Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Feed speed control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

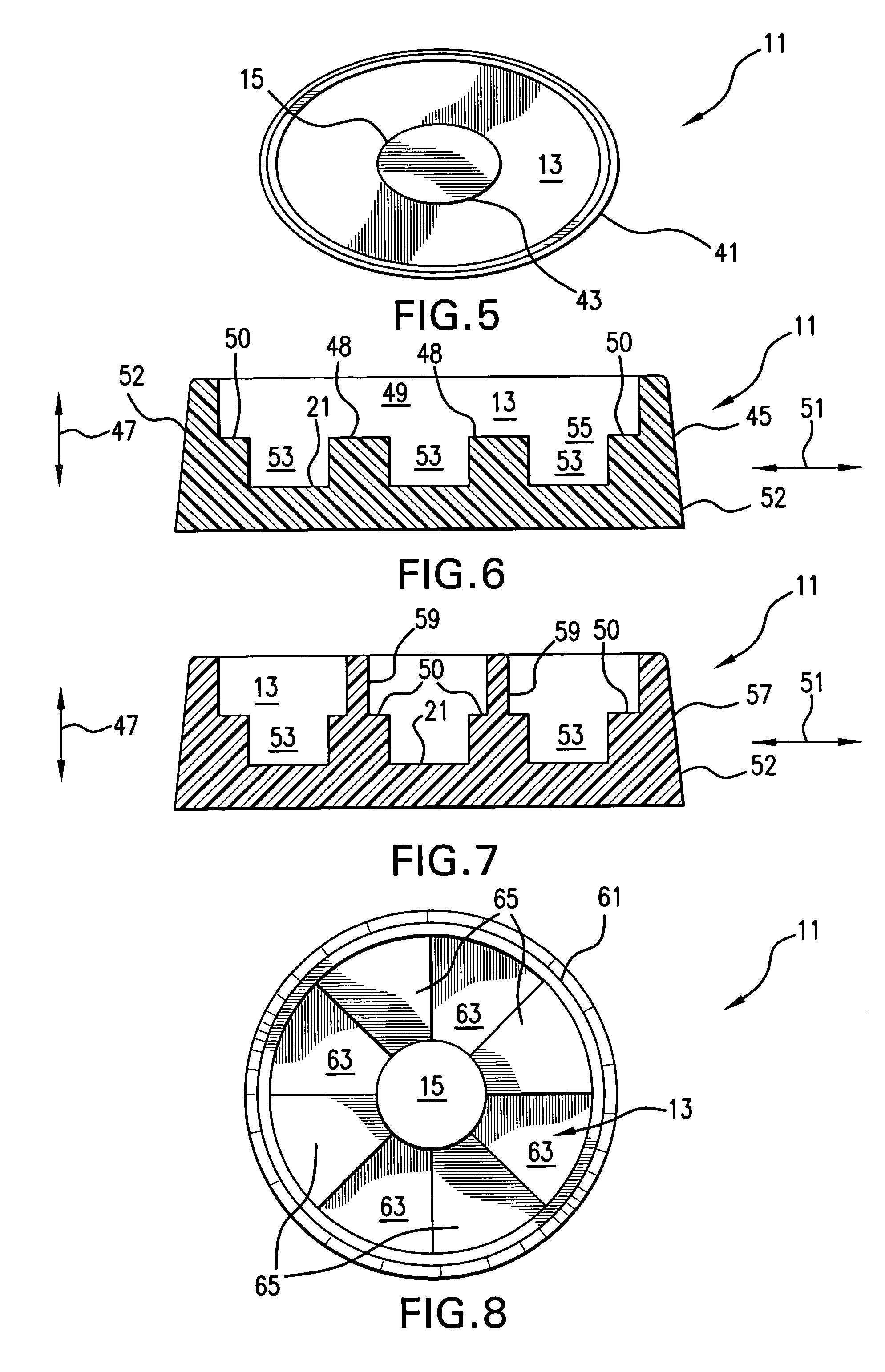

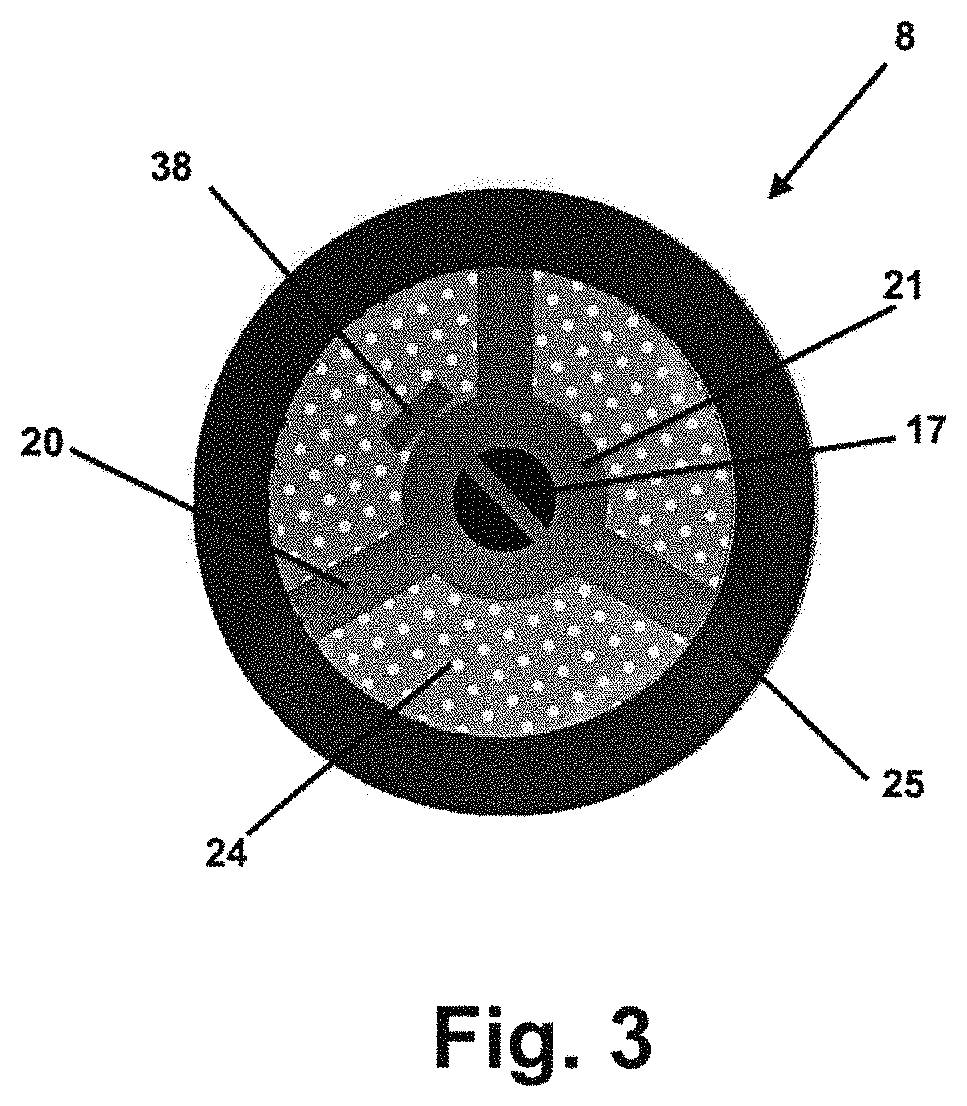

Restricted access food dish for animals

InactiveUS20060231039A1Feed speed controlMinimumAnimal feeding devicesAnimal housingEngineeringRestricted access

An animal feeding dish having a main receptacle with a volume for holding food and a body tenaciously attached within, or formed integrally within, the volume of the main receptacle limits the feeding rate of a ravenous animal to prevent negative consequences of high rate devouring of food placed within the dish.

Owner:ABINANTI SHARON M +1

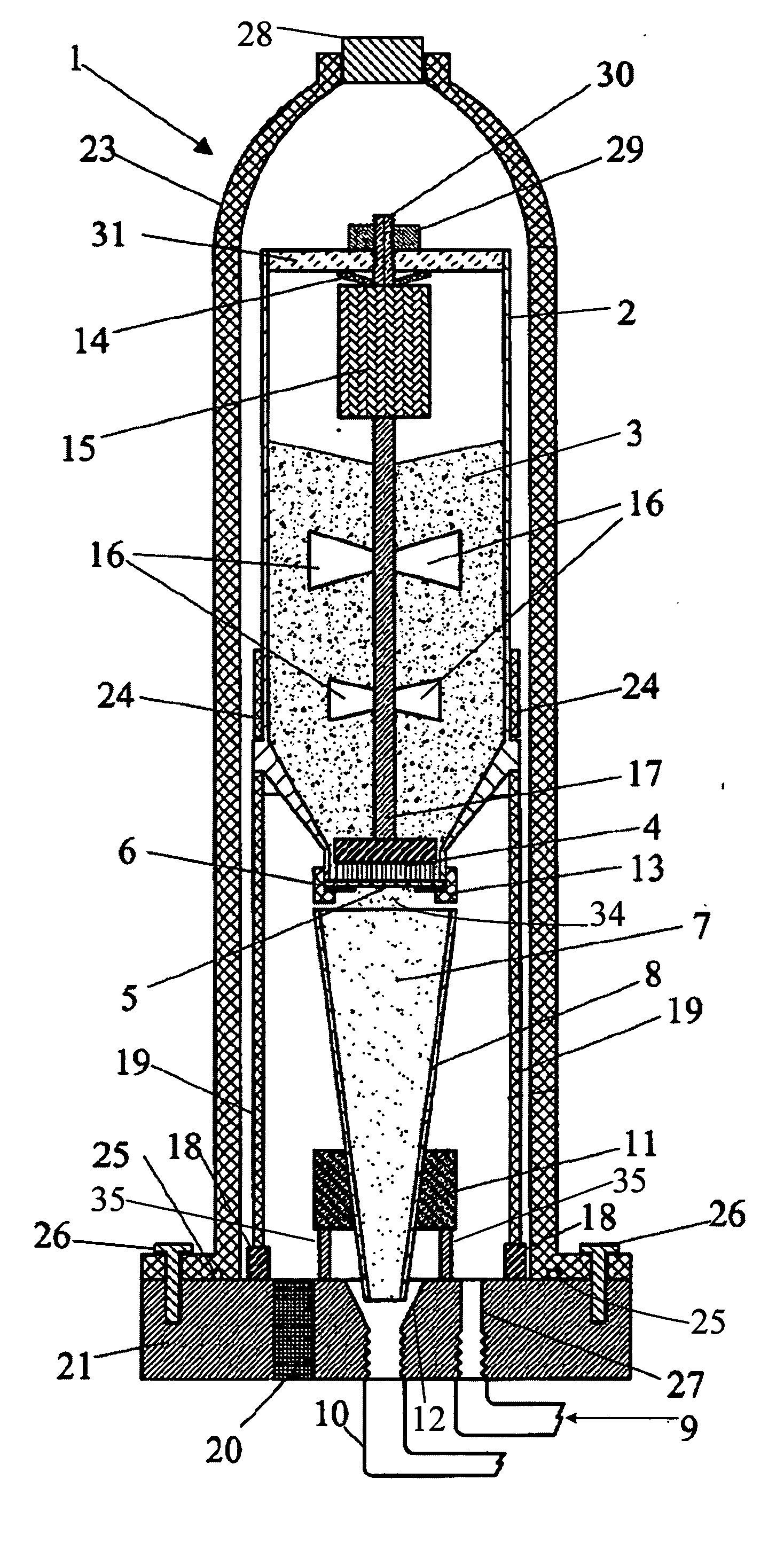

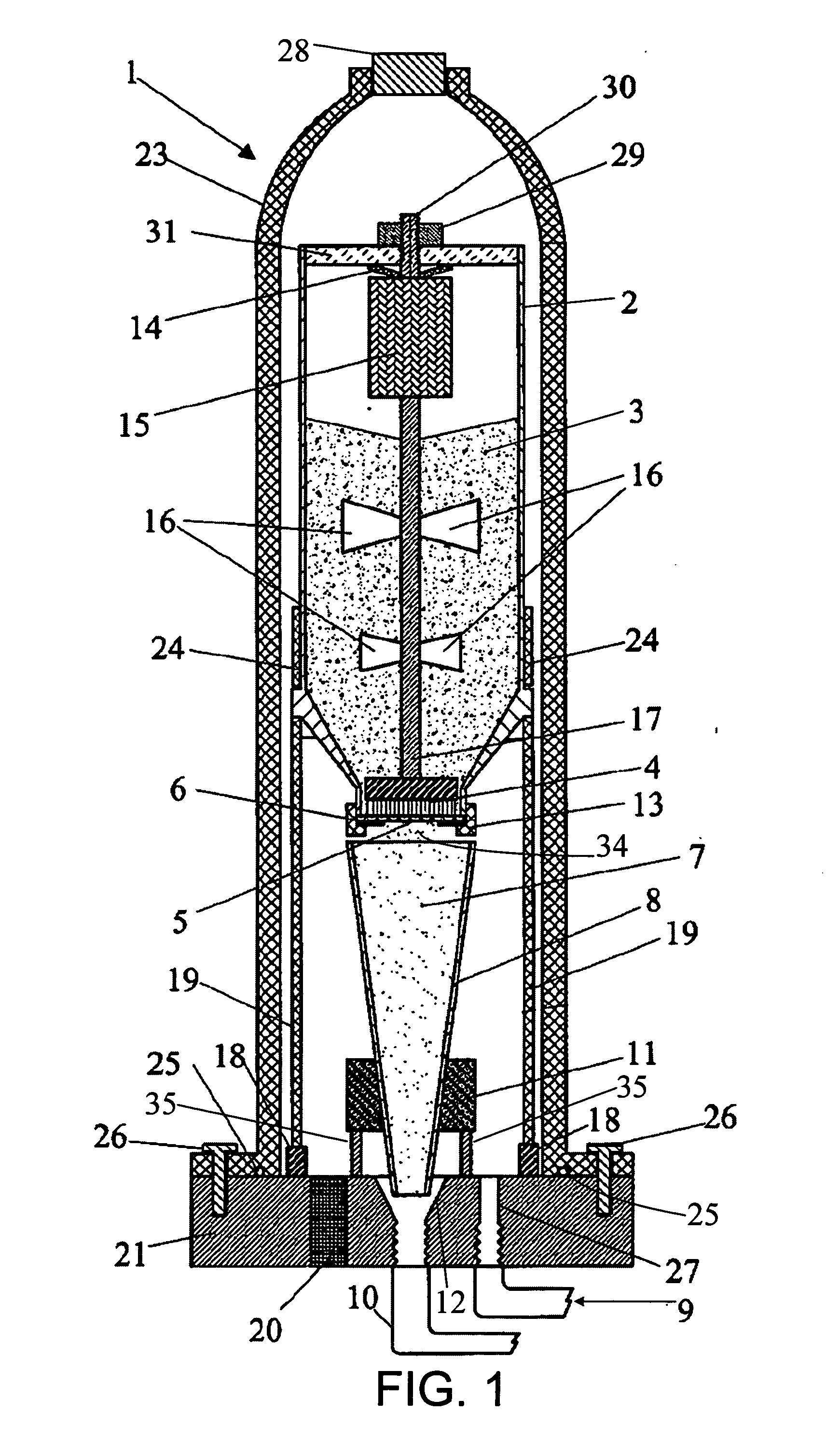

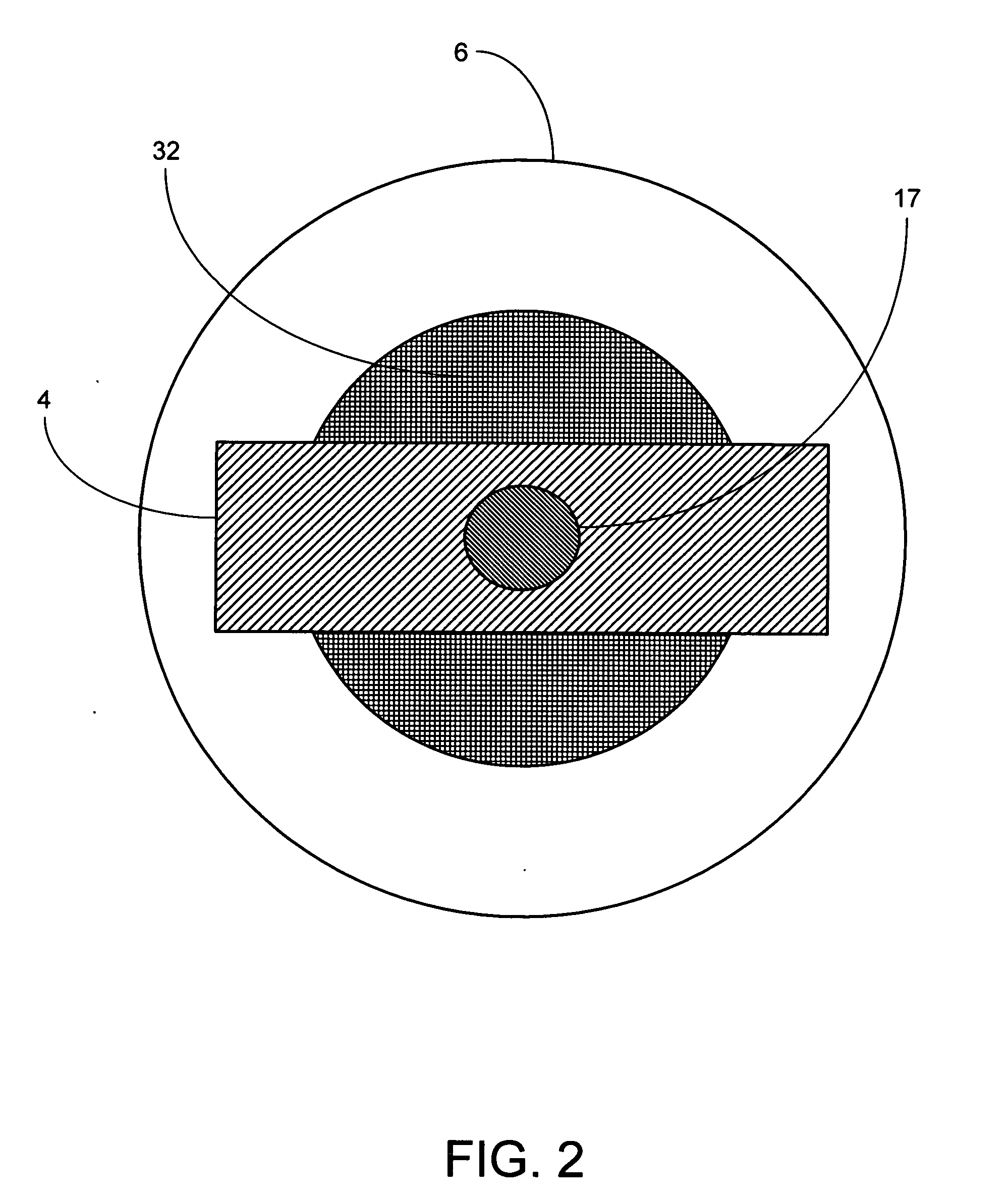

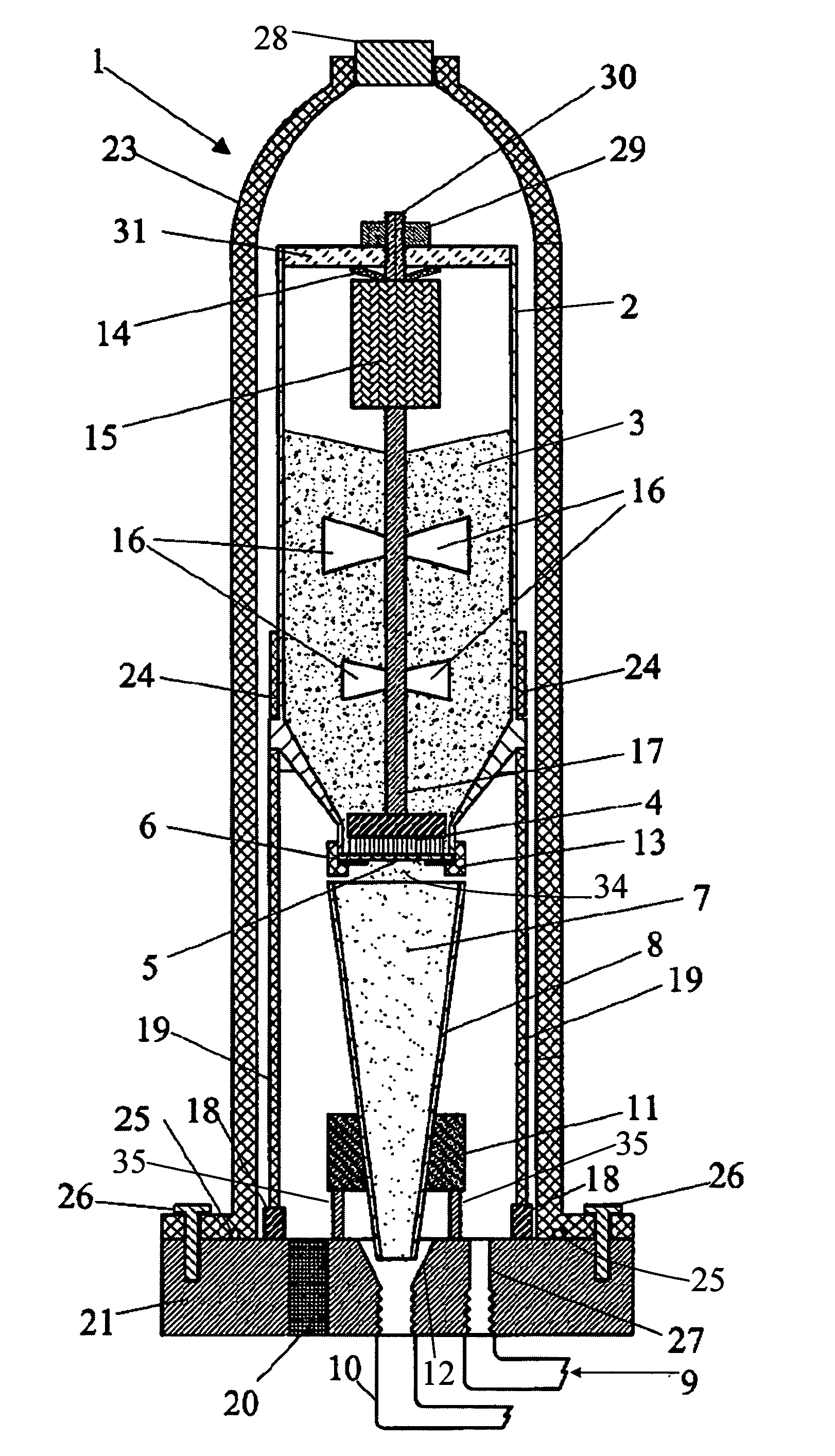

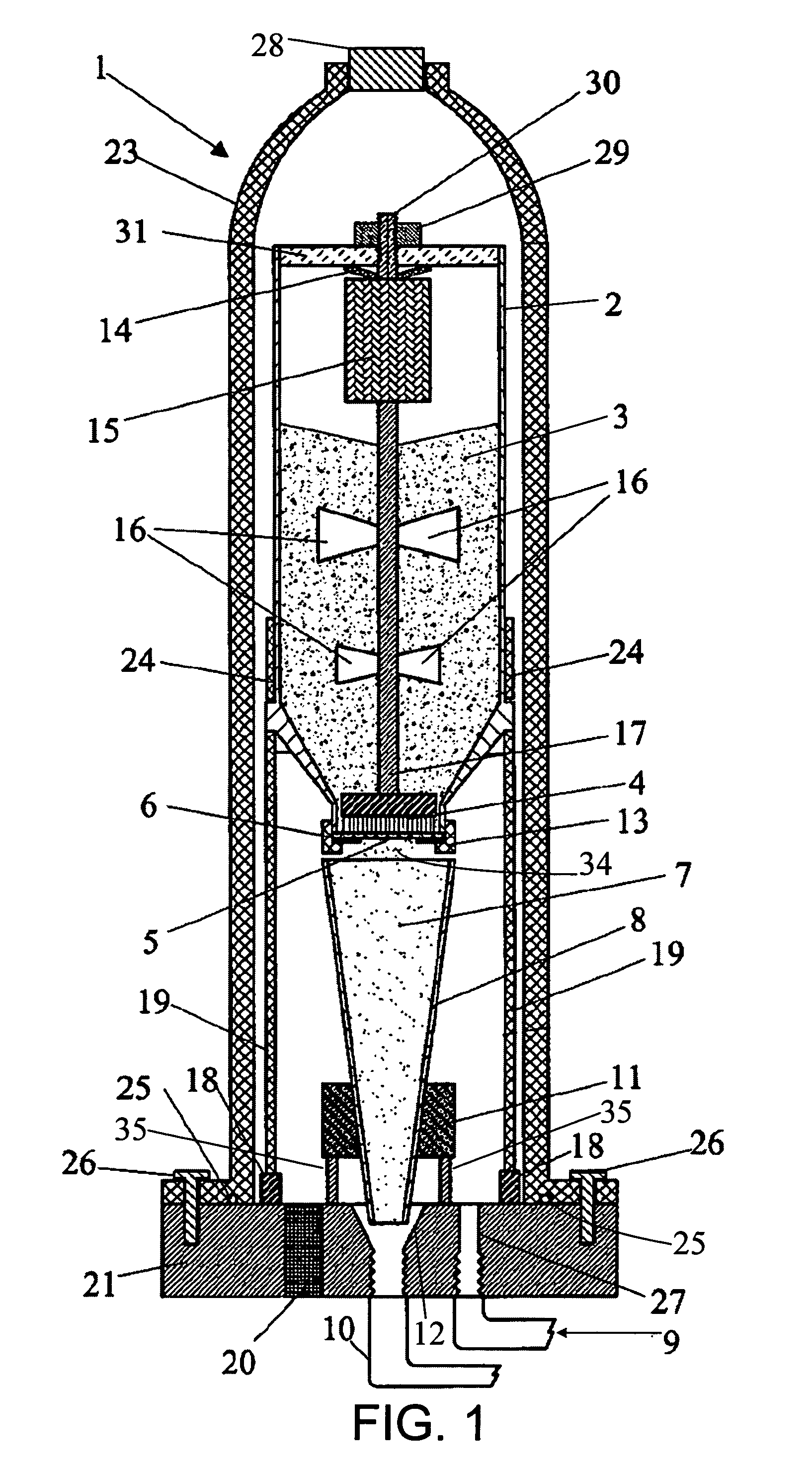

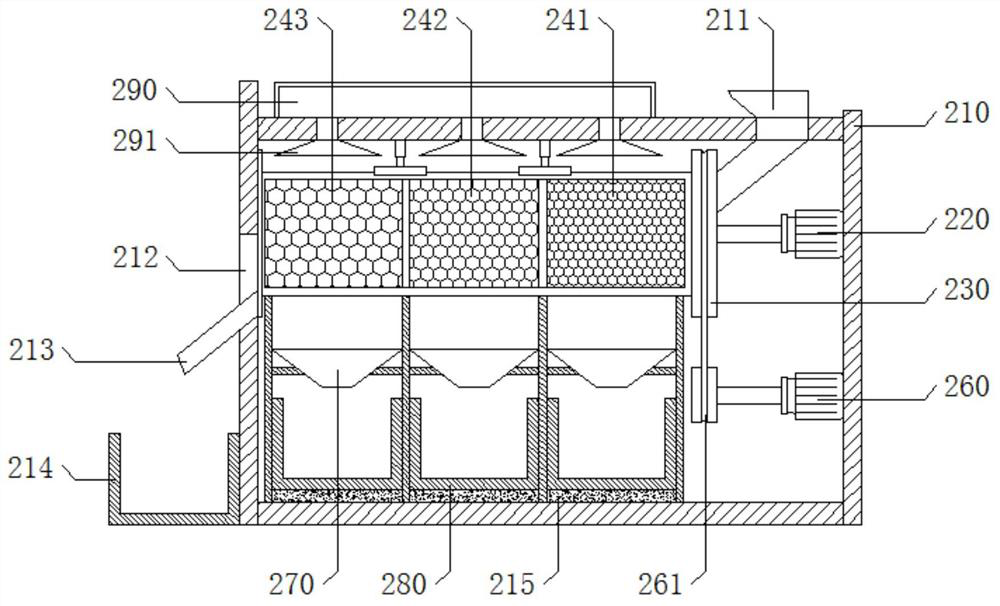

Brush-sieve powder-fluidizing apparatus for feeding nano-size and ultra-fine powders

ActiveUS20070193646A1Increase materialSimple materialRotary stirring mixersLiquid transferring devicesNanometreUltra fine

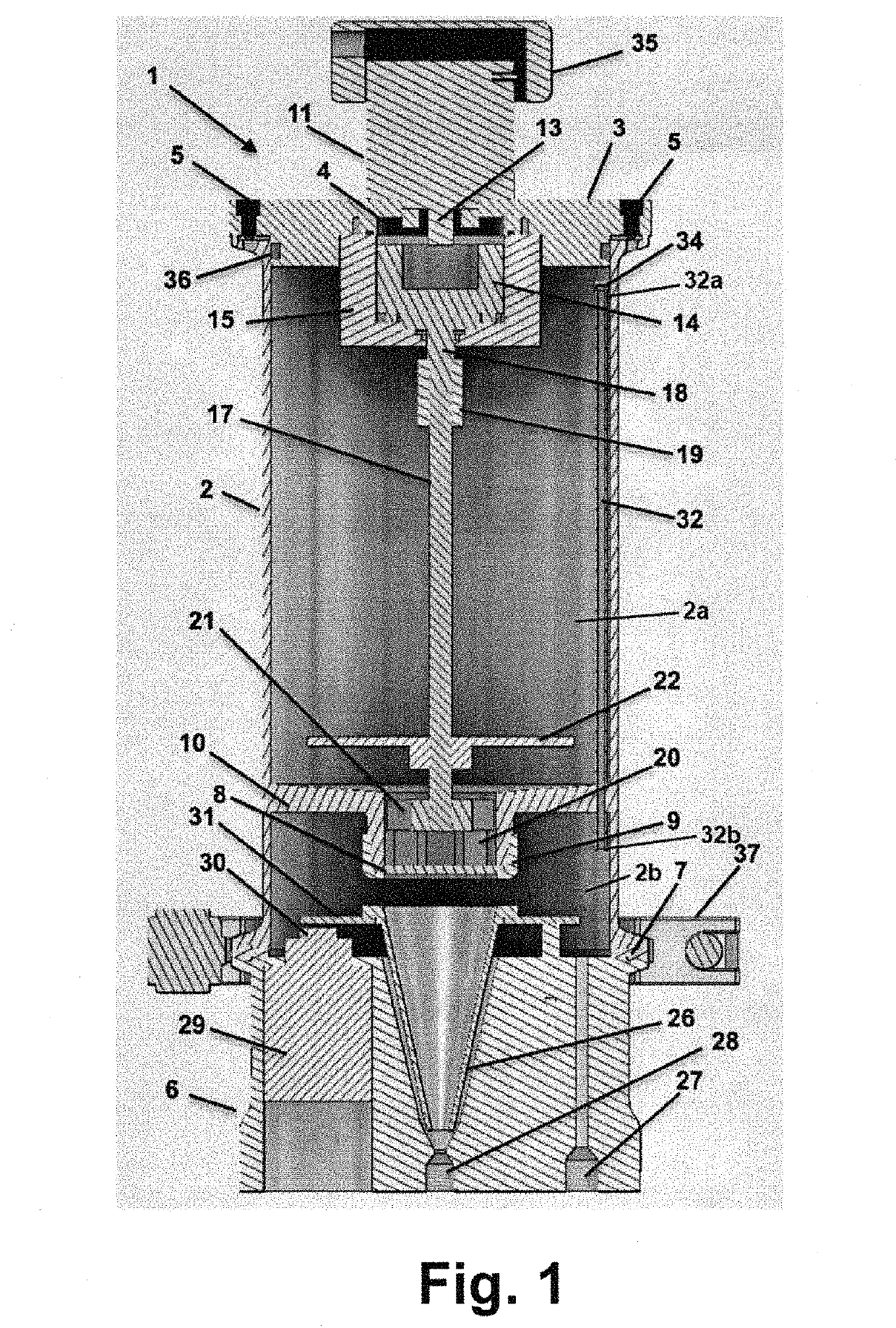

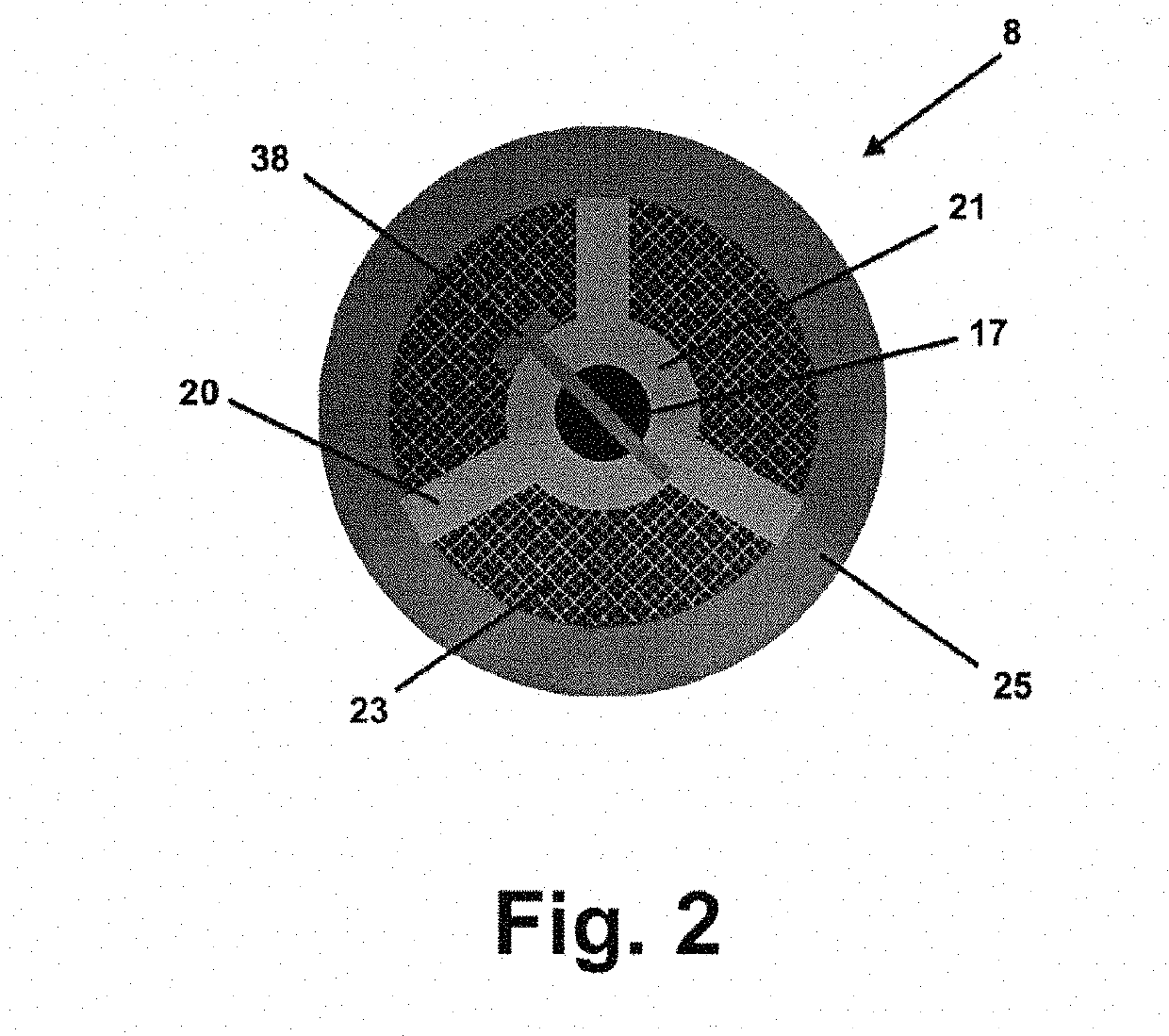

A powder-fluidizing apparatus is presented which is applicable to feeding ultra-fine and nano-size powders, and powders with a broad particle size distribution, in a uniform manner over a long period of time. Generally, this is accomplished by using a rotating brush to sweep the powder through holes in a removable sieve plate, which breaks up agglomerated particles in the powder and controls the powder feed rate. The powder then drops from the holes into a funnel, where it is fluidized by being entrained into a carrier gas, and then flows through the funnel out of the apparatus to an applicator. The funnel surface is vibrated to avoid powder build-up on the surface that can break loose and cause pulses of increased material in the powder flow. Ultrasonic waves are introduced into the funnel to break up any agglomerated particles remaining in the powder before it reaches the applicator.

Owner:INNOVATION TECH INC

Brush-sieve powder-fluidizing apparatus for feeding nano-size and ultra-fine powders

ActiveUS7273075B2Simple materialFeed speed controlRotary stirring mixersLiquid transferring devicesUltra fineNanometre

A powder-fluidizing apparatus is presented which is applicable to feeding ultra-fine and nano-size powders, and powders with a broad particle size distribution, in a uniform manner over a long period of time. Generally, this is accomplished by using a rotating brush to sweep the powder through holes in a removable sieve plate, which breaks up agglomerated particles in the powder and controls the powder feed rate. The powder then drops from the holes into a funnel, where it is fluidized by being entrained into a carrier gas, and then flows through the funnel out of the apparatus to an applicator. The funnel surface is vibrated to avoid powder build-up on the surface that can break loose and cause pulses of increased material in the powder flow. Ultrasonic waves are introduced into the funnel to break up any agglomerated particles remaining in the powder before it reaches the applicator.

Owner:INNOVATION TECH INC

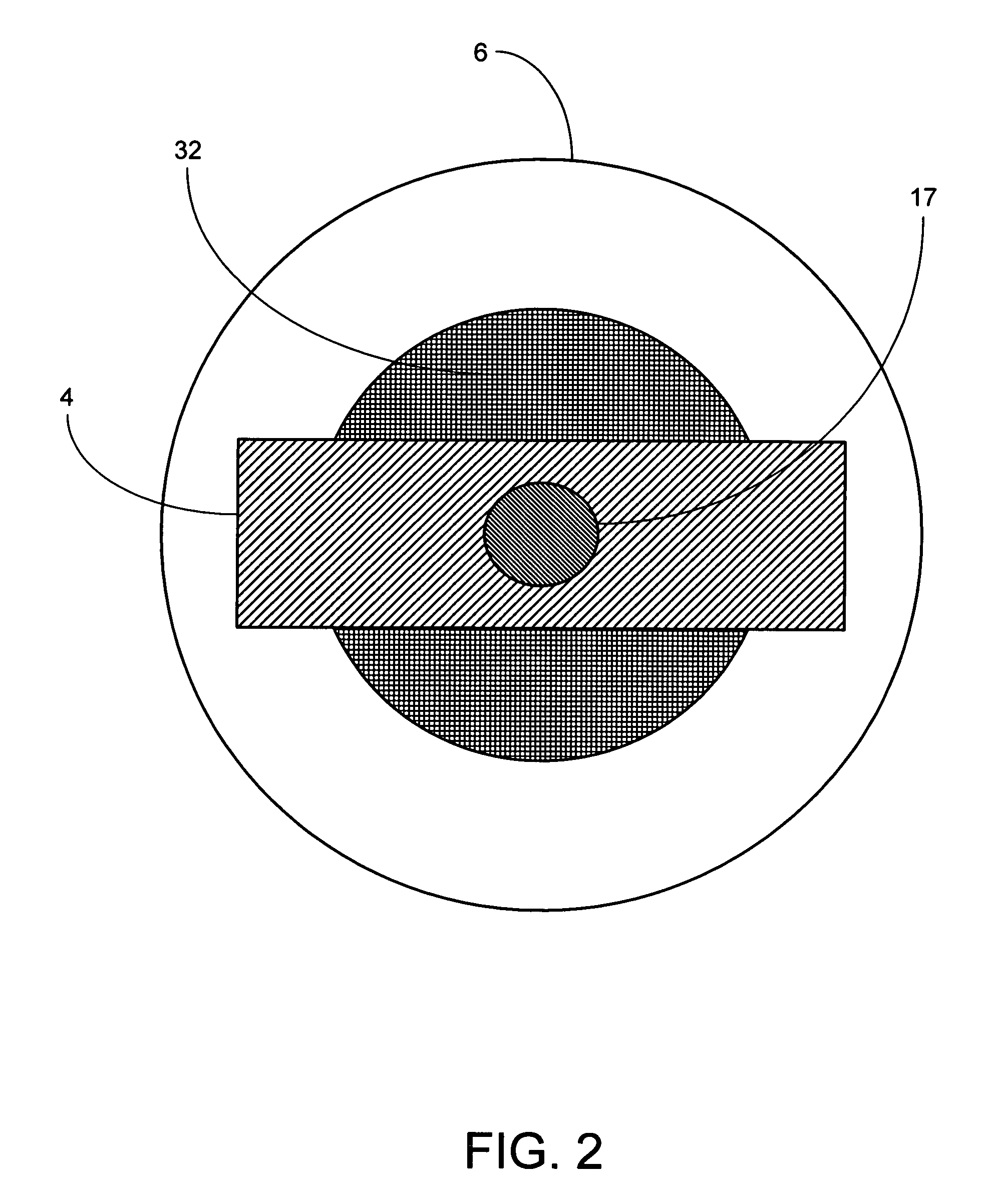

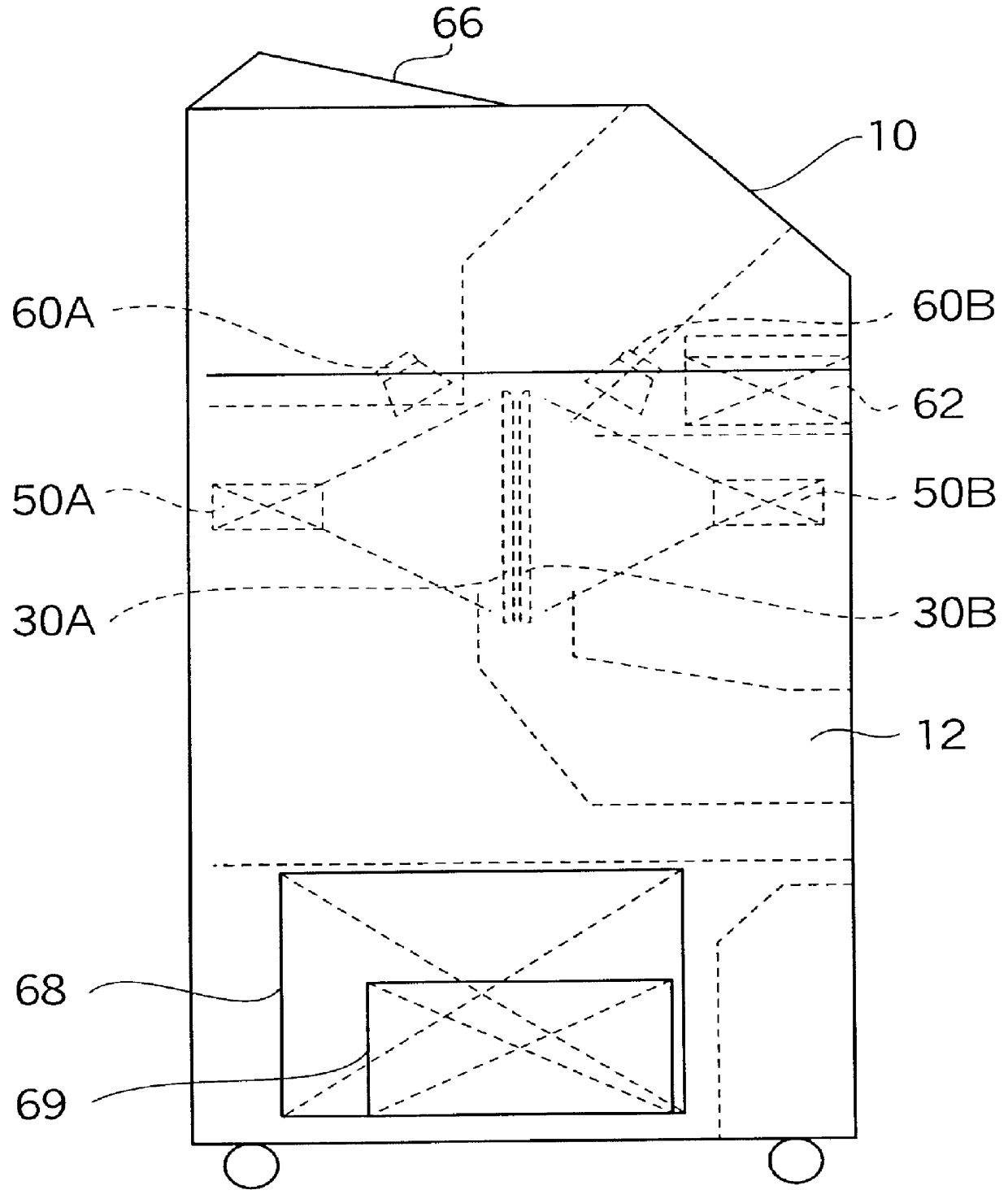

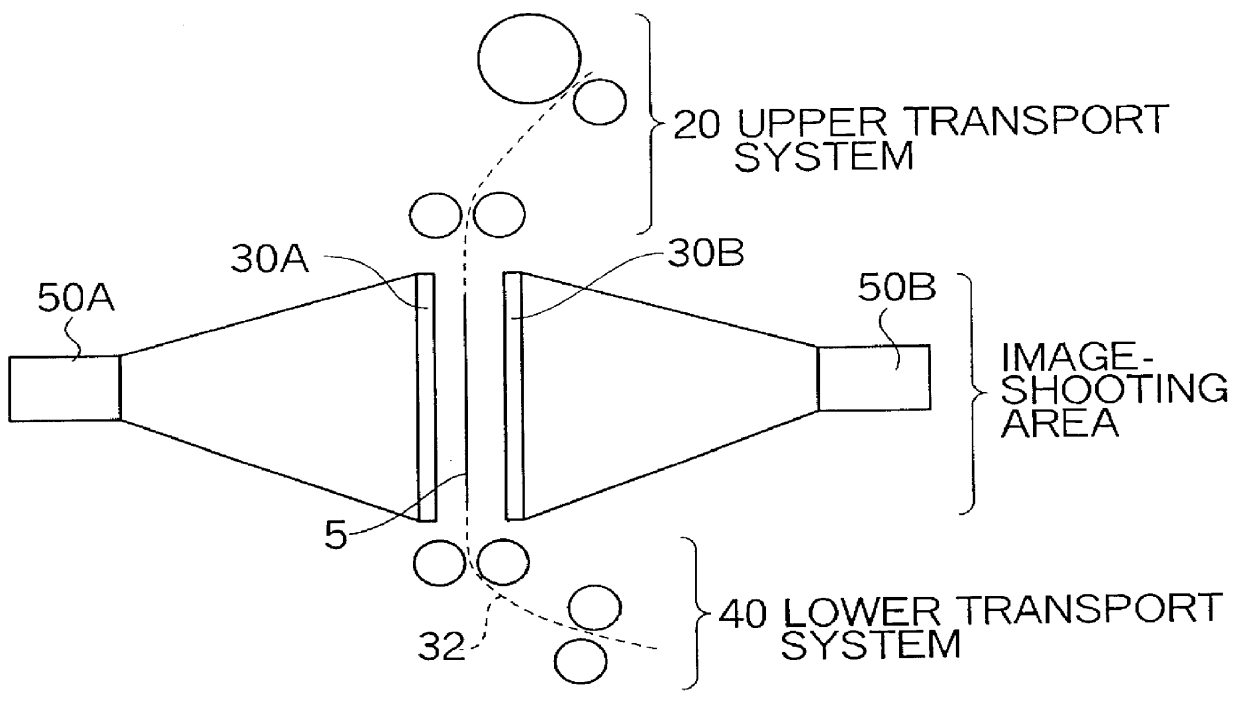

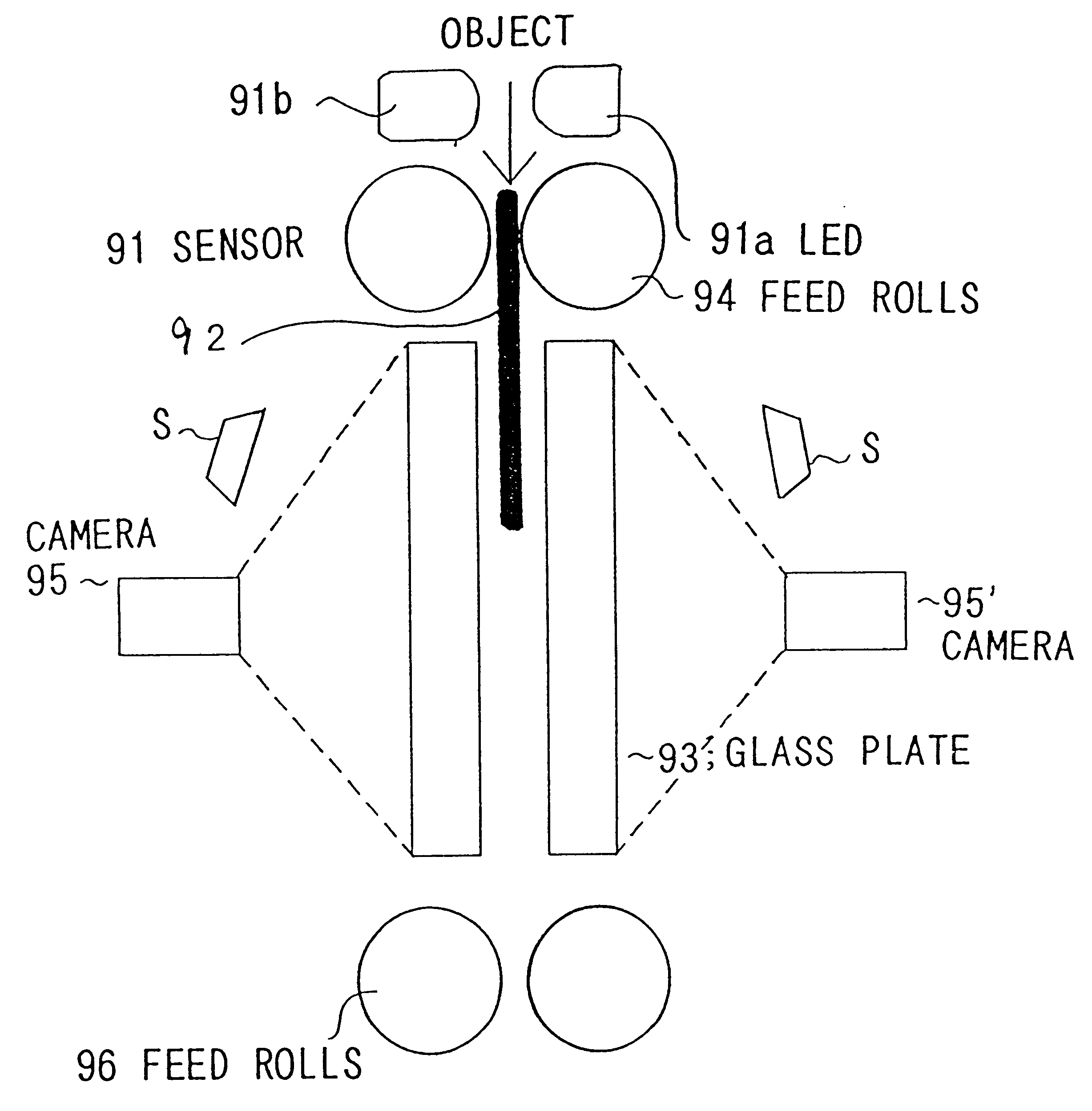

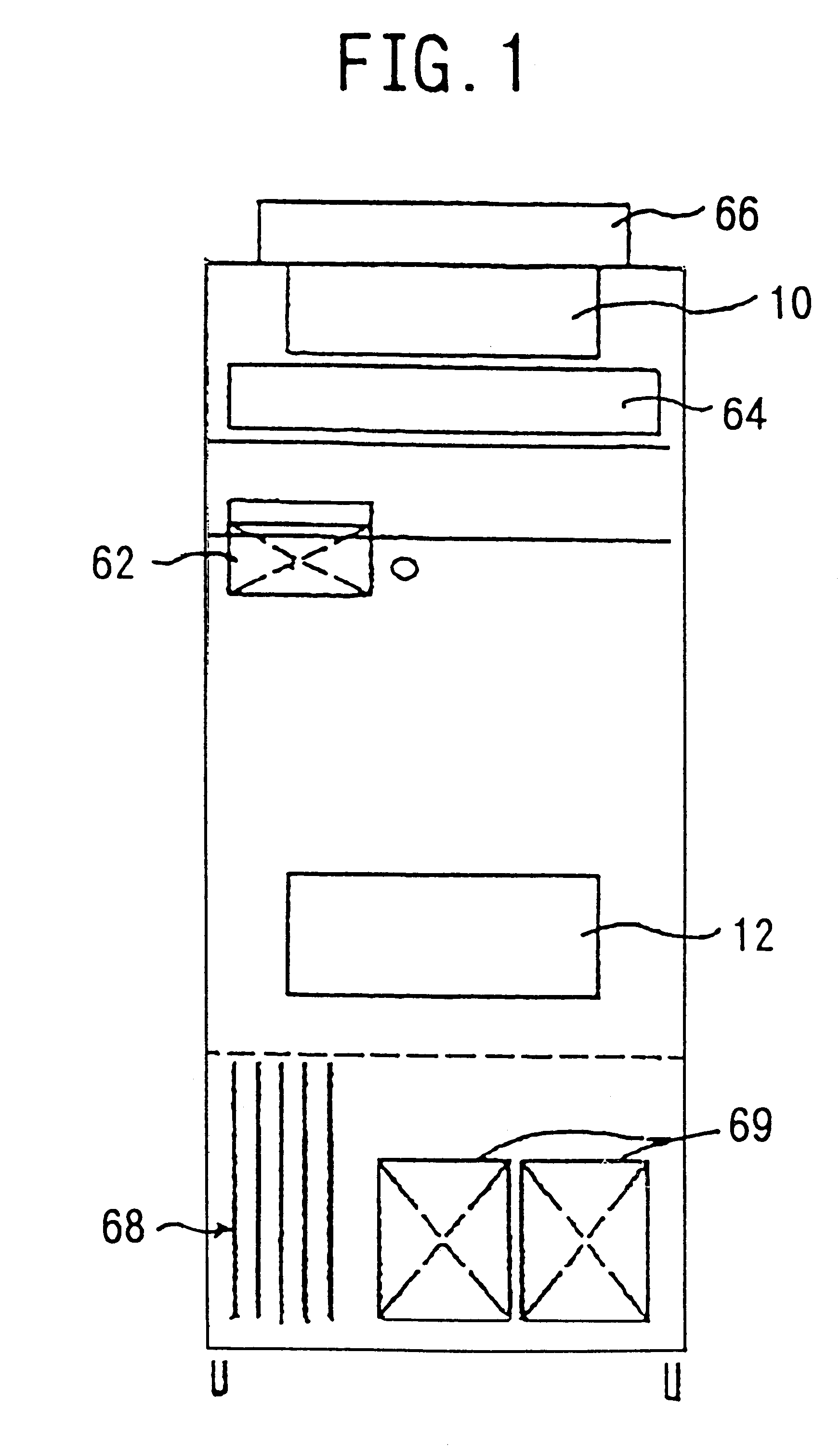

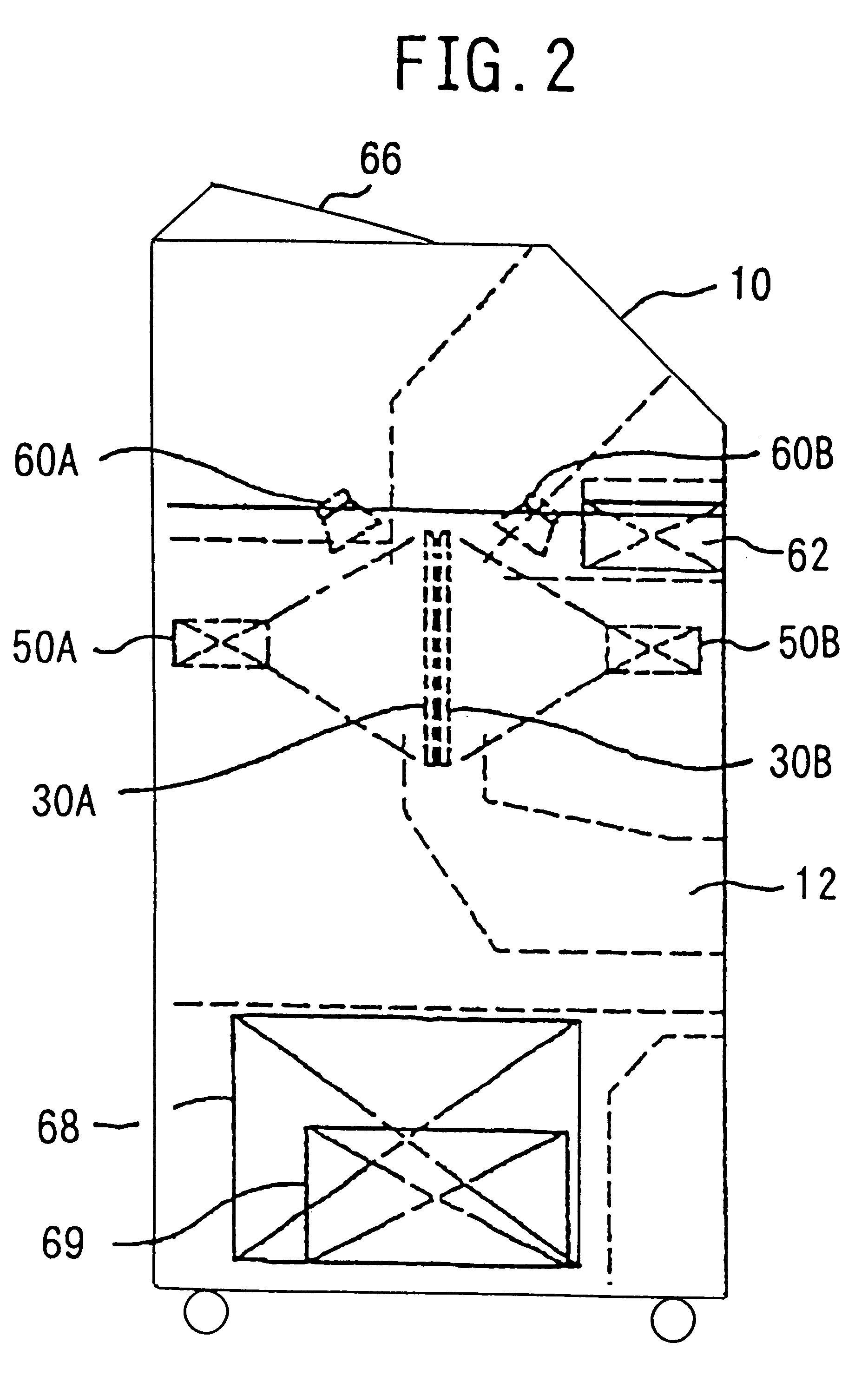

Device for image shooting both sides of documents

InactiveUS6069681AIncrease speedReliably obtainedPhotographic printingPictoral communicationTransport systemHigh rate

A novel device for image-shooting both surfaces of documents at a high rate by electronic means. The device has an upper transport system for allowing plural documents to descend / move by a pre-set number at a time towards the downstream and image-shooting means for image- shooting the descending / moving document. Image-shooting can be done simultaneously on both sides or side by side, either during free movement or controlled movement by tranporting means etc.

Owner:FUJIFILM HLDG CORP +1

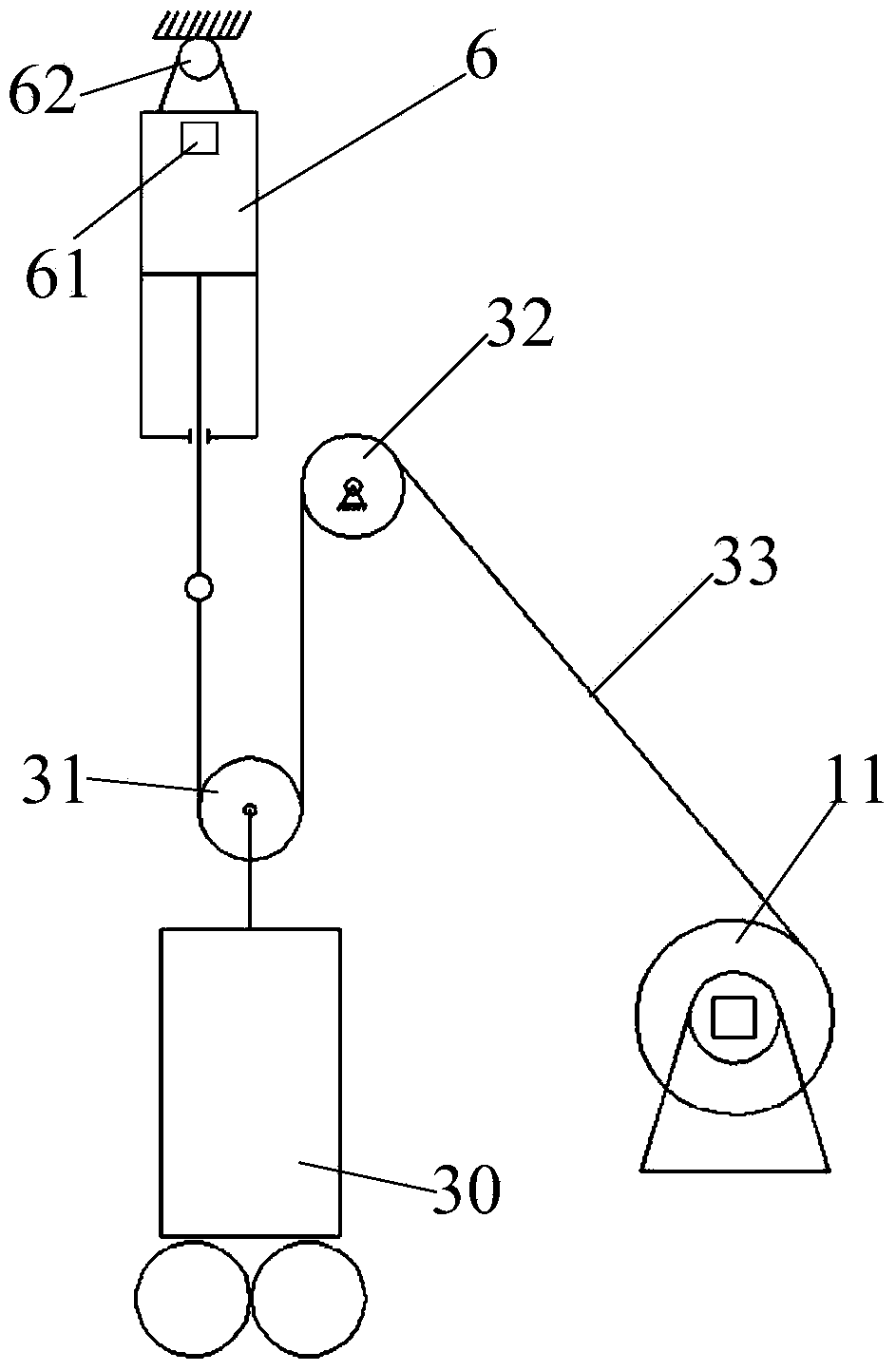

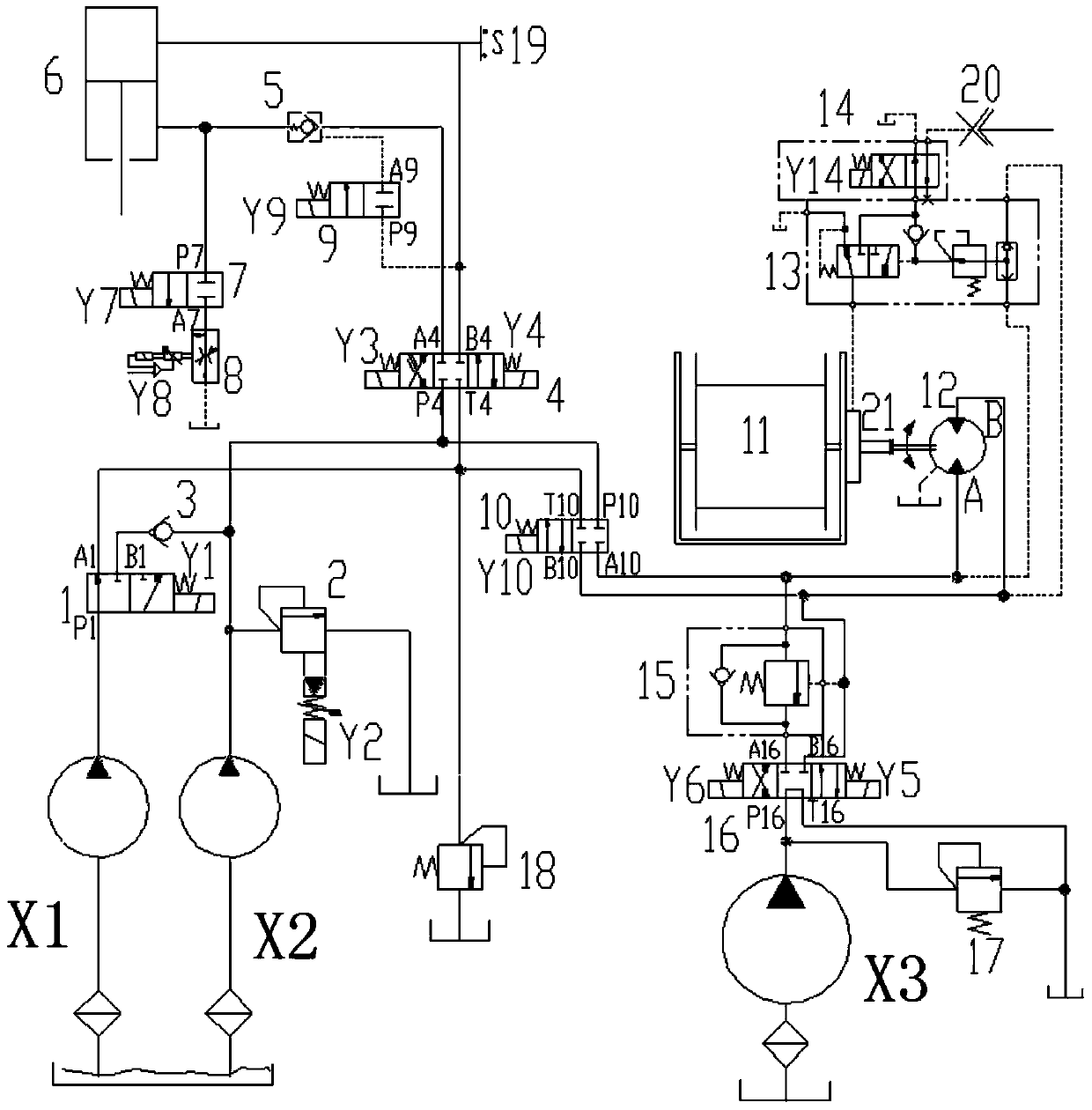

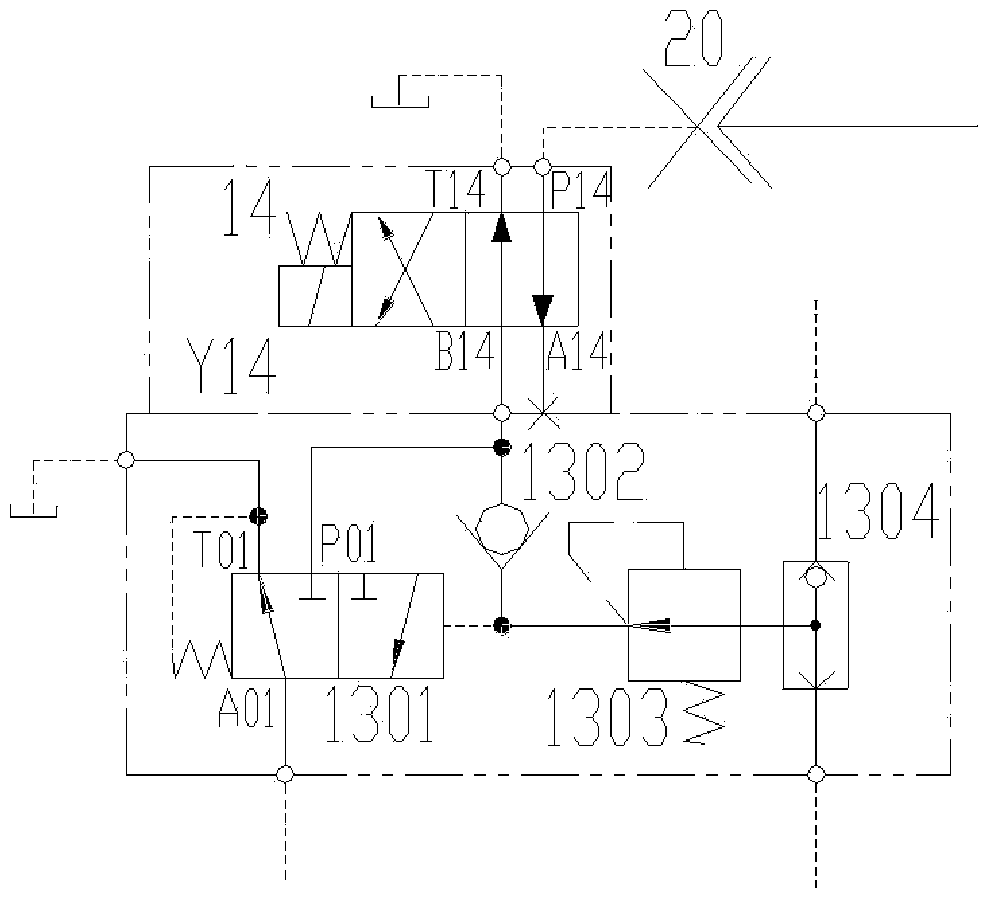

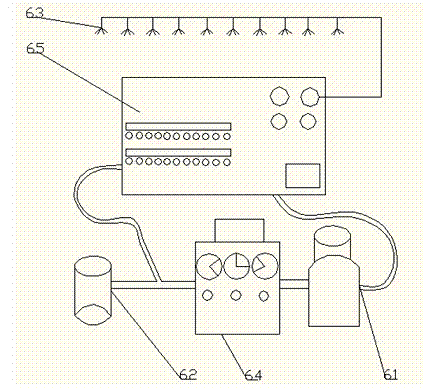

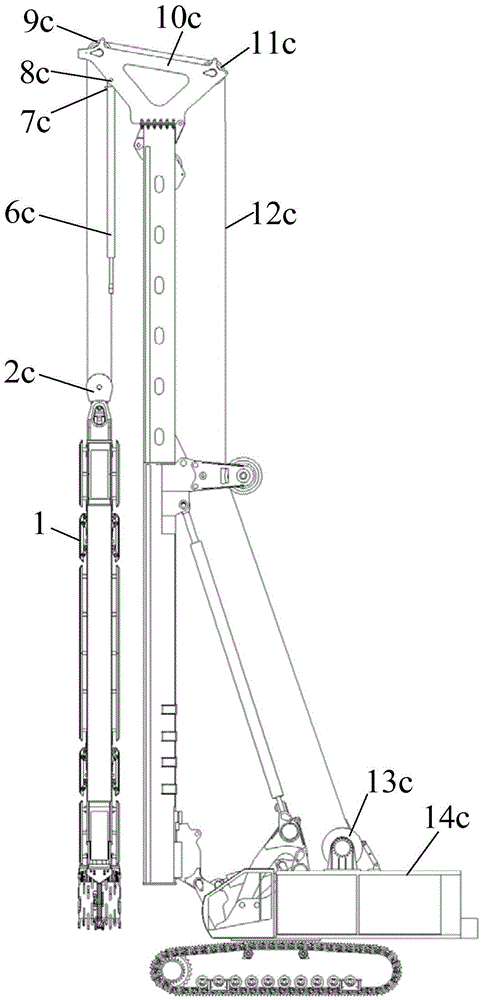

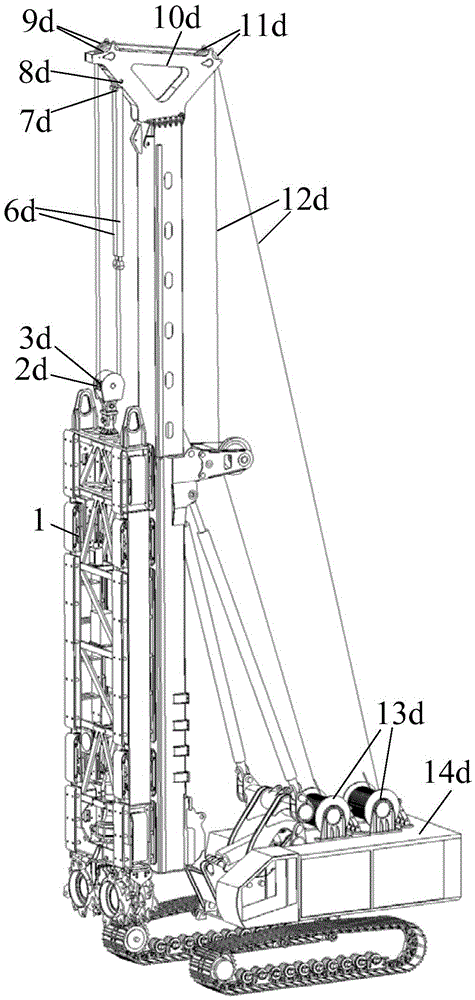

Hydraulic control feeding system and hydraulic control feeding method

ActiveCN103807238AImprove corrosion resistanceImprove sealingServomotor componentsMechanical machines/dredgersHydraulic pumpEngineering

The invention relates to a hydraulic control feeding system and a hydraulic control feeding method. The system comprises a hydraulic pump component, a first executing element, a second executing element, a pulley component and a feeding device, wherein a second reversing valve is arranged on an oil way for connecting the hydraulic pump component and the first executing element; the on-off state of the oil way between the hydraulic pump component and the first executing element is controlled by the second reversing valve; a fifth reversing valve is arranged on the oil way for connecting the hydraulic pump component and the second executing element; the on-off state of the oil way between the hydraulic pump component and the second executing element is controlled by the fifth reversing valve; the first executing element and the second executing element are both connected with the feeding device through the pulley component; a differential relation can be formed between the first executing element and the second executing element. The hydraulic control feeding system and the hydraulic control feeding method do not require the executing elements, and have high corrosion resistance, high sealing performance, impact resistance and the like, the pressure loss is low, the power loss is low, the construction cost is low, and the stable feeding of the feeding device can be guaranteed.

Owner:XCMG CONSTR MACHINERY

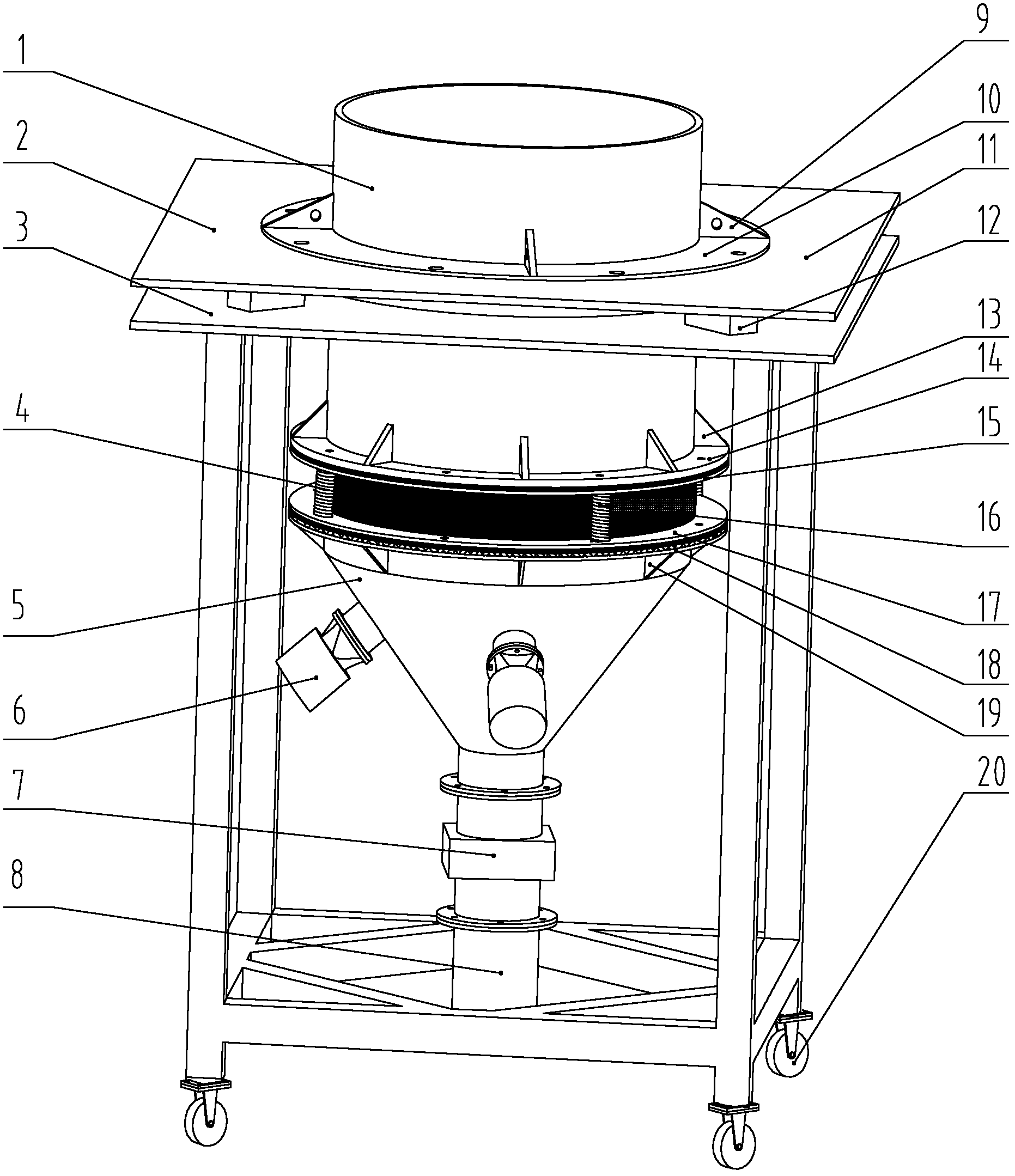

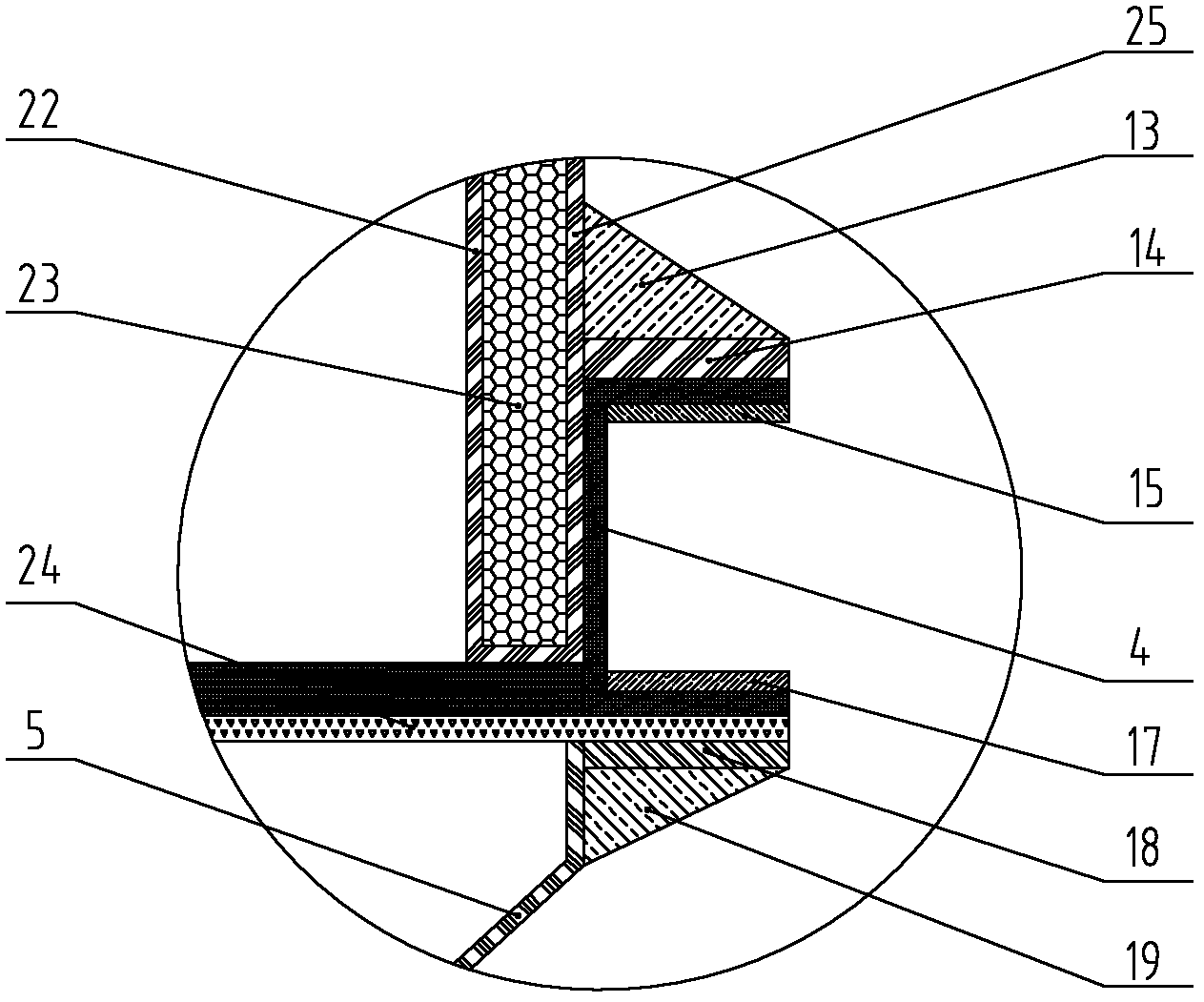

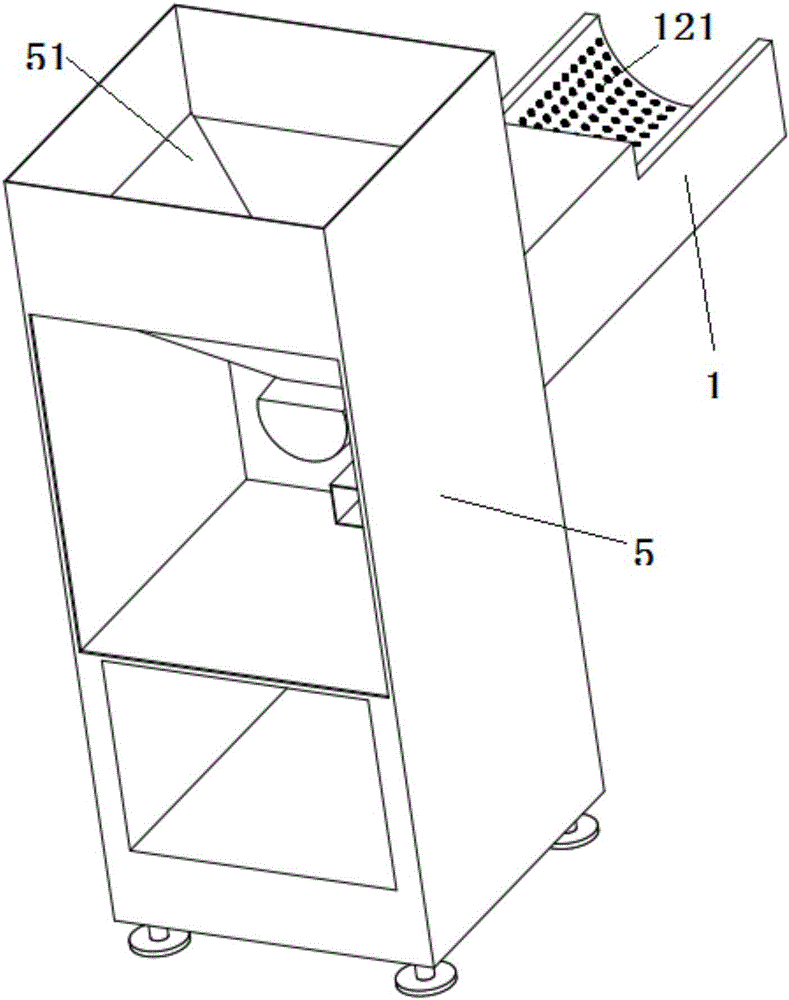

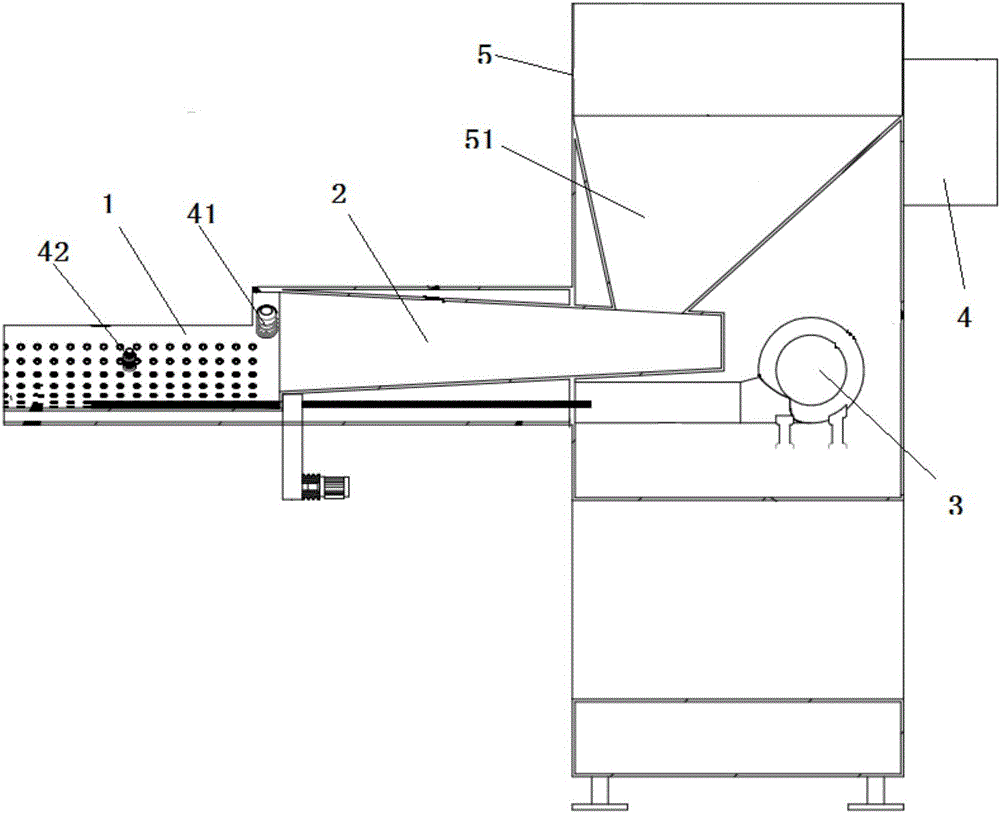

Powder feeding device

InactiveCN102616501ARemote control of blanking speedSimple structureLarge containersTank wagonsEngineeringVibration exciter

The invention provides a powder feeding device, belonging to a vibrating feeding device and solving the problems that the existing vibrating feeding device has potential safety hazards, can not vibrate to sieve and lacks heat-preservation treatment. The powder feeding device comprises a heat-preservation material cylinder, a weighing device, a bracket, a hopper and a controller, wherein the weighing device is arranged on the bracket; the upper part of the heat-preservation material cylinder is connected with the weighing device; the lower end of the heat-preservation material cylinder is flexibly connected with the hopper; the upper end face of the hopper is provided with a sieving net; the side face of the hopper is provided with a pneumatic vibration exciter; the bottom part of the hopper is connected with a pneumatic rubber pipe valve and a material discharging pipe; the weighing device is connected with the controller through a cable; the controller is connected with an electric ratio adjusting valve through the cable; an air inlet of the electric ratio adjusting valve is connected with an air source; and an air outlet of the electric ratio adjusting valve is respectively connected with the pneumatic vibration exciter and the pneumatic rubber pipe valve. The powder feeding device provided by the invention has the advantages of simple structure, safety and reliability, capability of vibrating to sieve, capability of remotely controlling a powder falling speed, convenience in operation and easiness in transportation; and in a feeding process, the heat-preservation treatment can be carried out, thus the powder feeding device is suitable for adding combustible and explosive powder.

Owner:HUAZHONG UNIV OF SCI & TECH

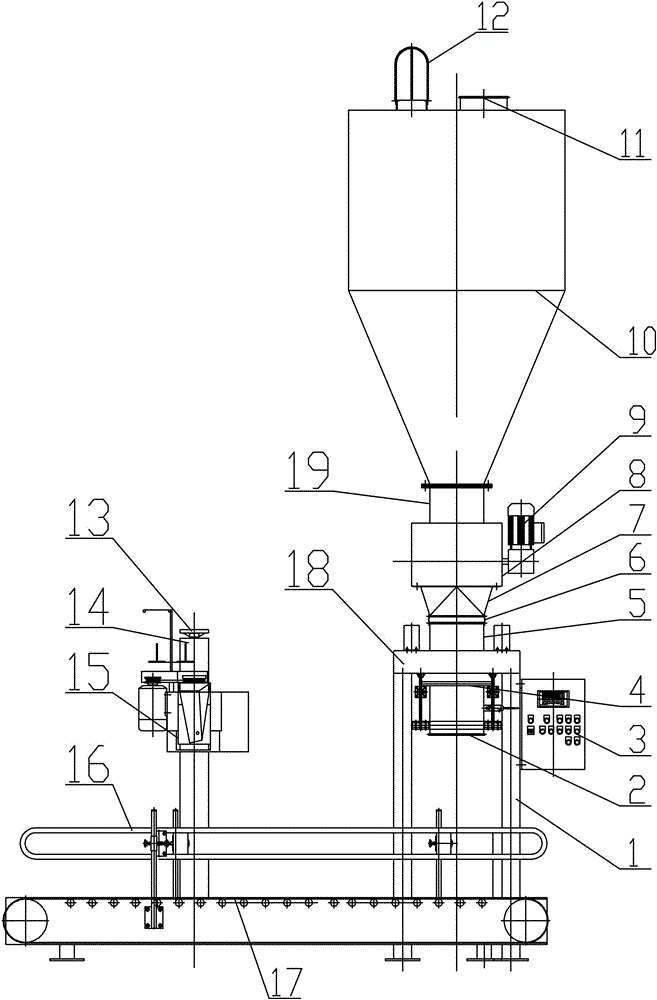

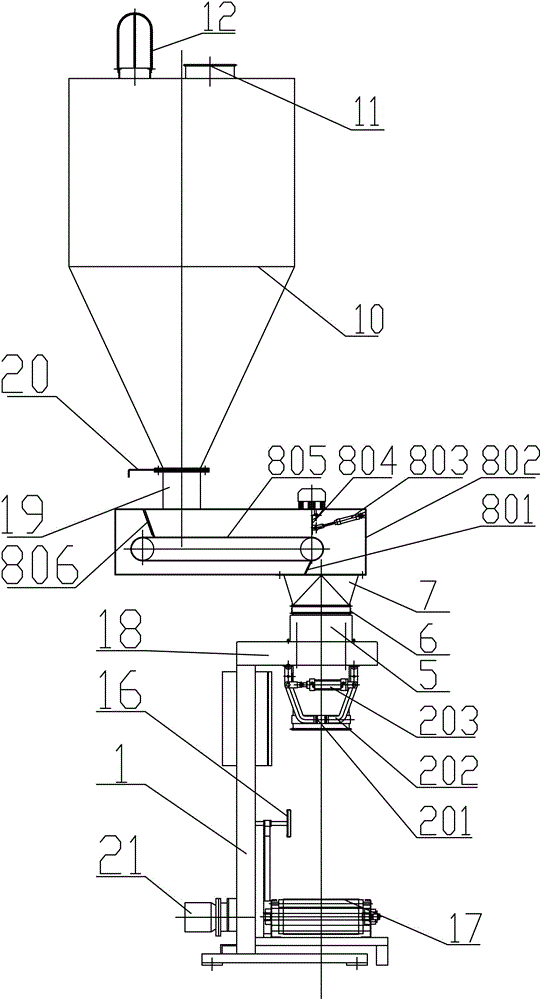

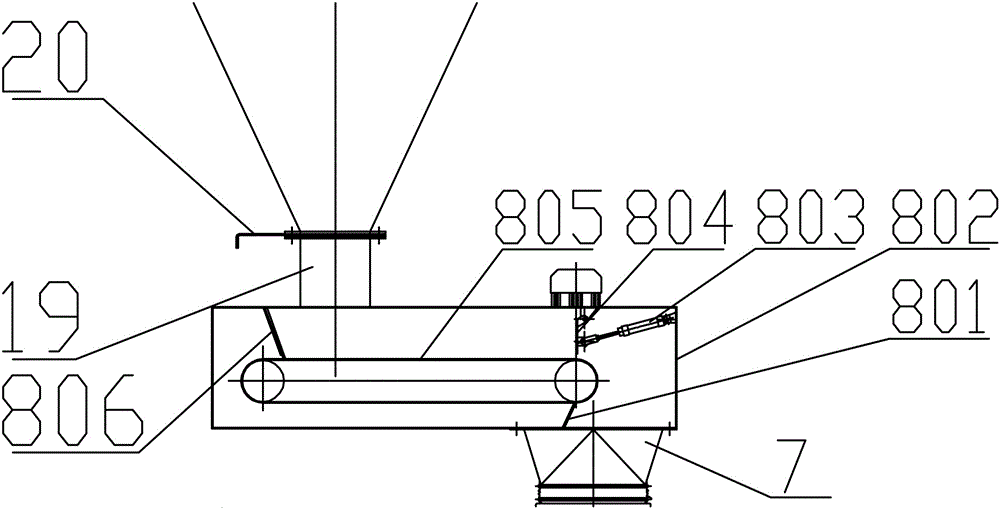

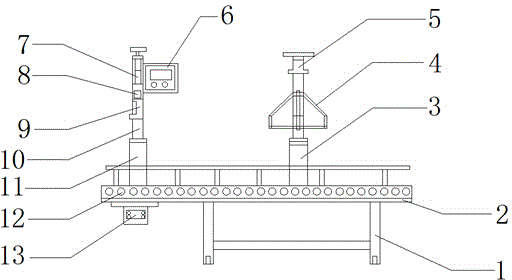

Quantitative packaging scale and quantitative packaging method capable of precisely controlling supply quantity

InactiveCN106240860AEasy maintenanceEasy unloading and loadingSolid materialConveyor partsEngineeringMechanical engineering

The invention relates to a quantitative packaging scale and quantitative packaging method capable of precisely controlling supply quantity. The scale comprises a rack, an automatic weighing device is mounted on the end face of the bottom of a top work platform of the rack and is provided with a pneumatic clamping device, and a receiving hopper is mounted on the end face of the top of the top work platform and is connected with a bottom discharging hopper through a flexible connecting cylinder; the bottom discharging hopper is arranged at the discharging end of a quantitative feeding device, the feeding end of the quantitative feeding device is connected with a top discharging hopper, the top discharging hopper is arranged at the bottom of a storage hopper, a bearing conveying belt is arranged at the bottom of the rack, a protection plate is mounted in the conveying direction of the bearing conveying belt, and an automatic package sewing device is arranged on the side face of the bearing conveying belt; the packaging scale can automatically complete material feeding, automatic discharging is achieved, automatic weighing is achieved, it is ensured that the weight in each-time discharging is kept consistent, and automatic packaging and conveying are carried out.

Owner:CHINA THREE GORGES UNIV

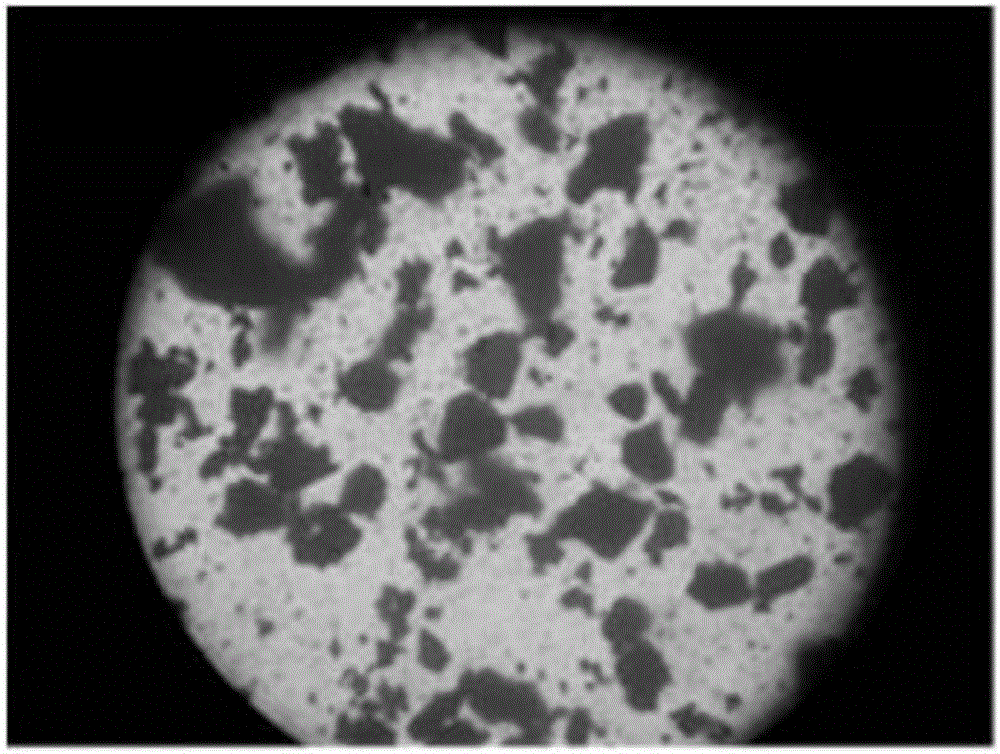

Spherical iron oxide and ultra-high density drilling fluid adopting spherical iron oxide as weighting agent

InactiveCN106753280AAcid solubleFeed speed controlFerric oxidesDrilling compositionHigh pressure oxygenVolumetric Mass Density

The invention provides spherical iron oxide. The spherical iron oxide is prepared from hematite by high-temperature flame melting, the hematite is conveyed by high-pressure oxygen to main combustion oxygen and natural gas combustion flame at a temperature being 2400 DEG C or higher, the hematite is molten by flames to form dispersed droplets, the droplets rapidly enter a cooling area under the action of negative pressure and are condensed into small spherical particles, and the spherical iron oxide is prepared accordingly. The feeding rate of the hematite is 10-40 Hz, the conveying amount of high-pressure oxygen is 110-190 m<3> / h, the amount of the main combustion oxygen is 550-660 m<3> / h, the consumption of the natural gas is 220-330 m<3> / h, and the oxygen enrichment coefficient is 1.0-1.3. According to ultra-high density drilling fluid adopting the spherical iron oxide as a weighting agent, the ultra-high density drilling fluid is prepared by taking the mixed spherical iron oxide as the weighting agent, and has good rheological property and settling stability, low water loss, high compressive strength and good cementing performance; the density of the drilling fluid is higher than 2.6 g / cm<3>.

Owner:天津泽希矿产加工有限公司

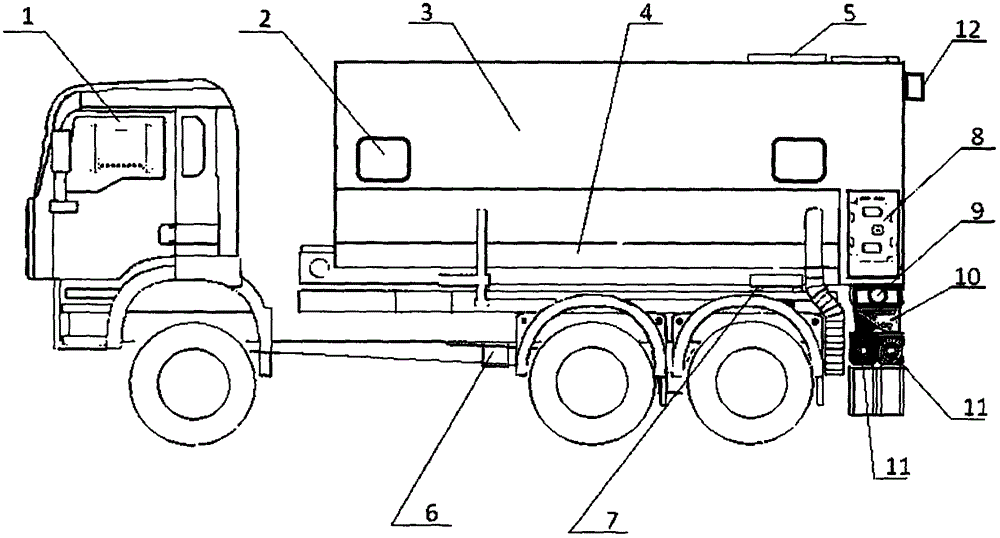

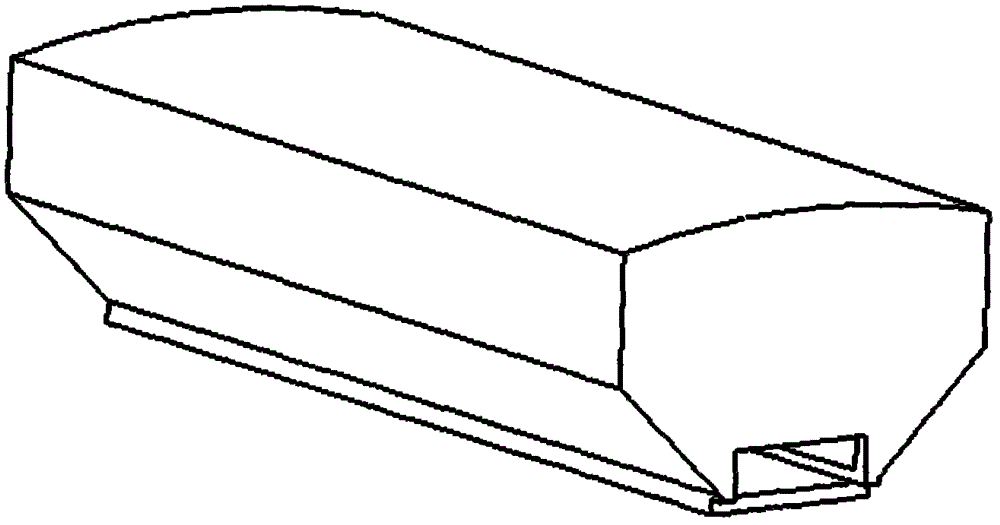

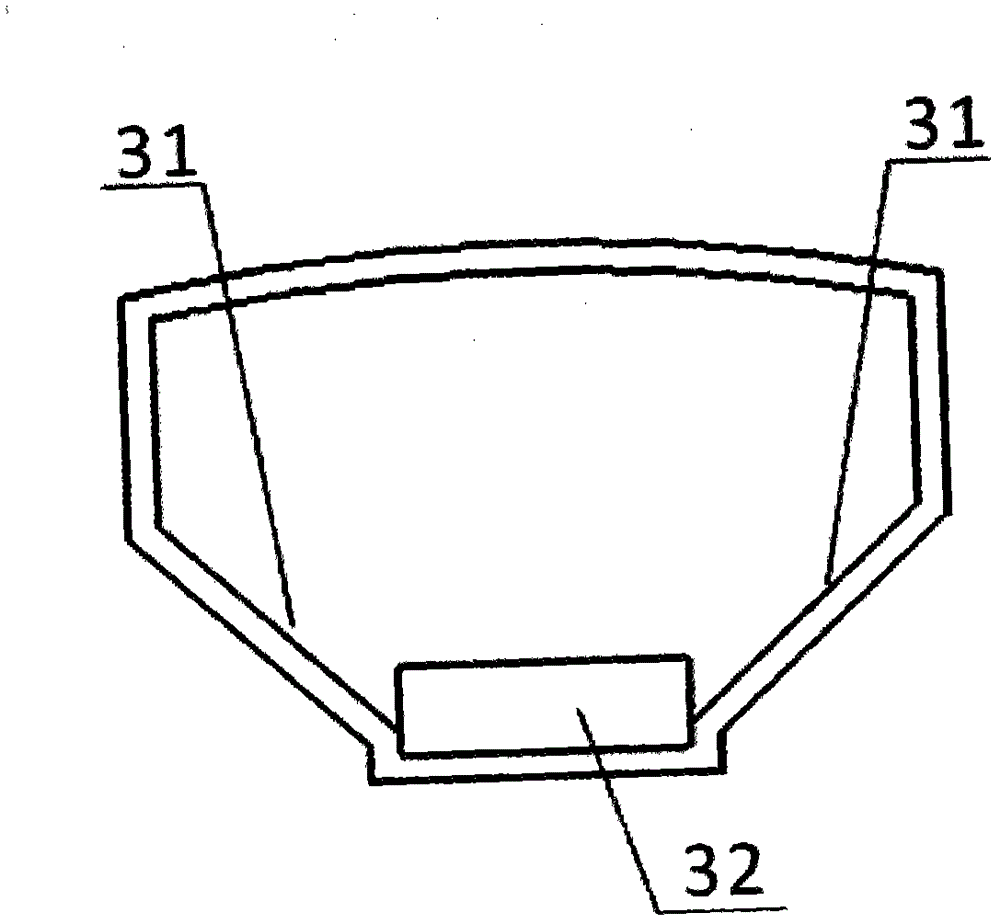

Powder spreading vehicle

InactiveCN104612026AGuaranteed spreading accuracyRealize remote monitoring and remote operationRoads maintainenceChain typeTextile

The invention discloses a powder spreading vehicle. The powder spreading vehicle comprises an automobile chassis, a powder bin, a chain conveying device, a small spreading bin, a precise spreading device and an electrical hydraulic system, wherein the powder bin is installed on the automobile chassis; the chain conveying device is arranged in an outlet groove in the bottom of the powder bin, and mainly comprises a driving chain wheel, a driven chain wheel and chains; connecting ribs are arranged between the chains; the driving chain wheel is driven to rotate by a hydraulic motor and a speed reducer; the driven chain wheel is provided with an encoder; the outlet part of the chain conveying device is provided with a small spreading bin which is internally provided with a spiral device; a precise spreading device is arranged on the bottom of the small spreading bin. With the powder spreading vehicle, the powder spreading amount can be accurately controlled, and the powder spreading width can be controlled, the powder spreading vehicle can adapt to different powder spreading amount with the spreading range of 3Kg / m<2>-35Kg / m<2>, can adapt to different traveling vehicle speeds to guarantee the powder spreading precision, and can achieve remote monitoring and remote operation; unique chain type drive is adopted by the powder bin, and the feeding speed can be controlled.

Owner:李金祥

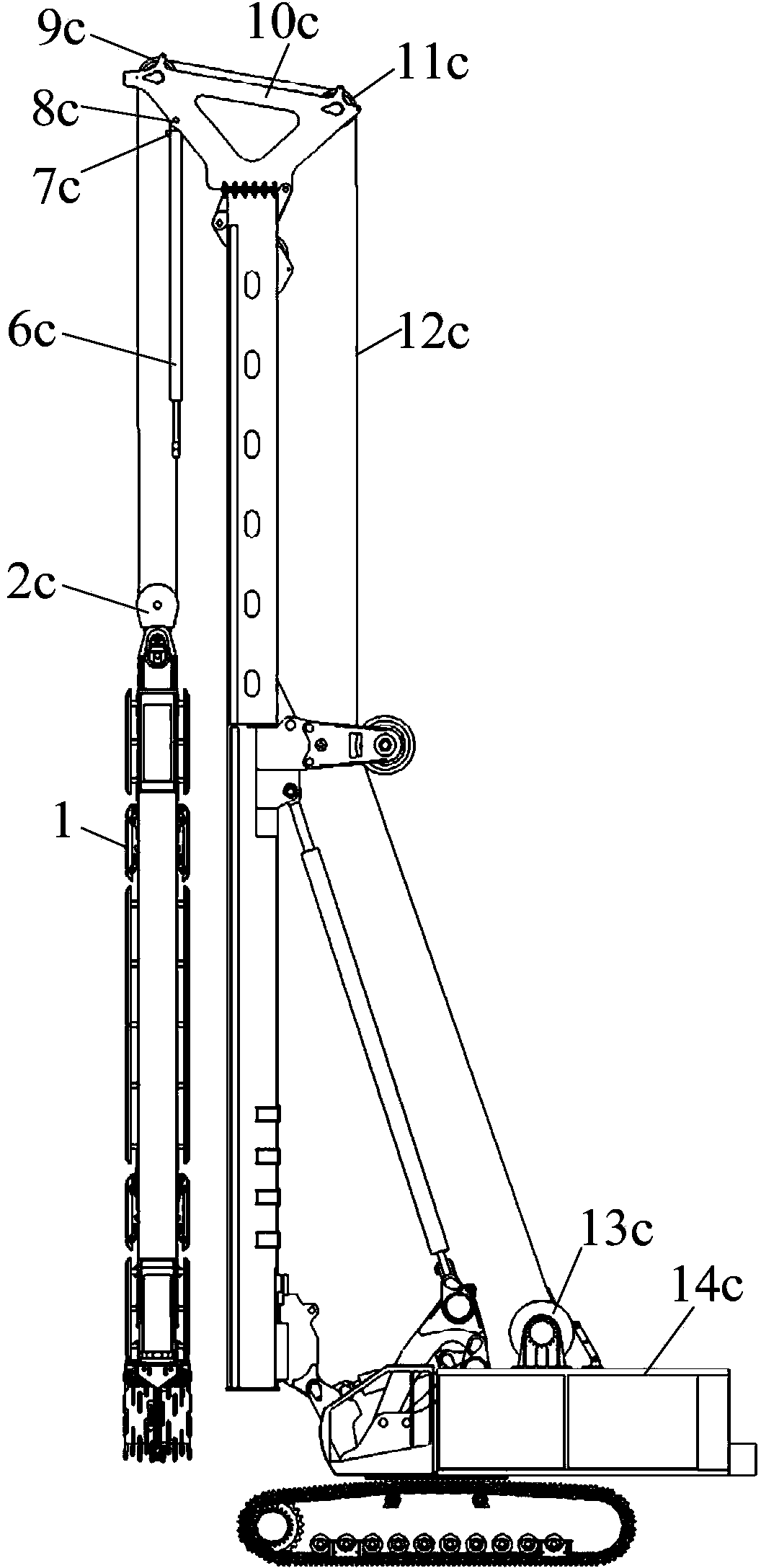

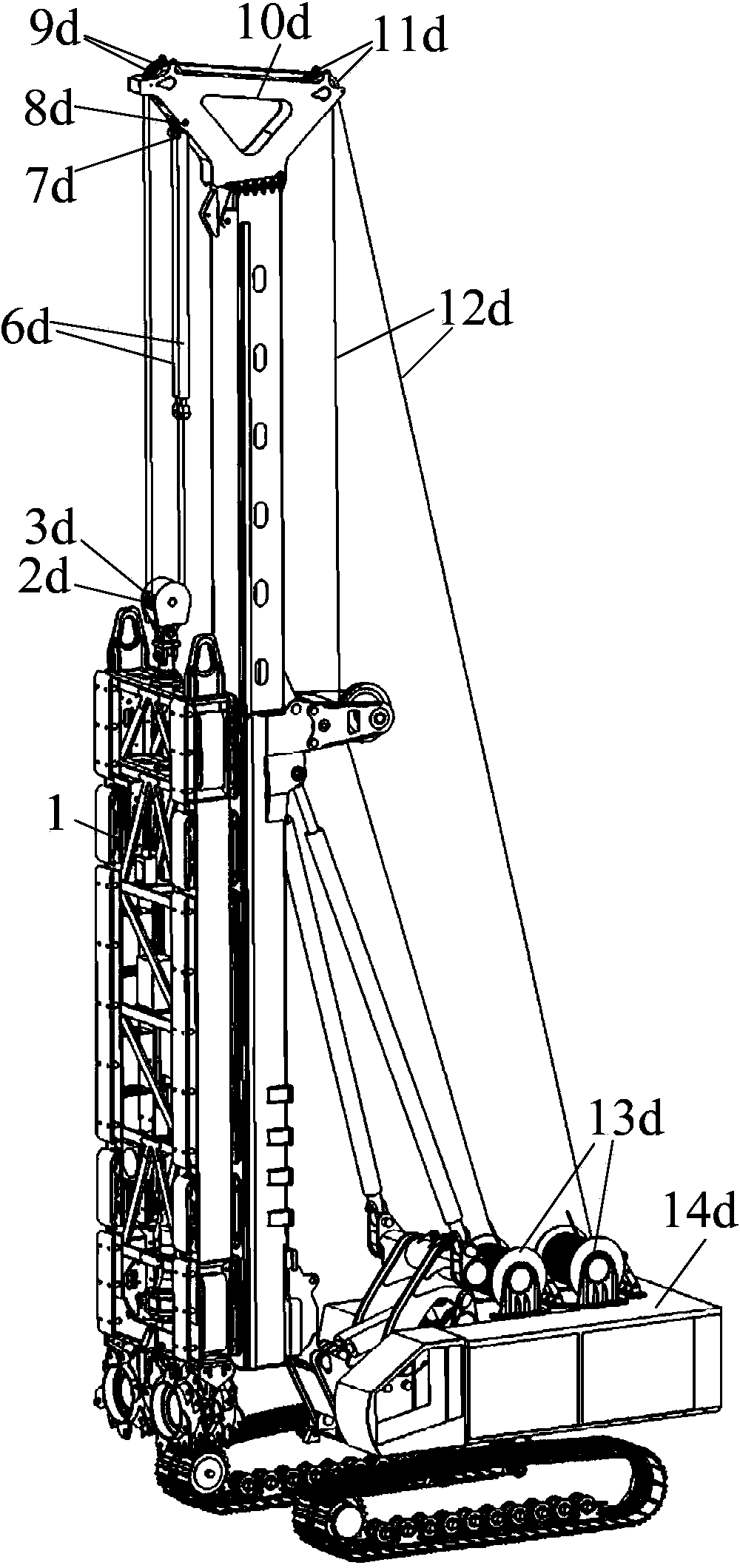

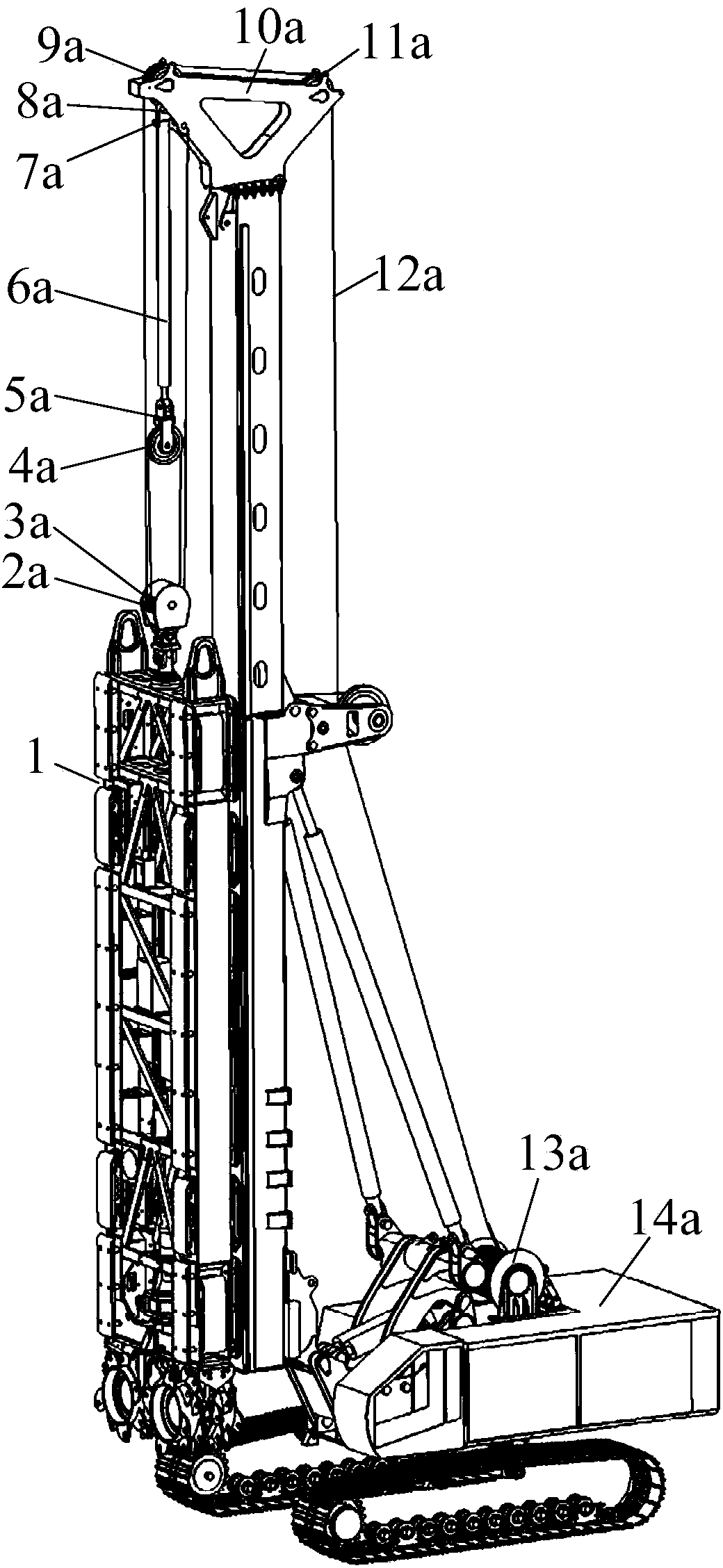

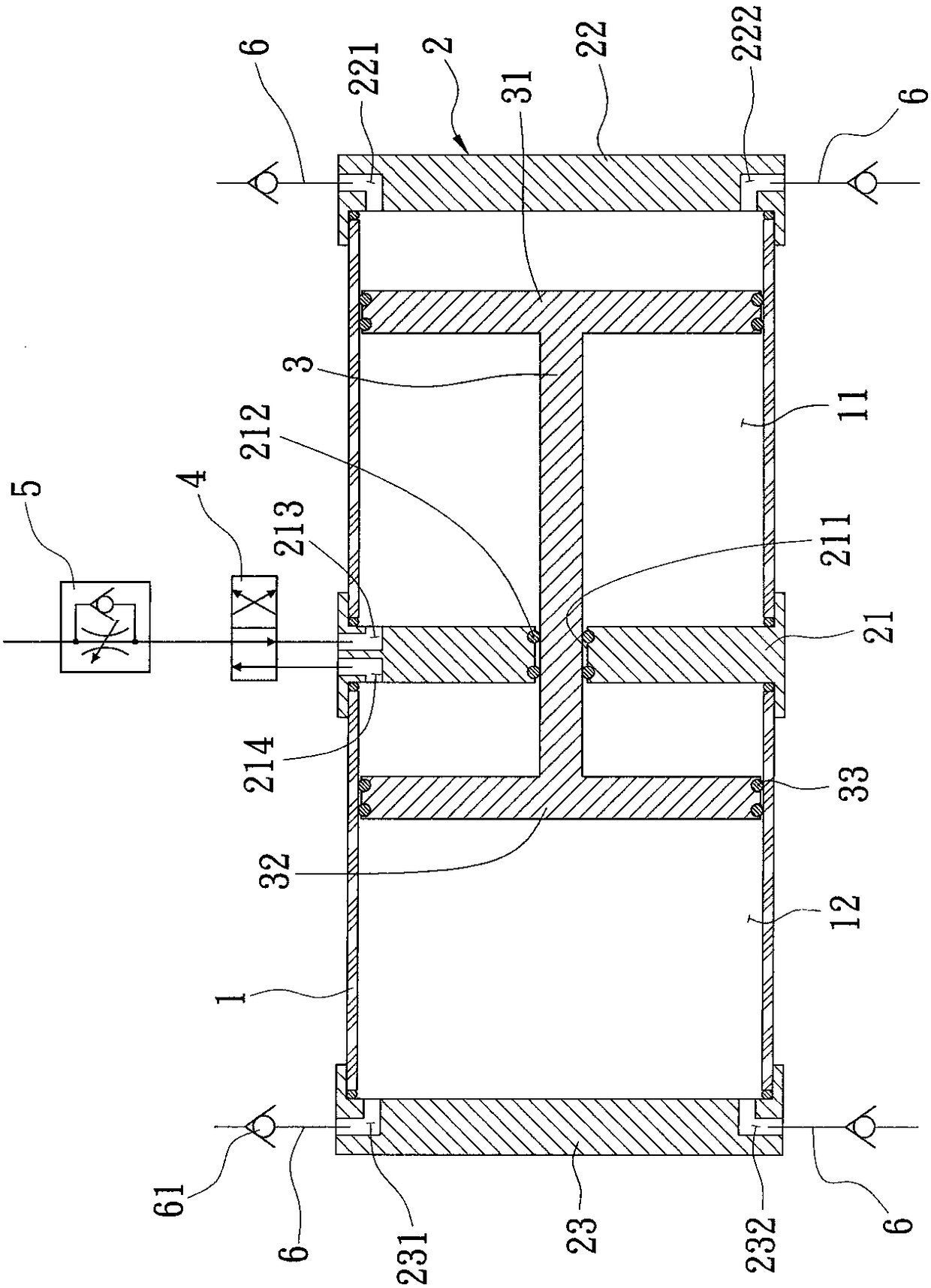

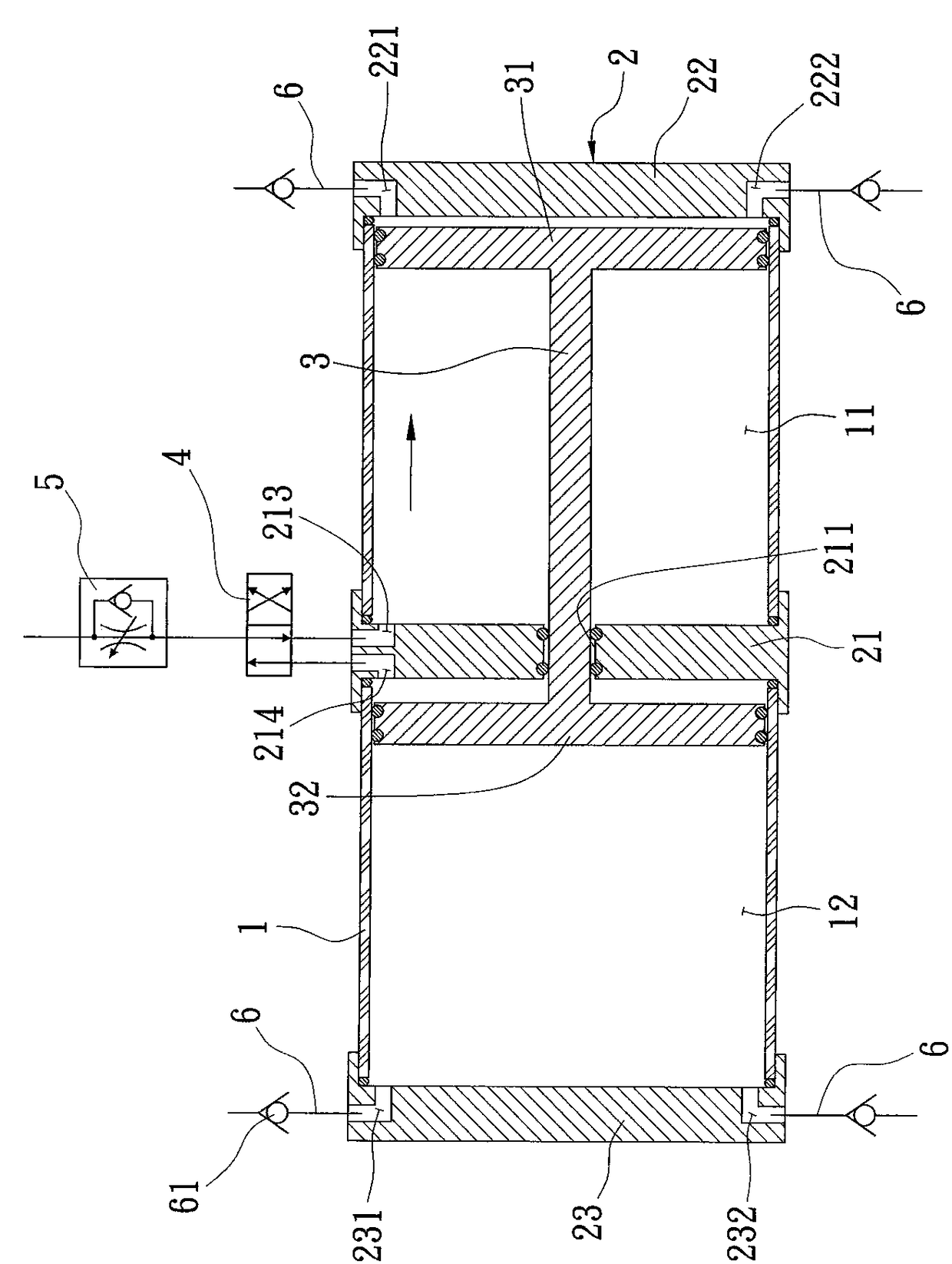

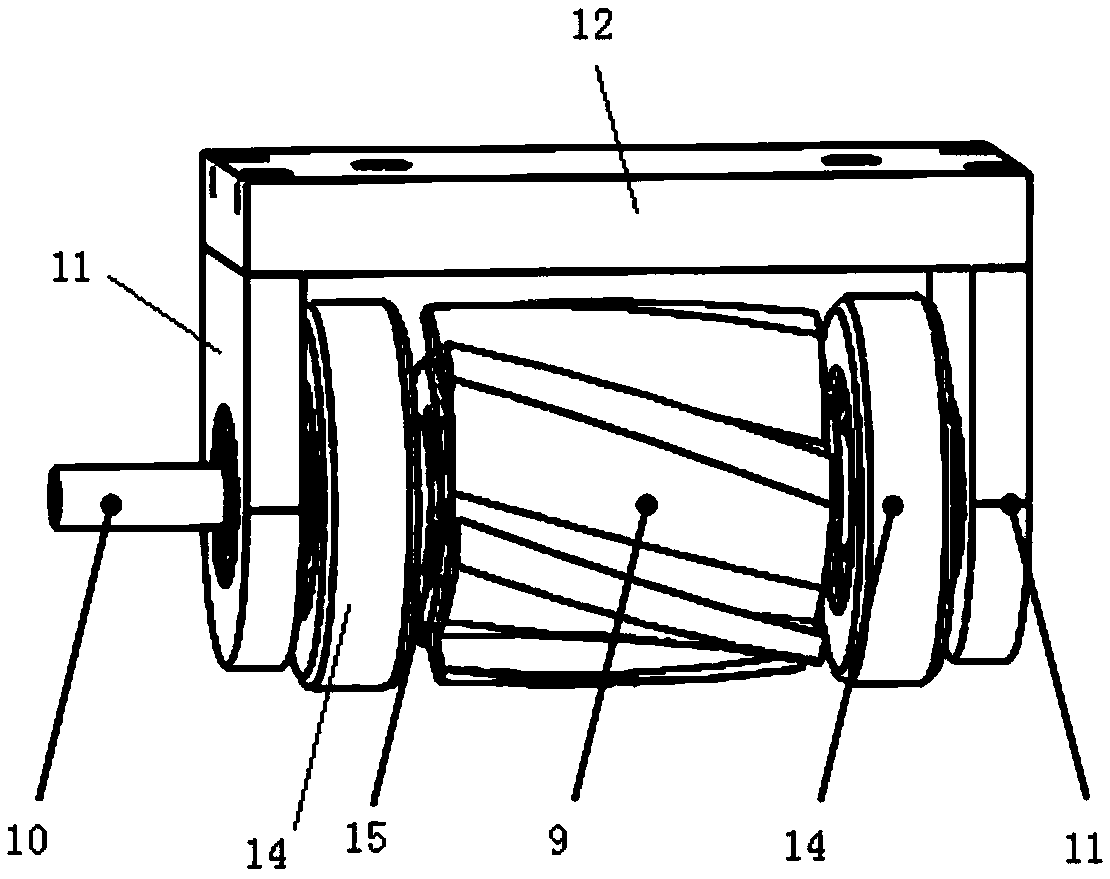

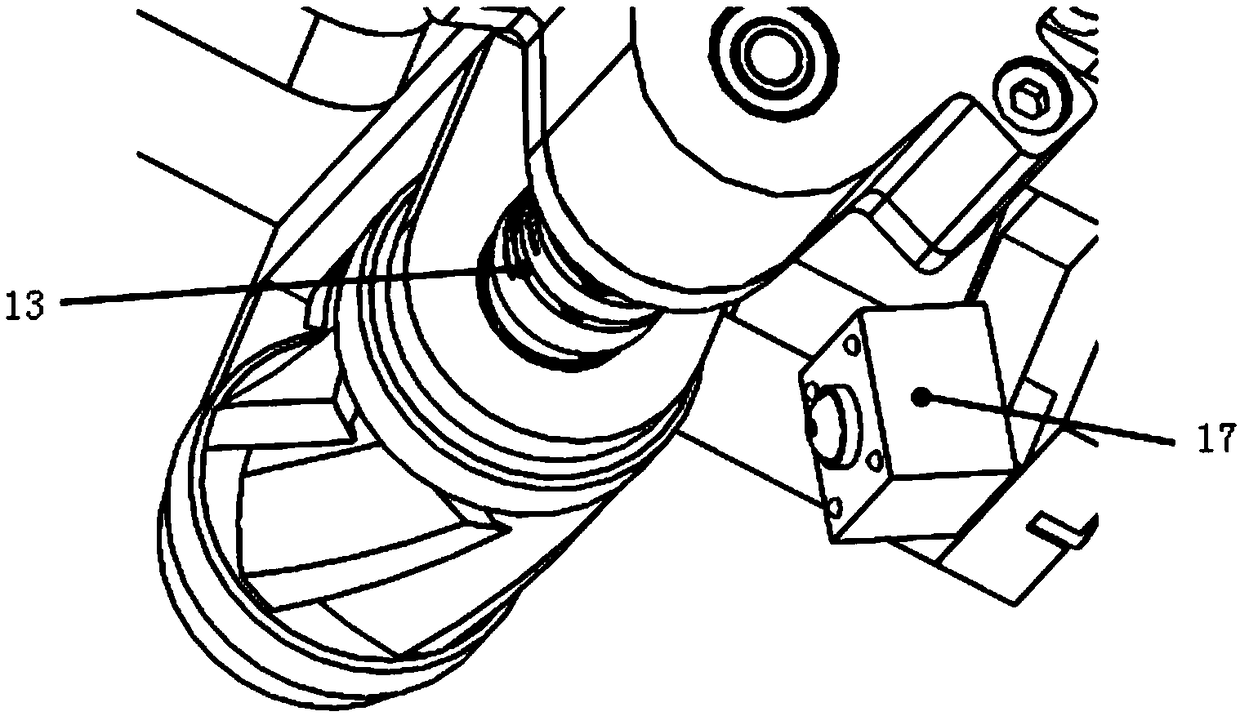

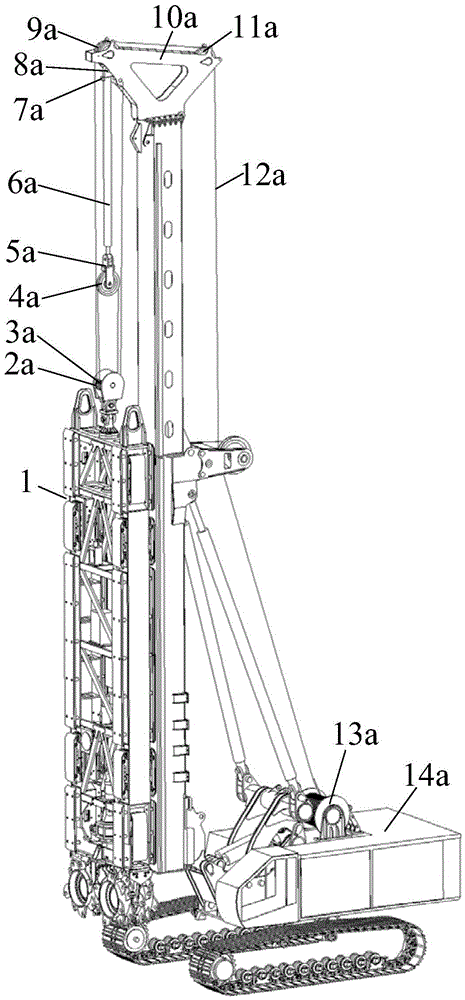

Feeding device of double-wheel slot milling machine and double-wheel slot milling machine

ActiveCN103770224AFeed speed controlControl pressureStone-like material working toolsEngineeringConductor Coil

The invention discloses a feeding device of a double-wheel slot milling machine and the double-wheel slot milling machine. The feeding device comprises an oil cylinder, wherein a cylinder barrel of the oil cylinder is hinged to a mast or a gooseneck boom of the double-wheel slot milling machine; a piston rod of the oil cylinder is connected with a milling device arranged below the oil cylinder; the oil cylinder can achieve differential motion together with a winding drum motor through a pulley device. According to the feeding device and the double-wheel slot milling machine, the oil cylinder does not need to be specially protected, the feeding speed and the feeding pressure of the milling device can be better controlled, the stroke replacement efficiency is improved, the structure is simple, the cost is lower, and the repair operation is convenient.

Owner:XCMG CONSTR MACHINERY

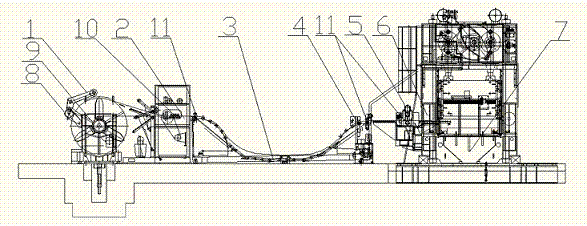

Aluminum coil stamping automation device and stamping method thereof

ActiveCN104759514AGuaranteed feed speedGuaranteed degree of deformationShaping toolsMetal-working feeding devicesControl engineeringProcess engineering

The invention discloses an aluminum coil stamping automation device and a stamping method thereof. The aluminum coil stamping automation device comprises an uncoiling mechanism, a leveling mechanism, a feeding mechanism, an oil injection mechanism and a machine tool which are arranged in turn; the uncoiling mechanism comprises a servo motor and a rolling wheel which are connected with each other; the rotational speed of the rolling wheel does not exceed 115 rounds every minute; the feeding mechanism comprises a servo motor and a feeding roller which are connected with each other; the clearance feeding of the feeding mechanism is performed and the feeding speed of the feeding mechanism and the stamping frequency of the machine tool are synchronized; a material lifting and conveying mechanism is arranged between the leveling mechanism and the feeding mechanism; a material buffering area is formed between the material lifting and conveying mechanism and the leveling mechanism; the deformation degree of aluminum coils does not exceed 30 I in the process that the aluminum coil are fed into the machine tool from the uncoiling mechanism. According to the aluminum coil stamping automation device and the stamping method thereof, the rotational speed of the feeding mechanism is controlled so as to effectively ensure that the deformation degree of the aluminum profile can be within the acceptable range in the production process, the quality of subsequent machining products is ensured, meanwhile the machining speed requirement can be met by the feeding speed of the materials, and the production efficiency is ensured.

Owner:奇昊汽车系统(苏州)有限公司

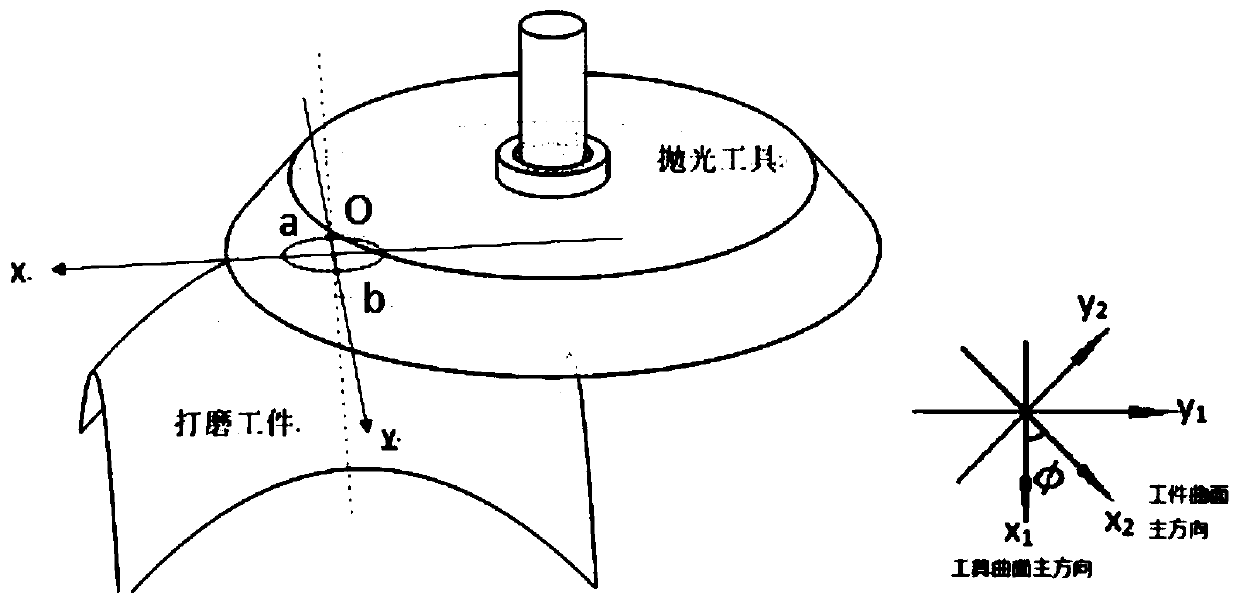

Force-position mixing control method for grinding and polishing of force-controlled robot

InactiveCN109927028AControl pressureFeed speed controlProgramme-controlled manipulatorPositive pressureRobot position

The invention provides a force-position mixing control method for grinding and polishing of a force-controlled robot. According to the method, on the basis of a workpiece three-dimensional model, a grinding and polishing tool machining track and / or a five-axis NC program matched with a workpiece is generated according to different machining surfaces, and then a robot position control program is generated; based on a Hertz contact theory, suppose the pressure intensity of each position grinding and polishing contact point is the same, the grinding and polishing positive pressure of the contactarea is obtained according to the contact surface pressure stress distribution rule; the feeding speed is obtained through a feeding speed self-adaptive model; and in the grinding and polishing process, the position of the robot is controlled, the grinding and polishing pressure and the feeding speed of the grinding and polishing tool are controlled at the same time, so that the grinding and polishing precision and the surface uniformity of a complex curved surface workpiece can be effectively improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Vibrating feed combustor and control method thereof

ActiveCN106642192ASave man hoursReduce electric powerFuel supply regulationSolid fuel combustionSlagFlue

The invention discloses a vibrating feed combustor, comprising a combustion grate, a feeder, a blower and a controller, wherein the combustion grate comprises a grate enclosure, a first division plate and a second division plate arranged horizontally are arranged in the grate enclosure to divide the space encircled by the grate enclosure into a combustion trough, a combustion trough air flue and a slag receiving chamber, the first division plate is provided with vents, the combustion trough air flue is provided with an air inlet in one side in the horizontal direction, and the blower is communicated with the combustion trough air flue via the air inlet; the feeder is an electric vibrating feeder and comprises a feed pipe, the lower port of the feed pipe is arranged above the combustion trough, a first temperature sensor is arranged in the combustion grate, a second temperature sensor is arranged in a baking room, and the controller is connected with the blower, the electric vibrating feeder, the first temperature sensor and the second temperature sensor and used for controlling the frequency or magnitude of the electric vibrating feeder and the air quantity of the blower according to the temperature in the combustion trough and the difference between the current temperature in the baking room and a preset temperature.

Owner:湖南驱动源电气技术有限公司

Device for image-shooting both sides of documents

InactiveUS6348962B1Increase speedReliably obtainedElectrographic process apparatusPhotographic printingTransport systemHigh rate

A novel device for image-shooting both surfaces of documents at a high rate by an electronic device. The device has an upper transport system for allowing plural documents to descend / move by a pre-set number at a time towards the downstream and an image-shooting device for image-shooting the descending / moving document. Image-shooting can be done simultaneously on both sides or side by side, either during free movement or controlled movement by a transporting device.

Owner:FUJIFILM CORP

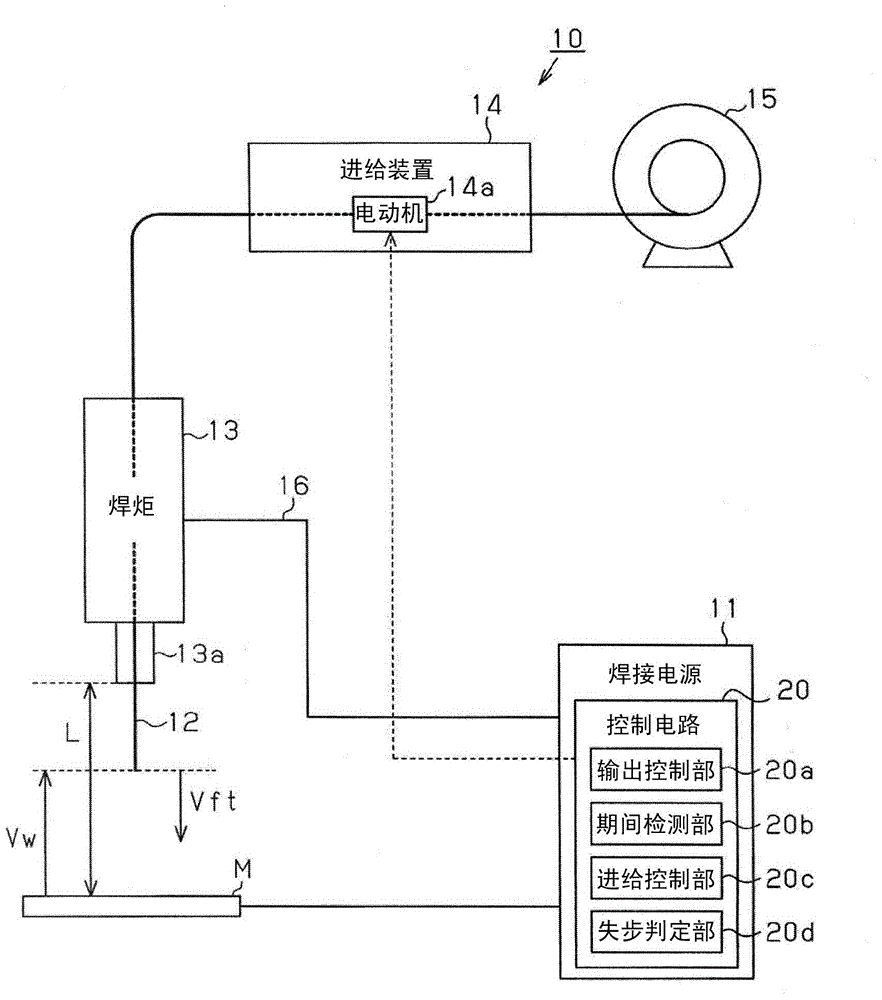

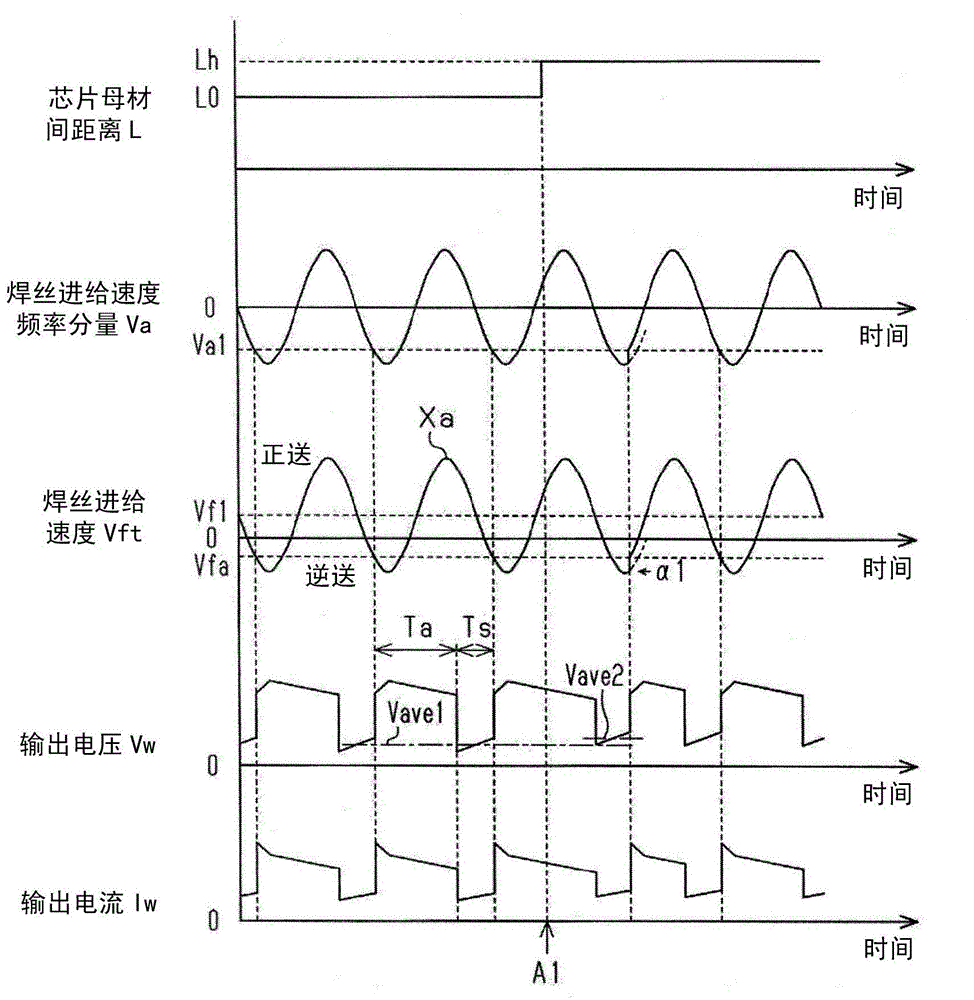

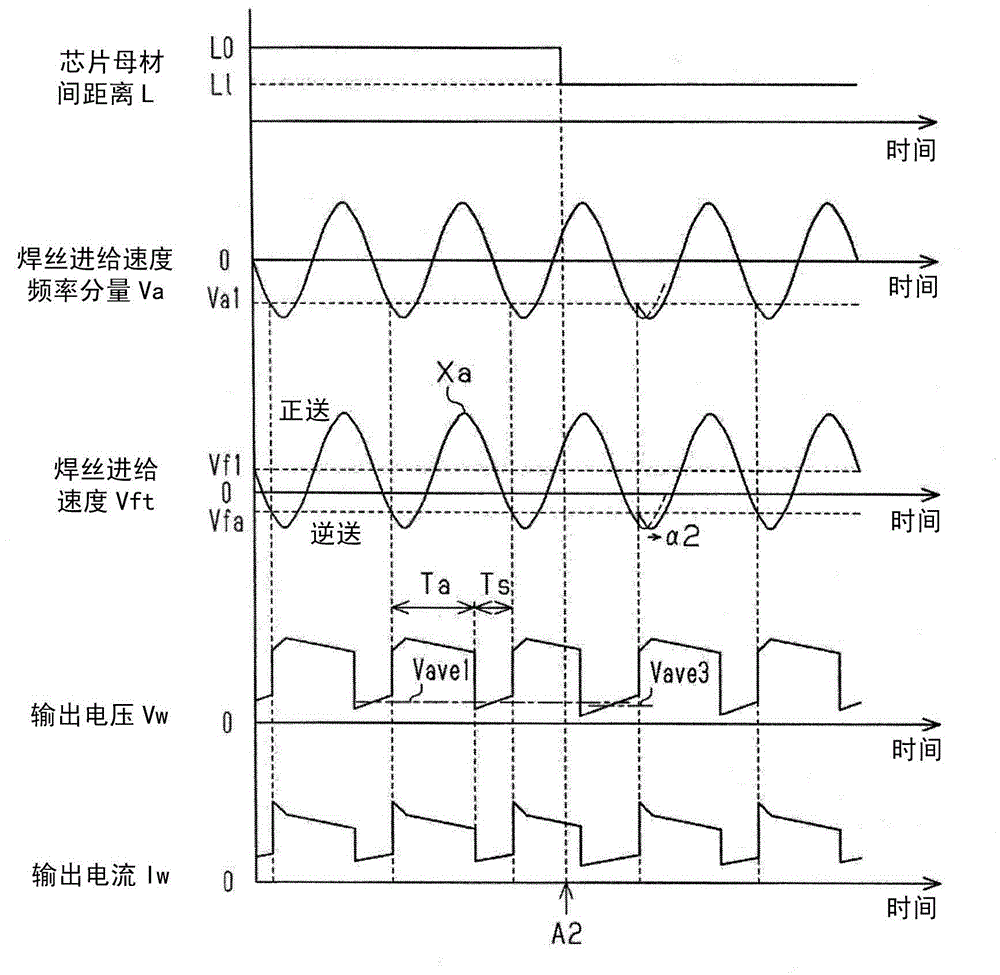

Power Supply Device For Electrical Arc Welding And Controlling Method Therefor

ActiveCN104057179AFeed speed controlGood arc weldingArc welding apparatusAcceleration controlArc welding

The invention provides a power supply device for electrical arc welding and a controlling method therefor. Great electrical welding can be achieved when feedingspeed of welding wires can be properly controlled. Feeding speed (Vft) of a welding wire (12) can be controlled to periodically change, so the welding wire (12) in switch between positive and negative feeding can be switched to an electric arc period and during negative feeding of the welding wire, the feeding speed (Vft) of the welding wire (12) can be adjusted; when the feeding speed (Vft) of the welding wire (12) is determined to be slower than certain speed, acceleration control in the negatie feeding direction can be applied; and when the speed (Vft) of the welding wire (12) is determined to be quicker than the certain speed, deceleration control in the negatie feeding direction can be applied.

Owner:DAIHEN CORP

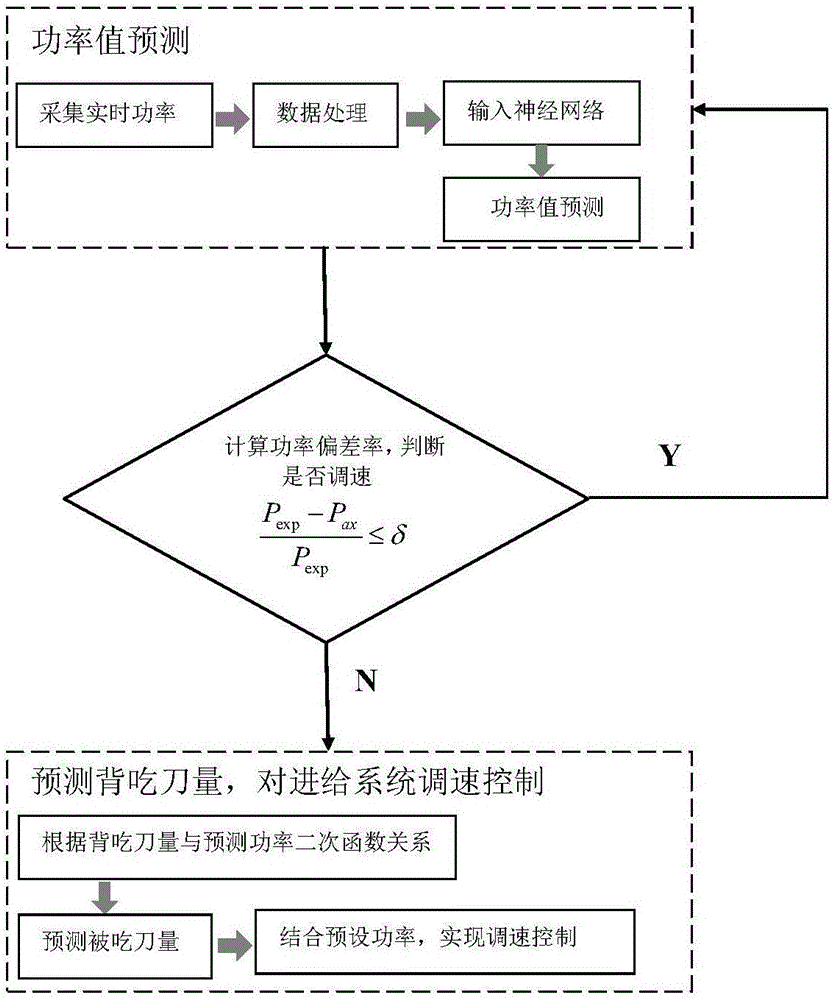

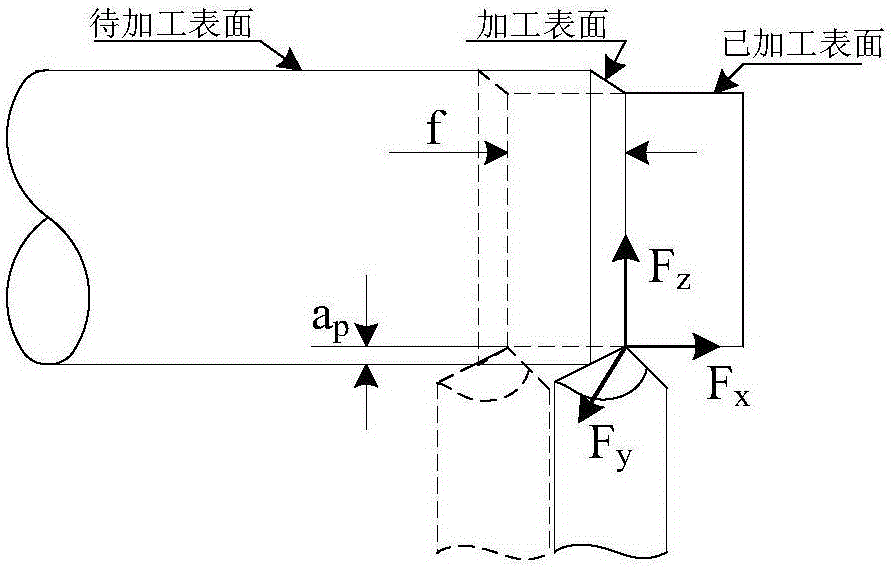

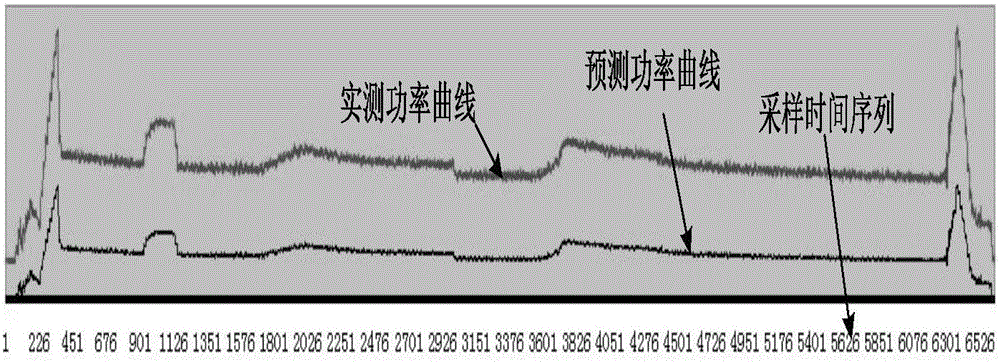

Numerically-controlled machine tool feed system speed regulation method based on power prediction

InactiveCN105945311AIncrease profitImprove cutting efficiencyAuxillary equipmentNumerical controlBack cutting

The invention relates to a numerically-controlled machine tool feed system speed regulation method based on power prediction. During a rough turning process of a numerically-controlled machine tool, the minimum feed speed is generally set according to the maximum cutting depth, and machining is performed by taking the minimum feed speed as a constant feed speed. However, the problem of low efficiency caused by constant-speed machining is especially acute in case of a large amount of rough turning operation and a large machining batch. Aiming at the problem, the invention provides the numerically-controlled machine tool feed system speed regulation method based on power prediction. The method comprises the following steps: Step 1, acquiring power signals and inputting the power signals to a neural network to predict a power value of next moment; Step 2, calculating a deviation ratio of preset power and predicted power to judge whether speed regulation is needed; and Step 3, predicting a back cutting depth, and finishing speed regulation control over a feed system through combination of the back cutting depth and a preset power value. The method effectively solves the problem of lagging of speed regulation under different cutting conditions, reduces the machining cost and greatly improves the utilization rate and cutting efficiency of the machine tool.

Owner:CHONGQING UNIV

Pneumatic double-acting pump

InactiveCN108730149AFeed speed controlAchieve the output effectPositive displacement pump componentsPump controlMechanical engineeringPiston rod

The invention relates to a pneumatic double-acting pump. A pump main body is divided into two chambers by three partition plates; a piston rod penetrate through the first partition plate located between the two chambers; a first piston and a second piston arranged at the two ends of the piston rod are positioned in the two chambers correspondingly; an inlet of the first partition plate is sequentially connected with a switching valve and an air flow valve through pipelines; the other ends, connected with the first partition plate, of the two chambers are assembled with the second partition plate and the third partition plate correspondingly; and an inlet and an outlet of the second partition plate and an inlet and an outlet of the third partition plate are connected with working pipelinescorrespondingly. Therefore, by switching the valve position of the switching valve, the pistons in the two chambers can be pressurize and output fluid in the chambers of the pistons, in addition, thepiston feeding speed can be controlled through the air flow valve, thereby achieving the effects of outputting the fluid in at least two different regions at a time, and movably adjusting the fluid delivery frequency and flow rate, etc.

Owner:STPAPE CO LTD

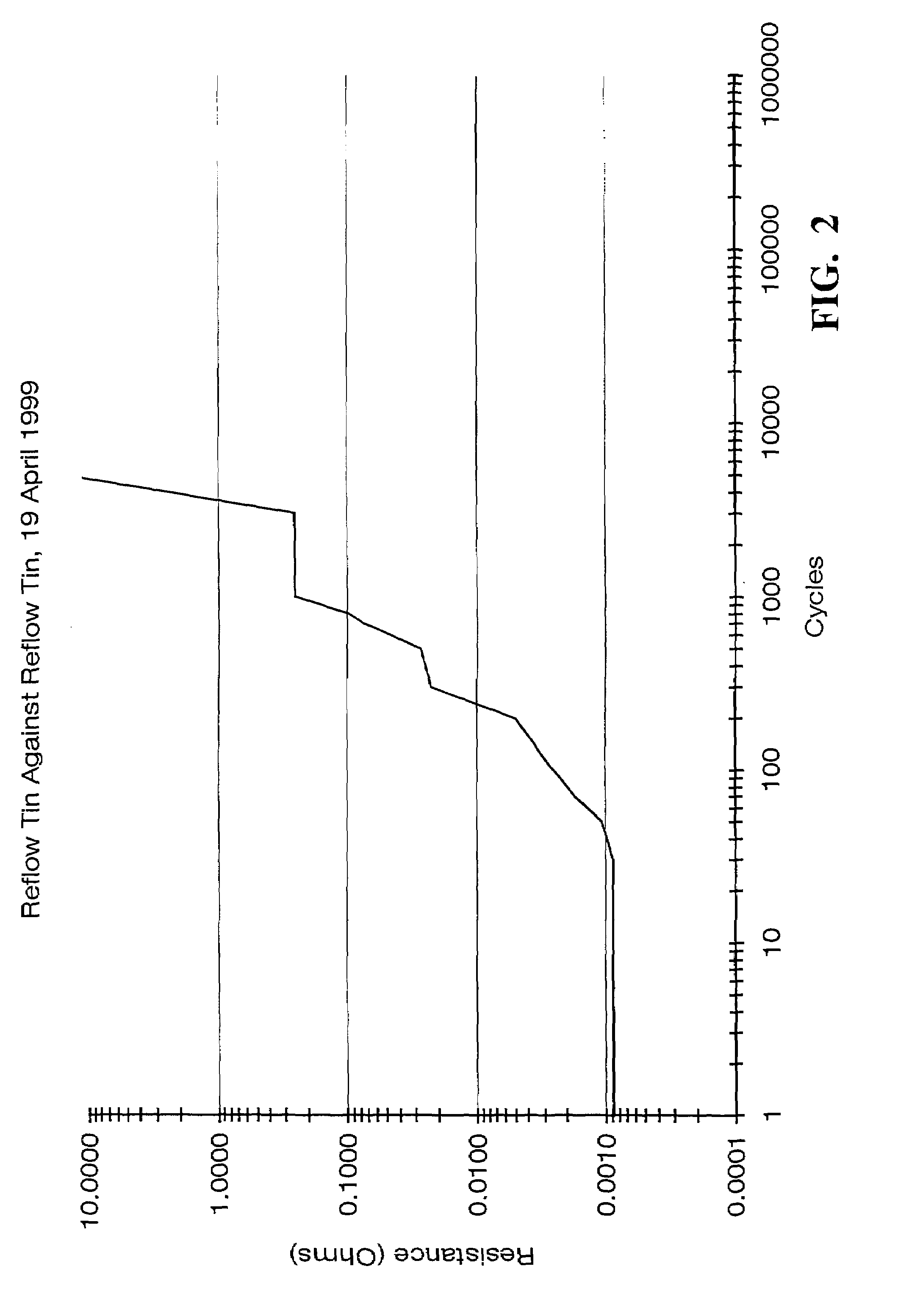

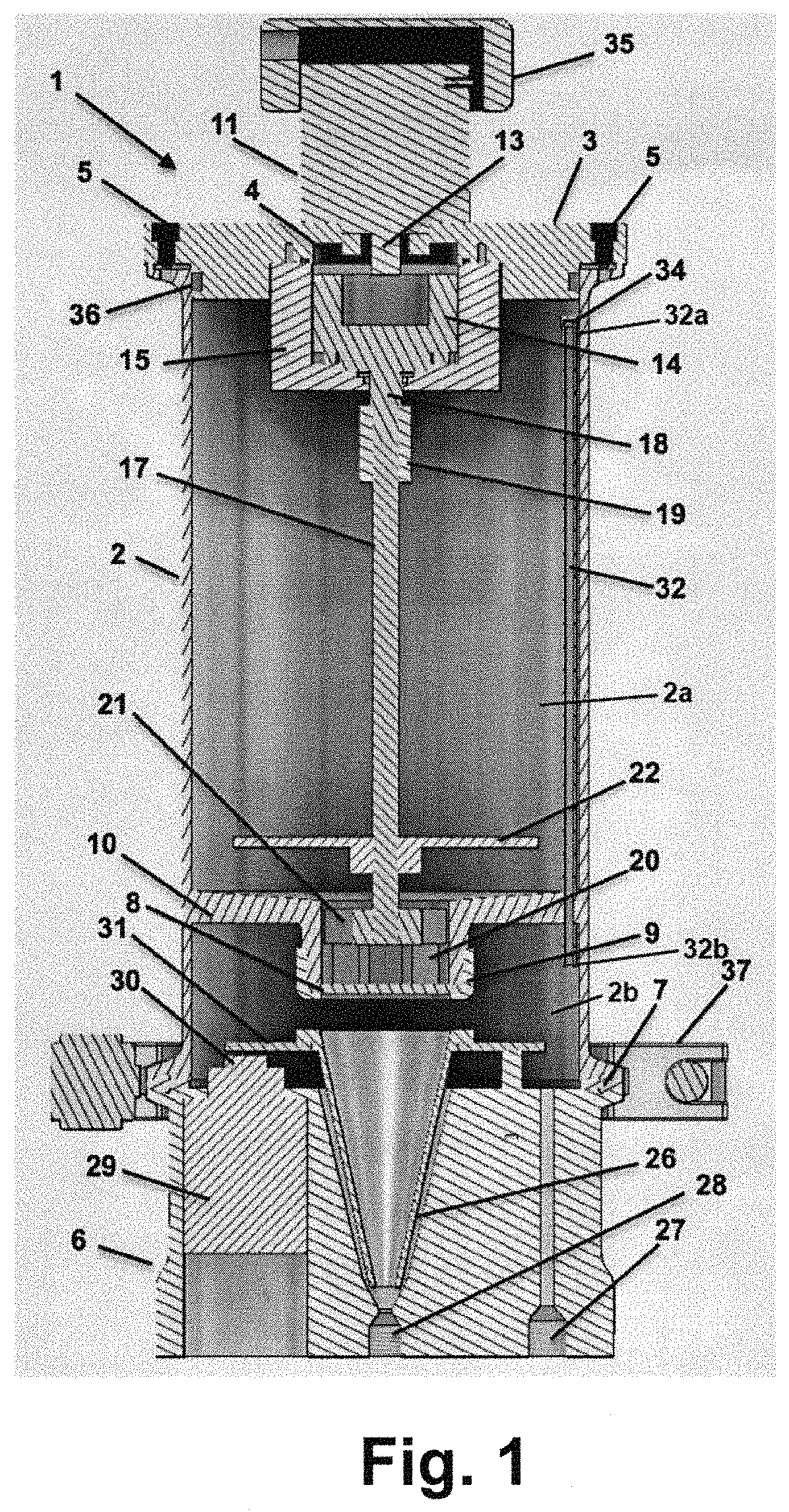

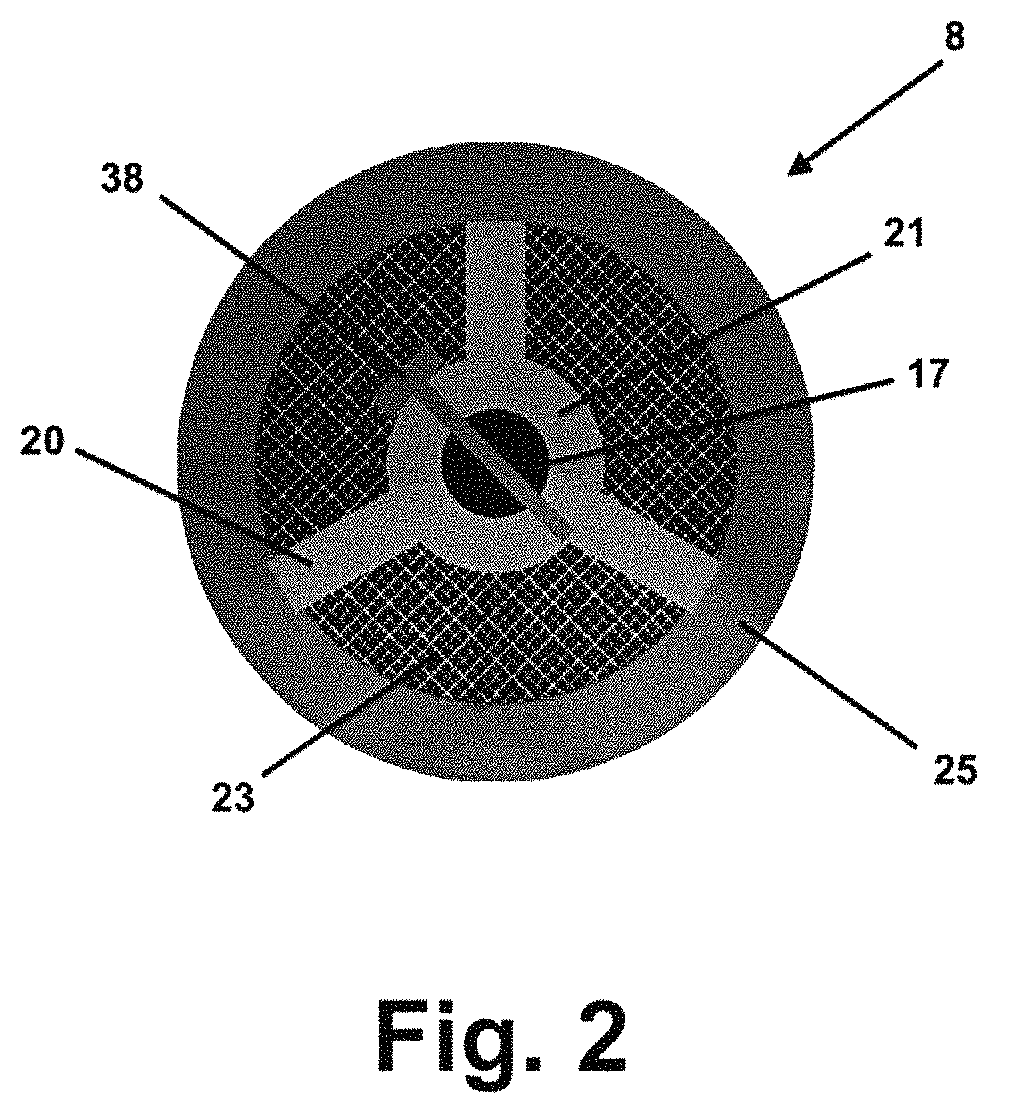

Kinetic sprayed electrical contacts on conductive substrates

InactiveUS7001671B2Reduce contact resistanceHigh surface-to-surface contactCoupling contact membersLiquid/solution decomposition chemical coatingElectrical resistance and conductanceElectrical conductor

The present invention is directed to electrical contacts that comprise spaced electrically conductive particles embedded and bonded into the surface of conductors in which the particles have been kinetically sprayed onto the conductors with sufficient energy to form direct mechanical bonds between the particles and the conductors in a pre-selected location and particle number density that promotes high surface-to-surface contact and reduced contact resistance between the conductors.

Owner:FLAME SPRAY IND

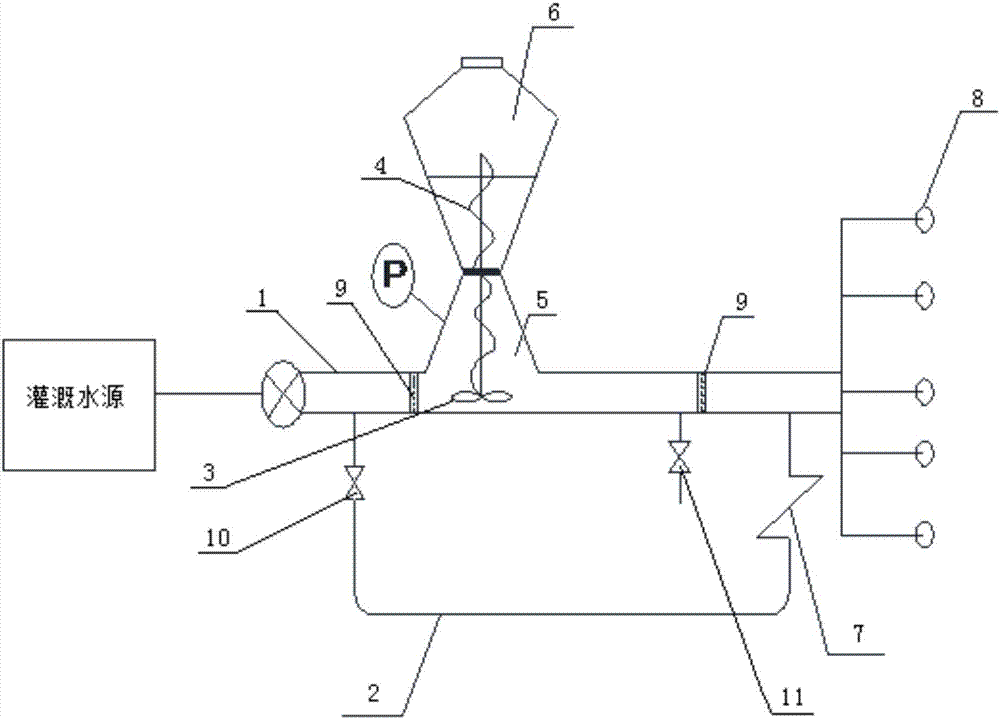

Irrigation system capable of adjusting water and fertilizer solubility

ActiveCN107969204AImprove spraying effectAdjust the mixing ratioPressurised distribution of liquid fertiliserSolubilityWater source

The invention discloses an irrigation system capable of adjusting water and fertilizer solubility. The irrigation system comprises a main water supply pipeline, wherein a water inlet of the main watersupply pipeline is connected with an irrigation water source, and a plurality of sprinklers are connected in parallel with a water outlet; a concentration adjusting bin is arranged between the waterinlet and the water outlet; the concentration adjusting bin is communicated with the main water supply pipeline; and the upper part of the concentration adjusting bin is provided with a chemical fertilizer bin. The irrigation system also comprises a spiral shaft, wherein the spiral shaft extends from the chemical fertilizer bin to the concentration adjusting bin; the lower part of the spiral shaftis connected with a driving blade which is arranged in the main water supply pipeline; and the driving blade can rotate under the push of water flow and drives the spiral shaft to rotate synchronously. The rotation of the spiral shaft can bring a chemical fertilizer into the concentration adjusting bin. The problems that in the prior art, irrigation and fertilization are carried out separately, asolution preparation process is tedious and waste is caused easily are solved. The irrigation system provided by the invention can fertilize crops while irrigating, uniformly dissolve a chemical fertilizer in water, and transport the chemical fertilizer to a farmland, thus saving the chemical fertilizer and achieving a good spraying effect.

Owner:NORTHWEST UNIV

Brush-sieve powder fluidizing apparatus for nano-size and ultra fine powders

ActiveUS20190358656A1Easy to manufactureFeed speed controlLiquid surface applicatorsSolid materialNano sizeUltra fine

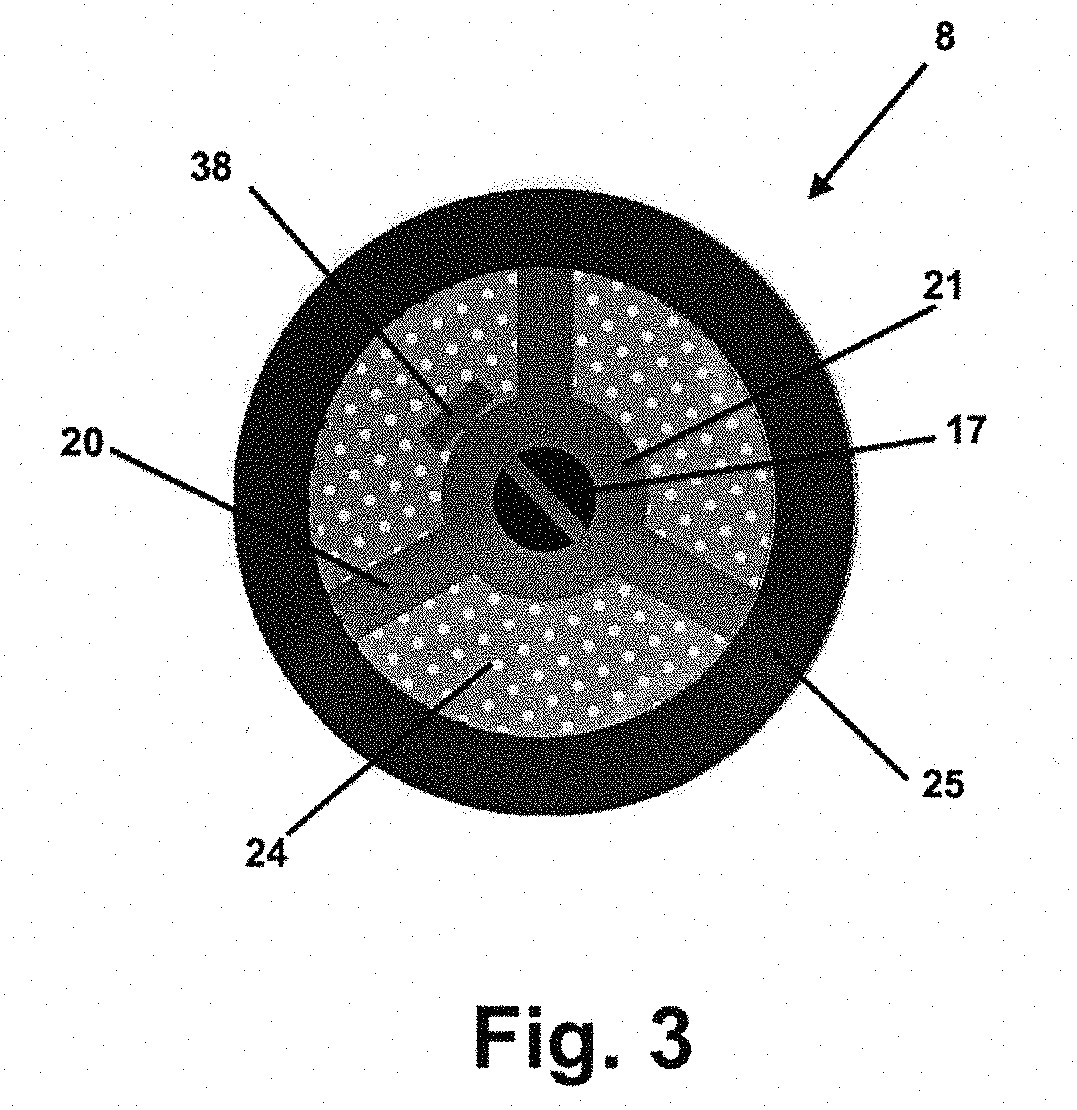

Powder fluidizing apparatus includes a unitary pressure vessel having a powder compartment and a transfer compartment, a lid on a first open end of the powder compartment and a base on a second end of the unitary pressure vessel, the second end sealing an open end of the transfer compartment. A plate separates the powder compartment from the transfer compartment, the plate being located between the lid and the base. A coupling collar secures a sieve disk packet in an opening in the plate. A tube extends from the transfer compartment to the powder compartment, the tube extending to a location near the lid of the unitary pressure vessel. When the transfer compartment is pressurized with a carrier gas, pressure in the transfer compartment and pressure in the powder compartment are equalized by the tube. The unitary pressure vessel is configured to contain the carrier gas in both the powder compartment and the transfer compartment and simultaneously perform as a reservoir for holding a quantity of powder in the powder compartment;

Owner:INNOVATION TECH INC

Chemical liquid precise quantitative filling device

InactiveCN104817049AControl volumeFeed speed controlLiquid fillingBottle-handling machinesAutomatic controlSmall footprint

The invention discloses a chemical liquid precise quantitative filling device. A weighing platform is arranged on a weighing bracket. A conveying roller path is arranged on the weighing platform. A weighing sensor is arranged on the left side at the bottom of the weighing platform. A weighing upright column is arranged on the left side of the weighing platform. A filling lifting device is connected with the weighing upright column. A filling nozzle is arranged in the middle of the filling lifting device. The filling nozzle is provided with a flow controller. An automatic control device is arranged at the upper portion on the right side of the filling lifting device. A filling air cylinder is arranged at the upper portion of the filling lifting device. A gland upright column is arranged in the middle of the weighing platform. A press catching device is arranged in the middle of a gland lifting device. The gland lifting device is connected with the gland upright column. The flow controller and the weighing sensor are both electrically connected with the automatic control device. The chemical liquid precise quantitative filling device is simple in structure, flexible and convenient in installation, small in space occupation, and high in precision.

Owner:王英英

Integral spin-forming method for damping shell with cooling fin

ActiveCN110732581AUniform growthUniform force makes the growth process stable during the shoveling processSpinningDynamic balance

The invention discloses an integral spin-forming method for a damping shell with a cooling fin, and the integral spin-forming method solves the problem that the radiating effect for the damping shellequipped with the cooling fin or welded with the cooling fin is not good. Integral forming and manufacturing production for the damping shell with the cooling fin is accomplished through five processes of laser unloading, inner barrel shoveling and spinning, radiating slot spinning and pressing, outer barrel shoveling and spinning, and machining. Different position layouts, operation sequences andcontrol parameters achieve key effect on whole product processing. The integral spin-forming method adopts spin-forming to realize integral forming and processing of the radiating sheet and the damping shell, mechanical property distribution is uniform, product dynamic balance is good, production quality of the damping shell is improved, the service life of the damping shell is prolonged, marketneeds are met, and a popularization value is relatively high.

Owner:河南贵族轮毂技术有限公司

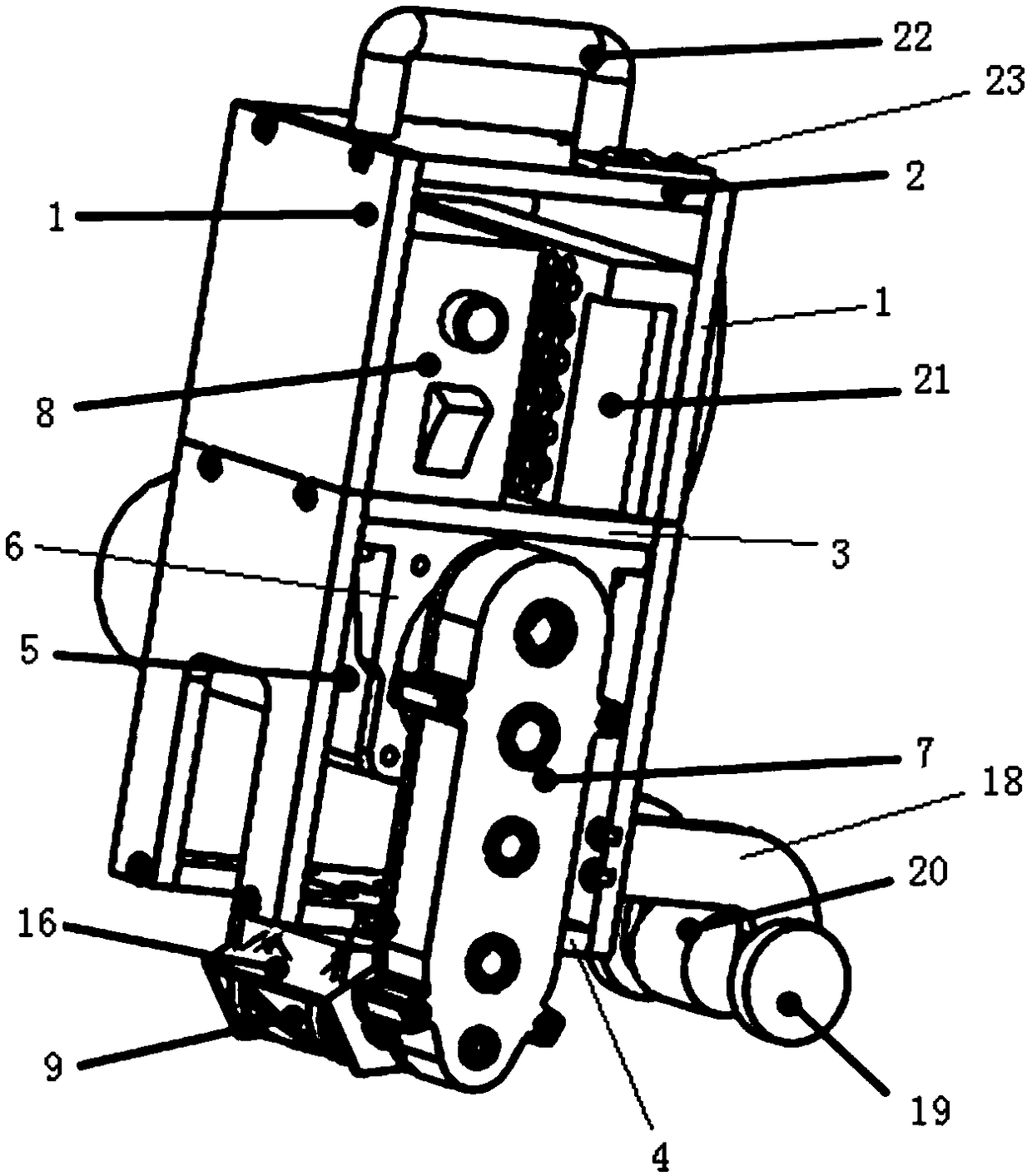

Handheld weld joint polishing device capable of protecting welding base materials, and working method

PendingCN109226847AImprove cutting performanceImprove surface qualityMeasurement/indication equipmentsMilling equipment detailsEngineeringWeld metal

The invention relates to a handheld weld joint polishing device capable of protecting welding base materials, and a working method. The handheld weld joint polishing device comprises a frame; a driving mechanism is fixed to the frame, and is connected with a cylindrical cutter to drive the cutter to operate; circular positioning members, larger than the cutter in diameter, are arranged on two sides of the cutter, and the circular positioning members can roll along the surfaces of the welding base materials during polishing; the excess weld metal of weld joints is controlled through differencevalues between the diameters of the circular positioning members and the cutter. The handheld weld joint polishing device provided by the invention has the advantages that the welding base materials can be effectively protected, the polishing feed speed can be conveniently controlled, the polishing effect is good, and accordingly, the handheld weld joint polishing device is applicable to differentprocessing scenes.

Owner:SHANDONG UNIV

Feed device of a double-wheel slot milling machine and the double-wheel slot milling machine

ActiveCN103770224BFeed speed controlControl pressureStone-like material working toolsEngineeringConductor Coil

The invention discloses a feed device of a double-wheel slot milling machine and the double-wheel slot milling machine, comprising an oil cylinder, the cylinder barrel of the oil cylinder is hinged with the mast or goose head of the double-wheel slot milling machine, and the piston rod of the oil cylinder is connected with the The milling device below is connected, and the oil cylinder can realize differential motion between the pulley device and the reel motor. In the feeding device of the double-wheel slot milling machine and the double-wheel slot milling machine of the present invention, the oil cylinder does not need special protection and can better control the feed speed and feed pressure of the milling device, which improves the efficiency of changing strokes and has a simple structure. Low cost and easy maintenance.

Owner:XCMG CONSTR MACHINERY

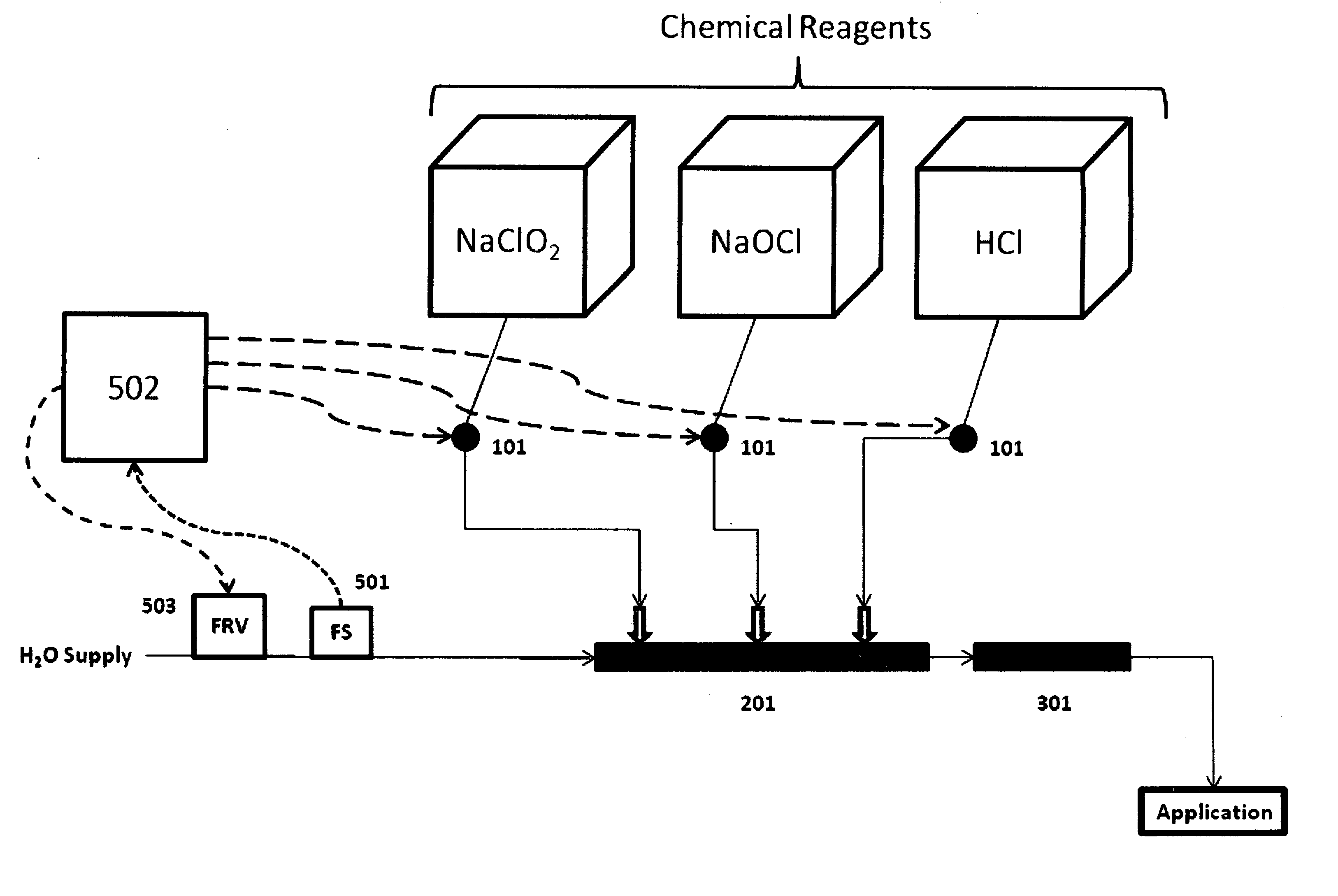

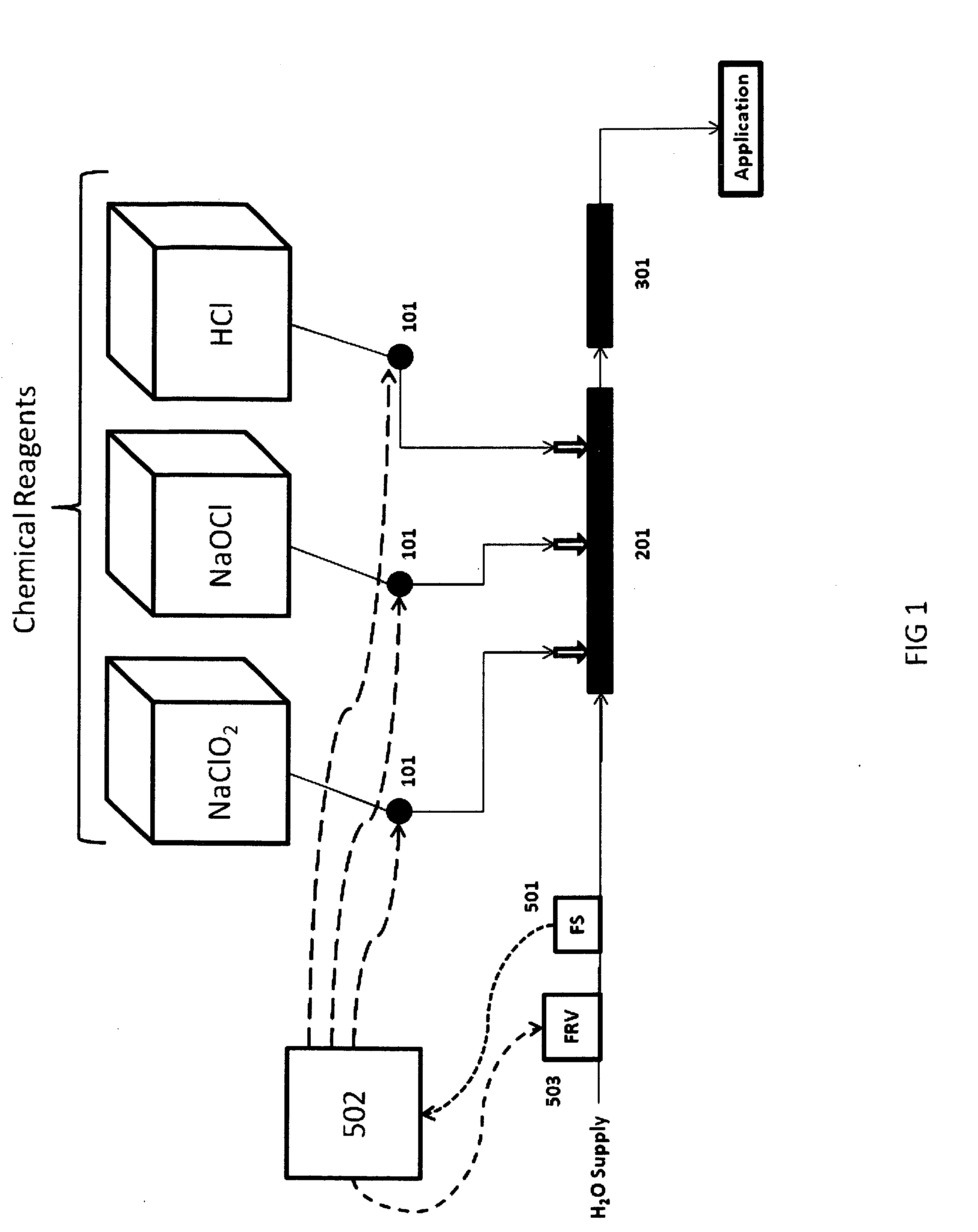

Chlorine dioxide generator for the efficient generation of chlorine dioxide in dilute solutions

ActiveUS20150065403A1Limited abilityGood flexibilityWaste water treatment from quariesBiocideChlorine dioxideProcess engineering

Disclosed is a process for the safe and efficient generation of chlorine dioxide while achieving a variable chlorine dioxide mass flow rate, with a turn-down to turn-up ratio of at least 1 to 200. The process allows for a single chlorine dioxide generating system to safely provide variable mass flow rate of chlorine dioxide to applications that have wide ranging chlorine dioxide demand, like those experienced in oil and gas applications.

Owner:TRUOX

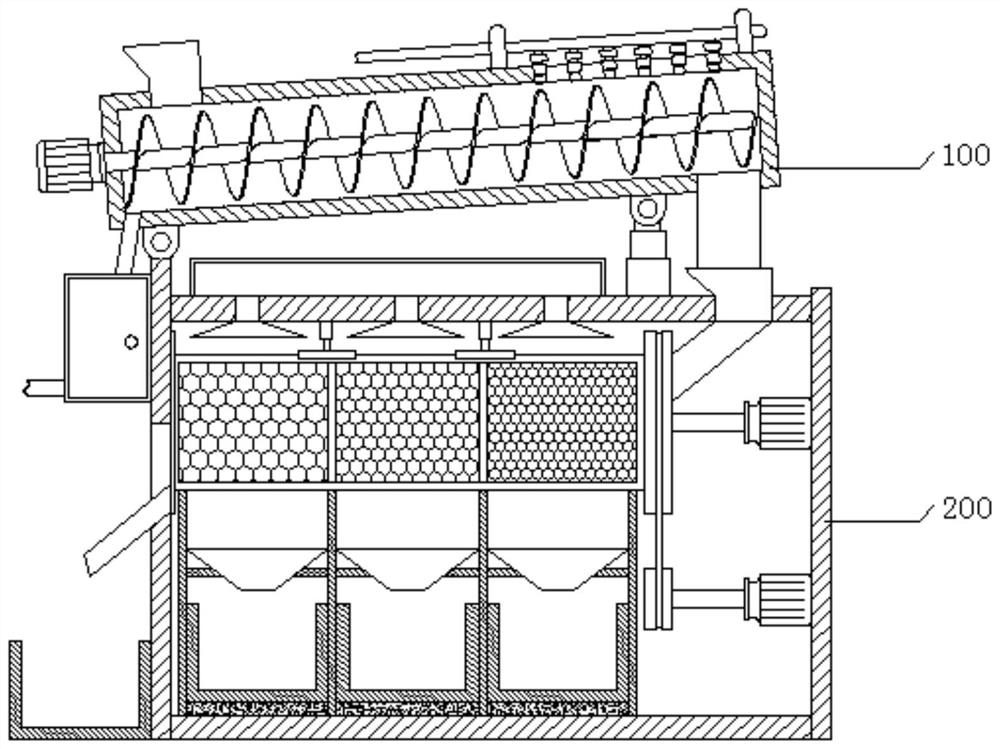

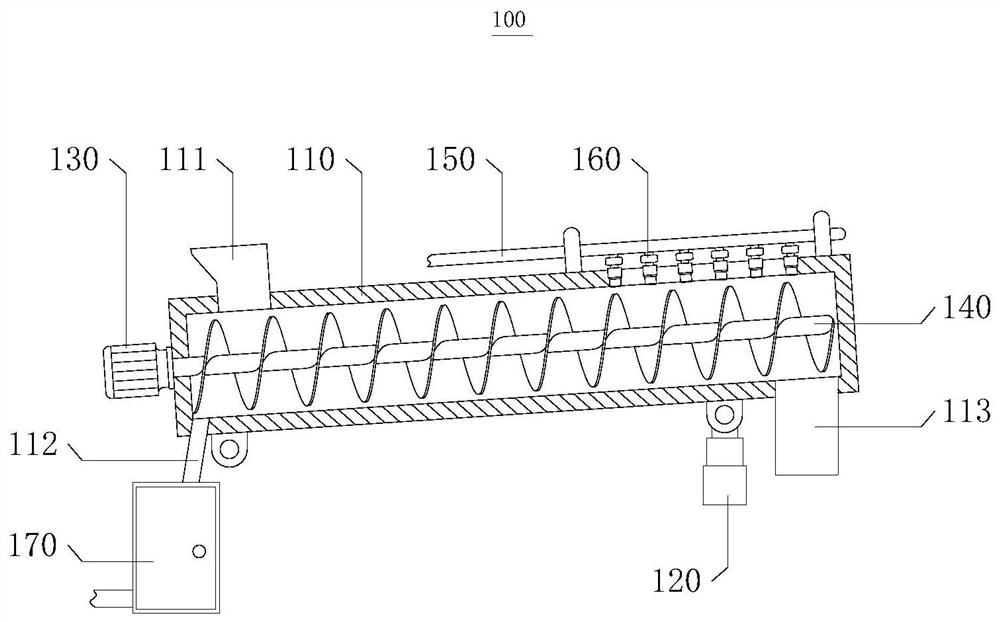

Environment-friendly concentrating machine

InactiveCN113083659ARotation does not affectImprove screening effectSievingScreeningAugerDust control

The invention provides an environment-friendly concentrating machine, and belongs to the technical field of ore processing equipment. The concentrating machine is characterized by comprising a dust removal mechanism and a sorting mechanism, wherein a first auger is rotationally installed on the inner wall of an installation cylinder and is in key connection with an output shaft of a first motor, a spray head is inserted into the top of the installation cylinder and communicates with a water pipe, a first roller screen, a second roller screen and a third roller screen are sequentially installed on an installation frame, a first transmission wheel is fixedly installed at one end of the installation frame, and a second auger is rotationally installed on the installation frame and is in key connection with an output shaft of a second motor. According to the concentrating machine, dust removal is carried out on ores through the dust removal mechanism, and grading screening is carried out through the sorting mechanism, so that dust flying during operation of the machine is effectively avoided, and the screening effect is guaranteed through multi-stage screening; and meanwhile, the sorting mechanism of the machine is reasonably arranged, so that the feeding stability of the machine during operation is guaranteed.

Owner:吴丹丹

Brush-sieve powder fluidizing apparatus for nano-size and ultra fine powders

ActiveUS10722910B2Easy to manufactureFeed speed controlLiquid surface applicatorsSolid materialEngineeringUltra fine

Powder fluidizing apparatus includes a unitary pressure vessel having a powder compartment and a transfer compartment, a lid on a first open end of the powder compartment and a base on a second end of the unitary pressure vessel, the second end sealing an open end of the transfer compartment. A plate separates the powder compartment from the transfer compartment, the plate being located between the lid and the base. A coupling collar secures a sieve disk packet in an opening in the plate. A tube extends from the transfer compartment to the powder compartment, the tube extending to a location near the lid of the unitary pressure vessel. When the transfer compartment is pressurized with a carrier gas, pressure in the transfer compartment and pressure in the powder compartment are equalized by the tube. The unitary pressure vessel is configured to contain the carrier gas in both the powder compartment and the transfer compartment and simultaneously perform as a reservoir for holding a quantity of powder in the powder compartment.

Owner:INNOVATION TECH INC

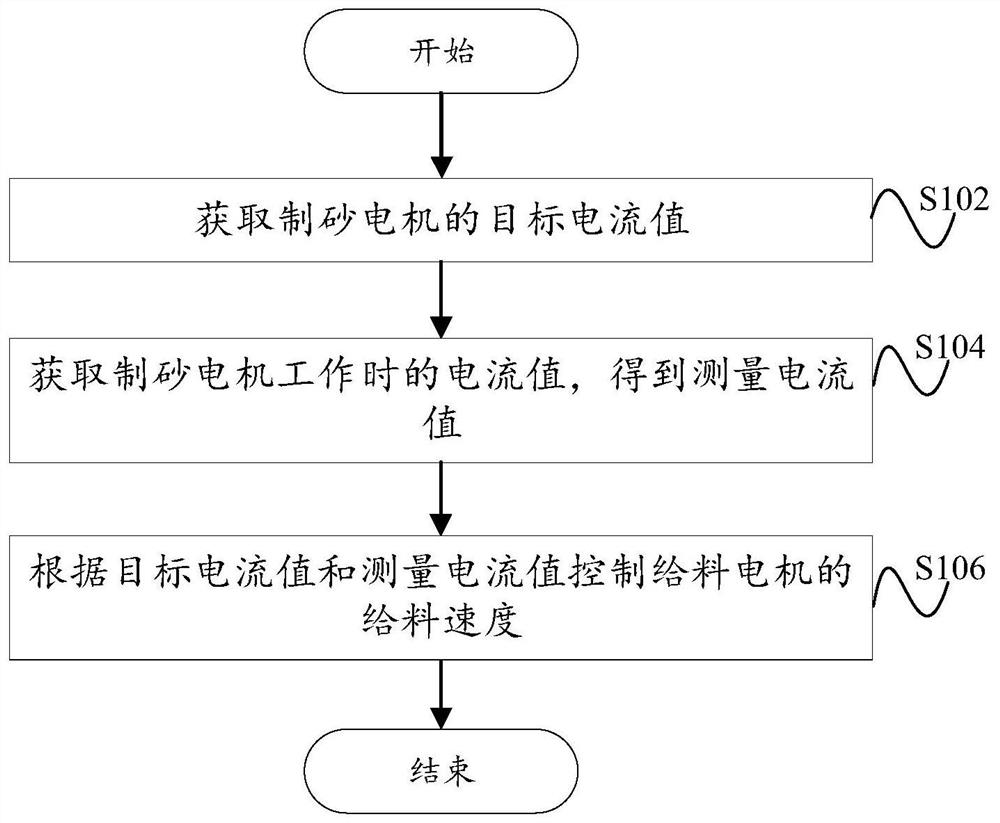

Control method and device for adjusting feeding speed of sand making building and sand making building

ActiveCN113696328AControl sand productionFeed speed controlCement mixing apparatusControl apparatusSystems engineeringControl engineering

The invention provides a control method and device for adjusting the feeding speed of a sand making building and the sand making building. The sand making building comprises a sand making machine and a feeding machine, the sand making machine comprises a sand making motor used for controlling the sand making amount, and the feeding machine comprises a feeding motor used for controlling the feeding speed. The control method for adjusting the feeding speed of the sand making building comprises the steps that the target current value of the sand making motor is obtained; a current value when the sand making motor works is obtained to obtain a measured current value; and the feeding speed of the feeding motor is controlled according to the target current value and the measured current value. Compared with a traditional feeding amount control method, the operation current of the sand making machine does not need to be manually observed in real time, the feeding speed does not need to be manually adjusted, the feeding speed of the sand making machine can be automatically adjusted, and the production efficiency is improved. Meanwhile, the feeding amount of the feeding machine can be effectively controlled, stable current can be generated, the service life of the sand making machine is prolonged, overload of the motor can be effectively prevented, and the sand making machine can stably run within the target current range all the time.

Owner:SANY HEAVY EQUIP

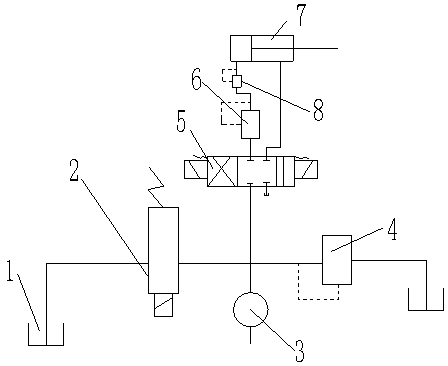

Novel solidification system capable of accelerating solidification of metal liquid

InactiveCN108302072ATime controllableStable and reliable speedServomotorsEngineeringElectromagnetic valve

The invention discloses a novel solidification system capable of accelerating solidification of metal liquid. The novel solidification system comprises an oil tank, a two-position two-way electromagnetic valve, a hydraulic pump, an overflow valve, a three-position four-way electromagnetic reversing valve and an extrusion oil cylinder, wherein the oil tank is connected with the hydraulic pump and the overflow valve; the two-position two-way electromagnetic valve is arranged between the oil tank and the hydraulic pump; the hydraulic pump is connected with the three-position four-way electromagnetic reversing valve; the three-position four-way electromagnetic reversing valve is connected with the extrusion oil cylinder; a speed adjusting valve is arranged between a pressure reducing valve andthe extrusion oil cylinder; the feeding speed of the extrusion oil cylinder is controlled by the speed adjusting valve. The action time of local pressurization can be adjusted; the effectiveness of the local pressurization can be met as far as possible; the stability of the local extrusion process can be improved.

Owner:GUANGDONG HONGTUNANTONGDIE CASTING +1

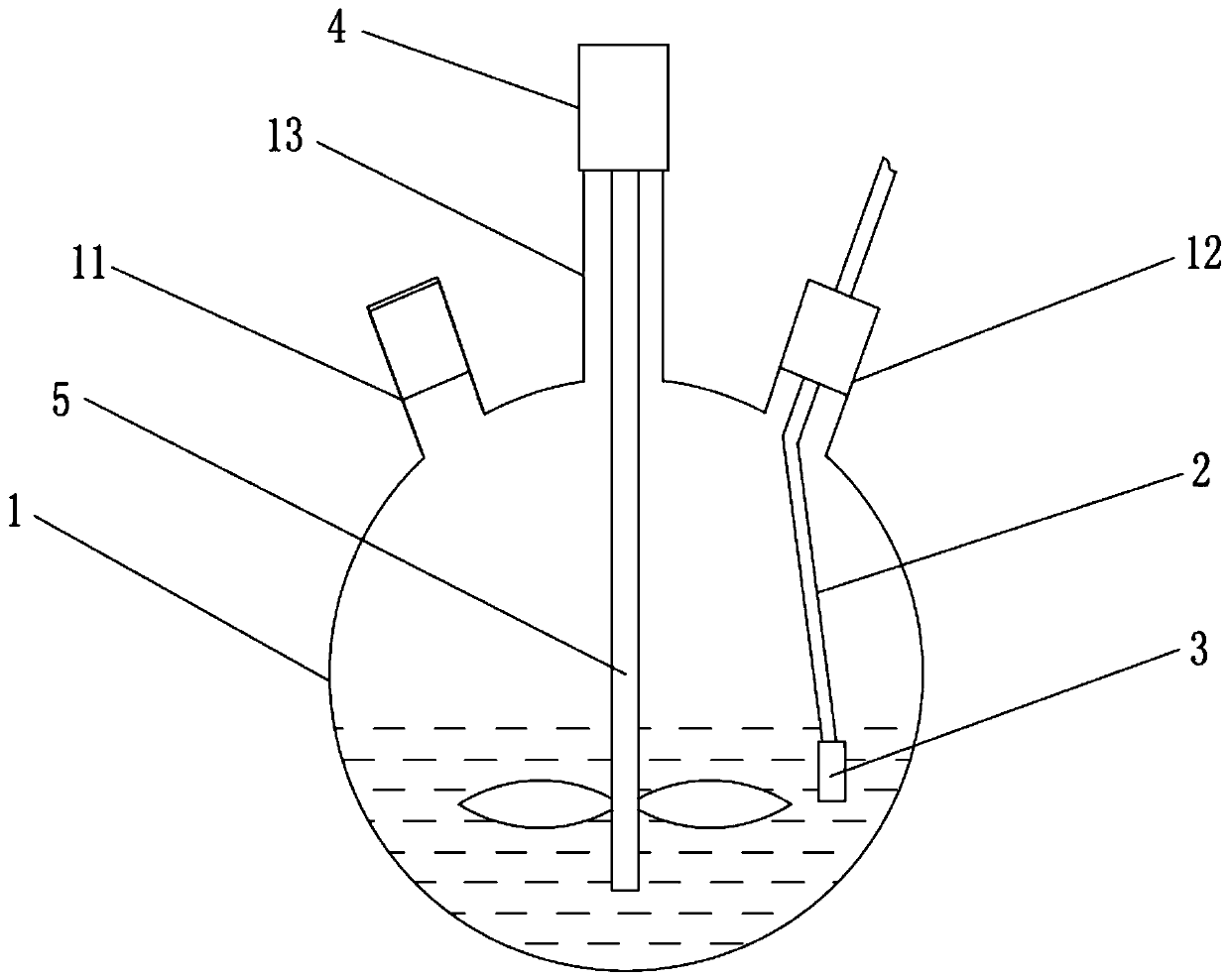

Preparation process and reaction device for synthesizing sodium dodecyl diphenyl ether disulfonate

PendingCN110526840APrevent volatilizationStable ratioSulfonic acids salts preparationChemical/physical/physico-chemical stationary reactorsSolventDiphenyl ether

The invention discloses a preparation process for synthesizing sodium dodecyl diphenyl ether disulfonate. The preparation process comprises the following steps: adding dodecyl diphenyl ether and a solvent into a reaction kettle in advance until the liquid level submerges a nozzle arranged in the reaction kettle, conveying a sulfonating agent to the nozzle, carrying out spraying and feeding under the liquid level, reacting the atomized sulfonating agent with the dodecyl diphenyl ether, and adding a sodium hydroxide solution after the reaction is finished to generate sodium dodecyl diphenyl ether disulfonate. The invention further discloses a reaction device for synthesizing the sodium dodecyl diphenyl ether disulfonate. Liquid sulfur trioxide is fed under liquid through the nozzle, so thaton one hand, volatilization of the liquid sulfur trioxide can be avoided; on the other hand, the contact area of reaction materials and sulfur trioxide is increased through atomization of the liquid sulfur trioxide, and local peroxidation is avoided; and therefore, the obtained sodium dodecyl diphenyl ether disulfonate finished product is light in color and is transparent.

Owner:南雄市汉科化工科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com