Pneumatic double-acting pump

A double-acting pump and pneumatic technology, applied in variable capacity pump components, pumps, piston pumps, etc., can solve the problems of loss of pump function, damage to fluid quality, energy-consuming components, etc., to achieve the adjustment of fluid delivery flow rate, convenient fluid Delivery flow rate, the effect of precision fluid delivery flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

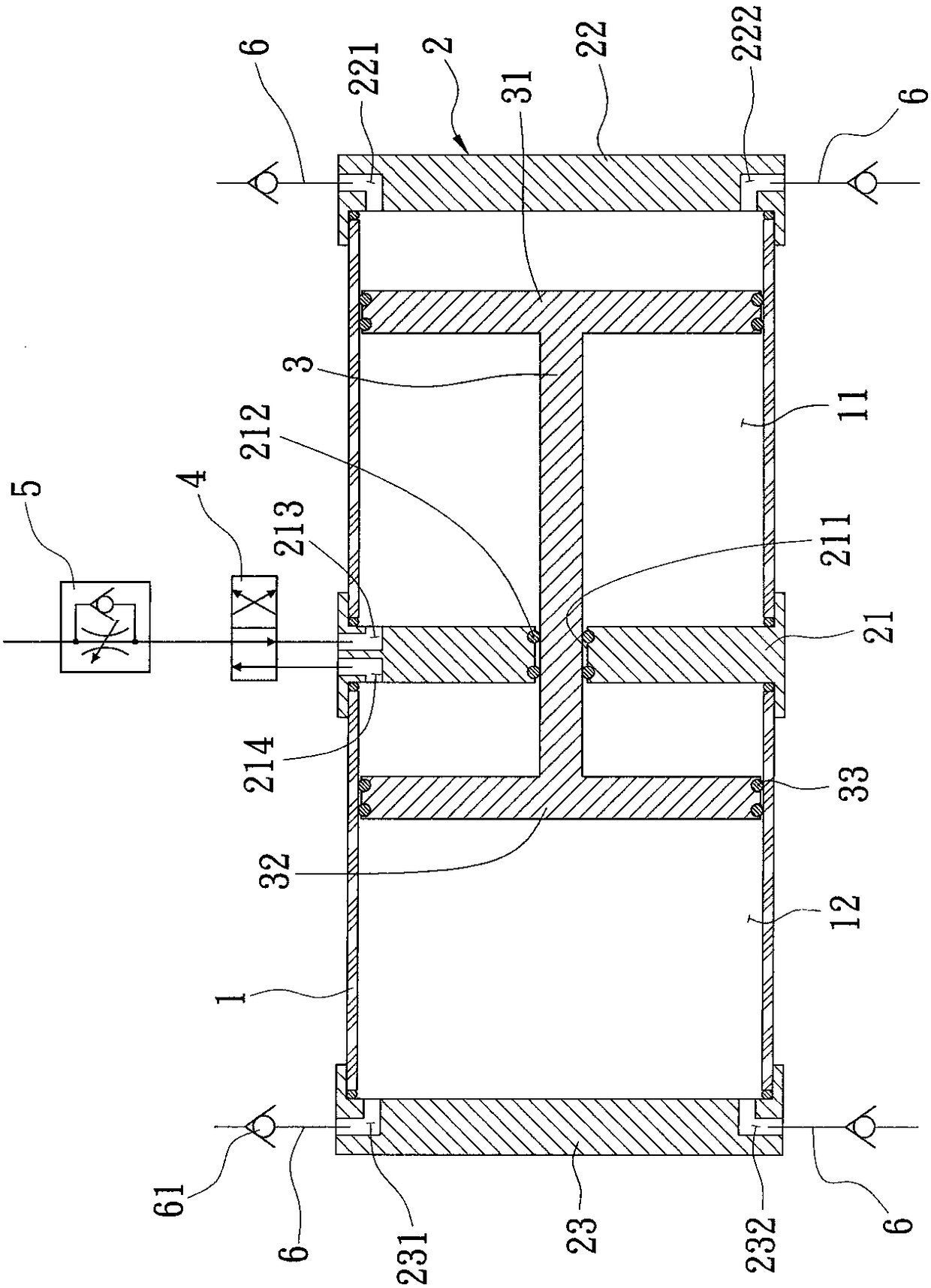

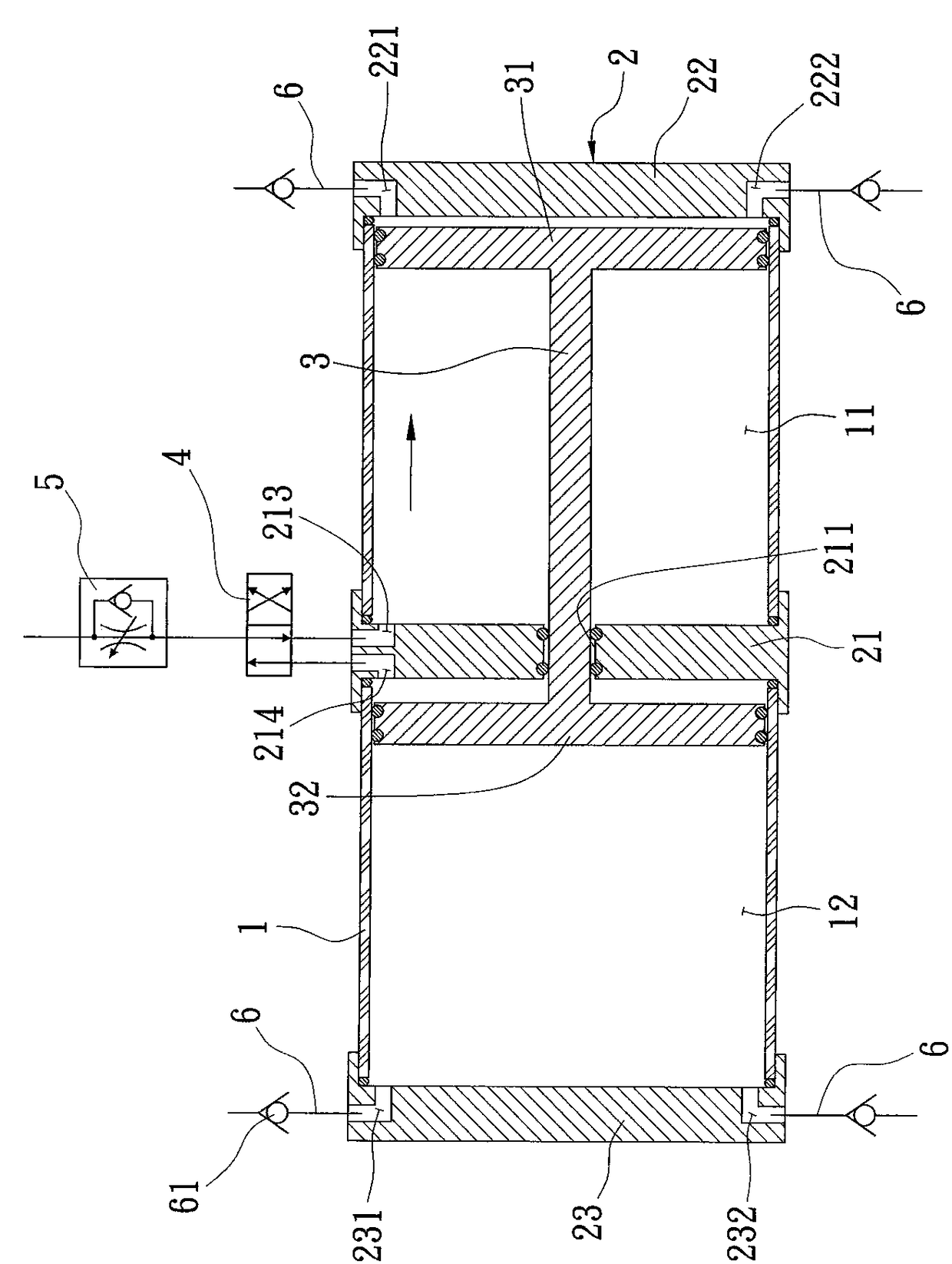

[0040] In order to enable a more complete and clear disclosure of the technical means of the present invention and the effects it can achieve, the detailed description is as follows. Please also refer to the disclosed drawings and figure numbers:

[0041] First, see figure 1 As shown, it is a pneumatic double-action pump of the present invention, which is provided with a hollow pump main body 1, and the hollow pump main body 1 is divided into at least two chambers by at least three partitions 2, and the partition between the two chambers Three partitions 2 respectively constitute the two end walls of the two chambers, the present invention defines the three partitions 2 as the first partition 21, the second partition 22 and the third partition 23, and the two chambers are defined as the second partition A chamber 11 and a second chamber 12, and make the partition 2 between the first chamber 11 and the second chamber 12 be the first partition 21, and make the first chamber and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com