Method for comprehensively recovering nickel and magnesium in bio-leaching process of high-magnesium low-nickel sulfide ore

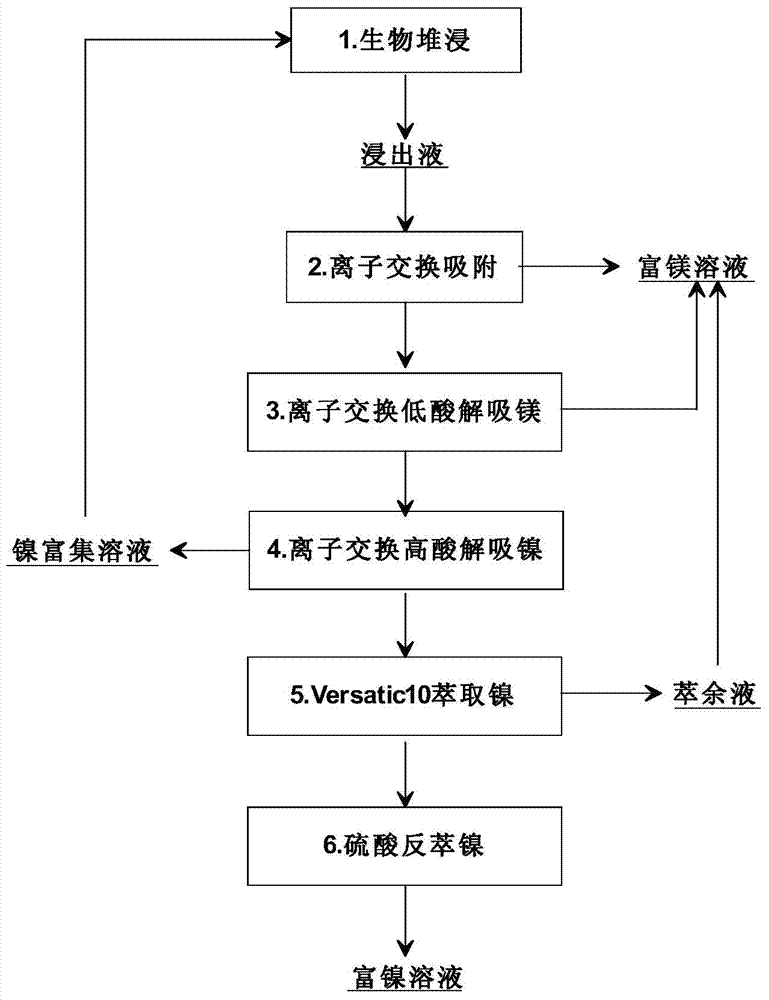

A technology of bioleaching and sulfide ore, applied in the direction of improving process efficiency, can solve problems such as inability to recover economically, difficult extraction and separation, and inability to comprehensively recover, and achieve the effect of reducing costs and improving separation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A certain nickel ore belongs to high magnesium and low nickel sulfide ore (produced in Laos, with magnesium content of 23wt%, nickel content of 0.2wt%, and iron content of 4wt%). After bioheap leaching to adjust the pH to 2.0-2.5, nickel ions in the obtained bioleaching solution It is 300mg / L, while the magnesium ion reaches 15g / L, Mg / Ni=50, and the total iron ion concentration is 25mg / L. The higher magnesium-nickel concentration ratio in the leaching solution will seriously affect the extraction and separation efficiency of nickel.

[0021] Step (1), take the leachate produced by bioheap leaching of high-magnesium and low-nickel sulfide ores, Mg / Ni=50 (mass concentration ratio), pH2.5, Mg 2+ 15g / L, total iron concentration 25mg / L;

[0022] Step (2), the leaching solution passes through the ion exchange resin column CN27, the nickel ions are adsorbed, the nickel ion adsorption rate reaches more than 99%, and the magnesium-rich solution flows out, and the solution Mg 2+...

Embodiment 2

[0029] A certain nickel ore belongs to high-magnesium and low-nickel sulfide ore (produced from Jinchuan tailings, with magnesium content of 15wt%, nickel content of 0.3wt%, and iron content of 5wt%). The nickel ion is 200mg / L, while the magnesium ion reaches 15g / L, Mg / Ni=75, and the total iron ion concentration is 27mg / L. The higher magnesium-nickel concentration ratio in the leaching solution will seriously affect the extraction and separation efficiency of nickel.

[0030] Step (1), take the leachate produced by bioheap leaching of high-magnesium and low-nickel sulfide ores, Mg / Ni=75 (mass concentration ratio), pH2.5, Mg 2+ 15g / L, total iron concentration 27mg / L;

[0031] In step (2), the leaching solution passes through the ion exchange resin column WP-1, and the nickel ions are adsorbed, and the adsorption rate of the nickel ions reaches more than 98%, and the magnesium-rich solution flows out, and the solution Mg 2+ Concentration 12g / L;

[0032] Step (3), using 20g / L s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com