Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53results about How to "Eat evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

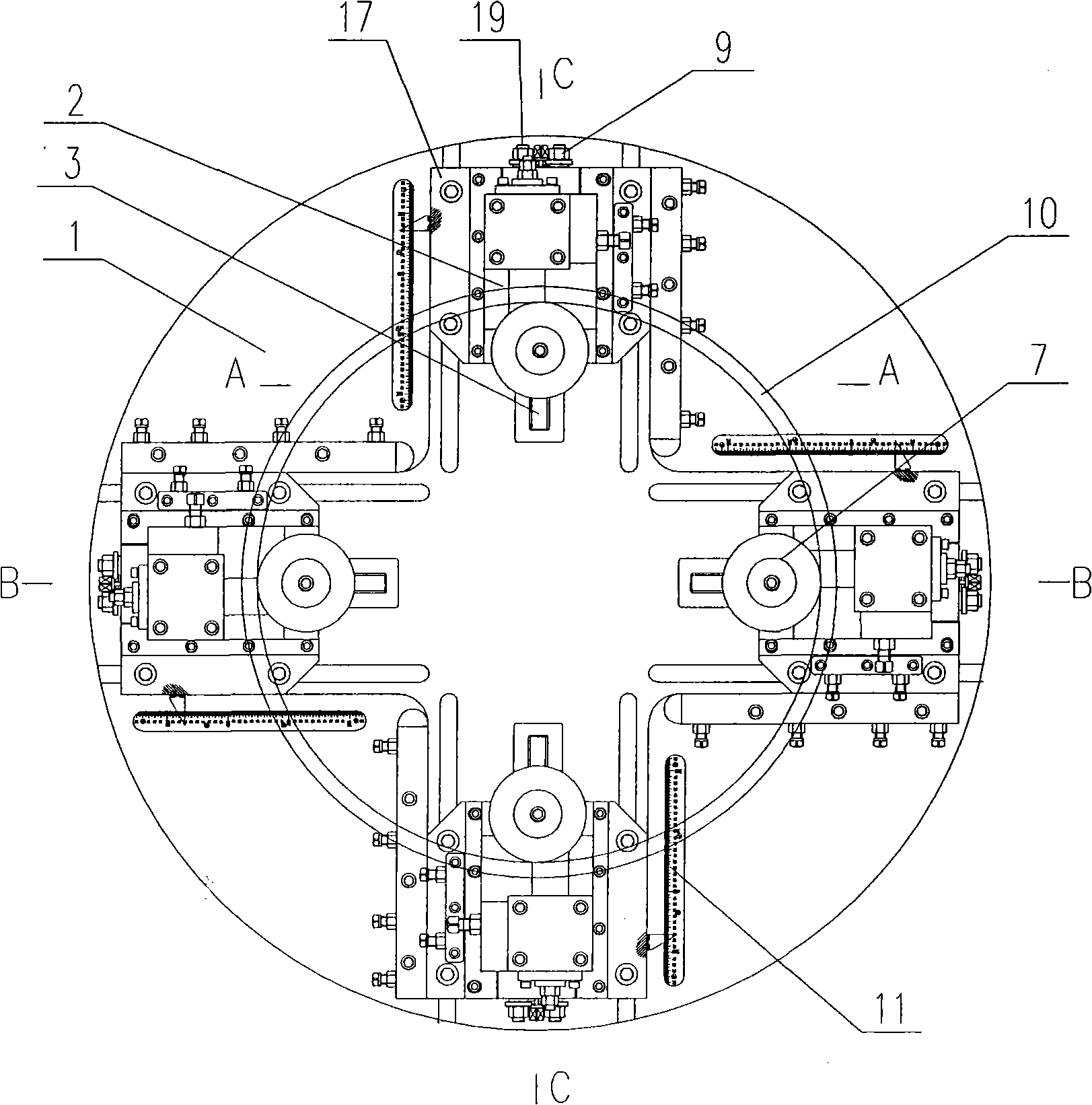

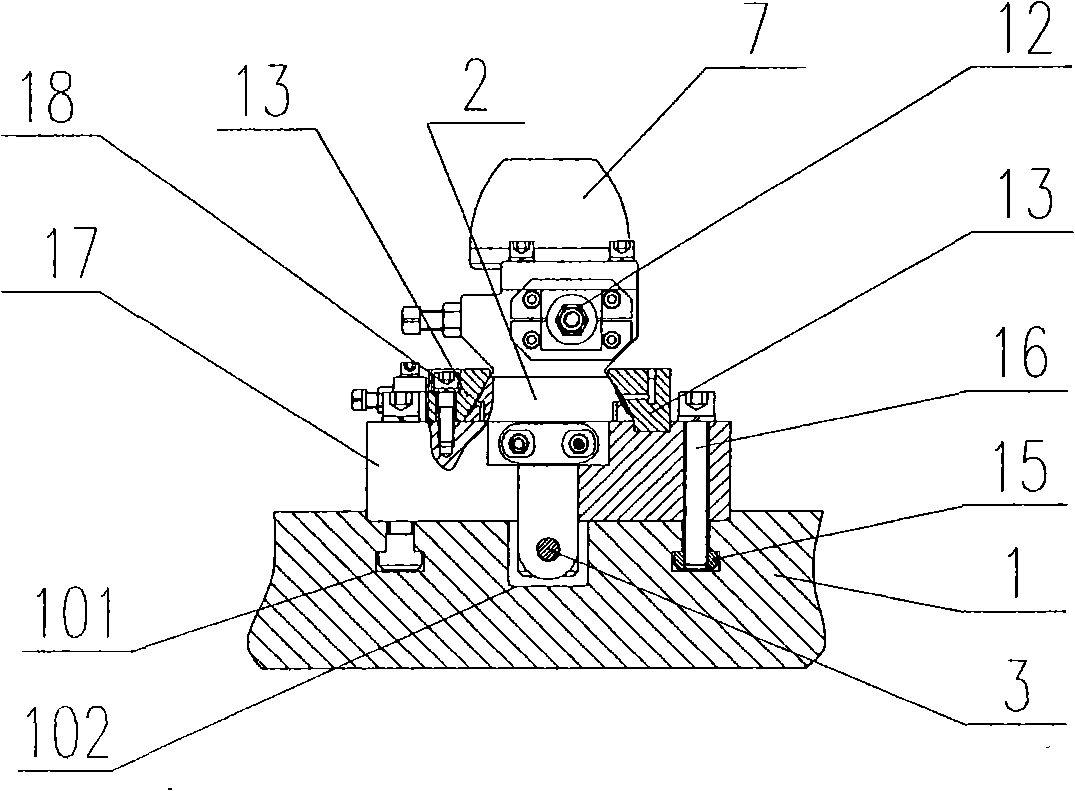

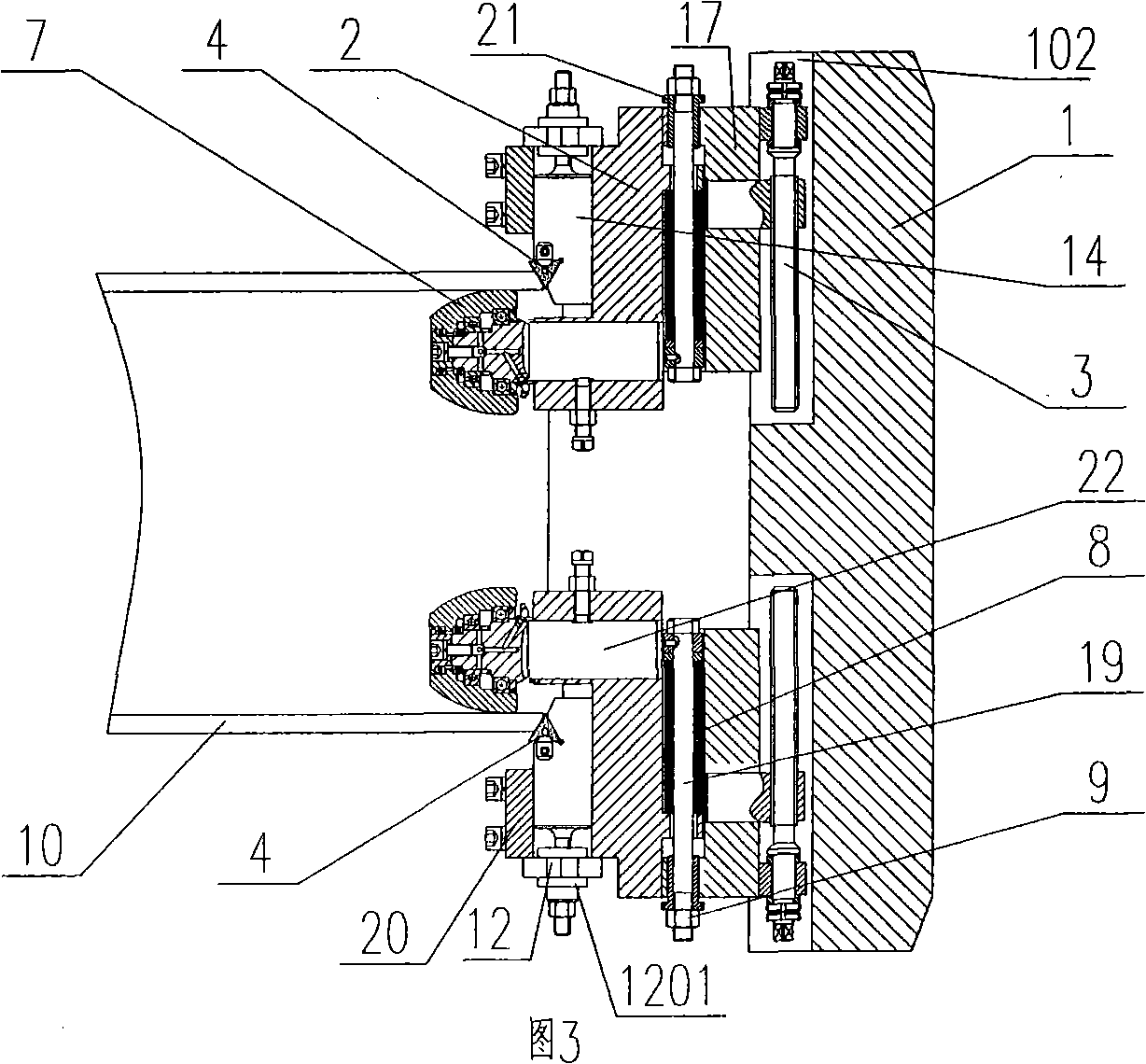

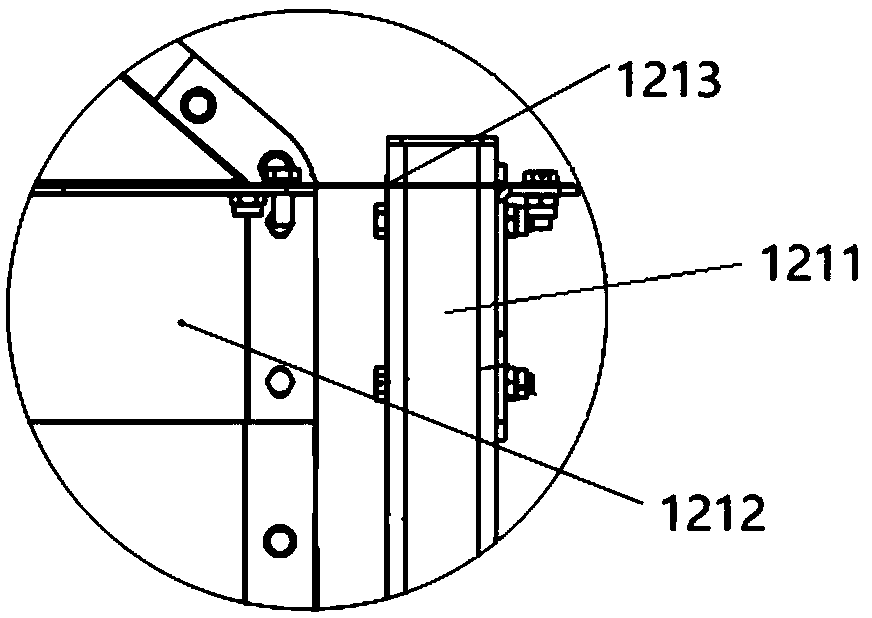

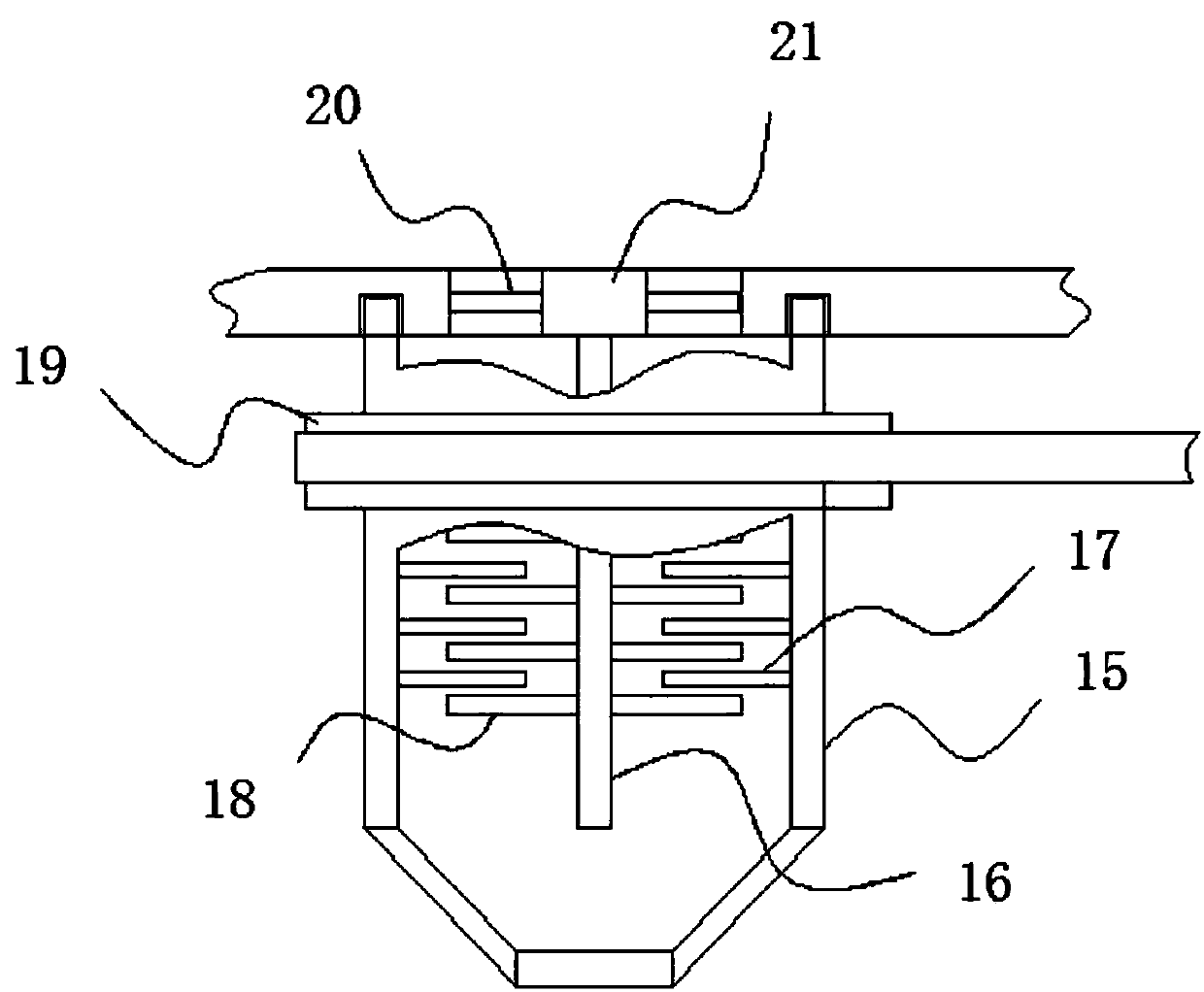

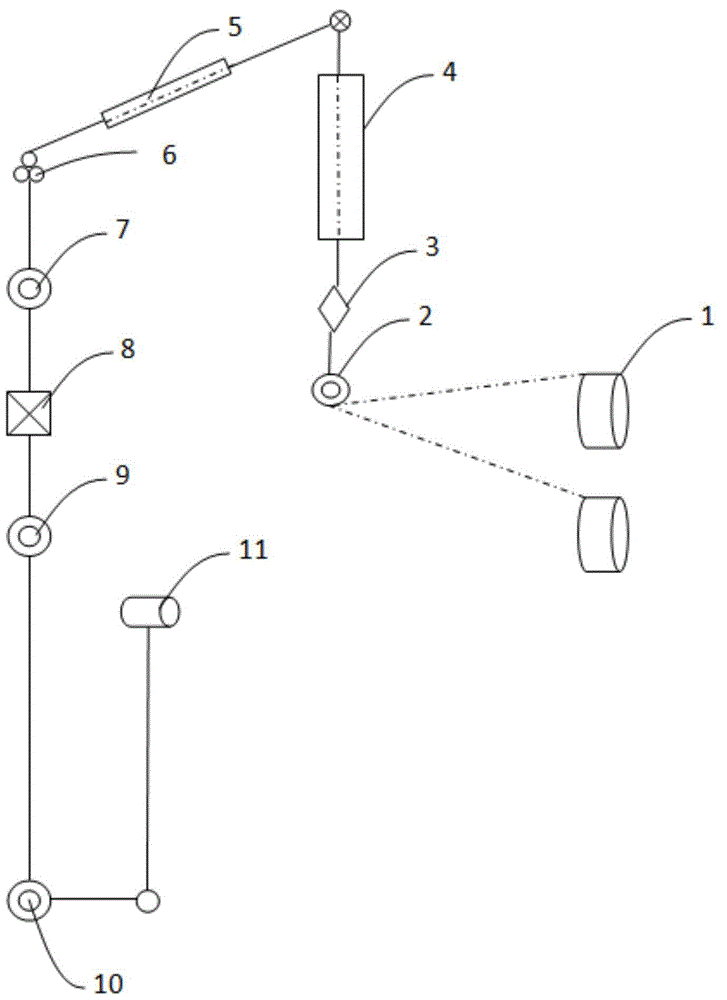

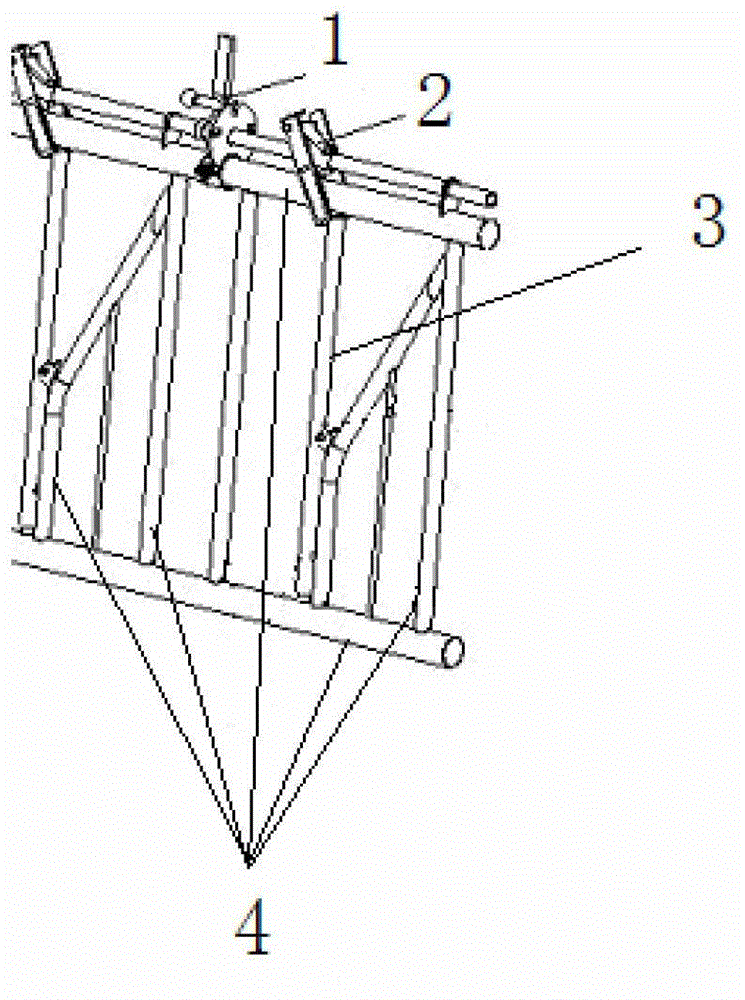

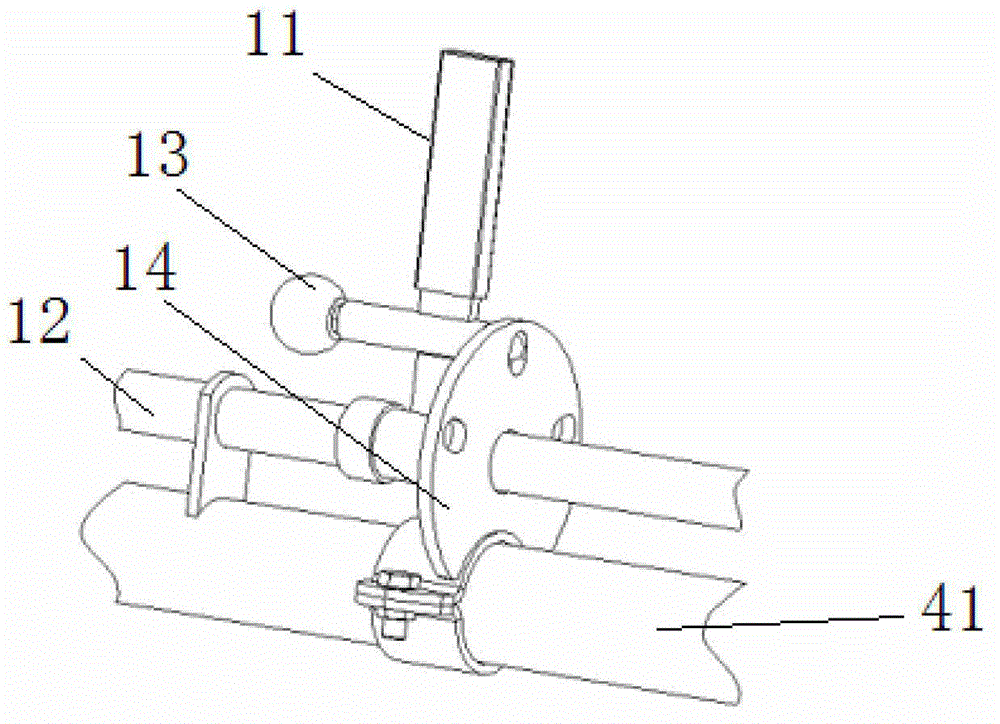

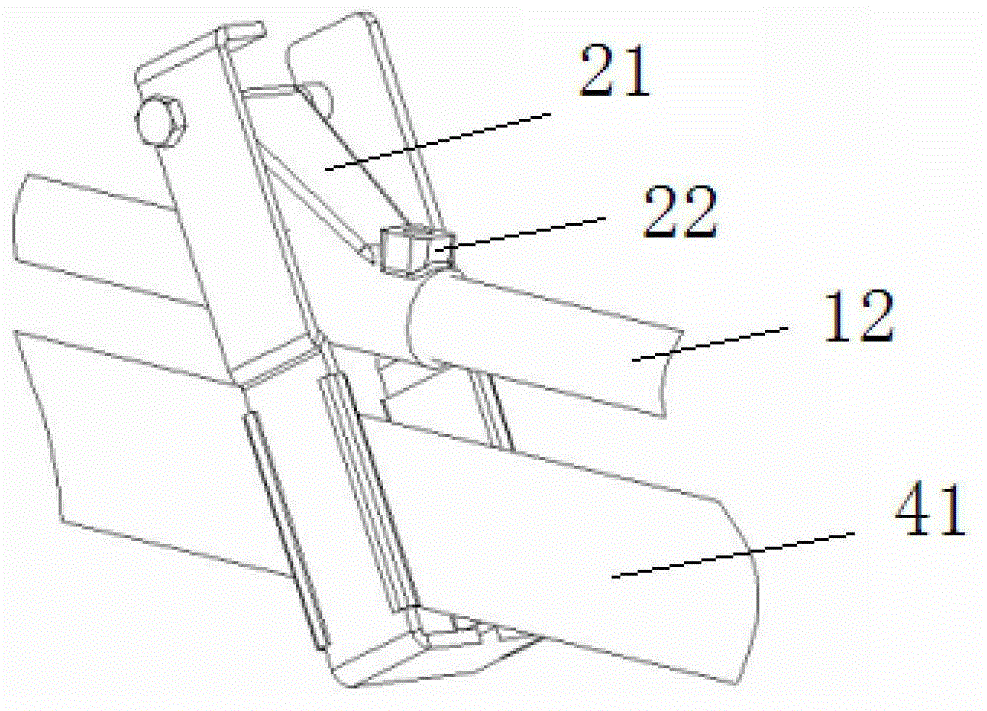

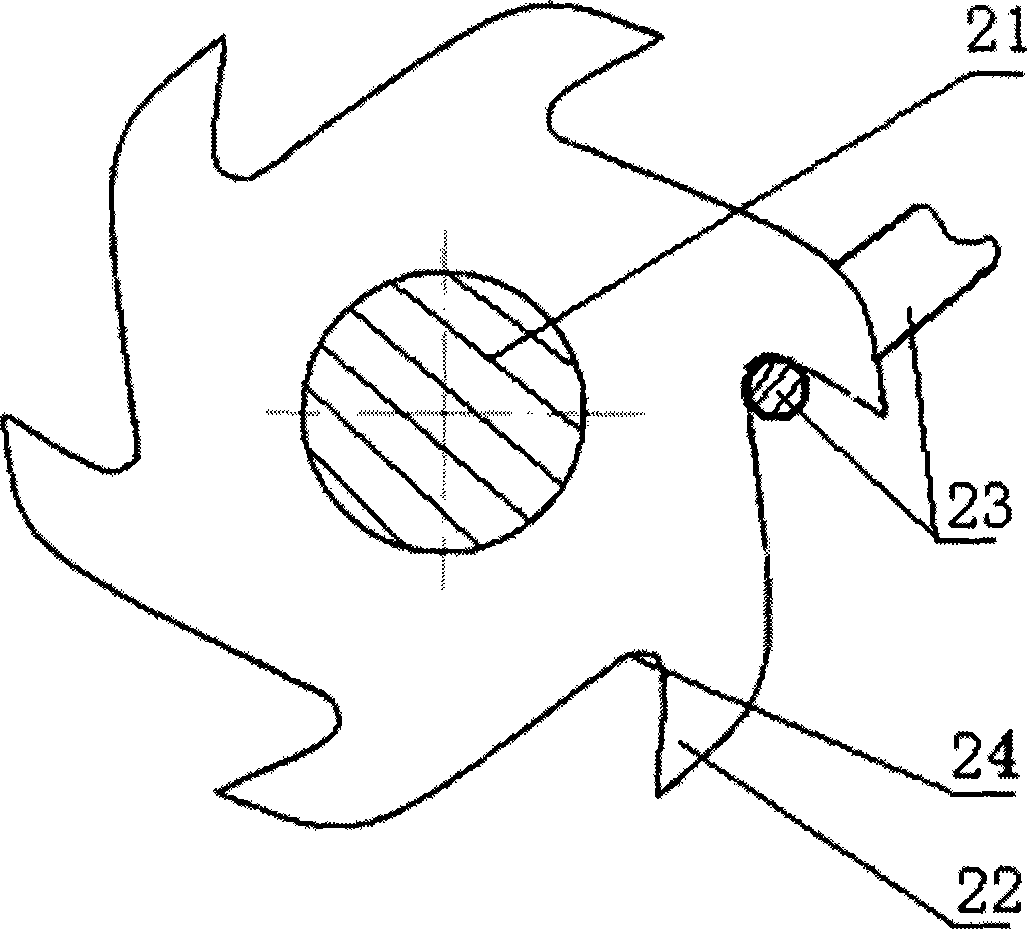

Adjustment method of inner-profile radial floating tool rest and tool

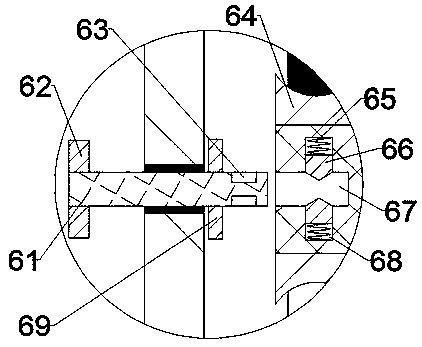

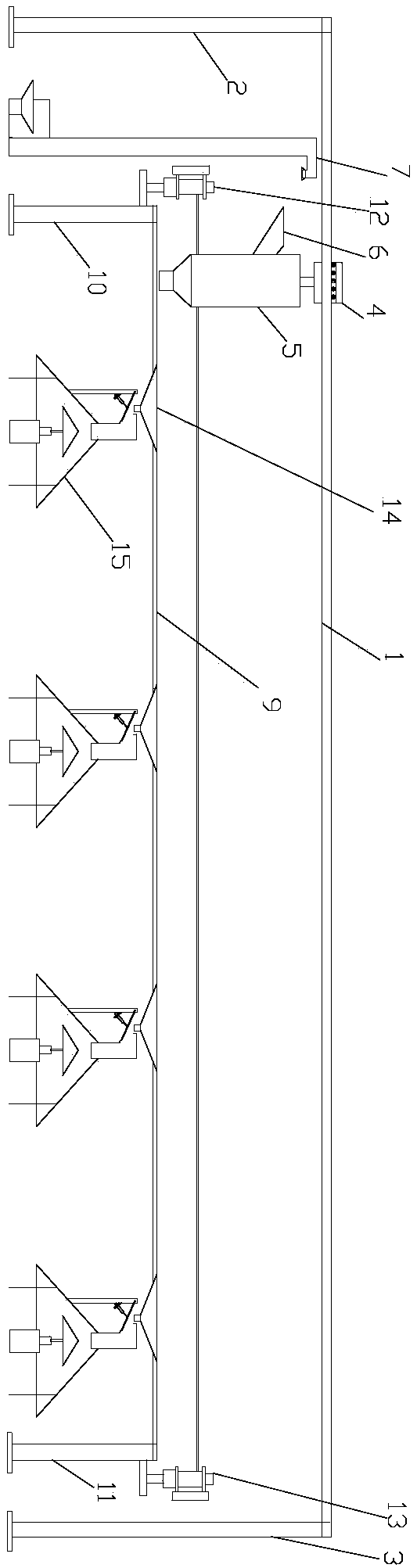

InactiveCN101357404AEat evenlyUniform turningAuxillary equipmentCopying process control systemsProduction lineEngineering

The invention relates to an internal profile modeling tool apron which is used in a steel pipe flat-end-face chamfering device in a large-dimensional and straightly welded seam pipe production line and floats along the radial direction; the tool apron comprises a cutter head, of which the end face are symmetrically provided with four sliding base bodies along the radial direction; each sliding base body is provided with a floating tool apron by a connecting screw rod; a cutter is vertical to the side wall of a steel pipe and arranged on the outer end of the floating tool apron, namely, the end far from an axis; the rear part of the cutter is provided with screw threads which are connected with a cutter adjusting mechanism; the end faces and the middle part of the sliding base bodies are provided with a spring slots; a plurality of dish-shape springs are sheathed on the connecting screw rod and arranged in the spring slots; the outer end of the connecting screw rod is provided with a spring adjusting nut; floating stroke adjusting nuts are arranged on the connecting screw rod and at the inner end of the spring adjusting nut; a profile modeling rolling is arranged at the inner end of the floating tool apron and rolls against the interior wall of the steel pipe; the position of the cutter and the steel pipe wall are relatively fixed, thereby simultaneous penetration of four cutters on the cutter head, even turning, no easy collision of the cutters and high production efficiency are ensured. The invention also relates to an adjusting method of the cutters.

Owner:TIANSHUI METALFORMING MACHINE TOOL GROUP

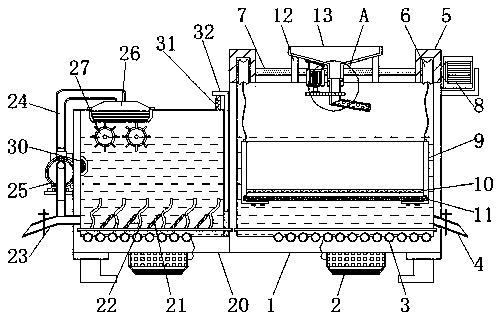

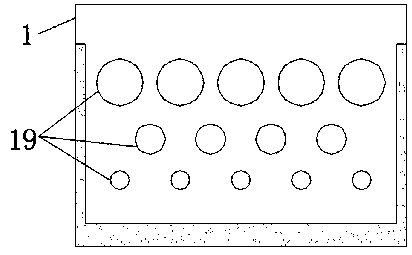

Fish breeding device convenient to clean

InactiveCN109864029AFacilitate the induction of fish activitiesConvenience for breeding workClimate change adaptationPisciculture and aquariaElectric machineryEngineering

The invention discloses a fish breeding device convenient to clean. The fish breeding device comprises a first breeding pond, a circulation pump and water turbines; heaters are fixedly installed at the lower end of the first breeding pond, and a first drainage pipe penetrates through the lower portion of the surface of the right end of the first breeding pond; a rotating roller is installed in a fixing block, the right end of a connecting shaft penetrates through the fixing block and is connected with a first motor, and the first breeding pond is internally provided with a collecting box; thelower end of a first filtering plate tightly fits a second filtering plate, and support legs are fixedly installed at the front and rear portions of the upper end of the first breeding pond. Accordingto the fish breeding device convenient to clean, the spaces for activities and feeding are separated, breeding ponds are conveniently cleaned and subjected to slag removal, the spreading range of a feeding device is uniform, it can be ensured that fishes of different sizes and body shapes uniformly feed, a screening and automatic fishing device for mature fishes and a temperature and light environment control device are arranged, and the activities of the fishes are better induced.

Owner:西安文贝科创科技有限公司

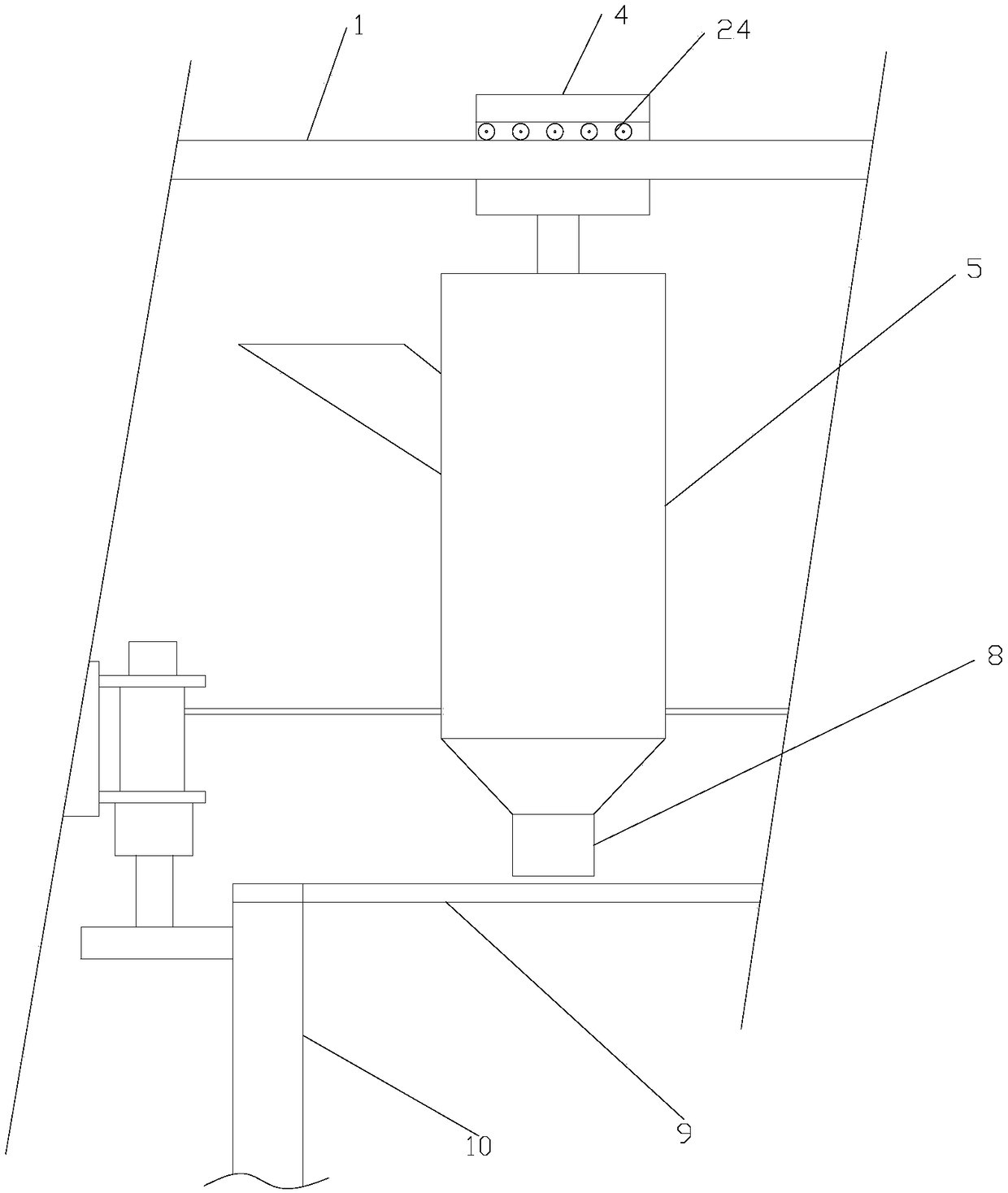

Liquid material feeding system and working method

PendingCN108739468AHealthy environmentReduce labor costsTransportation and packagingAnimal feeding devicesLivestockDisease

The invention discloses a liquid material feeding system and a working method. The liquid material feeding system comprises a stirring device, a conveying system and a control system; the stirring device comprises a stirring cylinder and a stirring cylinder bracket; the stirring cylinder adopts a mixing stirring mode; the stirring device further comprises a disinfecting system; an anti-collision strip is added outside the stirring cylinder bracket; liquid feed is prepared by adopting a new formula. According to the working method of the feeding system, double media are adopted to push the liquid feed to the stirring cylinder; pipelines can be cleaned without residue; the environment of a pig house is healthier, the spreading rate of diseases is reduced, and the growth of livestock is facilitated.

Owner:JIANGXI ZENG XIN HUSBANDRY TECH CO LTD

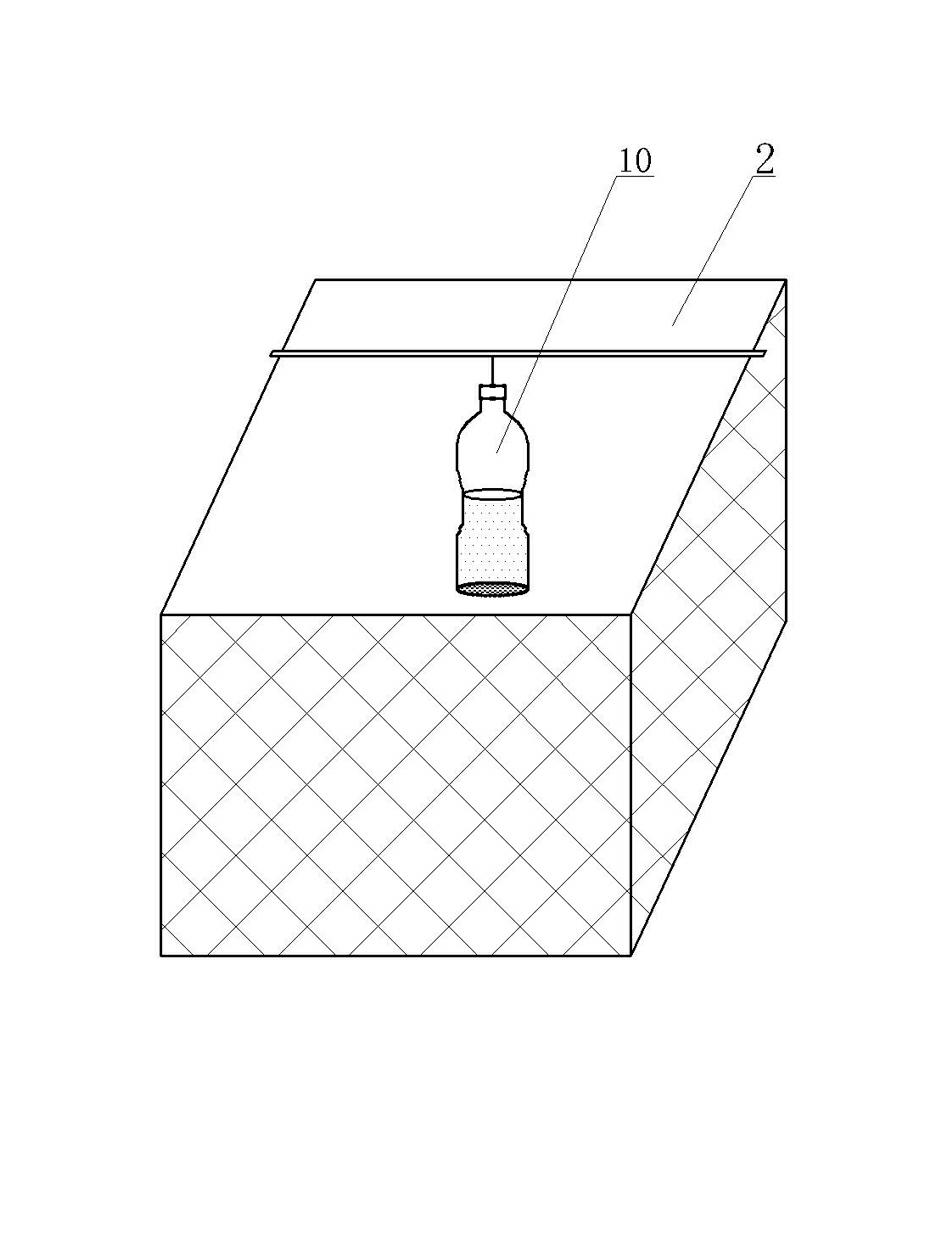

Method for cultivating stichopus japonicus seedlings in earth-pond net cage

ActiveCN102132679AGrow fastImprove survival rateClimate change adaptationPisciculture and aquariaStichopusWater quality

The invention relates to a method for cultivating stichopus japonicus seedlings in an earth-pond net cage, which comprises the following steps of: putting a net cage, namely putting up a sunshade net at the bottom of an earth pond, and suspending the net cage; injecting water, namely injecting clean filtered seawater 15 to 20 days before the seedlings are put till the net cage emerges 30 to 40 centimeters from a water surface; putting the seedlings, namely putting the seedlings from the end of June to the beginning of July; performing the management of water quality, starting to inject fresh seawater frequently 7 to 15 days after the seedlings are put to increase the depth of the seawater, so that the depth of the seawater is between 1.8 and 2 meters in high-temperature season; performingcultivating management, namely putting sea cucumbers into the net cage with feed every day during cultivating, so that the feed is released uniformly and slowly; and replacing the net cage and pouring the seedlings once at intervals of 20 to 25 days in the early stage of cultivation, high-temperature season and the later stage of the cultivation. In the method, the feed is released to the net cage uniformly and slowly in a feeding mode of 'proper amount of much feed, proper amount of less feed and proper amount of much feed again' to ensure that the sea cucumbers can eat the feed, so the ingestion of the sea cucumbers is more uniform in time and space, the survival rate and yield of cultivating the stichopus japonicus seedlings in the earth-pond net cage are improved, the cost is reduced,and the labor strength of operating workers is relieved.

Owner:辽宁每日农业集团有限公司

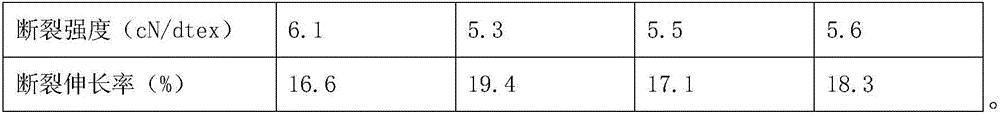

Preparation method of sewing thread

InactiveCN108754669AHigh strengthImprove wear resistanceElectroconductive/antistatic filament manufactureConjugated synthetic polymer artificial filamentsPolyvinyl alcoholGraphene

The invention provides a preparation method of a sewing thread. The preparation method comprises that polyacrylamide, polyvinyl alcohol and graphene undergo a reaction, the product, polypropylene, polyethylene, bamboo charcoal fibers and an emulsifier are uniformly mixed in an internal mixer, and the mixture is molten and spun into the sewing threads. The preparation method comprises simple processes and does not produce pollution. The sewing thread has high strength, good wear resistance, high temperature resistance and good antistatic properties and is suitable for promotion and application.

Owner:HEFEI YUANKE GARMENT DESIGN CO LTD

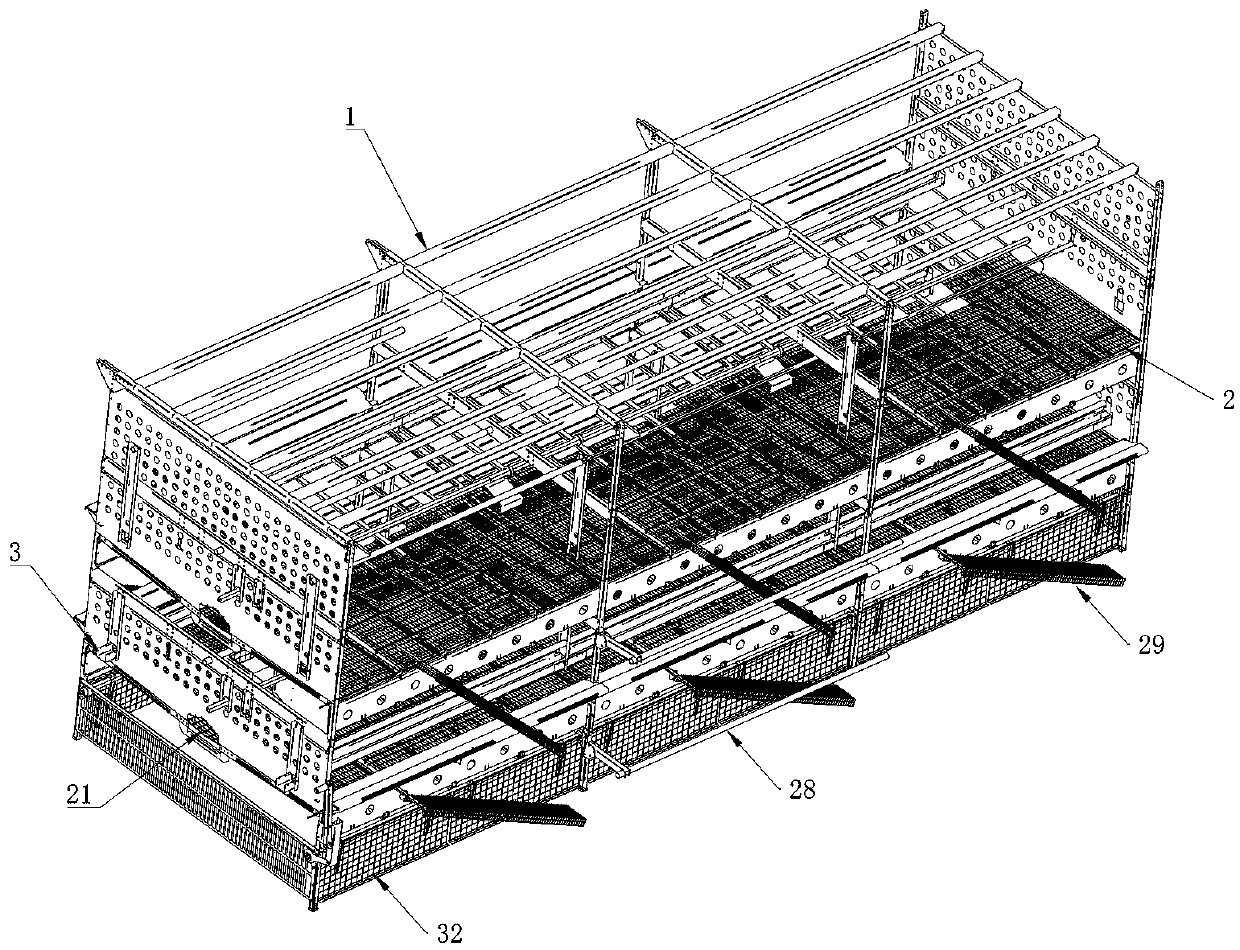

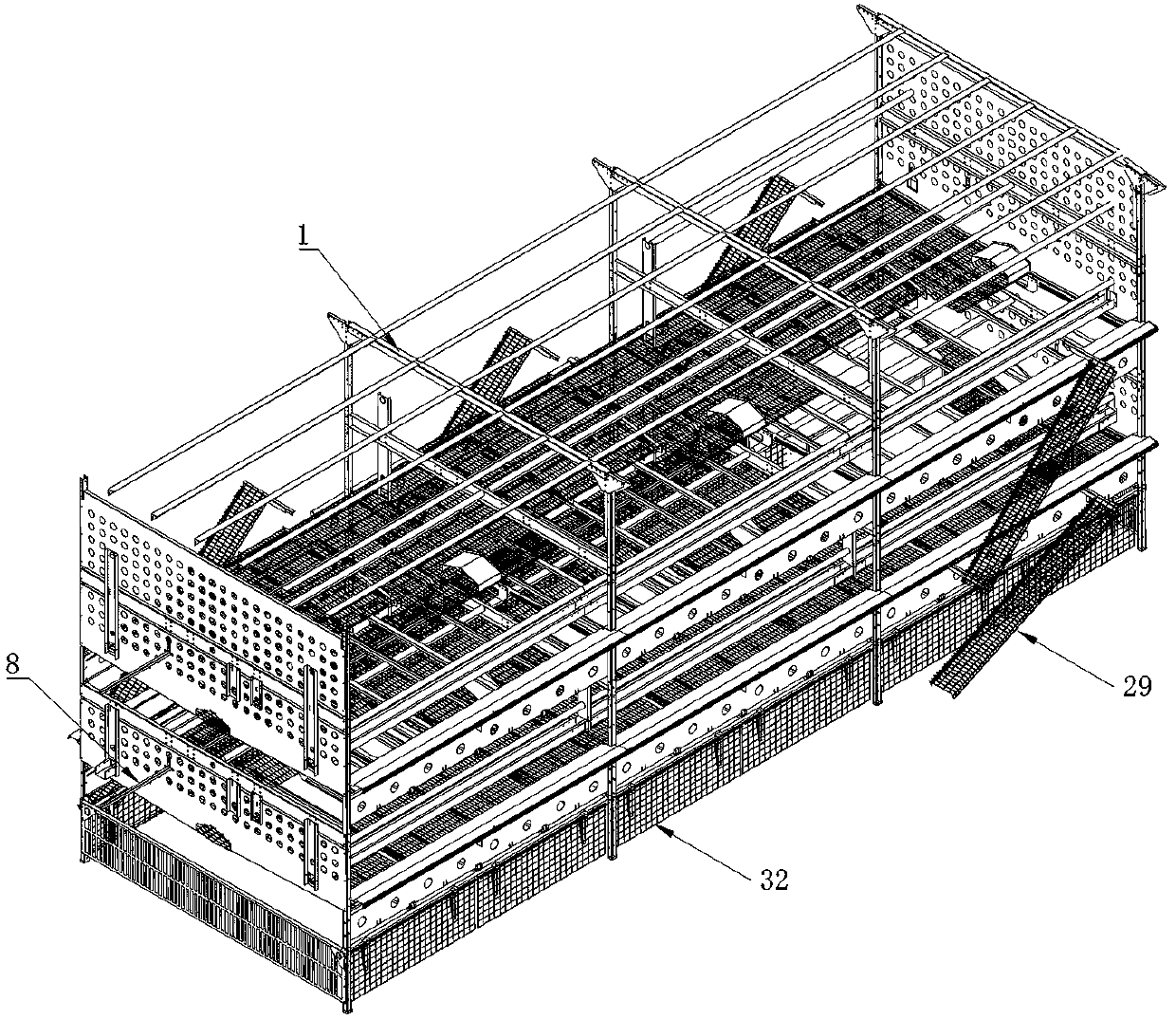

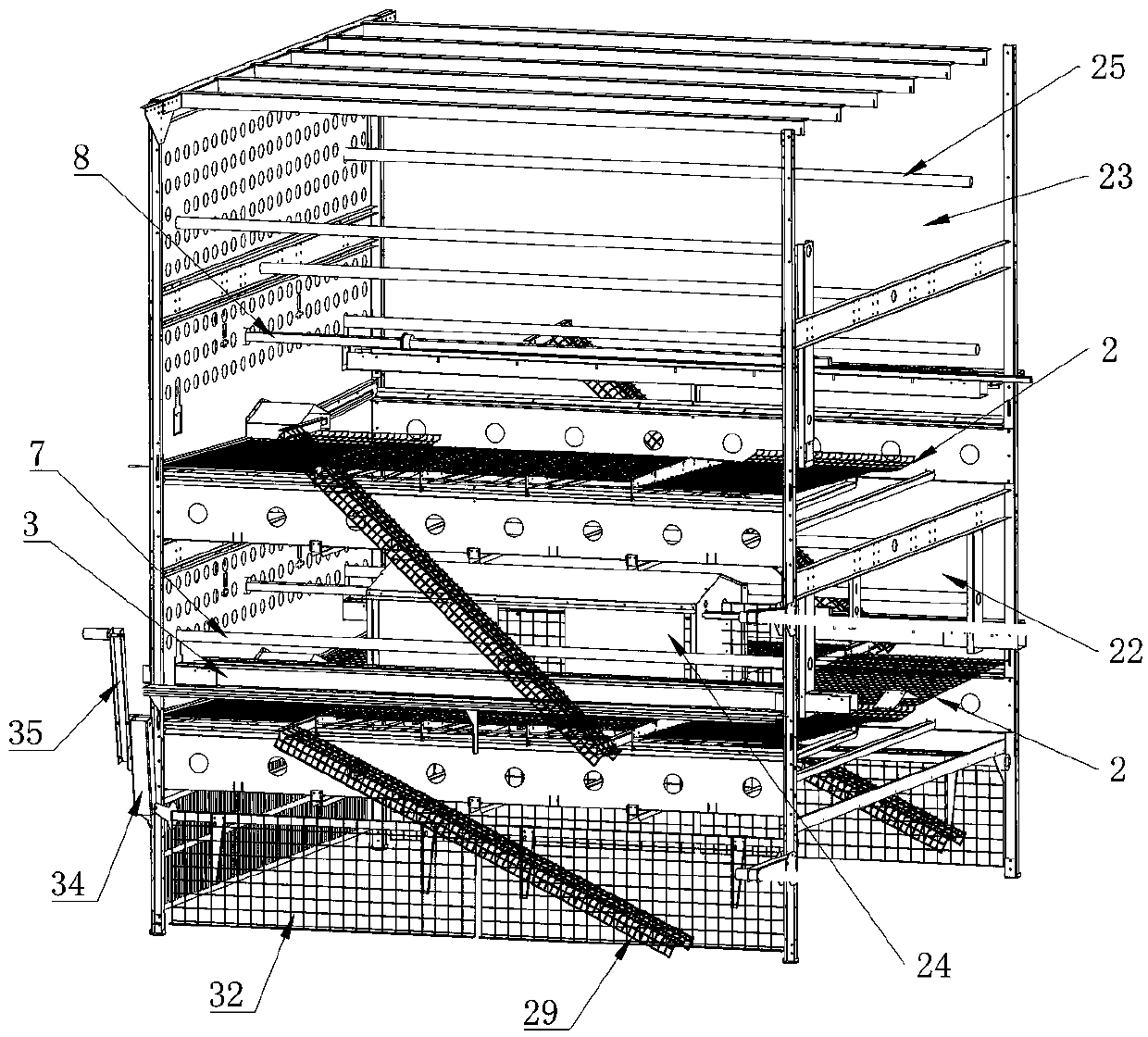

Welfare breeding system with complete functions

PendingCN111512994APromote growthImprove farming efficiencyBird housingsDorking chickenAnimal science

The invention provides a welfare breeding system with complete functions. The problem that the quality of produced eggs is low due to facts that an existing cage-rearing henhouse is excessively crowded, the cage-rearing environment is poor, laying hens cannot move freely and animal welfare is low is solved. The welfare breeding system comprises a cage frame, a left end of the cage frame is connected with a feeding device, a right end of the cage frame is connected with a manure cleaning device, multiple layers of bottom nets are installed in the cage frame, an egg collecting device penetratingthrough the cage frame is rotationally installed between the feeding device and the manure cleaning device, food troughs are installed between a left side face and a right side face of the cage frameand connected with the feeding device, a manure belt penetrating through the cage frame is rotationally installed between the feeding device and the manure cleaning device, climbing devices are fixedly installed on a front side face and a rear side face of the cage frame respectively, and chicken blocking devices are rotationally installed at the bottoms of the front side face and the rear side face of the cage frame respectively. The cage frame is placed in a room with a certain space for free-ranging, so that chicken can move like outdoors, growth of the chicken can be well promoted, and the breeding efficiency is improved.

Owner:HENAN WINWORLD LIVESTOCK MASCH CO LTD

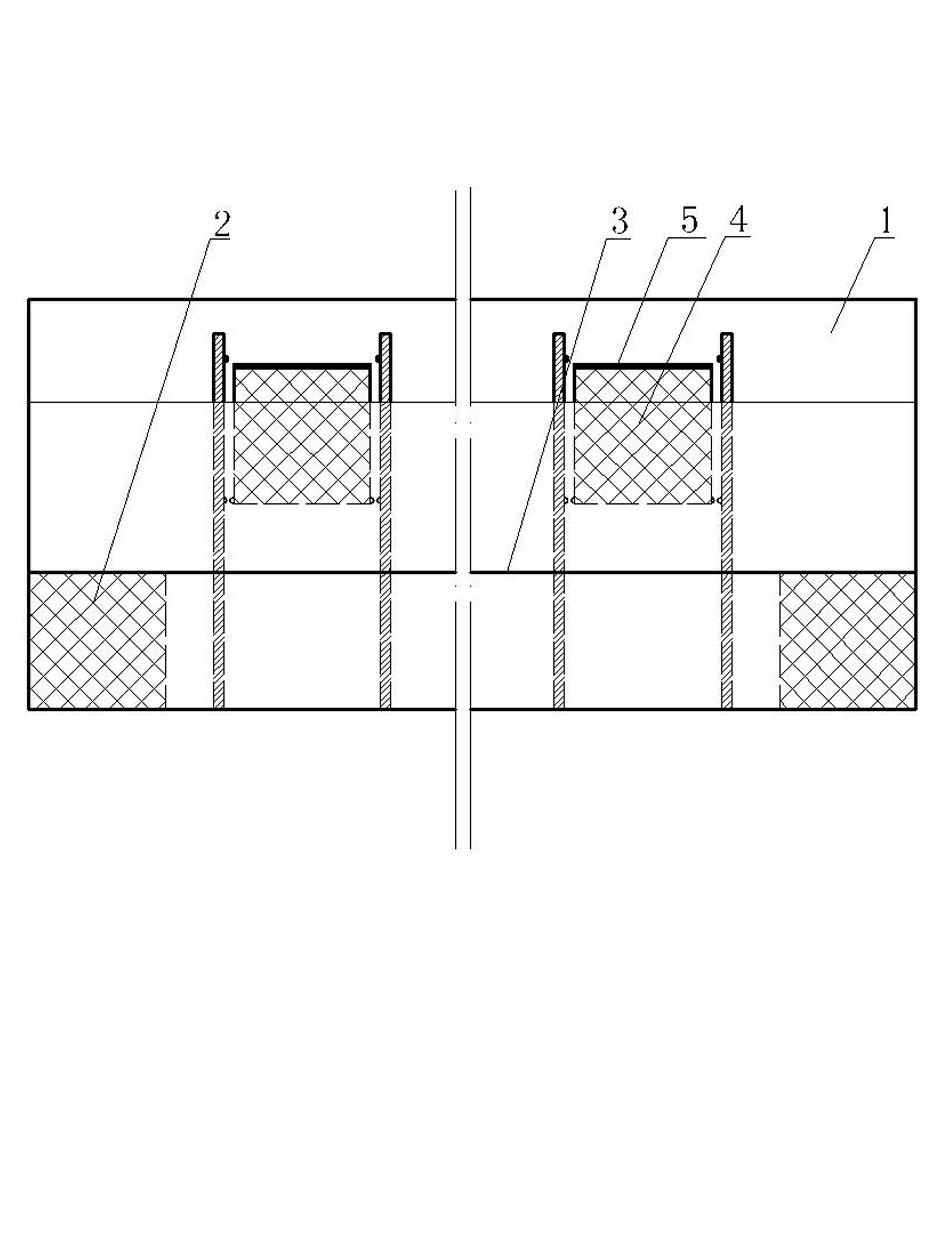

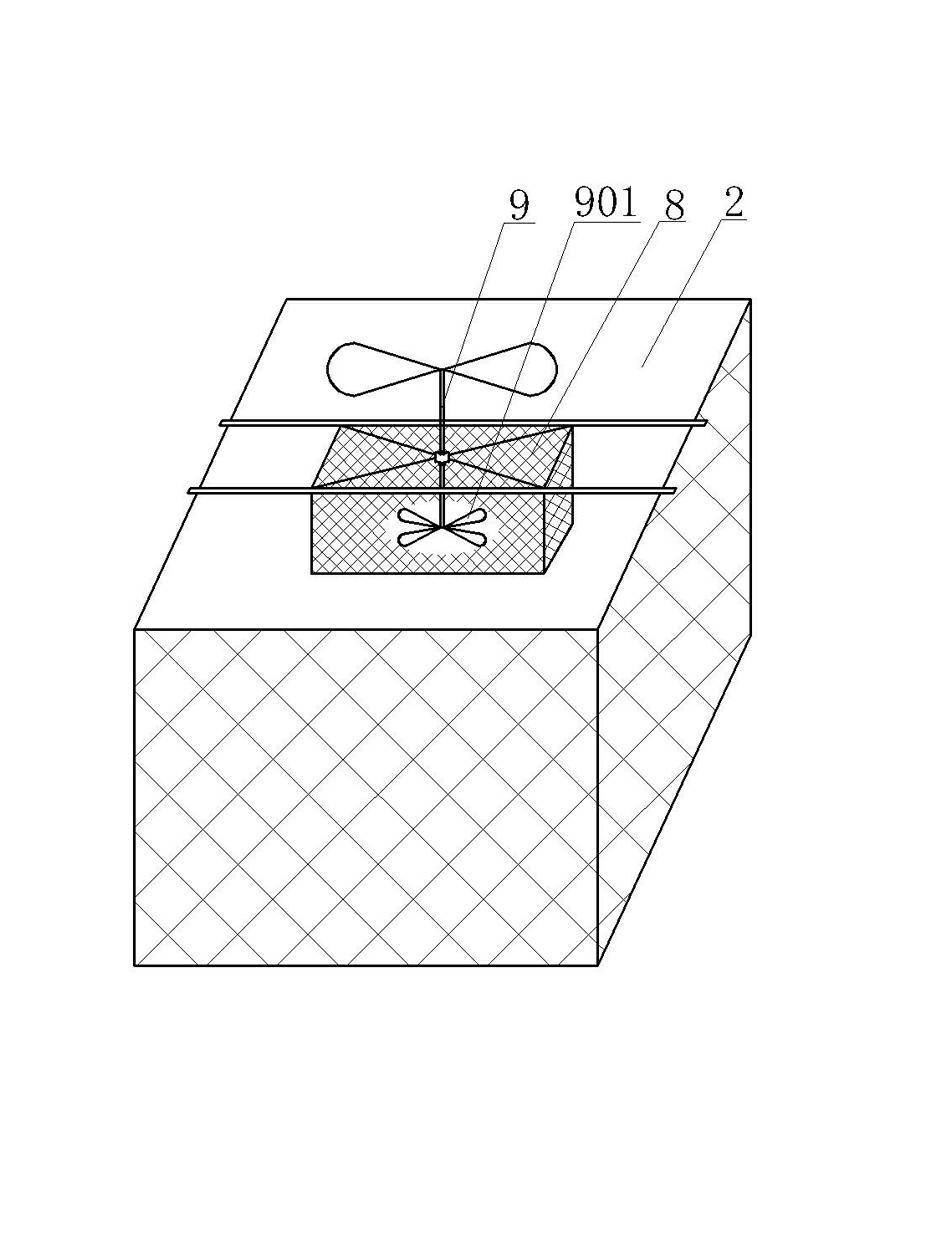

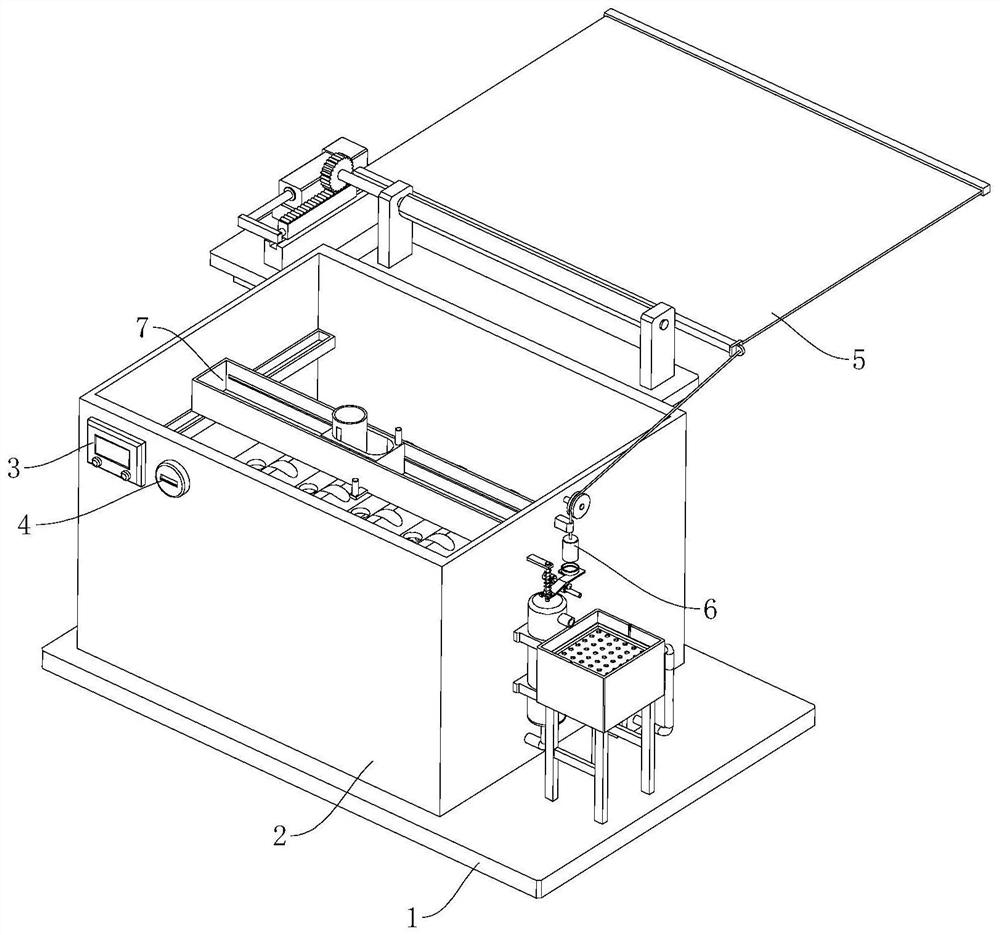

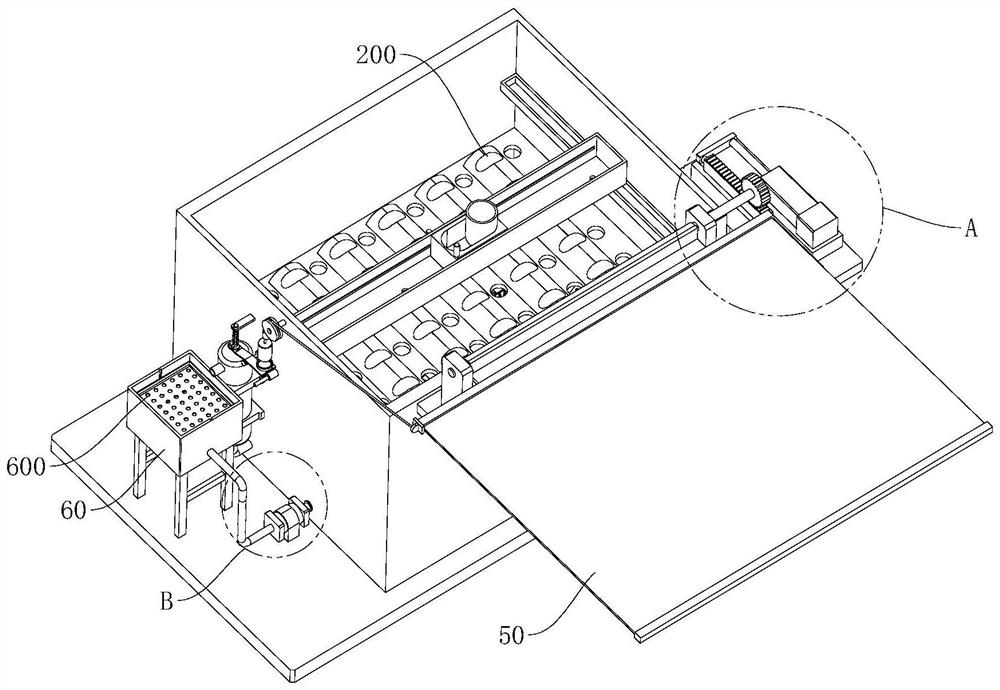

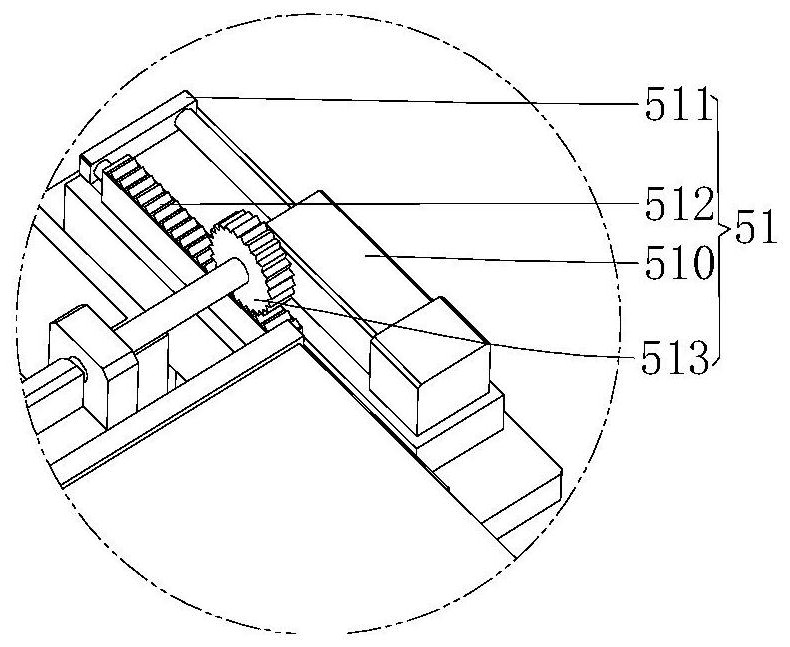

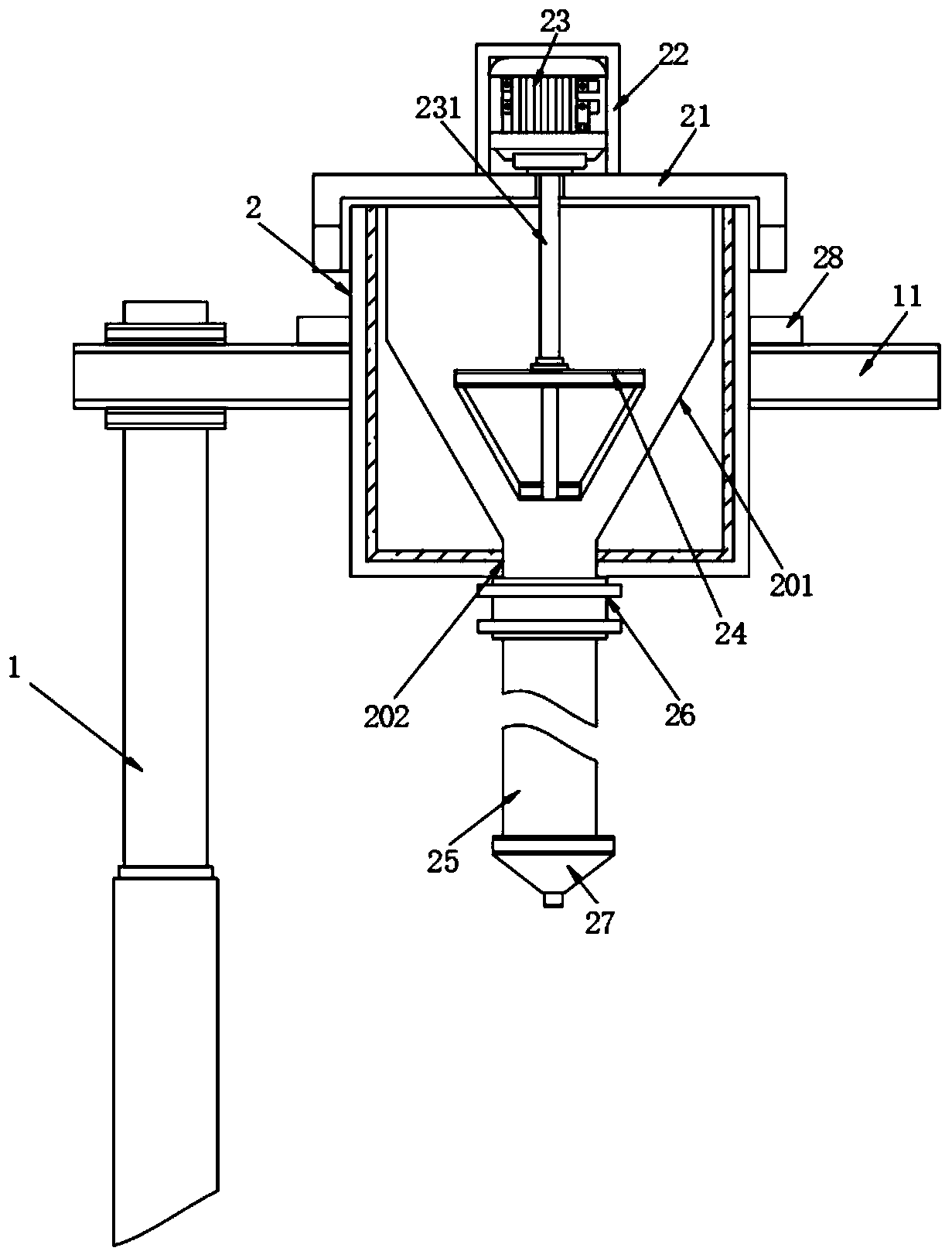

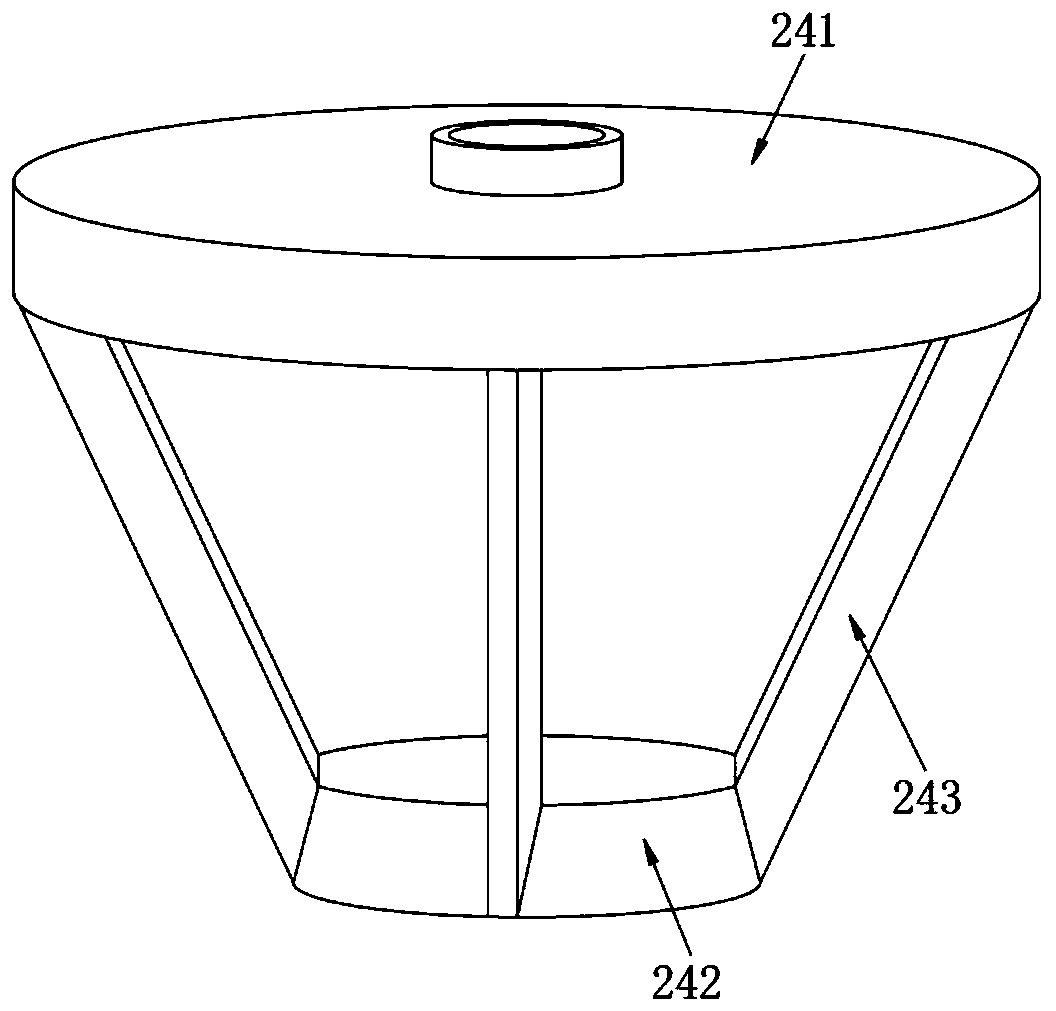

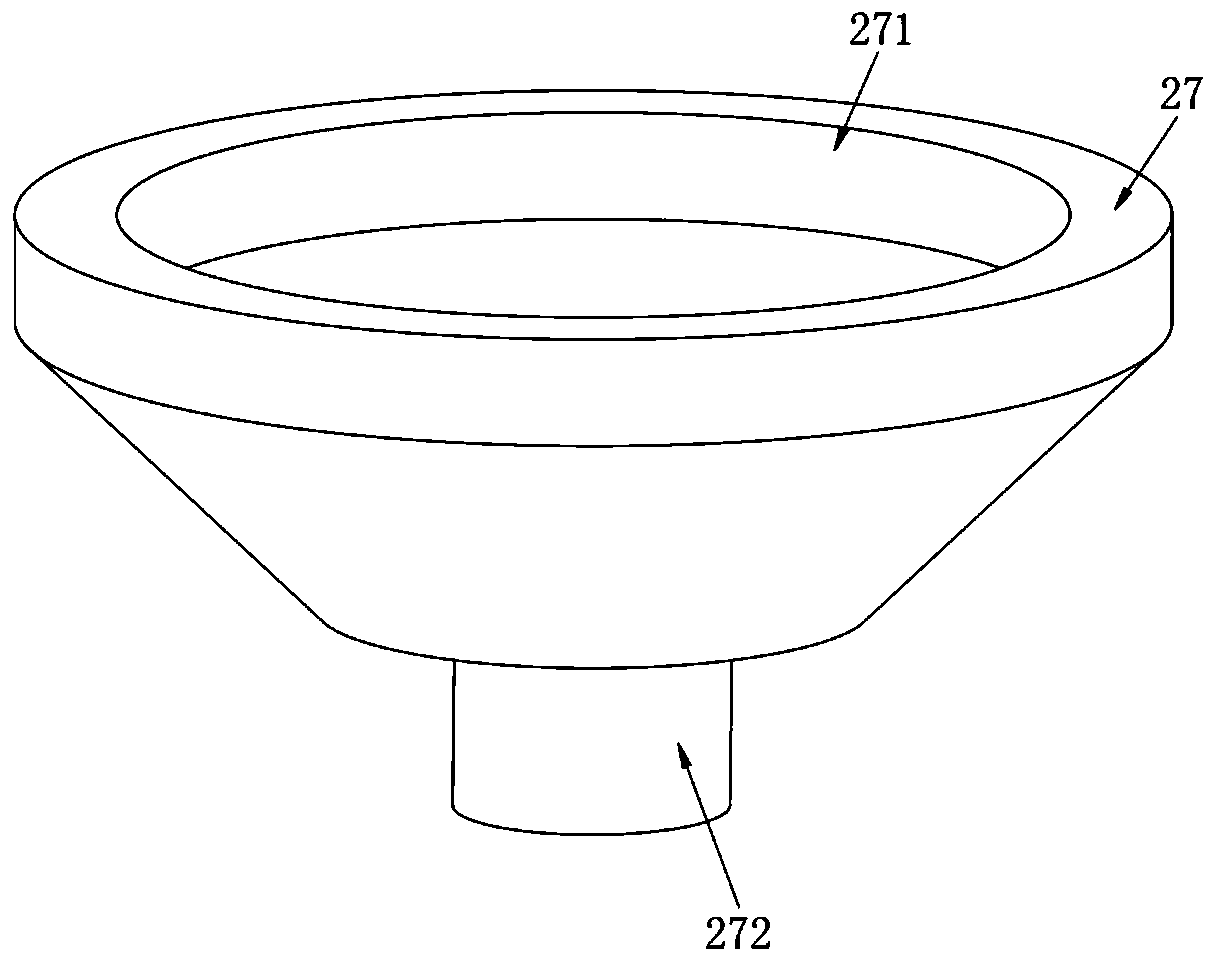

Holothurian culture equipment

ActiveCN112314508AControl the amount of rotationAvoid deathClimate change adaptationPisciculture and aquariaAnimal scienceAquaculture of sea cucumbers

The invention relates to the technical field of aquaculture, in particular to holothurian culture equipment. The holothurian culture equipment comprises a base and a culture box, and further comprisesa controller, a digital display thermometer, a sun shading mechanism, a water level adjusting mechanism and a feeding mechanism; the sun shading mechanism comprises a sun shading net and a driving assembly, and the water level adjusting mechanism comprises a collecting box, a traction assembly, an extraction assembly and a conveying assembly; and the feeding mechanism comprises a batching tank and a sliding assembly, the sliding assembly is arranged in the culture box, the batching tank is arranged in the sliding assembly, and the digital display thermometer, the driving assembly and the conveying assembly are all electrically connected with the controller. According to the holothurian culture equipment, sun shading and water level adjustment are carried out synchronously, so that holothurian can be effectively prevented from being harmed by bottom oxygen deficit and bottom mud stinking of an aquaculture water body; and meanwhile, various kinds of holothurian feed can be accurately matched, so that the holothurian can conveniently eat and absorb nutrients, the power consumption is relatively low, and the culture cost is favorably reduced.

Owner:烟台立尚海水养殖有限公司

High-strength composite sewing thread and preparing method thereof

InactiveCN105696140AHigh strengthImprove wear resistanceMelt spinning methodsConjugated synthetic polymer artificial filamentsHigh intensityTemperature resistance

The invention discloses a high-strength composite sewing thread. A preparing method includes the specific steps that weighed polypropylene resin, weighed polyethylene resin, weighed poly-4-methyl-1-pentene and weighed reinforcing fibers are put into an internal mixer to be internally mixed for 15-20 min, the internally-mixed sample is smashed, the smashed sample, a brightening agent in a certain weight ratio and an assistant in a certain weight ratio are mixed to be even, and a premix compound is obtained; the a premix compound is put into a double-screw melt spinning machine to be extruded, spun and formed to obtain the composite sewing thread. According to the high-strength composite sewing thread and the preparing method thereof, the high-strength composite sewing thread is obtained in the mode that the resin and the reinforcing fibers are synthesized, and the obtained sewing thread is high in strength, excellent in abrasion performance and high temperature resistance and suitable for wide application in the industrial field.

Owner:WUJIANG ZHENYU SEWING EQUIP

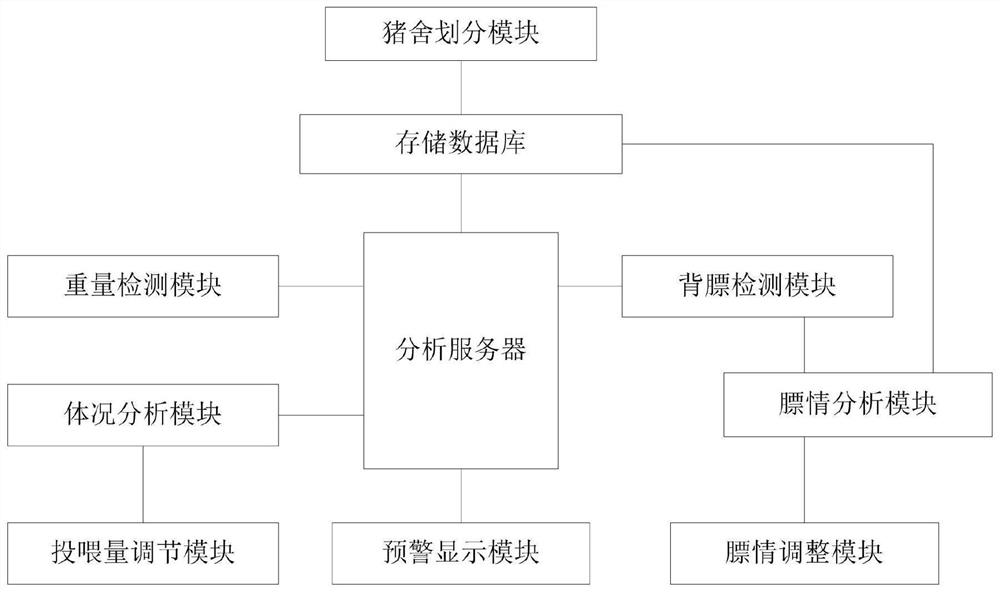

Intelligent pig raising growth health dynamic monitoring management system based on big data

InactiveCN111742853AProtect healthEat evenlyMeasurement devicesOther apparatusAnimal scienceMedicine

The invention discloses an intelligent pig raising growth health dynamic monitoring management system based on big data. The system comprises a pig house division module, a weight detection module, abody condition analysis module, a feeding amount adjustment module, a backfat detection module, a fat condition analysis module, a fat condition adjustment module, an early warning display module, ananalysis server and a storage database. According to the system, pig houses are divided according to pregnancy stages of pregnant sows, the weight of each pregnant sow in each pig house is detected, the average difference value of the weight of the pregnant sows in each pig house is calculated, the body condition of the pregnant sows in each pig house is analyzed, the feeding amount is adjusted, the backfat of each pregnant sow in each pig house is detected, the fat condition of each pregnant sow is analyzed and adjusted, the embryo life health safety coefficient of each pregnant sow in each pig house is comprehensively calculated, the pregnant sows with the embryo life in danger are treated, the health of the pregnant sows is guaranteed, and the growth and development of embryos are promoted.

Owner:刘同友

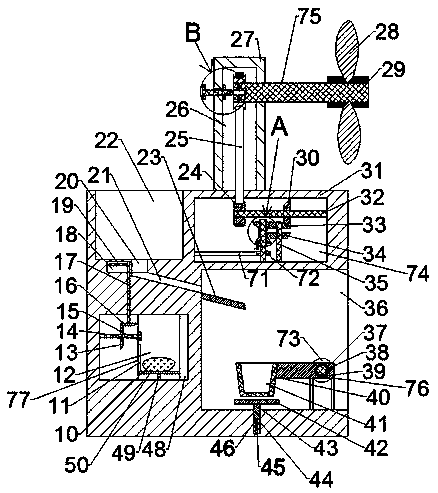

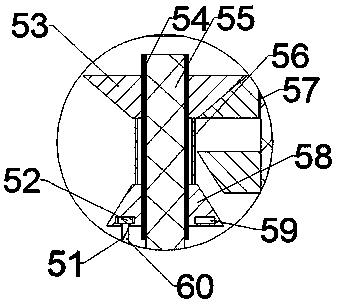

Wind-power fish food thrower

InactiveCN110999843AEat evenlyReduce manpower consumptionClimate change adaptationAgricultural fishingFish stockingEngineering

The invention discloses a wind-power fish food thrower. The wind-power fish food thrower comprises a feeding box, wherein an upright plate is fixedly arranged on the upper end face of the feeding box,a rotating chamber is formed in the upright plate, a starting mechanism is arranged in the rotating chamber, a working chamber is formed in the feeding box, a feed throwing mechanism is arranged in the working chamber and comprises a first rotating shaft which is rotatably arranged on the lower end wall of the working chamber, a transmission chamber is formed in the feeding box, a vertical grooveis formed in the rear end wall of the transmission chamber, and a transmission mechanism is arranged in the transmission chamber. According to the wind-power fish food thrower, fish food can be thrown into a sea by the device through wind power as long as the fish food is placed in a food storage box, so that manpower consumption is effectively lowered; and through wind-power feeding, the fish food can be better thrown into a fish pond even if the area of the fish pond is relatively large, and thus, fish stocks in the fish pond can relatively uniformly share the fish food.

Owner:ZHUJI DUGAO WIND ENERGY TECH CO LTD

Method for producing film coating agent for phytase coating

InactiveCN101485391ABright colorGood water solubilityAnimal feeding stuffAccessory food factorsSolubilityPhytase

The invention relates to a method for preparing a film coating agent for coating phytase, in special coating multilayer outside phytase feed additive granules. The film coating agent is prepared from polyvinyl alcohol, co-povidone iodine, hydroxypropyl methylcellulose, talcum powder, magnesium stearate, tween-80 and ricinus oil which are evenly mixed at a high speed according to certain weight percentage. The method has the advantages that because of the presence of an isolated layer, the phytase feed additive granules can keep property of enzyme stable during usage, storage and sale, and have remarkably enhanced capability of resisting external adverse environments such as high temperature, high moisture and the like. After the surfaces of the granules are coated, the granules have better compactness, the activity content evenness of the enzyme is high, the animal feed is easy to be mixed evenly, and the animal is fed in balance; the granules have bright color, are round and beautiful, and have good flowing property; the granule specific gravity is similar to the feed specific gravity, and the granules are easy to be mixed evenly, and do not grade, generate static electricity, mutually adsorb and unite; and the coating material has good water solubility, can be quickly disintegrated and released in gastric juice, and has high bioavailability.

Owner:伦西全 +4

Early-stage and medium-stage granulum fodder for broiler chicken and preparation method of same

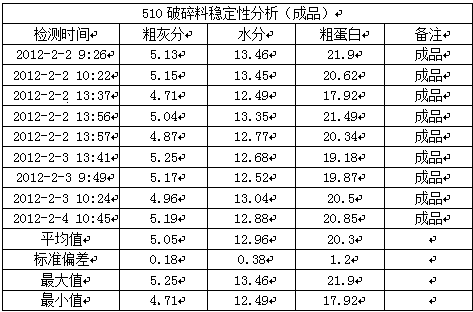

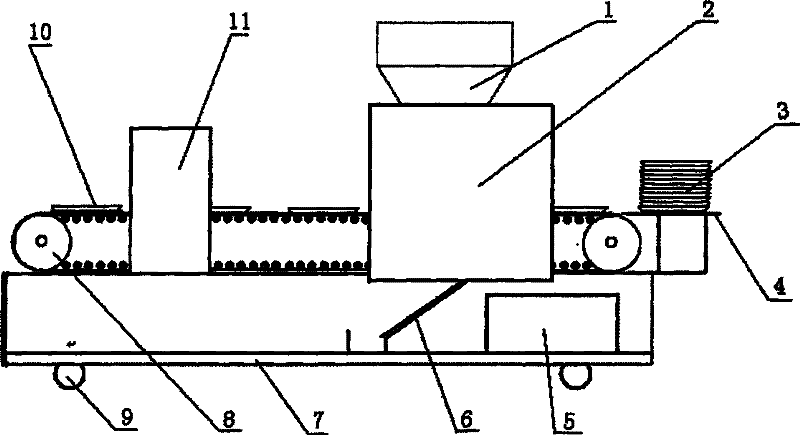

InactiveCN103416622AImprove uniformityEliminate the phenomenon of high probability of returnAnimal feeding stuffBroiler chickFood consumption

The invention discloses a granulum fodder with the diameter of 2.0 mm, and a preparation method of the granulum fodder. The granulum fodder is 2.0 mm in diameter, 0.5-2.0 d in length, and 1-3.0 kg in rigidity. According to the invention, a 420 stainless steel ring die with the diameter of 2.0 mm and the ratio of compression of 1:(5-8) is adopted; and a 420 stainless steel ring die with the diameter of 3.0-4.5 mm and the ratio of compression of 1:(5-10) is adopted. Tests show that the scheme is feasible. According to the invention, the following advantages are achieved: the granulum fodder with the diameter smaller than 2.0 mm can completely replace crushed materials, and moreover, the product quality is more stable, and the production efficiency is improved. During the using of the granulum fodder, the food consumption and the growth effect of the broiler chicken at the early stage are not affected, the crowd uniformity can be better improved, the sick chicken amount can be reduced, and the mortality and elimination rate is also reduced, and therefore, a better cultivation benefit is brought to farmers.

Owner:SHANDONG NEW HOPE LIUHE GROUP

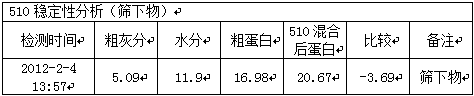

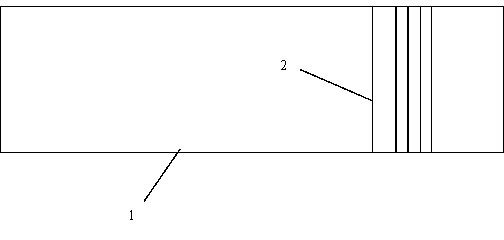

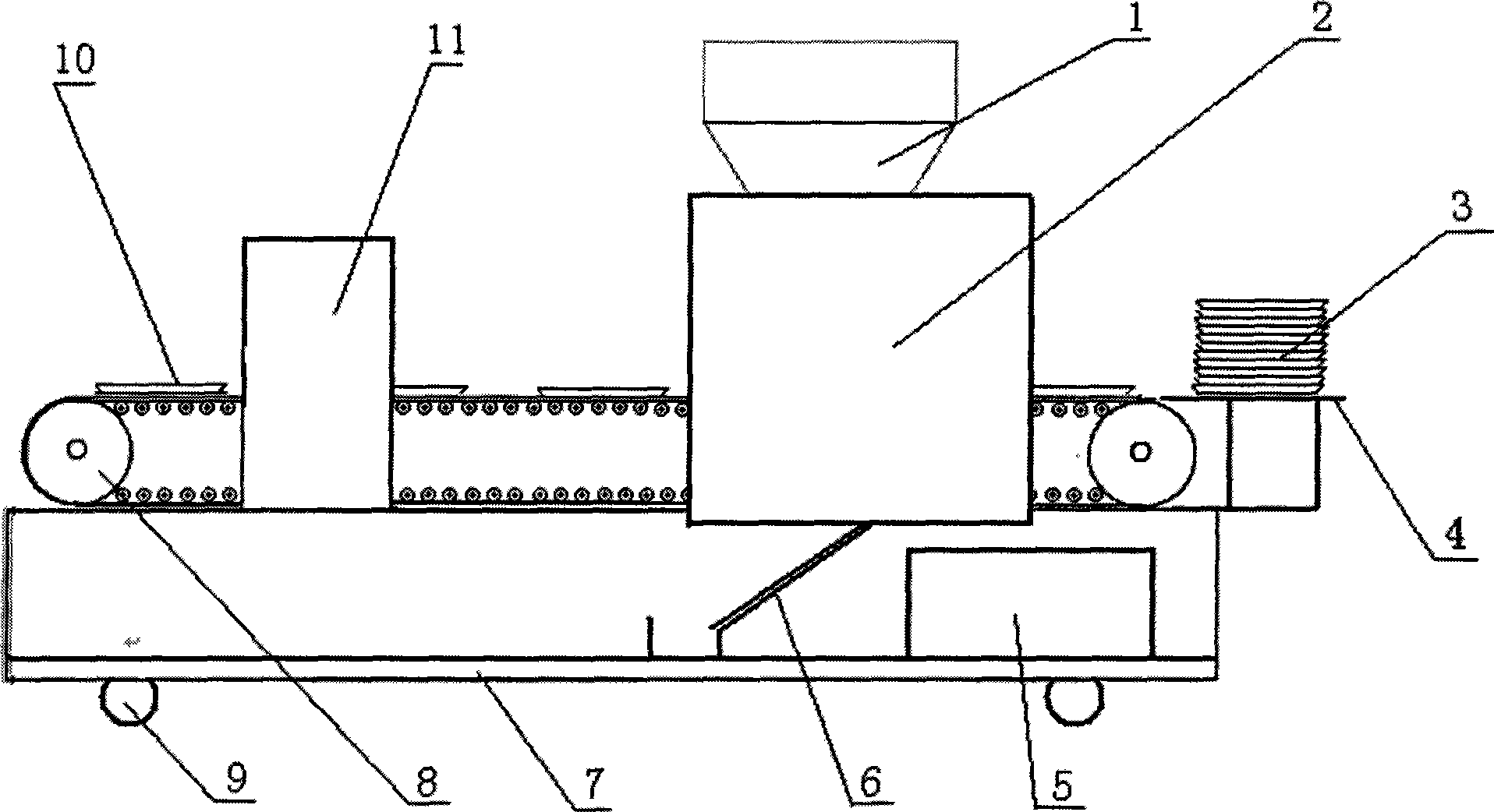

Mechanization rice spreading device

InactiveCN101455296BAvoid wastingQuality controllableFood shapingFood preparationEngineeringSprocket

The invention discloses mechanized rice laying apparatus, including a machine frame (7), a rice laying plant (2), a material placing platform (4), a sprocket drive mechanism (8), a drive mechanism (5) and an electronic control box (11) placed on the machine frame, wherein, the material placing platform (4) is located at the terminal of the machine frame (7), the sprocket drive mechanism (8) is transversely placed on the upper side of the machine frame (7), the rice laying plant (2) is adjacent to one side of the material placing platform (4), and a gradient slope plate (6) access to the rice groove is provided at the lower sided of the rice laying plant (2). A mechanized rice laying apparatus of the invention adopts the above structure, to improve productivity, reduce labor intensity and avoid the waste of rice, so that the rice in each tray is guaranteed to be uniform and identical and the quality of rice crust is easy to control.

Owner:芜湖源生食品有限公司

Machining method of large modulus inner gear ring

The invention relates to a machining method of a large modulus inner gear ring, which relates to the field of machining, in particular to a machining method of a large modulus inner gear ring. The machining method comprises the following steps: roughly turning the inner gear ring, remaining machining allowance of 6mm to 8mm on the top circle of each tooth and two ends of each tooth part, remaining machining allowance of 10mm to 12mm on other parts, marking a benchmark surface, and guaranteeing a surface roughness value Ra to be 6.3 micrometers; detecting a flaw, and ultrasonically detecting the flaw of the gear ring so as to enable the gear ring to meet the drawing requirement; positioning the gear ring on a machine tool by adopting the benchmark surface, centering the top circles of the teeth, roughly milling the teeth by utilizing a finger-shaped milling cutter, and remaining machining allowance of 5mm to 6mm for each tooth thickness and tooth depth; tempering according to the requirement; centering by adopting the top circle of each tooth, finely turning the size of each part, and marking on the benchmark surface; positioning the gear ring on the machine tool by adopting the benchmark surface, centering the top circles of the teeth, aligning the knife strictly to the center of a tooth groove by ensuring uniform cutter penetration on two side surfaces of the teeh, and inserting the teeth to meet the required size of a drawing. By adopting the machining method, the service life of the gear ring can be prolonged, the production efficiency is high, the abrasion to a tooth insertion knife is alleviated, the production period is shortened, and the production cost is reduced.

Owner:陕西天财工程造价咨询有限公司

Feeding frame for livestock breeding

InactiveCN107912311AEat evenlyAvoid predation situationsAnimal feeding devicesAnimal housingLivestock breedingEngineering

The invention discloses a feeding rack for livestock breeding, which includes a feeding assembly, a feeding assembly, and a stirring assembly. Each rectangular gap is hinged with a door panel. The feeding assembly includes a storage box, a top plate, a pressing plate, and a driving mechanism. The top plate and the pressing plate are connected by a driving mechanism. A sealing plate is movable at the feed hole, a feed box is provided at the outer port of the feed hole, the bottom plate of the storage box is evenly distributed with discharge holes, and a stirring assembly is provided at the outer port of each discharge hole. The mixing assembly includes a movable material cylinder and a central rod. The movable material cylinder is in the shape of a circular cylinder with two ends open. The bottom surface of the storage box is provided with a motor, and the motor drives each movable material cylinder to rotate. The invention effectively avoids the mutual interference between livestock grabbing food, and can fully stir and mix the feed.

Owner:BOZHOU WOYE INTPROP SERVICE CO LTD

Heat preservation type feeding device based on gastroenterology nursing

InactiveCN111568773AEvenly distributed ingredientsAvoid blockageRotary stirring mixersTransportation and packagingAnimal scienceMedicine

The invention belongs to the technical field of medical nursing equipment, and particularly relates to a heat preservation type feeding device based on gastroenterology nursing. The device comprises atelescopic rod fixed on a sickbed and a heat preservation barrel fixed on the telescopic rod, wherein the top of the telescopic rod is fixedly connected with a placement plate; the heat preservationbarrel penetrates through the placement plate and extends to the bottom of the placement plate; a barrel cover is fixedly connected to the top of the heat preservation barrel in a threaded mode; a fixing frame is fixedly connected to the top of the barrel cover; a motor is fixedly connected to the interior of the fixing frame; and a rotating shaft is fixedly connected to the output end of the motor. Semi-liquid food is stirred, so that food residues accumulated at a discharge hole are displaced; and the food residues flow into a space among four connecting rods and are mixed with the liquid food, so that components in the food are uniformly distributed, the situation that the discharge hole is blocked by the accumulated food residues is avoided, a patient can eat the semi-liquid food uniformly, and the eating effect is improved.

Owner:曾伯军

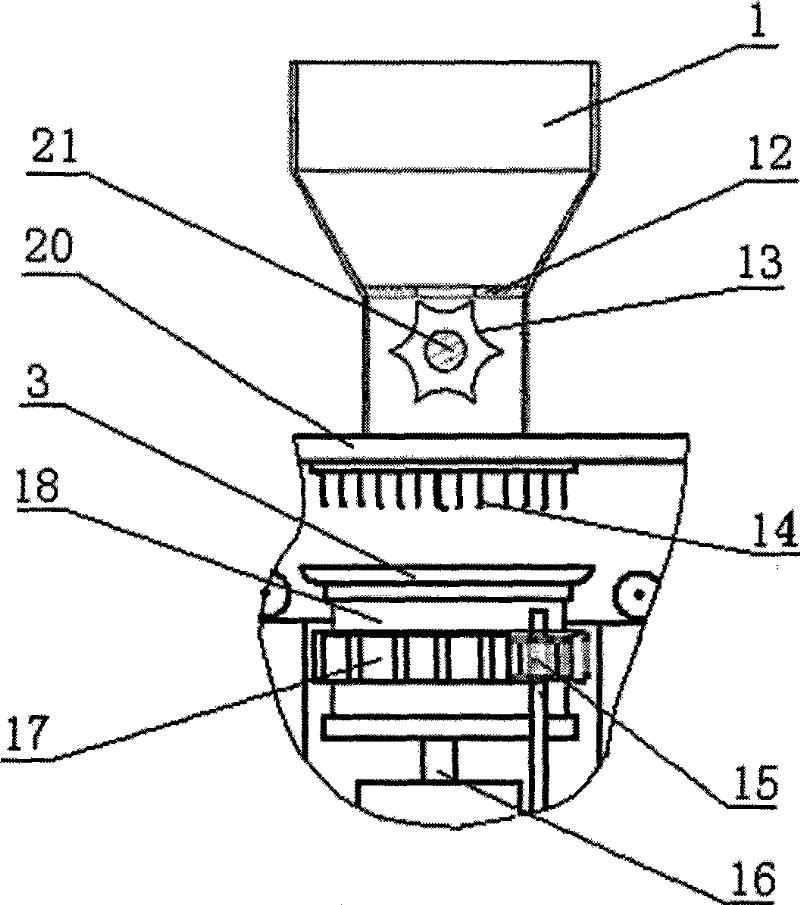

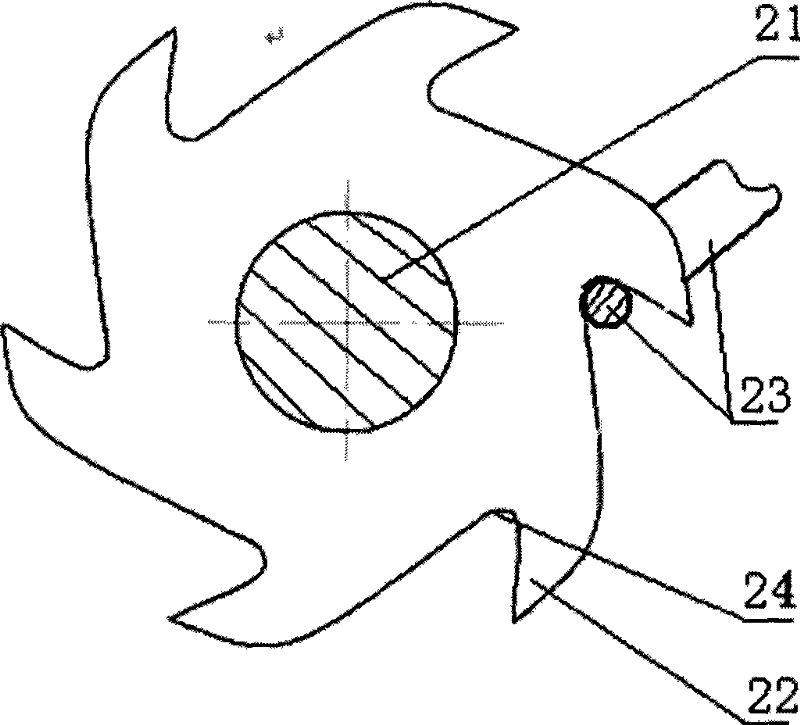

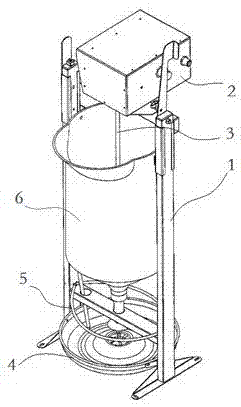

Automatic feeder

InactiveCN106900593ARealize automatic mixingAvoid stacking bugsAvicultureEngineeringAutomatic testing

The invention discloses an automatic feeder, which comprises: a bracket, a material cylinder arranged in the bracket, a control box arranged on the bracket, a material tray arranged under the material cylinder, and a device connected to the control box arranged in the material cylinder. The mixing rod and the water pipe arranged on the support, the water outlet end of the water pipe is arranged in the material pan. The automatic feeder of the present invention realizes automatic stirring and uniform discharge through a controller, ensures that the feed can be evenly discharged onto the feeding tray, avoids manual mixing process, and realizes automatic feeding with mixing.

Owner:刘俊

Rana grylio high density feeding method

InactiveCN106721623AEat evenlyAvoid PlaguesFood processingClimate change adaptationDiseaseHigh density

A rana grylio high density feeding method comprises the steps: (1) putting metamorphic froglets during the same period in a pond and guaranteeing that 5000-6000 froglets are put every square meter; (2) using a floating bed in the water so that the froglets can land in time to be beneficial for food training, wherein the froglets begin to take a large mount of foods after 3 days food training; and (3) after the froglets begin to take a large mount of foods, using a method of feeding less foods more frequently and adding traditional Chinese medicine to complete feeds. The rana grylio high density feeding method provided by the invention has the advantages that the froglets are easily trained to eat foods, the froglets are fed in a balanced manner; individual differences are small; a phenomenon that bigger fogs eat smaller fogs is substantially avoided; the method can eliminate fetal virulence and help digestion; the frog disease phenomenon is avoided; and the economic benefits can be also improved.

Owner:衡阳茂晨农业开发有限公司

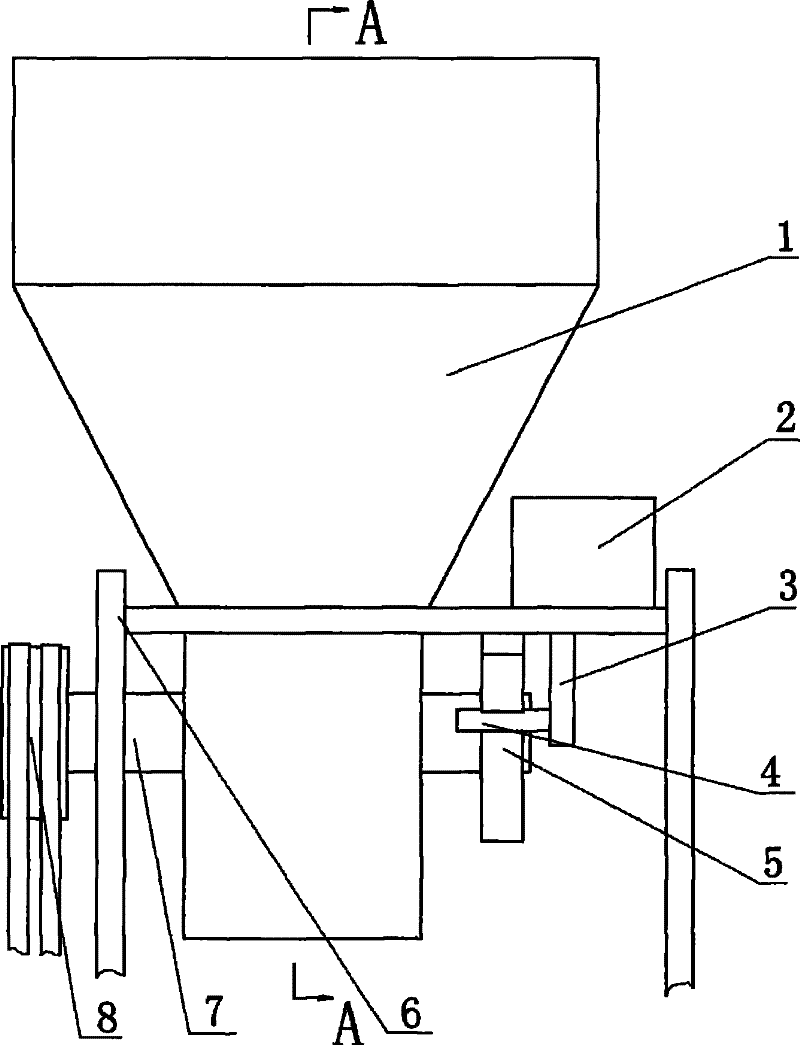

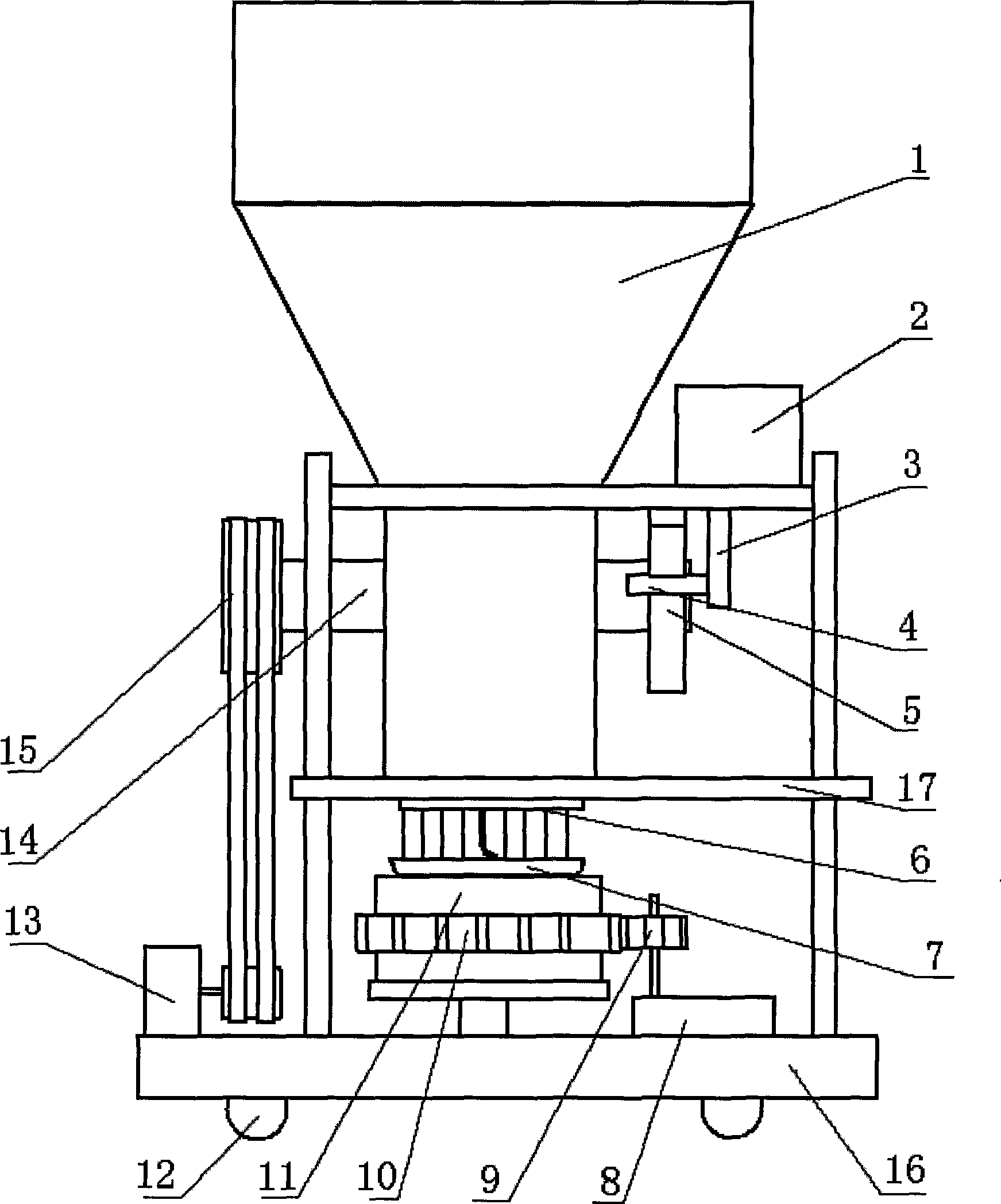

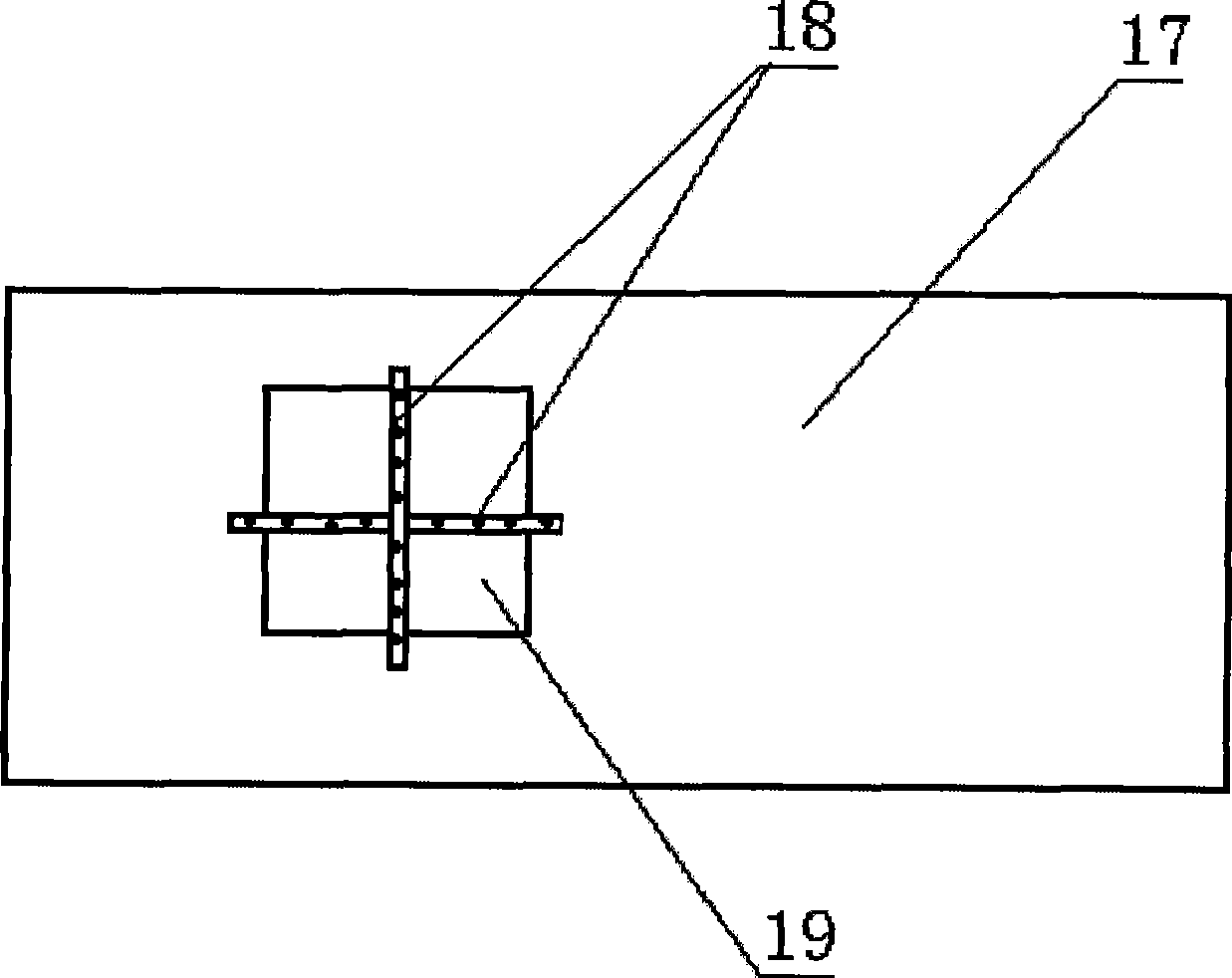

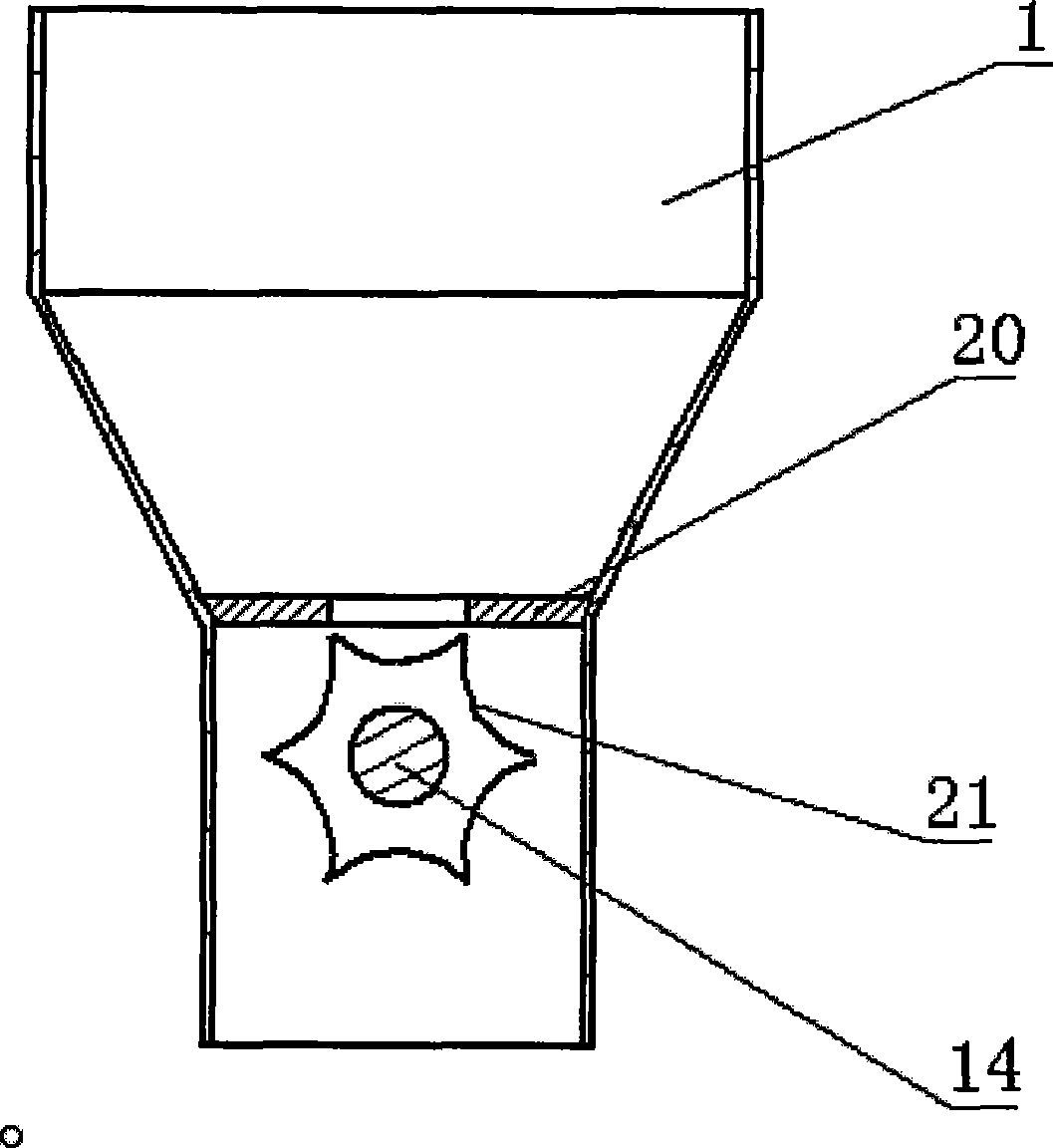

Rice bucket for making crispy-rice laying device

The invention discloses a rice bucket device for producing rice crust laying apparatus, including a rice bucket, a machine frame and timing control mechanism. A partition with an opening is provided in the rice bucket, a rotary rice container is provided beneath the opening of the partition, the rotary rice container has more than four rice containing tanks equispaced on a concentric circle, the chord length of each rice containing tank is identical to the opening width of the partition, the maximum excircle of the rotary rice container has a 1-3 mm interval to the partition, the rotary rice container is in fixed connected with the mandrel, the end of the mandrel extending out the rice bucket is connected to a revolving gear, and the other end of the mandrel extending out the rice bucket is provided with a telescopic brake mechanism driven by the timing control mechanism. The inventive rice bucket device for producing rice crust laying apparatus adopts such a structure that rice the rice containing amount of each rice containing tank is guaranteed to be identical, so the rice in each stainless steel tray is guaranteed to be uniform and identical and the quality of rice crust is easy to control.

Owner:芜湖源生食品有限公司

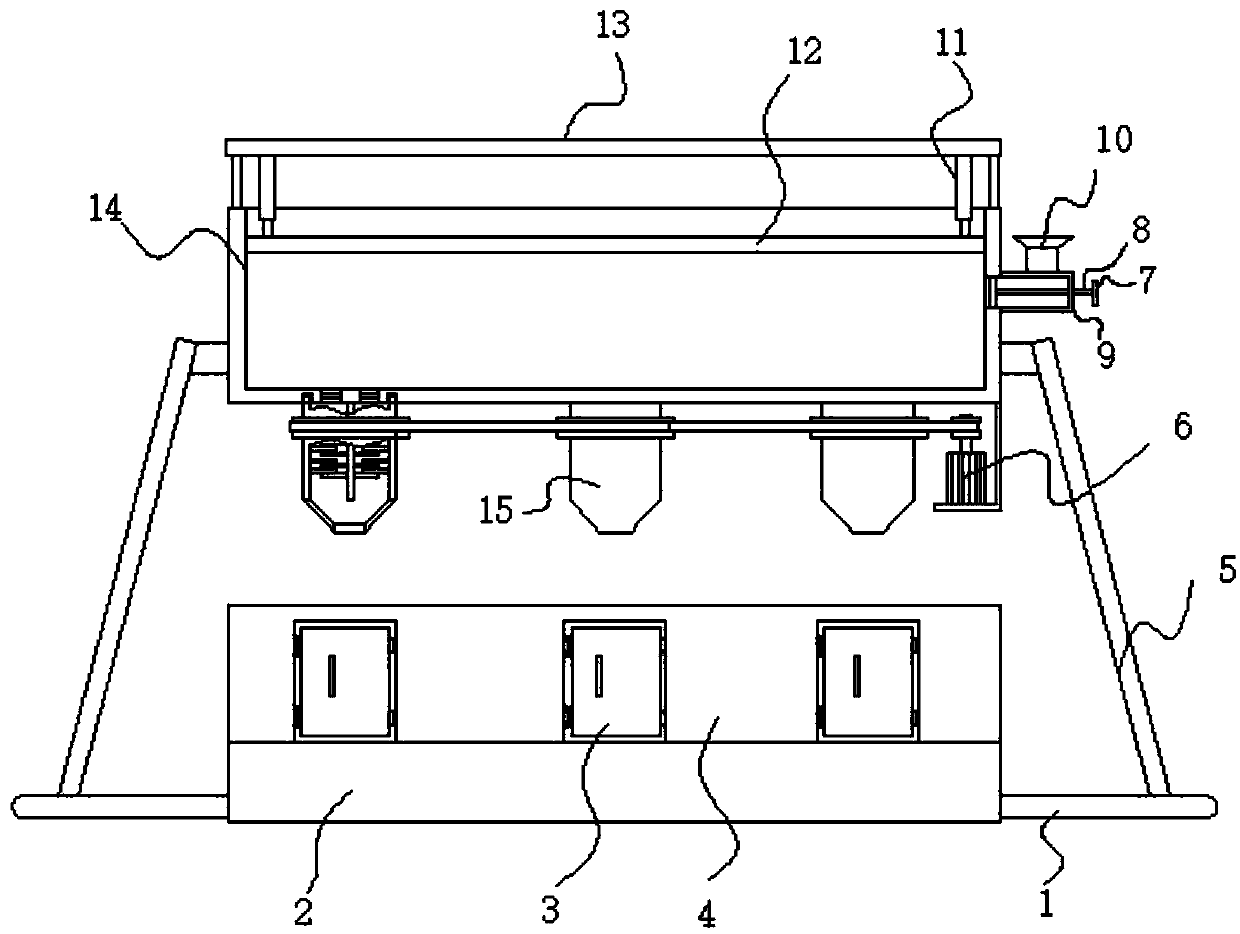

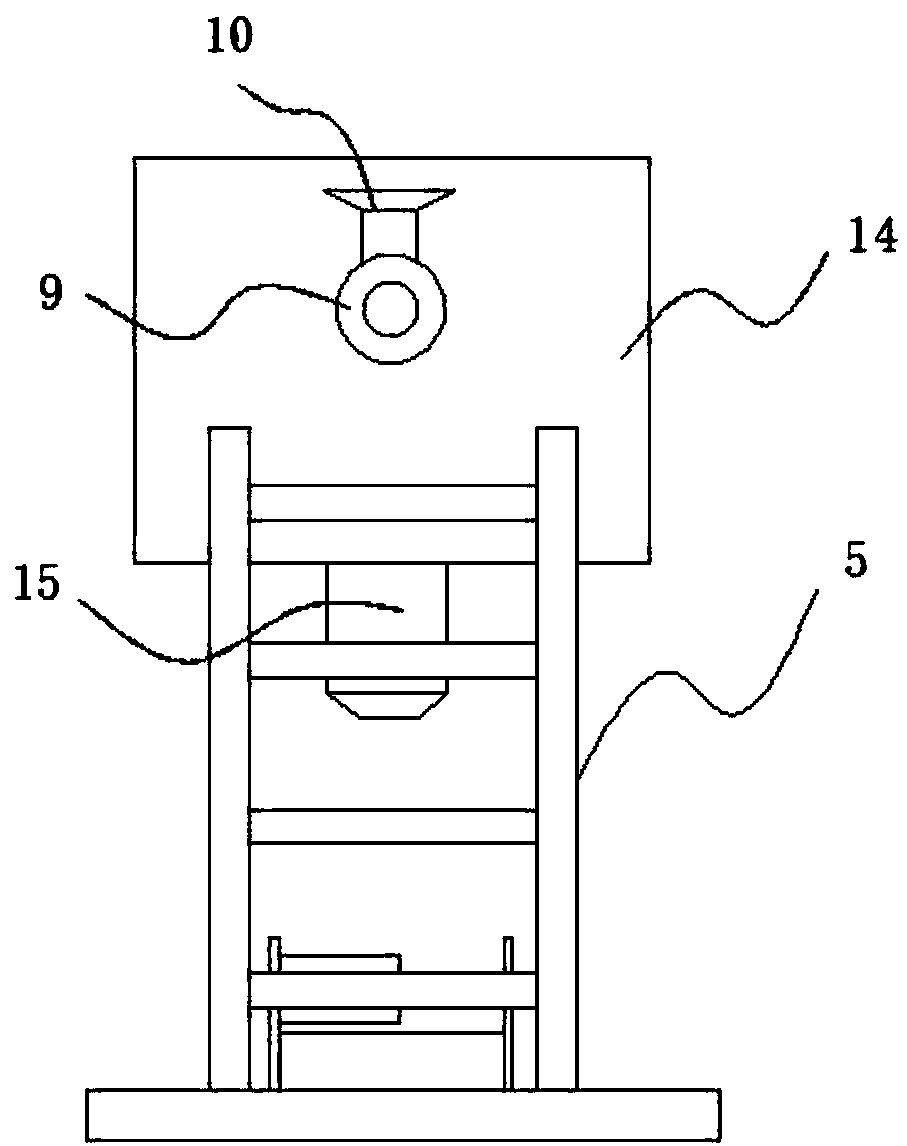

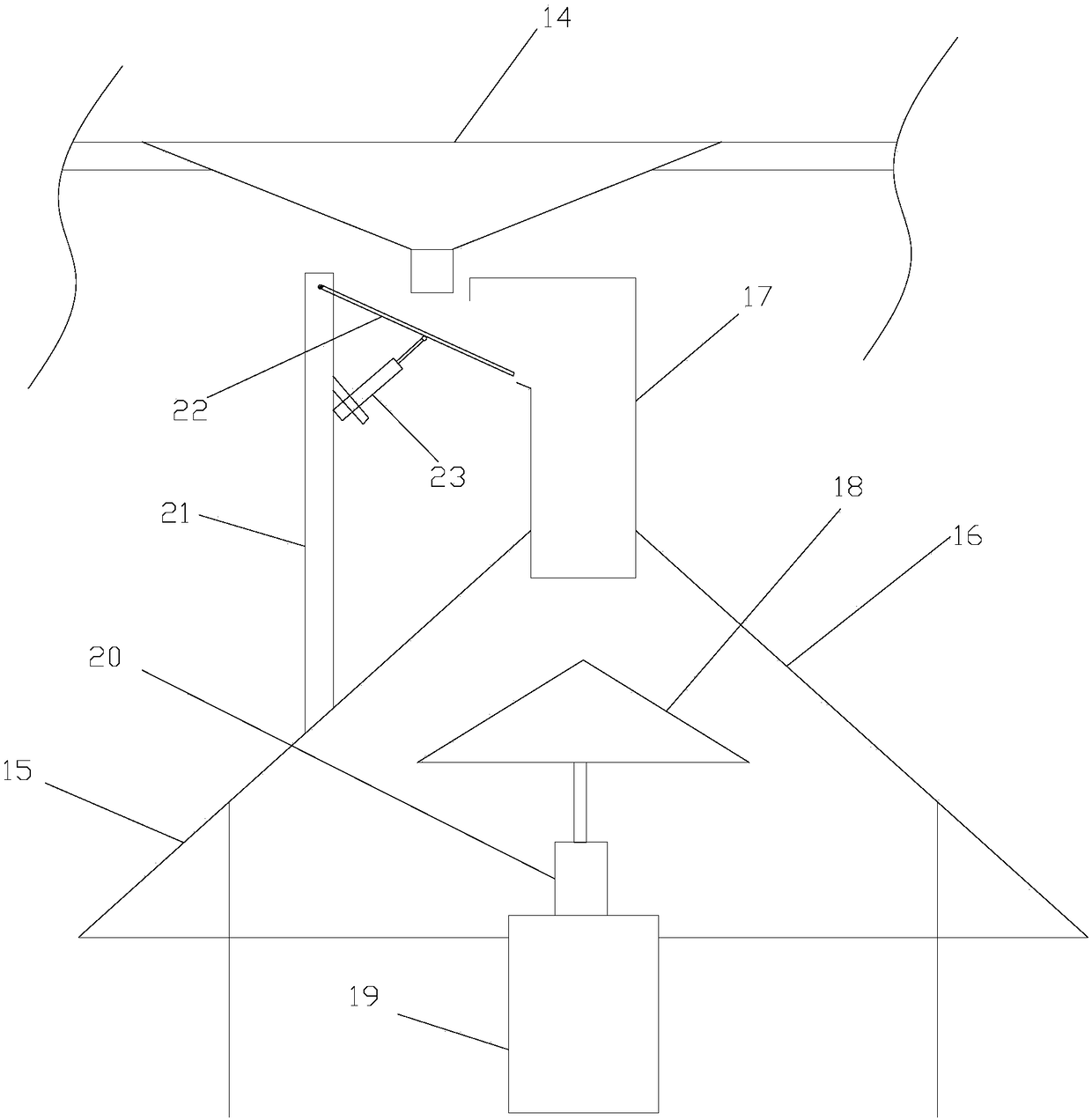

Granulated feed adding equipment for chicken raising

The invention discloses granulated feed adding equipment for chicken raising. The equipment comprises a guide rail, wherein a slider is arranged on the guide rail; a feed bin is fixedly connected below the slider; the equipment also comprises a flat plate, and a front support and a rear support are arranged below the front side of the flat plate; a front electric winch is arranged on the front support, a rear electric winch is arranged on the rear support, a plurality of downwards concaved discharging hoppers are arranged on the flat plate, a feeding chamber is arranged below each discharginghopper, and a main body of the feeding chamber is a conical roof standing on the ground; a support rod is arranged on each conical roof and hinged with a guide plate. Compared with the prior art, thegranulated feed adding equipment has the benefits as follows: feed can be sent to multiple feeding chambers through a machine, the workload of workers is effectively reduced, raised chicken can be fedin multiple feeding chambers and take a shelter from the rain, and the equipment is safe; feed in each feeding chamber is more uniformly distributed in conical blocks, the condition that chicken rushto eat is prevented and the chicken uniformly feed. The feed adding equipment is applicable to scattered feeding on the flat ground and raising in forests.

Owner:绍兴晨拓进出口有限公司

Method for improving uniformity of sizes of juvenile crabs

InactiveCN103416334AEat evenlySynchronous growthClimate change adaptationPisciculture and aquariaEcologyWater body

Provided is a method for improving uniformity of sizes of juvenile crabs. The method is characterized by including the following steps: firstly, proper quantities of megalopae are selected according to the breeding water surface area; secondly, partitions are arranged in a breeding water surface, so that a small pool with an area not larger than 20% of the breeding water surface area is formed in a separated mode, the selected megalopae are placed in the small pool, uniformity of water in the small pool and water of the breeding water surface is kept, water in the small pool is communicated with the water of the breeding water surface and accordingly more than 80% of the megalopae in the small pool grow synchronously; thirdly, normal feeding is carried out until the megalopae grow to be V-stage juvenile crabs, the partitions are removed so that the V-stage juvenile crabs can enter the whole breeding water surface, and the V-stage juvenile crabs are cultivated to grow to be crabs in a common crab cultivation method. The method is simple, the sizes of the crabs are uniform, and the yield is high.

Owner:FRESHWATER FISHERIES RES INSITUTE OF JIANGSUPROVINCE

Processing technique for chemical fibre composite brushed fabric

InactiveCN101215747ASmall finenessGood flexibilityLoomsHeating/cooling textile fabricsFiberCost savings

The invention discloses a process for preparing chemical fiber composite sanding fabric, which comprises following steps: adopting 150D / 48f positive ion DTY and 150D / 144POY as raw material, carrying out network process, and finishing process technology through double twisting, shaping, warping and weaving. Chemical fiber composite sanding fabric which is processed by the technology has good softness, villus is fine, even and elegant, easy to dye and bright in color, times for sanding can be reduced, and the invention has the advantages of time saving, labor saving, cost saving, which increases productive efficiency.

Owner:SHAOXING COUNTY BAFANG TEXTILE

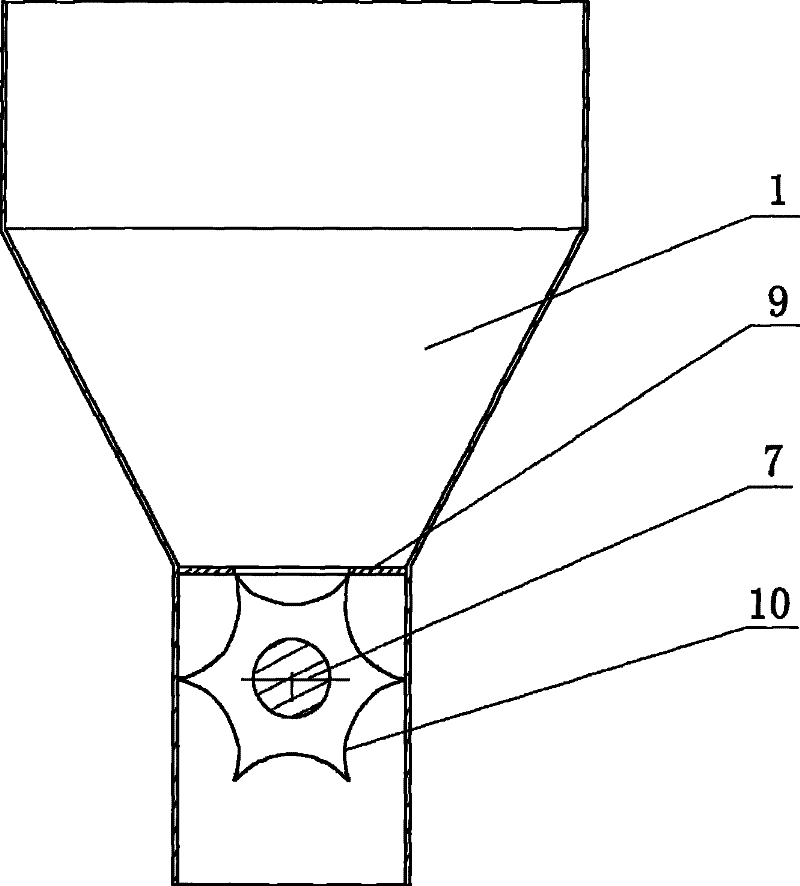

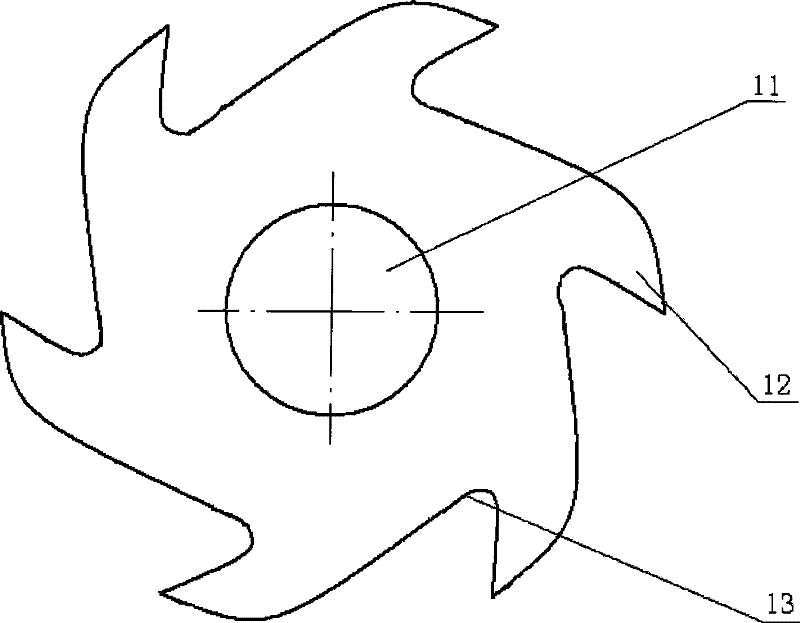

Crispy-rice rice-laying device

The invention discloses a rice crust rice laying apparatus, including a machine frame, a rice bucket mechanism, a drive mechanism and a laying mechanism located below the rice bucket mechanism. The laying mechanism includes an upper plate, an equal share machine below the upper plate, a rotation disc with gearwheel below the equal share machine, and a pinion wheel which is controlled by the drive mechanism and is meshed with the gearwheel, wherein, the upper plate is provided with a square figure placket corresponding to the opening at the lower part of the rice bucket mechanism, and a clearance for placing the tray is provided between the rotation disc and the equal share machine. The inventive rice crust rice laying apparatus has such a structure that the rice in each tray is guaranteed to be uniform and identical and the quality of rice crust is easy to control, and simultaneously productivity effect is greatly improved, labor intensity is reduced the and the working environment of the workshop is improved.

Owner:芜湖源生食品有限公司

Wrapping system of chinlon hemp grey yarn and preparing technology of chinlon hemp grey yarn

PendingCN105063839AEffective tension adjustmentEffectively adjust tension uniformityContinuous wound-up machinesYarnPolyesterYarn

The invention discloses a wrapping system of chinlon hemp grey yarn and a preparing technology of the chinlon hemp grey yarn. The chinlon hemp grey yarn are woven from chinlon yarn and polyester yarn. The wrapping system comprises a yarn feeding mechanism, a preprocessing mechanism, a covering yarn drafting mechanism and a coiling mechanism. The yarn feeding mechanism comprises two yarn bobbins for containing the chinlon yarn and the polyester yarn and a yarn feeding roller, and the yarn on the yarn bobbins is driven by the yarn feeding roller to enter the wrapping system. The preprocessing mechanism comprises a heating box and a cooling plate, wherein the heating box is a transformable heating box and is used for conducting heating and plasticizing on the yarn, and the cooling plate is used for fixing a curled structure after the yarn is twisted. The covering yarn drafting mechanism comprises a false twister, a second roller, a yarn stitching machine and a third roller. Drafting force is produced by the second roller and the yarn feeding roller and by the second roller and the third roller. An auxiliary roller is arranged between the yarn stitching machine and the third roller. By means of an existing elasticizer structure, a yarn path is lengthened to be about 5 m, and the tension of the yarn and the overall tension uniformity are effectively adjusted.

Owner:FUJIAN HUAFENG NEW MATERIALS

Feeding fence device

InactiveCN102742513AGood farming managementRealize large-scale factory farmingAnimal housingSelf lockingSemi automation

The invention discloses a feeding fence device which comprises a controller, a self-locking device, a rocking bar and a fence body. The controller comprises a handle, a rotating cross bar, a bolt and a support disk with a bolt hole. The self-locking device comprises a locking rocking plate and a locking boss. The fence body comprises an upper cross bar, longitudinal bars and a lower cross bar. A feeder uses the controller to control rotation of the rocking bar so as to limit movement of cattle, fighting for feed is avoided, and feeding time and feeding amount are controlled effectively. The feeding fence device helps realize semi-automation of large-scale factory farming, improve work efficiency and lower farming cost, and accordingly maximizing of benefits is achieved.

Owner:南京熊猫机电制造有限公司

Mechanization rice spreading device

InactiveCN101455296AAvoid wastingQuality controllableFood shapingFood preparationRice dishesSprocket

The invention discloses mechanized rice laying apparatus, including a machine frame (7), a rice laying plant (2), a material placing platform (4), a sprocket drive mechanism (8), a drive mechanism (5) and an electronic control box (11) placed on the machine frame, wherein, the material placing platform (4) is located at the terminal of the machine frame (7), the sprocket drive mechanism (8) is transversely placed on the upper side of the machine frame (7), the rice laying plant (2) is adjacent to one side of the material placing platform (4), and a gradient slope plate (6) access to the rice groove is provided at the lower sided of the rice laying plant (2). A mechanized rice laying apparatus of the invention adopts the above structure, to improve productivity, reduce labor intensity and avoid the waste of rice, so that the rice in each tray is guaranteed to be uniform and identical and the quality of rice crust is easy to control.

Owner:芜湖源生食品有限公司

Special crayfish feed for improving survival rate and raising method

InactiveCN108936094AEat evenlyEat completelyFood processingClimate change adaptationMonascusAdhesive

The present invention discloses a special crayfish feed for improving survival rate. The feed comprises the following raw materials in parts by weight: 30-40 parts of puffed blood powder, 10-20 partsof earthworm powder, 20-30 parts of coconut meal, 40-50 parts of whey protein powder, 20-30 parts of corn germ protein powder, 20-30 parts of soybean milk powder, 25-35 parts of an immunopotentiator,0.02-0.04 part of selenium-enriched yeast, 0.02-0.04 part of pectinase, 0.04-0.08 part of monascus, 0.06-0.12 part of composite amino acid and 8-16 parts of an adhesive. The adhesive comprises olive oil, shell powder, montmorillonite and a tackifier. The tackifier is prepared by the following process: stirring sweet potato powder and hydrochloric acid, conducting filtration, drying and grinding, adding beta-cyclodextrin with stirring, adding sodium hydroxide with stirring, conducting stirring under the protection of nitrogen, conducting cooling, regulating the system with hydrochloric acid until the system is neutral, conducting filtration, washing filtrate with absolute ethyl alcohol, and conducting drying so as to obtain the tackifier.

Owner:安徽涂远农业有限公司

Breeding method capable of reducing case fatality rate of red swamp crayfishes

InactiveCN108925479AQuality improvementGood yieldFood processingClimate change adaptationCase fatality rateWater source

The invention discloses a breeding method capable of reducing a case fatality rate of red swamp crayfishes. The method comprises the following steps: selecting a pond with a sufficient water source and no sludge, arranging a heat preservation shed above the pond, draining water in the pond, and performing solarization to obtain a vacant pond; pouring water into the vacant pond, performing disinfection, and planting aquatic plants to obtain a cultivation pond; selecting young red swamp crayfishes with 0.5-1.1 cm, and throwing the selected young red swamp crayfishes into the cultivation pond; performing feeding by feed specially used for the red swamp crayfishes; and changing water every 4-6 days during feeding until the red swamp crayfishes are mature, wherein the feed specially used for the red swamp crayfishes comprises the following raw materials in parts by weight: 24-35 parts of daphnia powder, 4-12 parts of locust powder, 10-18 parts of corn meal, 25-45 parts of peanut protein powder, 10-24 parts of sunflower seed meal, 12-20 parts of skim milk powder, 12-22 parts of houttuynia cordata, 1-4 parts of cortex phellodendri, 1-4 parts of broussonetia papyrifera powder, 0.01-0.02 part of selenium-enriched yeast, 0.01-0.02 part of cellulase, and 1-3 parts of a bean flour complex.

Owner:安徽涂远农业有限公司

Appetizing pig feed

The invention discloses appetizing pig feed which comprises, by mass, 50-70% of corn, 20-40% of wheat bran, 5-10% of rapeseed meal, 7-13% of soybean meal, 0.01-0.05% of salt and 0.25-0.3% of auxiliary materials. The auxiliary materials comprise, by mass, 30-40% of diospyros kaki, 8-15% of dried ginger, 20-30% of felwort, 20-30% of radix curcumae and 15-25% of hawthorn. Diospyros kaki, dried ginger, felwort, radix curcumae and hawthorn are ground into powder to be mixed into the feed. The appetizing pig feed has the advantages of promoting appetite, strengthening the spleen and promoting digestion to eliminate stagnation and the like.

Owner:颍上县博陵家庭农场

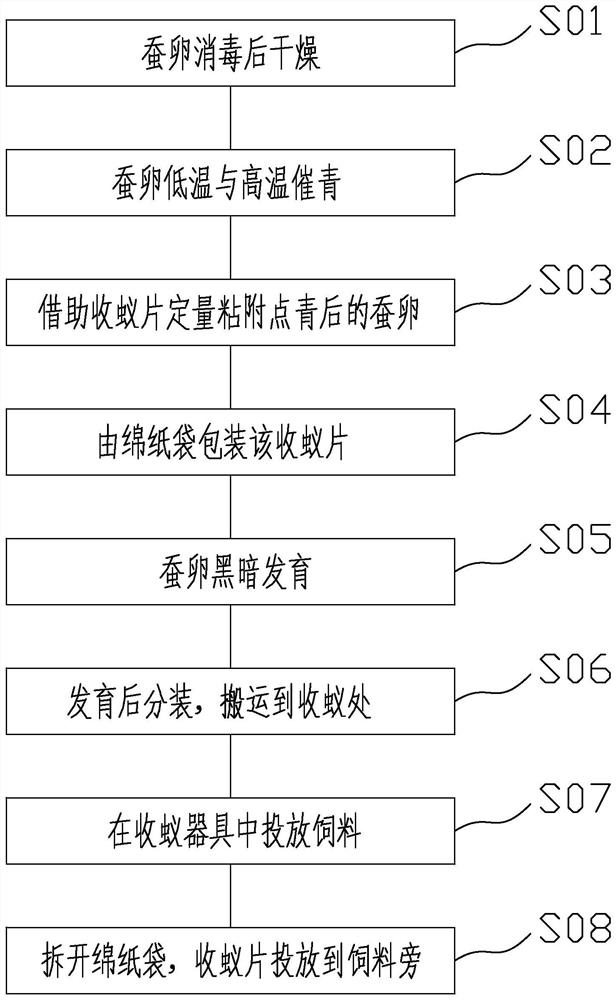

Factory silkworm breeding termite collecting sheet type termite collecting process

According to the process, silkworm eggs are quantitatively obtained through the silkworm egg collecting pieces, feed is put into a silkworm egg collecting appliance in advance, then the silkworm egg collecting pieces containing unhatched silkworm eggs are put beside the feed, the silkworm eggs are hatched and collected, and newly-hatched silkworms can autonomously climb to the feed to suck the feed. The newly-hatched silkworm collecting method is convenient to operate, the newly-hatched silkworm collecting work efficiency is remarkably improved, the procedure of beating down is replaced, and the problem that newly-hatched silkworms are damaged when falling down is solved; after being hatched, the newly-hatched silkworms can automatically crawl to the feed for feeding, so that the newly-hatched silkworms can quickly develop in the one-age period. Silkworm eggs can be quantitatively obtained through the silkworm egg collecting pieces, the deviation between the silkworm eggs is small, and therefore the purpose of quantitatively collecting the silkworms is achieved, the number of hatched newly-hatched silkworms corresponds to the weight of feed, and the problems that waste is caused by too much feed, and newly-hatched silkworm dysplasia is caused by lack of feed are solved.

Owner:SHENGZHOU MOSANG HI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com