Control method and device for adjusting feeding speed of sand making building and sand making building

A technology of feeding speed and control method, which is applied in the direction of control devices, clay preparation devices, cement mixing devices, etc., and can solve problems such as low production efficiency, overload of sand making machines, and unsatisfactory production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

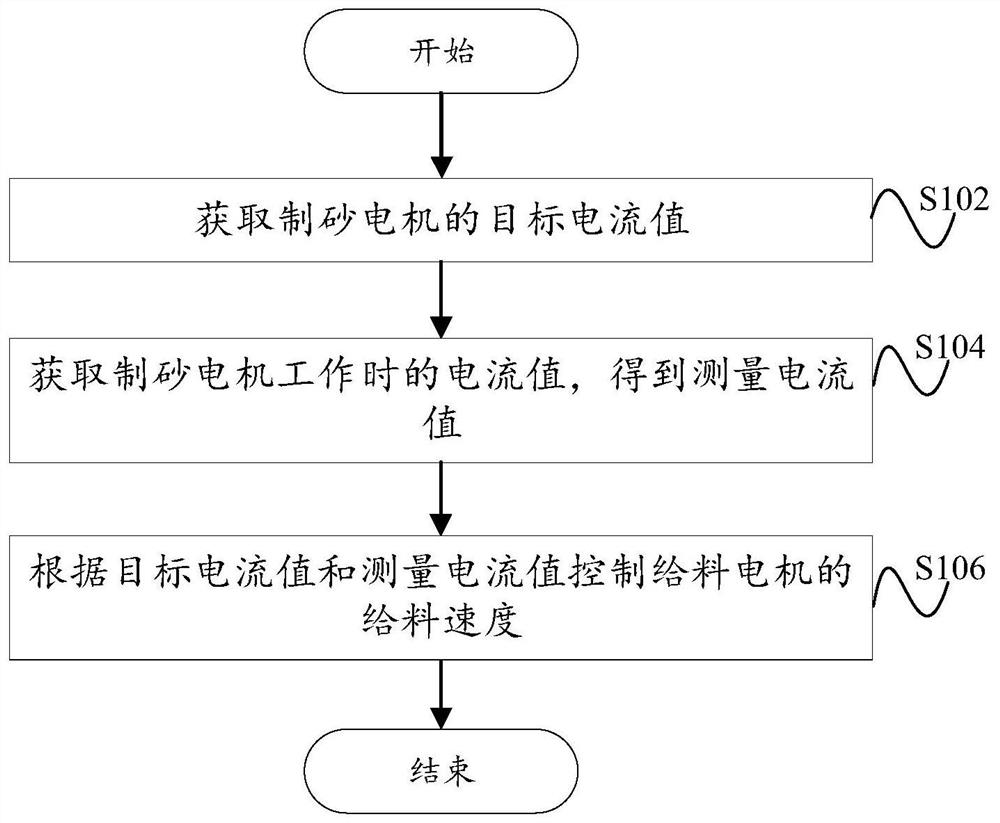

[0044] Such as Figure 1 to Figure 4 As shown, the embodiment of the first aspect of the present invention provides a control method for adjusting the feeding speed of the sand making building. The sand motor 4, the feeder includes a feeding motor 3 for controlling the feeding speed, and the control method for adjusting the feeding speed of the sand making building includes:

[0045] S102, obtaining the target current value of the sand making motor;

[0046] S104, obtain the current value of the sand making motor when it is working, and obtain the measured current value;

[0047] S106, controlling the feeding speed of the feeding motor according to the target current value and the measured current value.

[0048] According to the control method for adjusting the feeding speed of the sand making building provided by the present invention, it is used in the sand making building. The sand making building includes a sand making machine and a feeder. sand. The sand making machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com