Adjustment method of inner-profile radial floating tool rest and tool

A tool adjustment and tool holder technology, which is applied to the accessories of tool holders, tool holders, manufacturing tools, etc., can solve the problems of unable to complete the annual output of 500,000 tons of steel pipes, unable to meet the production capacity of the production line, and difficult to ensure the processing quality, etc. To solve the problem of axial positioning, the processing surface is small, and it is not easy to hit the knife

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

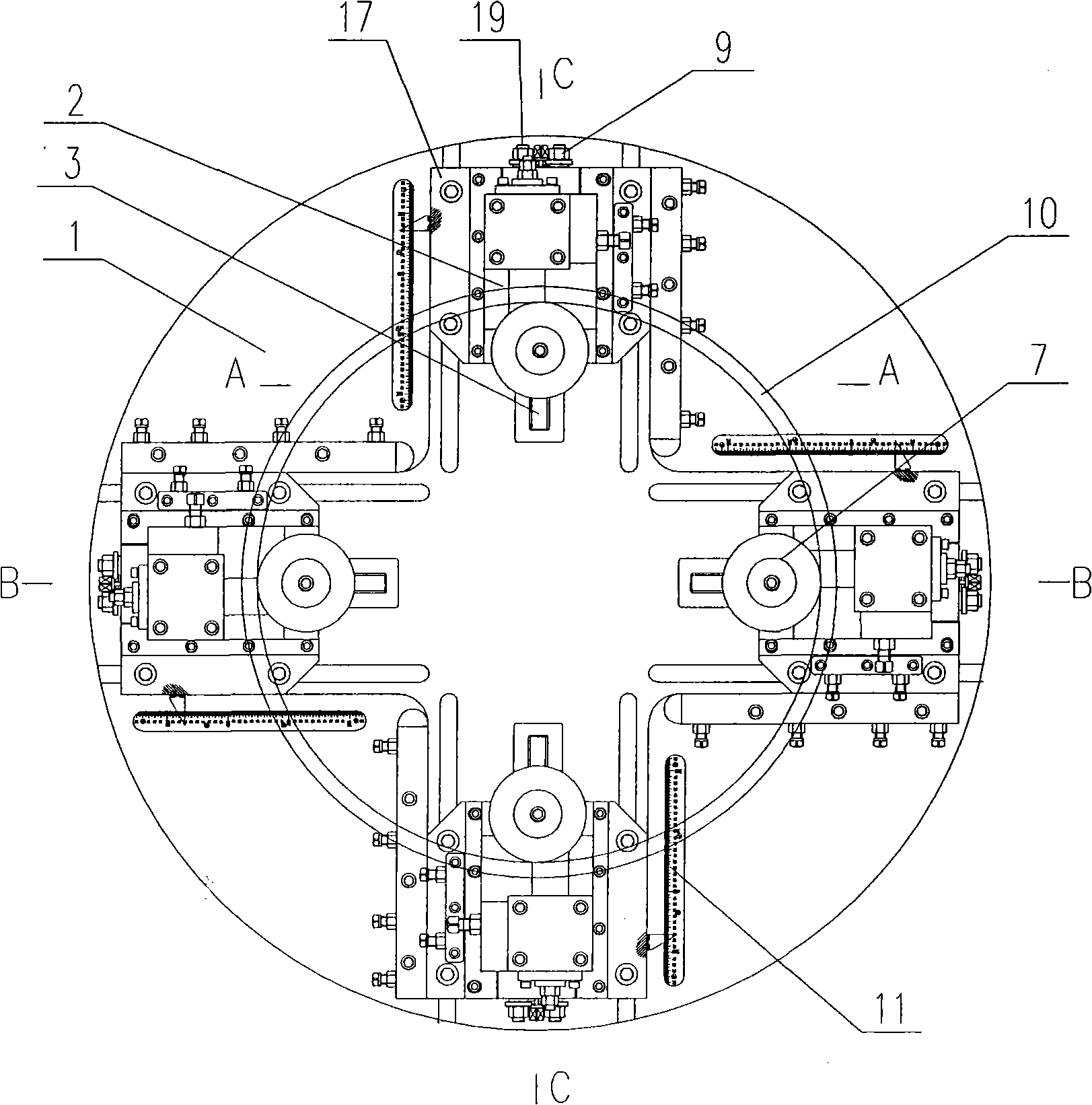

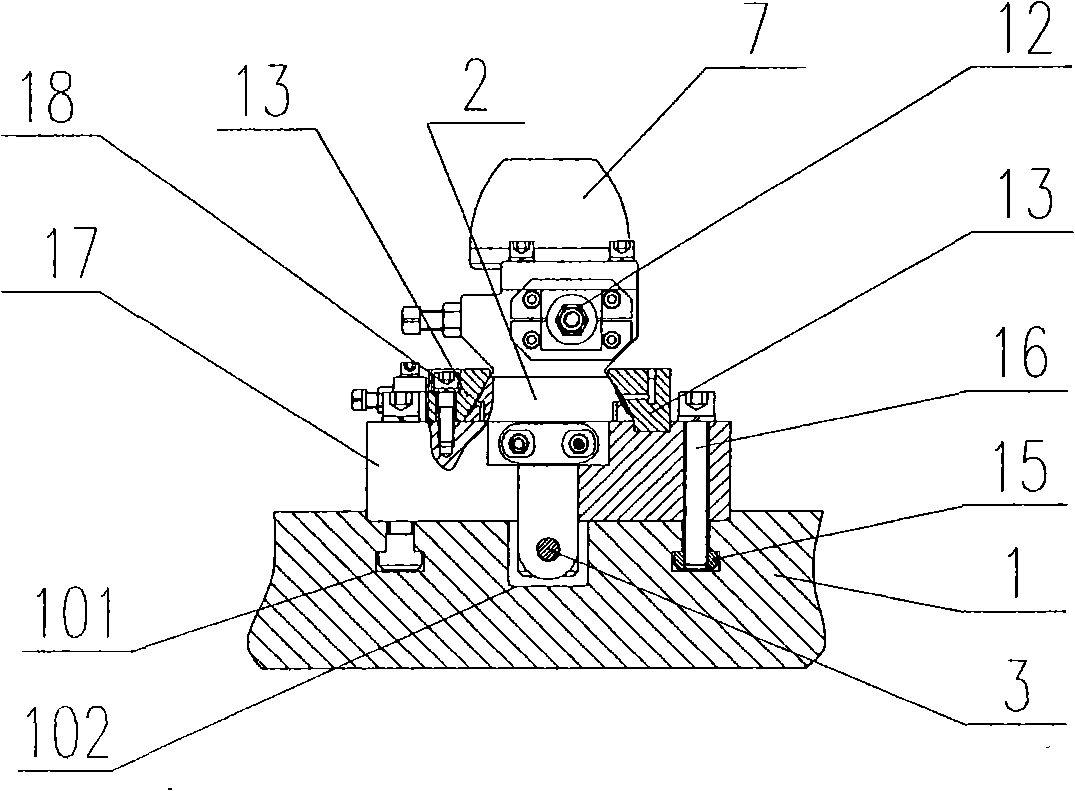

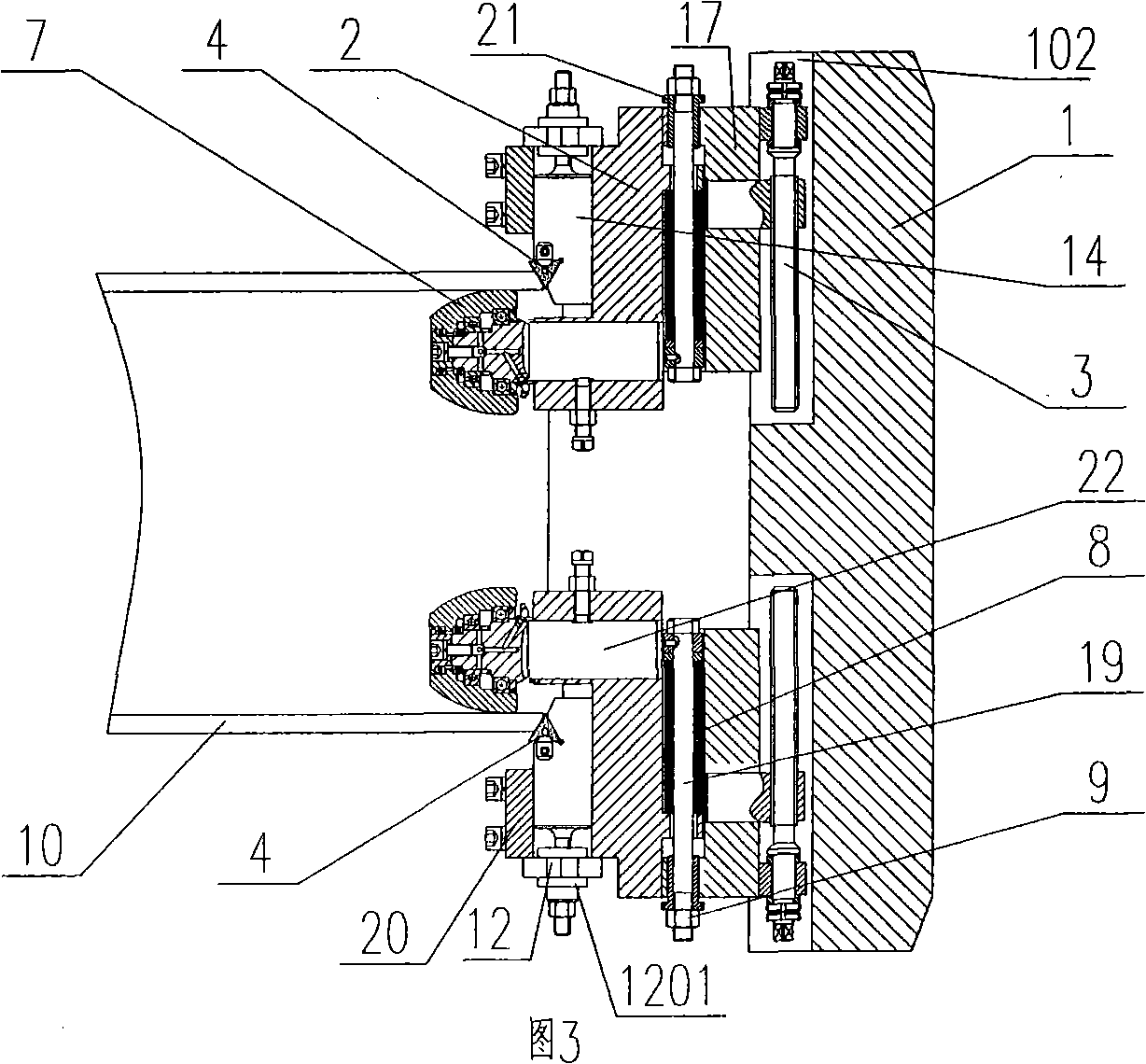

[0031] Product implementation such as figure 1 Shown: an internal profiling radial floating tool seat, including a cutter head 1; the end face of the cutter head 1 is radially symmetrically installed with four slider bodies 17 that can move radially; see figure 2 , four pairs of T-shaped guide grooves 101 are evenly opened radially in the middle part of the end face of the cutter head 1, and the T-shaped guide grooves 101 are equipped with T-shaped groove nuts 15, and the T-shaped groove nuts 15 are equipped with bolts 16, and the slide body 17 is installed on the bolts. 16 is connected with cutter head 1; see figure 2 With Fig. 3, lead screw groove 102 is provided between every pair of T-shaped guide grooves 101, and lead screw nut mechanism 3 is installed in lead screw groove 102, and the connecting rod of lead screw nut mechanism 3 is connected with sliding seat body 17; Adjust lead screw Nut mechanism 3, sliding seat body 17 moves radially along T-shaped guide groove 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com