraction is performed to obtain the high-purity manganese sulfate product which can meet the requirement of a ternary cell material on manganese sulfate; and the method has the advantages of short process flow, no fluoride pollution and the like.

Owner:ZHEJIANG HUAYOU COBALT

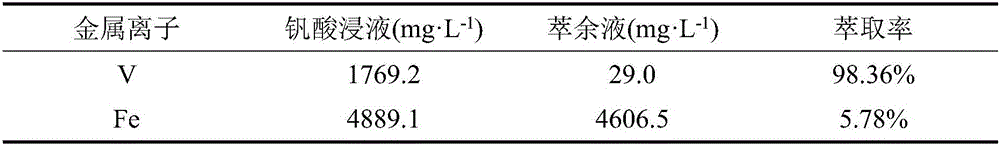

Process for abstracting vanadium from iron-smelting waste slag of vanadium ¿Ccontaining iron ore

InactiveCN101289705AReduce environmental pollutionFewer stages of extractionProcess efficiency improvementSal ammoniacSucrose

The invention relates to a method for extracting vanadium from ironmaking waste slag of vanadium iron ores. The method comprises the following steps: a. vanadium is leached out of ironmaking waste slag of vanadium iron ores by using dilute sulfuric acids; b. leach solution uses ethylene glycol, glycerin, glucose or sucrose as extraction promoters so as to complex vanadium; c. the pH value of the solution is adjusted, and mixed extracting agents are used for extraction; d. organic phase back extraction is extracted by using dilute sulfuric acids; e. ammonia water is used to adjust the pH value of the back extraction solution so as to deposit vanadium; f. the deposit is calcined for obtaining vanadium pentexide products with high purity. In the process, no harmful gases such as Cl2 and HCl, etc. are generated, and due to the adoption of ethylene glycol, glycerin, glucose or sucrose to treat the leach solution, no impurity ions are added in the solution; the use of the ammonia water deposition can improve the product purity, and the total extraction rate of vanadium reaches more than 90 percent.

Owner:BEIJING UNIV OF CHEM TECH

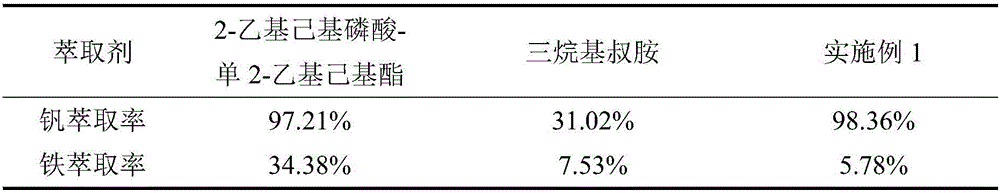

Method for performing extraction separation on cobalt and nickel by using microfluid technology

The invention provides a method for performing extraction separation on cobalt and nickel by using a microfluid technology. The method comprises the following steps of: uniformly mixing an extraction agent and diluent which are subjected to homogeneous phase saponification by using a mixed material liquid of Co<2+> and Ni<2+>, using 2-ethyl cthylhexyl phosphonate mono 2-ethyl cthylhexyl ester as the extraction agent and using No.260 solvent oil and using the extraction agent and the diluent as an oil phase; introducing the water phase and the oil phase into a micro-reactor by virtue of two flow pumps; mixing the two phases in the micro-reactor and performing extraction reaction at 25-50 DEG C; and collecting a product at an outlet of the micro-reactor and standing for separating the phases to ensure that Co<2+> enters the oil phase and Ni<2+> stays in the water phase so as to realize extraction separation of cobalt and nickel. According to the method, continuous flow micro-reactor with an enhanced hybrid channel structure is adopted, the extraction separation of cobalt and nickel is carried out, and the reaction time is shortened to be within a micro-second level range, so that single-level cobalt extraction efficiency is obviously improved, and the extraction levels are reduced; and moreover, standing layering on the water phase and the oil phase can be quickly carried out without any emulsion phenomenon.

Owner:KUNMING UNIV OF SCI & TECH

Method for extracting rare-earth elements through micro channels

InactiveCN105112658AShort staySmall footprintProcess efficiency improvementMicroreactorRare-earth element

The invention relates to a method for extracting rare-earth elements through micro channels, and belongs to the technical field of hydrometallurgy. The method comprises the steps that firstly, P507 or P204 is added into 260# solvent oil diluents according to the volume ratio of 3:10-10:3 to obtain an organic phase; a rare-earth salt solution serves as a water phase; the organic phase and the water phase are subjected to normal-temperature extraction through the micro channels in a microreactor according to the phase ratio of 5:1-1:5 and at the volume flowing speed of 5.55*10-10-4.17*10-8 m<3> / s; and finally, an extraction phase containing rare-earth elements and raffinate are obtained. In combination with the advantages that the micro channels are high in specific interfacial area, high in mass transfer rate, short in response time and the like, the purpose of achieving high-efficiency rare-earth extraction is realized through contact of two phase interfaces in the micro channels, and the method is safe, efficient and low in consumption.

Owner:KUNMING UNIV OF SCI & TECH

Method for purifying and enriching vanadium from stone coal pickle liquor

ActiveCN106350671AReduce lossesSpeed up extractionProcess efficiency improvementIron powderSulfite salt

The invention relates to a method for purifying and enriching vanadium from stone coal pickle liquor. According to the technical scheme, the method includes: adding calcium-containing substances into the stone coal pickle liquor to regulate pH, and performing solid-liquid separation to obtain neutral residues and neutral liquid; adding iron powder or sodium sulfite into the neutral liquid, and adding weak acid salt to obtain an extraction stock solution; extracting the extraction stock solution to obtain loading organic phase and raffinate, washing the loading organic phase to obtain washed loading organic phase, performing reverse extraction on the washed loading organic phase to obtain lean organic phase and rich-vanadium liquid; returning the lean organic phase to extraction after regeneration treatment. The method has the advantages that the pH of the solution during the extraction is stable, extraction stage is short, the separation effect of vanadium and various impurity ions is good, and the rich-vanadium liquid is low in impurity content.

Owner:WUHAN UNIV OF SCI & TECH

Method for extracting and separating beryllium

The invention relates to a method for extracting and separating beryllium. Beryllium-containing dosage liquor is a sulfuric acid solution containing beryllium ions, wherein the concentration of the beryllium ions is 0.2-30g / L. The method is characterized in that the method comprises the steps of: (1) a naphthenic acid-alcohol or isooctanol-kerosene organic phase is uniformly mixed with the beryllium-containing dosage liquor; an alkaline solution is added to the mixed liquid, such that the pH value of the liquid is 5-8; (2) an acidic solution is added to the organic phase obtained in the step (1) for stripping impurities, such that an organic phase which is an impurity-removed beryllium-containing organic-phase solution is obtained; and (3) an alkaline solution is added to the organic phase obtained in the step (2) for stripping beryllium, such that a water phase which is an impurity-removed beryllium-containing solution is obtained; and the organic phase is delivered back to the step (1) and is reused. With the method provided by the invention, beryllium can be selectively separated from impurities such as iron and aluminum. The extraction stages are few, the process is simple, a separation effect is good, and a beryllium recovery rate is high.

Owner:GUANGDONG INST OF RARE METALS

Method for separating ferrum and vanadium in vanadium pickle liquor

ActiveCN106086408AReduce consumptionEasy extractionProcess efficiency improvementEmulsionPhysical chemistry

The invention discloses a method for separating ferrum and vanadium in vanadium pickle liquor. The method comprises the following steps that Na2SO3 is added into the vanadium pickle liquor, stirring is conducted, and a reduction reaction is conducted at the temperature of 30-75 DEG C for 20-120 min, so that reduction liquor is obtained; the pH value of the reduction liquor is regulated to 1.0-2.5 by adding alkali liquor, so that emulsion is obtained; solid-liquid separation is conducted on the emulsion, so that an extracted stock solution and slag are obtained; a mixed extraction agent and the extracted stock solution are mixed according to the volume ratio of (0.2-1):1, and stirring is conducted, so that a mixed phase is obtained; and standing phase splitting is conducted on the mixed phase, so that a vanadium-carrying organic phase and ferrum-containing raffinate are obtained, wherein the mixed extraction agent is prepared by mixing an acid phosphorous extraction agent, an alkaline amine extraction agent and sulfonated kerosene. According to the method for separating the ferrum and the vanadium in the vanadium pickle liquor, different extraction agents are selected to form a mixed system, and through the characteristics of the different extraction agents, the mixed system can have better extraction capacity and selectivity. The technological process is simple, agent consumption is low, and the ferrum and the vanadium in the vanadium pickle liquor can be separated efficiently.

Owner:WUHAN UNIV OF TECH

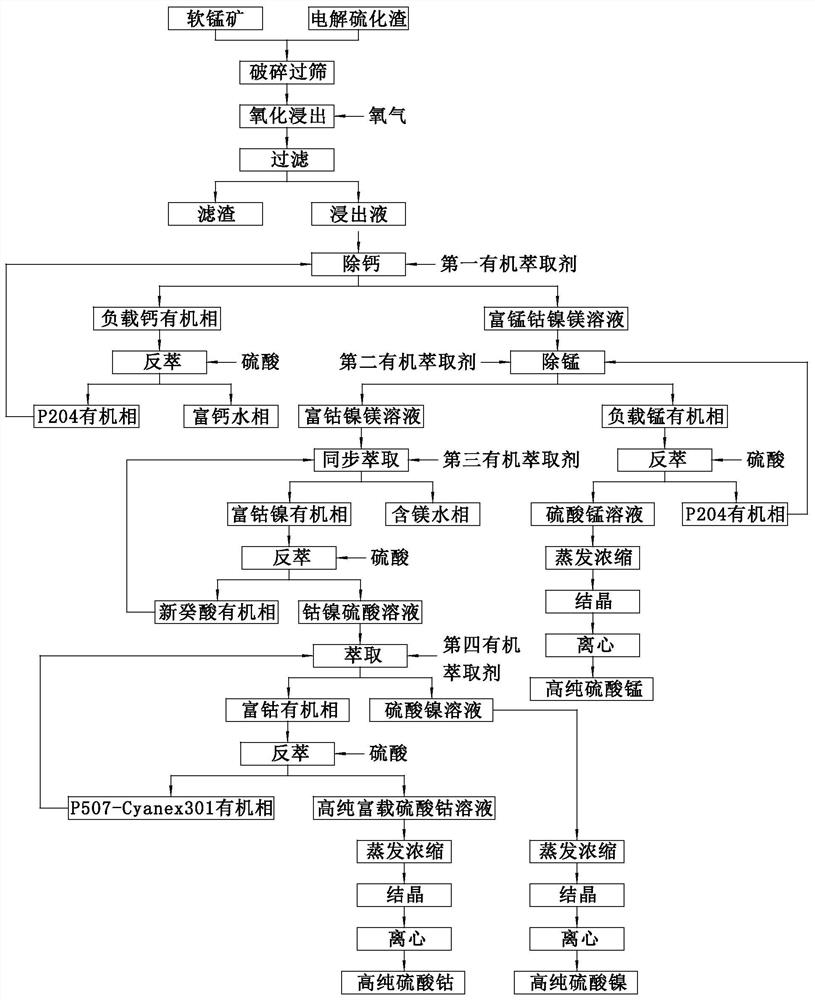

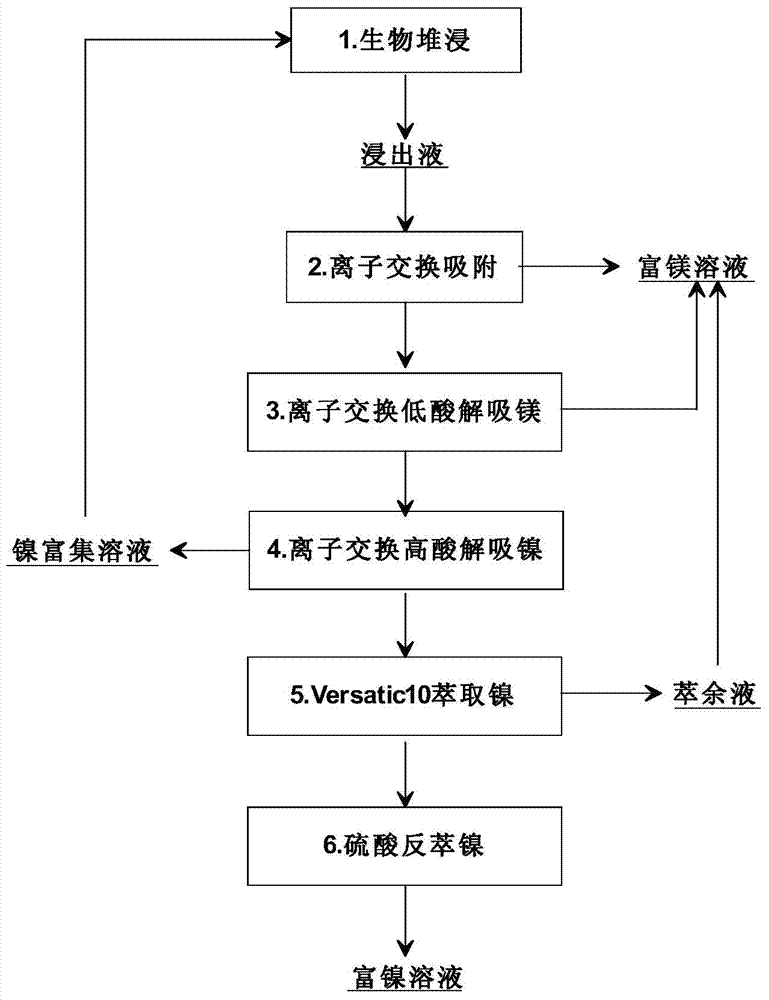

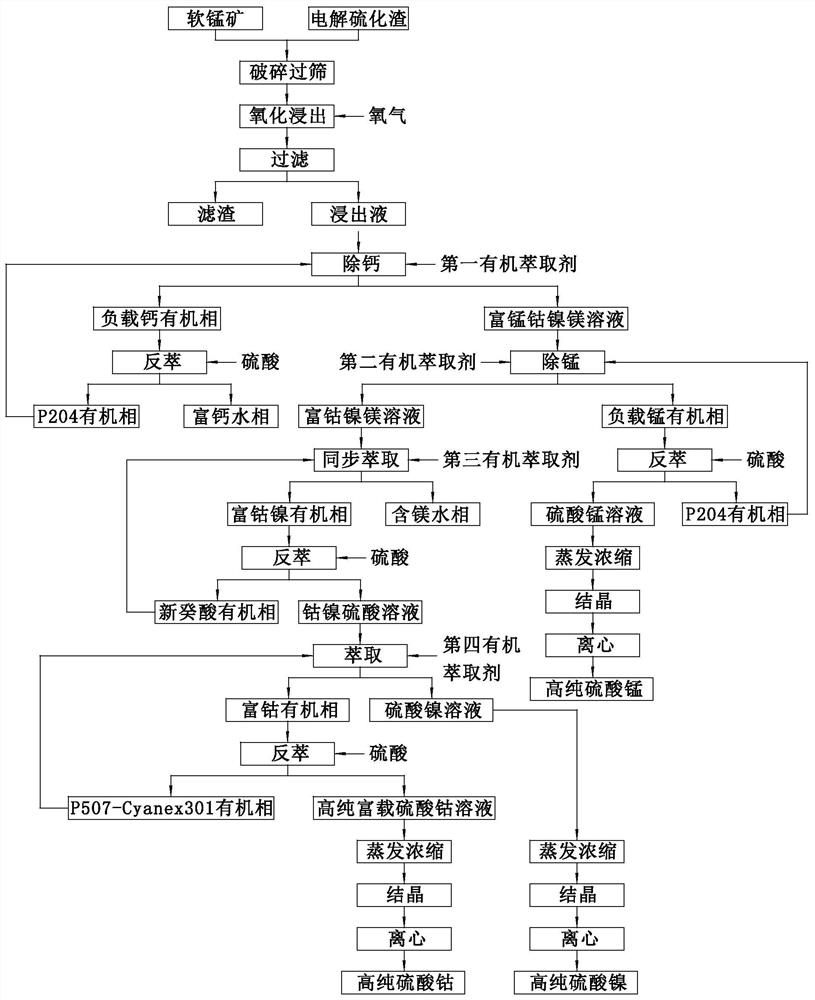

Method of preparing high-purity nickel sulfate from electrolytic manganese sulfide slag

PendingCN112662877AAchieve leachingSimple processCobalt sulfatesNickel sulfatesManganese sulfideSulfate

The invention discloses a method of preparing high-purity nickel sulfate from electrolytic manganese sulfide slag. The method comprises the following steps of (1) crushing and sieving; (2) oxidizing and leaching; (3) calcium removal; (4) manganese removal; (5) synchronous extraction of cobalt and nickel: taking a solution rich in cobalt, nickel and magnesium, and adding a third organic extractant formed by mixing saponified neodecanoic acid with sulfonated kerosene for extraction to obtain an organic phase rich in the cobalt and the nickel and a magnesium-contained aqueous phase; (6) cobalt removal: taking the organic phase rich in the cobalt and the nickel, adding dilute sulfuric acid for reverse extraction to obtain a cobalt-nickel sulfuric acid solution and a neodecanoic acid organic phase, separating out the cobalt-nickel sulfuric acid solution, and adding a fourth organic extractant formed by mixing saponified P507-Cyanex301 with sulfonated kerosene for extraction to obtain a cobalt-rich organic phase and a nickel sulfate solution; and (7) preparation of the high-purity nickel sulfate. The method has the advantages that the method is simple and feasible, leaching of nickel sulfate can be realized, and production of hydrogen sulfide gas, use of an iron precipitation process and a method of removing calcium and magnesium ions with precipitation of fluorine ions can be avoided.

Owner:GUANGXI NORMAL UNIV OF SCI & TECH

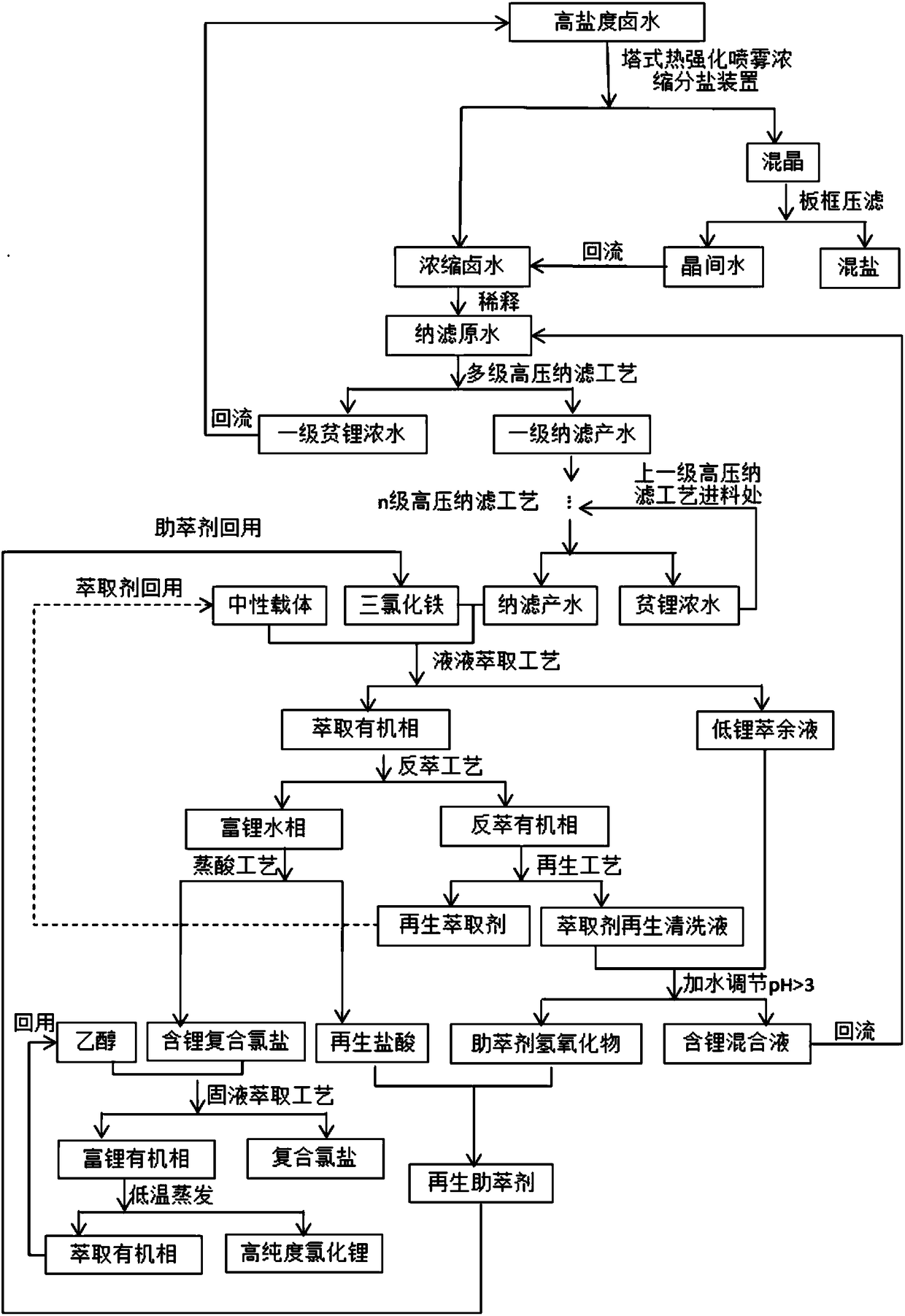

Energy-saving and environmentally-friendly salt lake brine lithium extracting technology

ActiveCN108359813AEmission reductionEasy to purifyProcess efficiency improvementLithium chlorideHigh pressure

The invention discloses an energy-saving and environmentally-friendly salt lake brine lithium extracting technology. The technology comprises the steps of atomizing and forcibly evaporating high-salinity brine through a tower type reinforcing atomizing circulating concentrating and salt separating device, thus realizing high-multiple concentration and salt reducing and lithium enriching of the brine; processing the concentrated lithium-enriched brine by multi-stage high-pressure nanofiltration to realize salt separating and magnesium removing; retuning the primary nanofiltration low-lithium concentrated water to a tower type concentrating liquid inlet part; extracting lithium from the lithium-enriched nanofiltration water in a liquid-liquid extraction manner; returning lithium-containing raffinate water phase and extracting agent regenerating washing liquid to a nanofiltration liquid inlet part, and further recovering lithium; evaporating high-lithium reverse extraction liquid, and recovering acid for regenerating an extraction additive; evaporating to remove acid to obtain solid high-lithium compound salt; performing solid-liquid extraction through ethyl alcohol; volatilizing theobtained lithium chloride ethyl alcohol extracting solution; and recovering ethyl alcohol to obtain high-purity lithium chloride. The technology is obvious in energy saving effect in the whole process, high in lithium recovery rate, low in production cost, safe, environmentally friendly, and applicable to extraction and production of lithium in various types of high-salinity and high-magnesium-lithium-ratio salt lake brine.

Owner:西安金藏膜环保科技有限公司

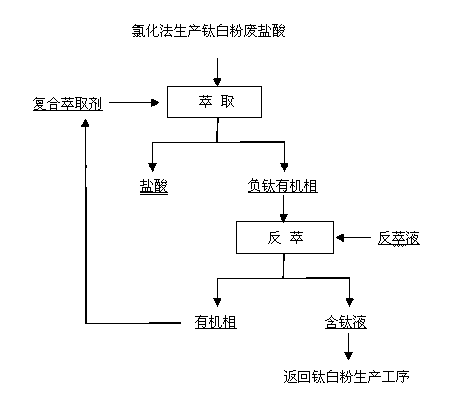

Method for recovering titanium from waste hydrochloric acid generated in production of titanium dioxide by chlorination process

ActiveCN103773962AWith low temperature selective extractionReduce extraction timeProcess efficiency improvementResource recoveryPhysical chemistry

The invention discloses a method for recovering titanium from waste hydrochloric acid generated in production of titanium dioxide by a chlorination process. The method comprises the following steps of: carrying out extraction reaction by using a countercurrent contact mode of the titanium dioxide and waste hydrochloric acid in production of the titanium dioxide by the chlorination process, extracting the titanium in the hydrochloric acid into an organic phase and obtaining hydrochloric acid and an organic phase of negative titanium; adopting acid liquor added with hydrogen peroxide as reverse extraction liquor, carrying out reverse extraction according to the countercurrent contact mode, reversely extracting the titanium from the organic phase of the negative titanium into a water phase and obtaining titanium-containing solution and an organic phase. The method disclosed by the invention has the advantages that the characteristic of low-temperature selective extraction is achieved, the extraction time is short, the saturation capacity of extraction is large and the number of extraction stages is less; recovery and utilization of resources such as the titanium and the hydrochloric acid are realized, the emission of the waste acid is reduced, the reutilization of the resources is realized and the environmental pollution is eliminated.

Owner:CITIC JINZHOU METAL

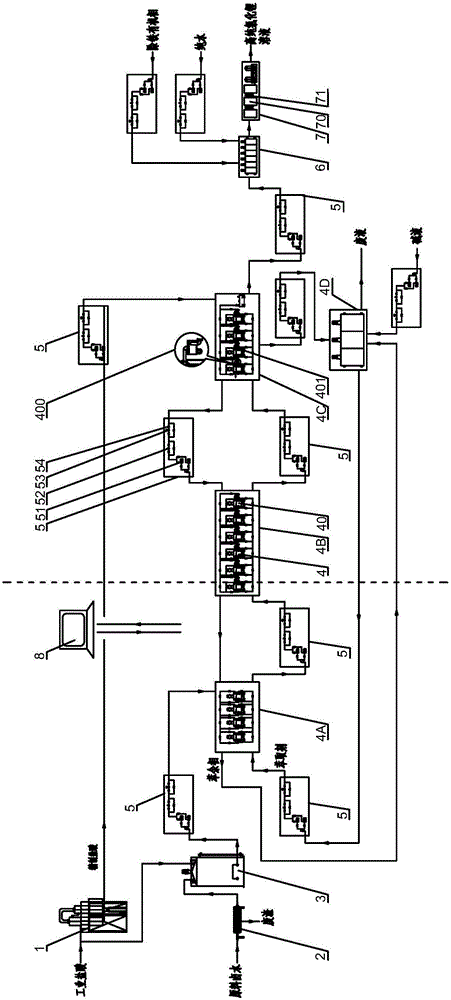

High-purity lithium chloride extraction device

ActiveCN106219579AImprove extraction efficiencyPhase equilibrium establishment time is fastLithium halidesSolventChemistry

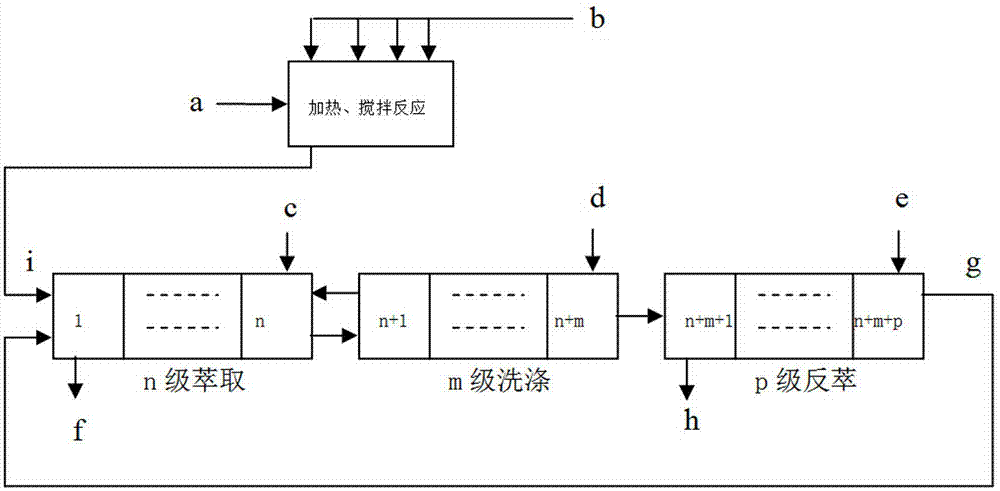

The invention discloses a high-purity lithium chloride extraction device. The high-purity lithium chloride extraction device comprises a filter press, a blending tank, an extraction system, a washing system, a reverse extraction system, a deironing system and an oil removal system which are sequentially connected through a pipeline, the blending tank is used for acid regulating treatment, and the extraction system, the washing system and the reverse extraction system are respectively formed by connecting multiple stages of centrifugal extractors in series. The reverse extraction solution outlet end of the reverse extraction system is connected with the washing system, the organic phase output end of the reverse extraction system is connected with a saponification system, and the saponification system is connected with the extraction system. A circulating loop is formed by the extraction system, the washing system, the reverse extraction system and the saponification system. The device is further provided with a data analysis system, and the work positions of the abnormal centrifugal extractors can be automatically switched to a standby centrifugal extractor through the system. Variable-frequency closed-loop flow control systems are arranged at the material input ends of all the systems in the circulating loop for obtaining the precise flow-input phase ratio through timely adjustment. The device is high in extraction efficiency, short in phase balance setting time, small in solvent needing amount, low in solvent consumption and continuous and reliable in process.

Owner:HEFEI GENERAL MACHINERY RES INST

High-purity lithium chloride production technology

The invention discloses a high-purity lithium chloride production technology. An apparatus in the production technology comprises a filter press, a blending pot for acid adjusting treatment, an extraction system, a washing system and a back-extraction system connected by the multistage centrifugation extraction machines in series respectively, an iron-removal system and an oil removing system which are connected in order through the pipelines, wherein, an output terminal of a back extraction solution of the back-extraction system is connected with the washing system, an organic phase output terminal of the back-extraction system is connected with a saponification system, the saponification system is connected with the extraction system; and the extraction system, the washing system, the back-extraction system and the saponification system form a circulation loop. The apparatus also comprises a data analysis system capable of switching an abnormal centrifugation extraction machine station to a backup centrifugation extraction machine. A frequency-conversion closed loop flow control system is arranged at a material input of each system of the circulation loop, and the accurate flowing and input phase ratio can be obtained by appropriate adjusting. The apparatus has the advantages of high extraction efficiency, fast establishing time for phase equilibrium, small solvent required amount, small consumption of a solvent, and continuous and reliable processes.

Owner:HEFEI GENERAL MACHINERY RES INST

Method of utilizing V5+ to extract and gather vanadium-containing solution

ActiveCN106282607AHigh recovery rateLoose requirementsProcess efficiency improvementOxidizing agentChemistry

The invention relates to a method of utilizing V5+ to extract and gather a vanadium-containing solution. The method includes: adjusting pH value of vanadium-containing material leaching stoste to below 7 to generate precipitate or floccule; adding an oxidizing agent while stirring for reaction, wherein when a reaction solution gradually becomes crineous, vanadium ions in the reaction solution are oxidized into V5+; filtering the reaction solution, wherein obtained filtrate is extraction stoste; adjusting pH value of the extraction stoste to below 7, adopting an extraction organic phase with a pH value equal to the pH value of the extraction stoste to perform countercurrent extraction on V5+ in the extraction stoste to obtain an organic phase rich in V5+ and extraction residual water, subjecting the organic phase rich in V5+ to reverse extraction through a stripping agent solution to obtain reverse water rich in V5+, and storing the reverse water to obtain the vanadium-containing solution extracted and gathered by utilizing V5+. Valent state of V5+ is utilized to extract, purify and gather the vanadium-containing solution, so that the valent state does not need to be changed repeatedly, and vanadium recovery rate is high.

Owner:陕西福盛钒业科技有限公司

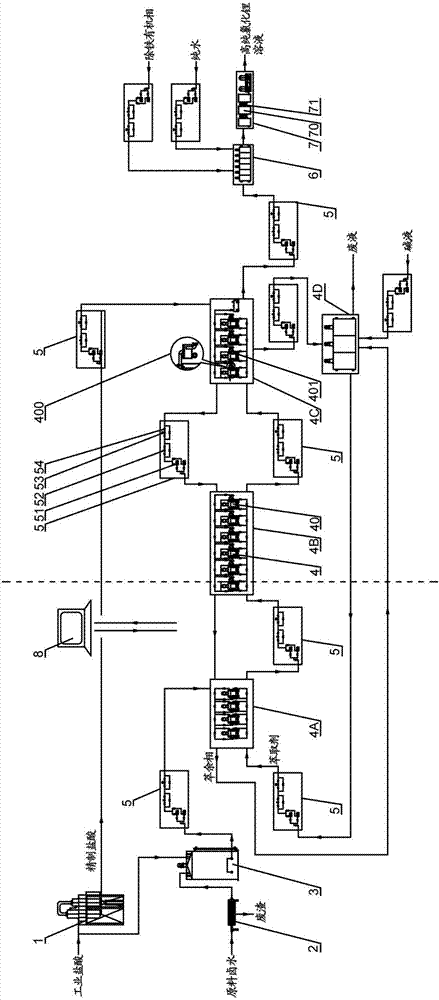

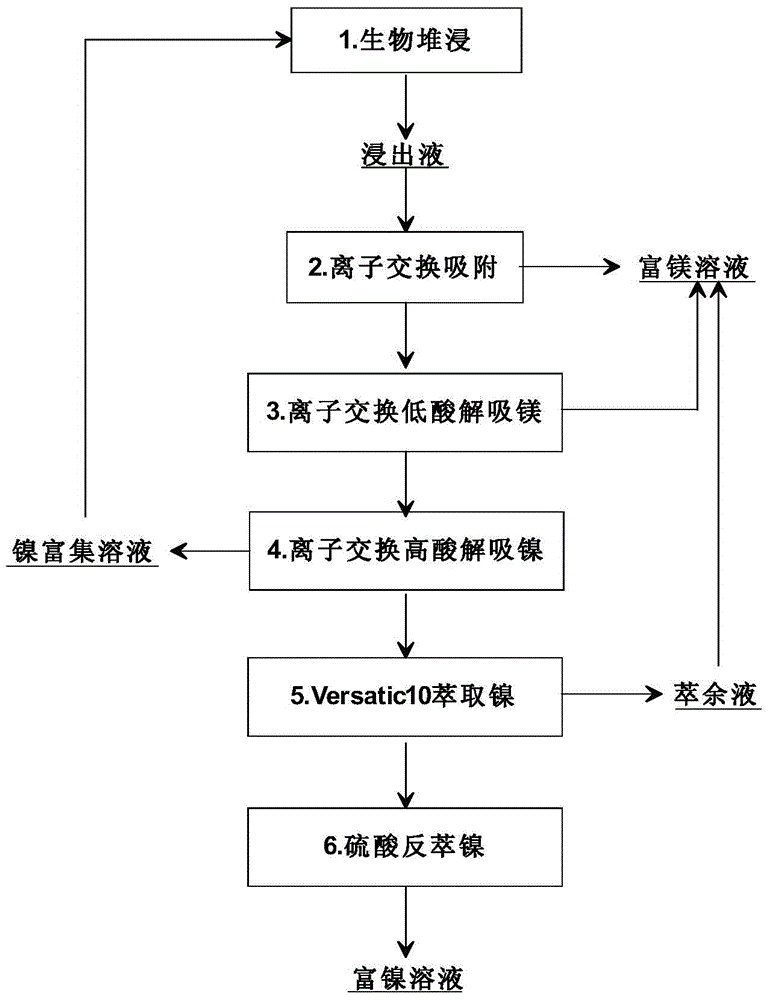

Method for comprehensively recovering nickel and magnesium in bio-leaching process of high-magnesium low-nickel sulfide ore

InactiveCN104745813AReduce lossesImprove separation and extraction efficiencyProcess efficiency improvementRecovery methodHigh magnesium

The invention discloses a method for comprehensively recovering nickel and magnesium in a bio-leaching process of high-magnesium low-nickel sulfide ore. The method comprises the following steps: treating the bio-leachate of high-magnesium low-nickel sulfide ore through an ion exchange resin column to adsorb nickel ions, and enabling the magnesium-rich solution to flow out; desorbing residual magnesium ions in the ion exchange resin by use of low-acidity sulfuric acid, desorbing nickel ions in the ion exchange resin by use of high-acidity sulfuric acid, and returning the nickel ion desorption solution to the yard; and when the mass concentration of Mg and Ni in the leachate of the yard is lower than 5, extracting nickel with Versatic 10 and performing back extraction of an organic phase to obtain a nickel-rich solution. According to the method, by increasing the nickel-magnesium concentration ratio and reasonably matching the technological parameters, nickel and magnesium are effectively separated, and a recovery method of nickel and magnesium in bio-leachate is realized.

Owner:有研资源环境技术研究院(北京)有限公司

Method of preparing high-purity cobalt sulfate from electrolytic manganese sulfide slag

ActiveCN112662878AAchieve leachingSimple processCobalt sulfatesProcess efficiency improvementManganese sulfidePhysical chemistry

The invention discloses a method of preparing high-purity cobalt sulfate from electrolytic manganese sulfide slag. The method comprises the following steps of (1) crushing and sieving; (2) oxidizing and leaching; (3) calcium removal; (4) manganese removal; (5) synchronous extraction of cobalt and nickel; (6) cobalt recovery: taking a cobalt-nickel rich organic phase, adding dilute sulfuric acid for reverse extraction to obtain a cobalt-nickel sulfuric acid solution and a neodecanoic acid organic phase, separating out the cobalt-nickel sulfuric acid solution, adding a fourth organic extracting agent formed by mixing saponified P507-Cyanex301 with sulfonated kerosene for extraction to obtain a cobalt-rich organic phase and a nickel sulfate solution, separating out the cobalt-rich organic phase, and adding sulfuric acid for reverse extraction to obtain a high-purity cobalt sulfate-rich solution and a P507-Cyanex301 organic phase; and (7) preparation of the high-purity cobalt sulfate. The method has the advantages that the method is simple and feasible, leaching of cobalt sulfate can be achieved, and production of hydrogen sulfide gas, use of an iron precipitation process and a method of removing calcium and magnesium ions through fluorine ion precipitation can be avoided.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Method for extracting and separating beryllium

ActiveCN102851502BTo achieve the purpose of separating and purifying berylliumFewer stages of extractionProcess efficiency improvementAlcoholKerosene

The invention relates to a method for extracting and separating beryllium. Beryllium-containing dosage liquor is a sulfuric acid solution containing beryllium ions, wherein the concentration of the beryllium ions is 0.2-30g / L. The method is characterized in that the method comprises the steps of: (1) a naphthenic acid-alcohol or isooctanol-kerosene organic phase is uniformly mixed with the beryllium-containing dosage liquor; an alkaline solution is added to the mixed liquid, such that the pH value of the liquid is 5-8; (2) an acidic solution is added to the organic phase obtained in the step (1) for stripping impurities, such that an organic phase which is an impurity-removed beryllium-containing organic-phase solution is obtained; and (3) an alkaline solution is added to the organic phase obtained in the step (2) for stripping beryllium, such that a water phase which is an impurity-removed beryllium-containing solution is obtained; and the organic phase is delivered back to the step (1) and is reused. With the method provided by the invention, beryllium can be selectively separated from impurities such as iron and aluminum. The extraction stages are few, the process is simple, a separation effect is good, and a beryllium recovery rate is high.

Owner:GUANGDONG INST OF RARE METALS

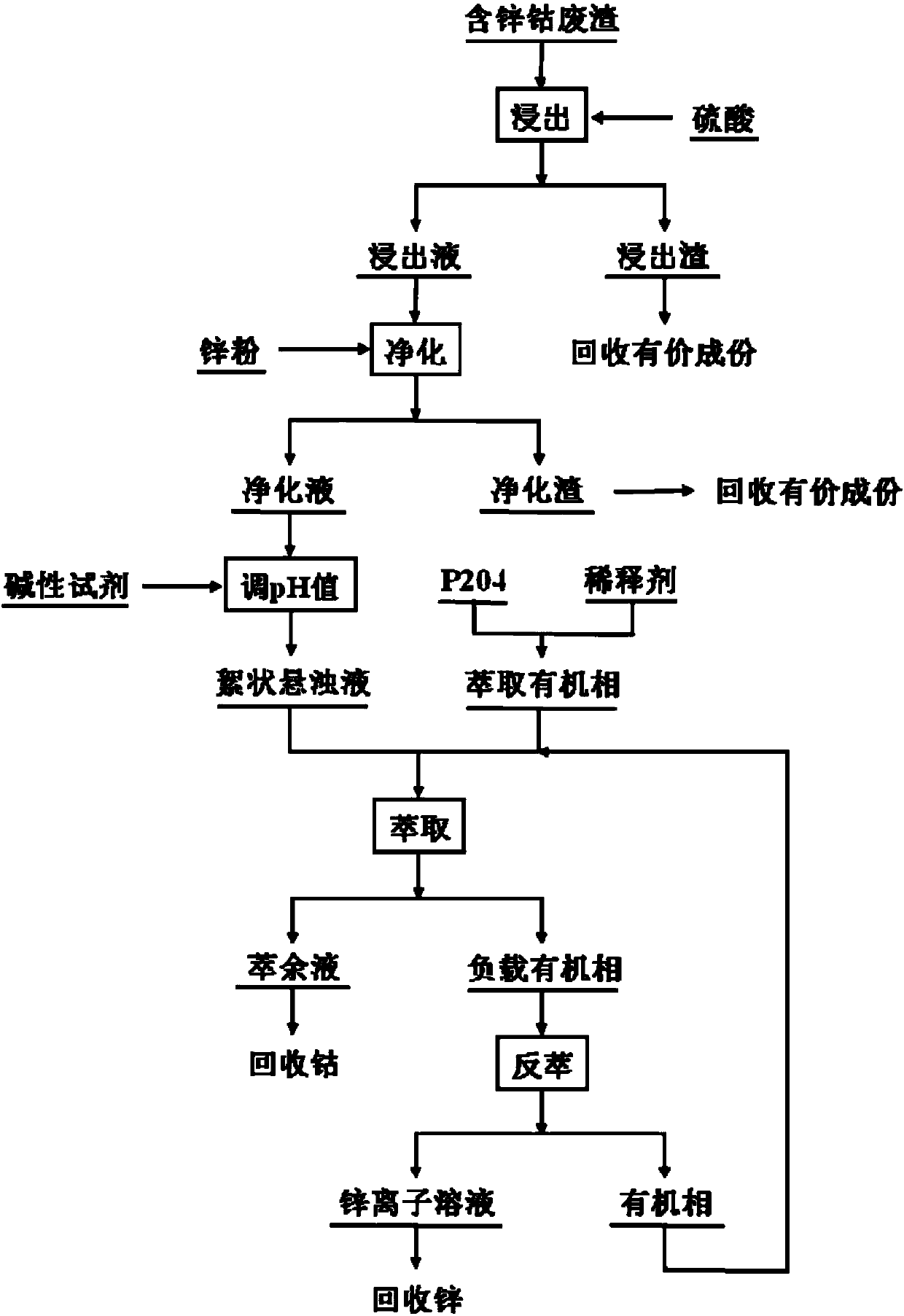

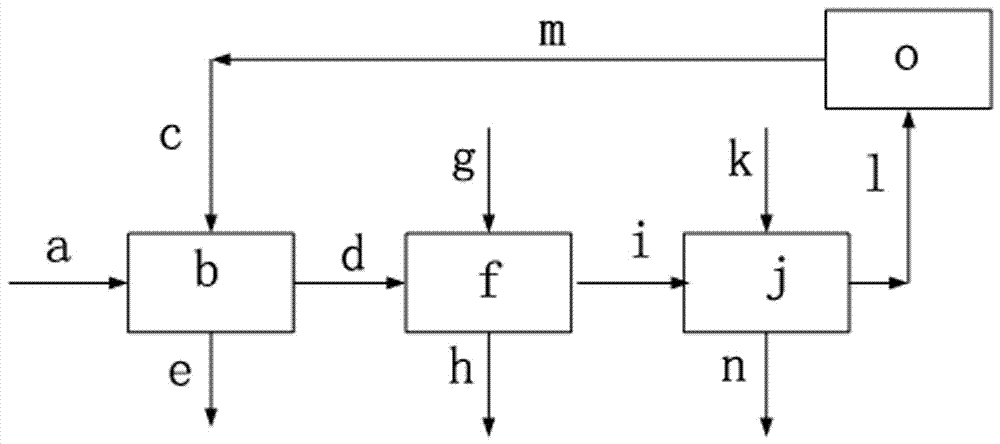

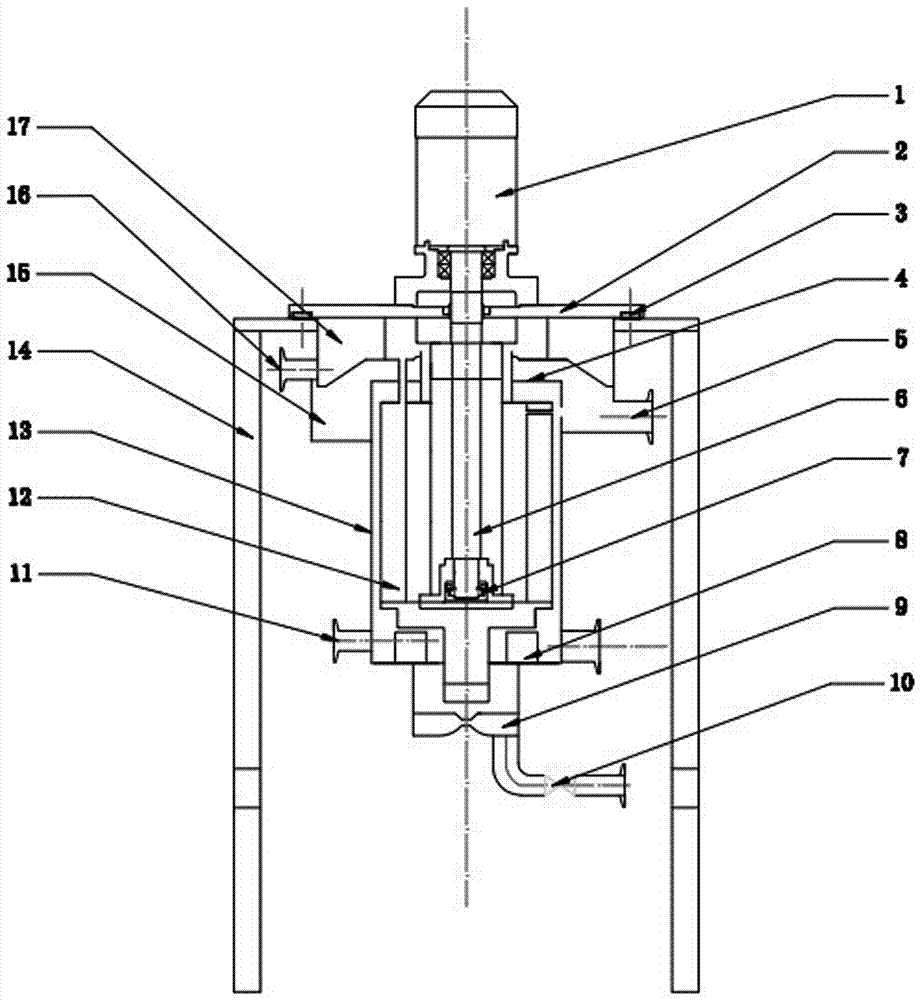

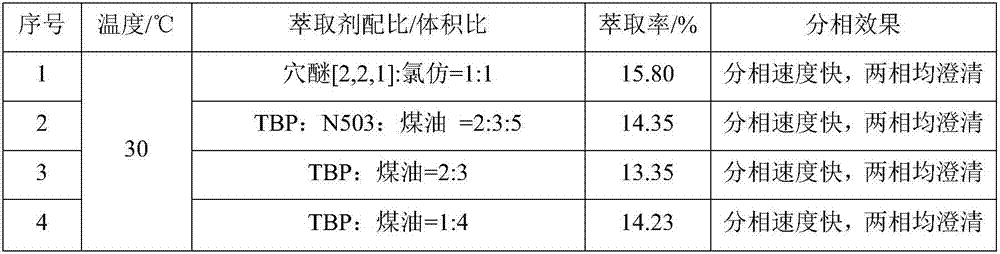

Flocculation extraction separation method of zinc and cobalt ions

ActiveCN107760874APromote the extraction reactionHigh surface energyProcess efficiency improvementSpecific surface energyChemistry

The invention provides a flocculation extraction separation method of zinc and cobalt ions, and relates to the technical field of extraction separation. The flocculation extraction separation method of zinc and cobalt ions comprises the following steps: leaching zinc-cobalt-containing waste residue with nitric acid or sulfuric acid to obtain a leachate; adding zinc powder to the leachate, and removing impurity components to obtain a purified liquid; adjusting the pH of the purified liquid with an alkaline reagent to obtain a flocculent suspension, mixing the flocculent suspension with an extracted organic phase containing P204, obtaining a loaded organic phase and a raffinate through an extraction reaction, and using the raffinate to recover cobalt; reversely extracting the loaded organicphase to obtain a zinc ion solution, and then recovering zinc. The alkaline reagent is added to convert metal ions to a hydroxide flocculent precipitate; the hydroxide flocculent precipitate has a large specific surface area, high specific surface energy and chemical reactivity, and can rapidly undergo an extraction reaction with acidic P204, the single-stage reaction rate is high, the extractionreaction is thorough, the amount of P204 is small, the separation effect is good, and the application prospect is broad.

Owner:SANMING UNIV

Method for extracting uranium and thorium from southern ionic rare-earth lixivium

The invention relates to a method for extracting uranium and thorium from a southern ionic rare-earth lixivium, which is characterized by comprising the following steps: (1) carrying out uranium and thorium extraction separation by using a 15-25 vol% naphthenate-15-25 vol% octanol or isooctanol-50-70 vol% kerosene extractant and a southern ionic rare-earth lixivium in a volume ratio of (0.5-5):1; and (2) carrying out back extraction on the loaded organic phase obtained in the step (1) and a 2-5 mol / L sulfuric acid, hydrochloric acid or nitric acid solution in a volume ratio of (0.1-10):1, wherein the organic phase after the back extraction returns to the step (1) for repeated use, and the water phase, which is the solution with enriched uranium and thorium, is used for recycling uranium and thorium. The method provided by the invention can selectively separate uranium and thorium from the rare-earth lixivium, has the advantages of fewer extraction stages, simple technique, favorable separating effect, no influence on subsequent rare-earth separation technique, and high extraction ratio of uranium and thorium.

Owner:GUANGDONG INST OF RARE METALS

Method of extracting lithium isotope <6>Li with centrifugal extraction machine

The invention discloses a method of extracting lithium isotope <6>Li with a centrifugal extraction machine. A device includes an extraction section, an alkali washing section, and a back extraction section. The lithium isotope extraction device in the invention is a novel and high-effective centrifugal extraction device, when the device is combined with a technology of extracting the lithium isotope through a solvent extraction method, stage efficiency and separation effect are greatly improved, the number of extraction stages is reduced, processing load is increased, and recovery rate of an extraction agent is increased. The method solves the problems of high cost, low processing load and difficulty in separation in the prior art, and has excellent market application prospect.

Owner:ZHENGZHOU TIANYI EXTRACTION TECH

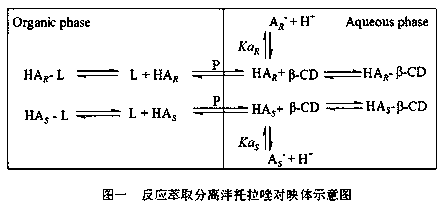

A kind of method of reactive extraction separation pantoprazole enantiomer

InactiveCN104277030BHigh separation factorEfficient continuous separationOrganic chemistrySeparation factorEnantiomer

The invention discloses a new method for separating pantoprazole enantiomers by reaction extraction, and a preparation method of new chiral pure pantoprazole. Racemic pantoprazole can be separated by biphasic recognition chiral extraction technology, and water soluble beta-cyclodextrin and tartaric acid ester are respectively used as chiral extractants in aqueous and organic phases. The invention discloses preparation methods of the aqueous and organic phases and repeated usage methods of the aqueous and organic phases. The extraction system has a very good separation performance on the racemic pantoprazole, distribution coefficients (kR and kS) are respectively 1.56 and 2.15, and separation factor (alpha) can reach 1.38.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

Process for abstracting vanadium from iron-smelting waste slag of vanadium -containing iron ore

InactiveCN101289705BReduce pollutionHigh vanadium selectivityProcess efficiency improvementSucroseSlag

The invention relates to a method for extracting vanadium from ironmaking waste slag of vanadium iron ores. The method comprises the following steps: a. vanadium is leached out of ironmaking waste slag of vanadium iron ores by using dilute sulfuric acids; b. leach solution uses ethylene glycol, glycerin, glucose or sucrose as extraction promoters so as to complex vanadium; c. the pH value of the solution is adjusted, and mixed extracting agents are used for extraction; d. organic phase back extraction is extracted by using dilute sulfuric acids; e. ammonia water is used to adjust the pH valueof the back extraction solution so as to deposit vanadium; f. the deposit is calcined for obtaining vanadium pentexide products with high purity. In the process, no harmful gases such as Cl2 and HCl,etc. are generated, and due to the adoption of ethylene glycol, glycerin, glucose or sucrose to treat the leach solution, no impurity ions are added in the solution; the use of the ammonia water deposition can improve the product purity, and the total extraction rate of vanadium reaches more than 90 percent.

Owner:BEIJING UNIV OF CHEM TECH

Method for extracting boron by solvent extraction-ion exchange adsorption combination

ActiveCN104445242BRealize development and utilizationReduce dosageBoron oxyacidsMagnesium saltIon exchange

The invention relates to a method for extracting boron with the combination of solvent extraction-ion exchange adsorption. According to the method, boric acid of relatively low content is extracted from old brine of a magnesium-containing salt lake after acidification boron precipitation; the energy consumption can be effectively reduced as an extraction procedure with relatively small grade numbers is adopted, and the use amount of an extraction agent is reduced; after extraction, an ion exchange adsorption procedure is performed, and the trace boron element is removed by using an ion exchange adsorption method with high selectivity, so that the boron extraction grade number is effectively reduced, and the energy consumption is reduced; as a novel mixed extracting agent system is adopted, the single-grade extraction rate is high, and the solution loss is small. The method can be implemented under the condition of low energy consumption, the boron of low content in old brine after acidification boron precipitation of the salt lake can be effectively extracted, the extract is a pure boron-containing solution, a high-quality boron product can be prepared, the boron resource can be sufficiently utilized, the quality of a later magnesium salt product is greatly improved, comprehensive development and utilization of the old brine after acidification boron precipitation of the salt lake are achieved, and the economic benefits are remarkably increased.

Owner:TIANJIN UNIV

Method for performing extraction separation on cobalt and nickel by using microfluid technology

The invention provides a method for performing extraction separation on cobalt and nickel by using a microfluid technology. The method comprises the following steps of: uniformly mixing an extraction agent and diluent which are subjected to homogeneous phase saponification by using a mixed material liquid of Co<2+> and Ni<2+>, using 2-ethyl cthylhexyl phosphonate mono 2-ethyl cthylhexyl ester as the extraction agent and using No.260 solvent oil and using the extraction agent and the diluent as an oil phase; introducing the water phase and the oil phase into a micro-reactor by virtue of two flow pumps; mixing the two phases in the micro-reactor and performing extraction reaction at 25-50 DEG C; and collecting a product at an outlet of the micro-reactor and standing for separating the phases to ensure that Co<2+> enters the oil phase and Ni<2+> stays in the water phase so as to realize extraction separation of cobalt and nickel. According to the method, continuous flow micro-reactor with an enhanced hybrid channel structure is adopted, the extraction separation of cobalt and nickel is carried out, and the reaction time is shortened to be within a micro-second level range, so that single-level cobalt extraction efficiency is obviously improved, and the extraction levels are reduced; and moreover, standing layering on the water phase and the oil phase can be quickly carried out without any emulsion phenomenon.

Owner:KUNMING UNIV OF SCI & TECH

A method for recovering titanium from waste hydrochloric acid produced by producing titanium dioxide by chlorination

ActiveCN103773962BWith low temperature selective extractionReduce extraction timeMetal recyclingProcess efficiency improvementResource recoveryPhysical chemistry

Owner:CITIC JINZHOU METAL

A method for preparing high-purity cobalt sulfate from electrolytic manganese sulfide slag

ActiveCN112662878BAchieve leachingSimple processCobalt sulfatesProcess efficiency improvementManganese sulfidePhysical chemistry

The invention discloses a method for preparing high-purity cobalt sulfate from electrolytic manganese sulfide slag, which is carried out according to the following steps: (1) crushing and sieving; (2) oxidation leaching; (3) calcium removal; (4) manganese removal; 5) Synchronous extraction of cobalt and nickel; (6) Recovery of cobalt: take cobalt-nickel-rich organic phase, add dilute sulfuric acid for back extraction, and obtain cobalt-nickel sulfuric acid solution and neodecanoic acid organic phase; separate cobalt-nickel sulfuric acid solution, add saponification P507-Cyanex301 mixed with sulfonated kerosene to form the fourth organic extractant extraction, to obtain cobalt-rich organic phase and nickel sulfate solution; separate the cobalt-rich organic phase, add sulfuric acid for back extraction, to obtain high-purity rich cobalt sulfate solution and P507- Cyanex301 organic phase; (7) Preparation of high-purity cobalt sulfate. The invention has the advantages of being simple and feasible, realizing the leaching of cobalt sulfate, avoiding the generation of hydrogen sulfide gas, the use of iron-precipitating process and the method of fluoride ion precipitation for removing calcium and magnesium ions.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Method for Comprehensive Recovery of Nickel and Magnesium in Bioleaching Process of High Magnesium and Low Nickel Sulfide Ore

InactiveCN104745813BReduce lossesImprove separation and extraction efficiencyProcess efficiency improvementRecovery methodHigh magnesium

The invention discloses a method for comprehensively recovering nickel and magnesium in a bio-leaching process of high-magnesium low-nickel sulfide ore. The method comprises the following steps: treating the bio-leachate of high-magnesium low-nickel sulfide ore through an ion exchange resin column to adsorb nickel ions, and enabling the magnesium-rich solution to flow out; desorbing residual magnesium ions in the ion exchange resin by use of low-acidity sulfuric acid, desorbing nickel ions in the ion exchange resin by use of high-acidity sulfuric acid, and returning the nickel ion desorption solution to the yard; and when the mass concentration of Mg and Ni in the leachate of the yard is lower than 5, extracting nickel with Versatic 10 and performing back extraction of an organic phase to obtain a nickel-rich solution. According to the method, by increasing the nickel-magnesium concentration ratio and reasonably matching the technological parameters, nickel and magnesium are effectively separated, and a recovery method of nickel and magnesium in bio-leachate is realized.

Owner:有研资源环境技术研究院(北京)有限公司

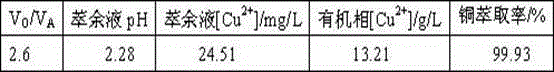

Method for increasing extraction efficiency of copper in water solution

InactiveCN102864306BReduced activityGood for continuous extractionProcess efficiency improvementHydrogenKerosene

The invention belongs to the technical field of extraction and separation and particularly relates to a method for increasing extraction efficiency of copper in a water solution. The method particularly comprises the steps of: adding a citrate with mole number equivalent to that of copper in a copper-containing solution of a strong acid system or adding a neutralizing reagent in a copper citrate solution system, regulating pH of the solution to 1.5-5; preparing an oxime extracting agent into a required organic phase by using kerosene according to the difference of concentrations of the copper in the water solution; and mixing the organic phase with the copper-containing solution, stirring and extracting for realizing efficient extraction of the copper. According to the invention, by using the citrate as a pH buffer agent, acid generated in a water phase in an extraction process is buffered by citrate radicals, the activity of hydrogen ions in the solution is reduced, therefore, the continuous extraction of the copper is facilitated; and because the copper extraction efficiency is high and the extraction stage number is reduced, the investment, the occupation area and the operation and maintenance cost of equipment are greatly lowered in practical use,.

Owner:NORTHEASTERN UNIV LIAONING

A method for extracting zinc from low-concentration zinc sulfate solution

ActiveCN103667697BImprove extraction efficiencyShort reaction timeProcess efficiency improvementSingle stageSulfate

The invention relates to a method for extracting zinc from a low-concentration zinc sulfate solution, belonging to the technical field of wet-process metallurgy. The method is characterized in that a low-concentration ZnSO4 solution is used as an aqueous phase, an extracting agent and a diluting agent jointly serve as oil phases, the aqueous phase and the oil phases are synchronously pumped into a micro-fluid passage with the diameter of 25-600 micrometers according to a volume ratio of (1:5)-(1:1) and are subjected to extraction reaction, after the reaction is ended, effluent mixed liquid stands still and is subjected to phase separation, and at the moment, Zn<2+> enters a loaded organic phase, so that the extraction separation of zinc in the low-concentration ZnSO4 solution is realized. According to the method, micro-fluid of a continuous flow enhanced mixed-type passage structure is used for zinc extraction, the reaction time is reduced to the millisecond-stage range, the single-stage zinc extraction efficiency is obviously improved, and the extraction stage number is reduced.

Owner:KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com