Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63results about How to "Solve the machining accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

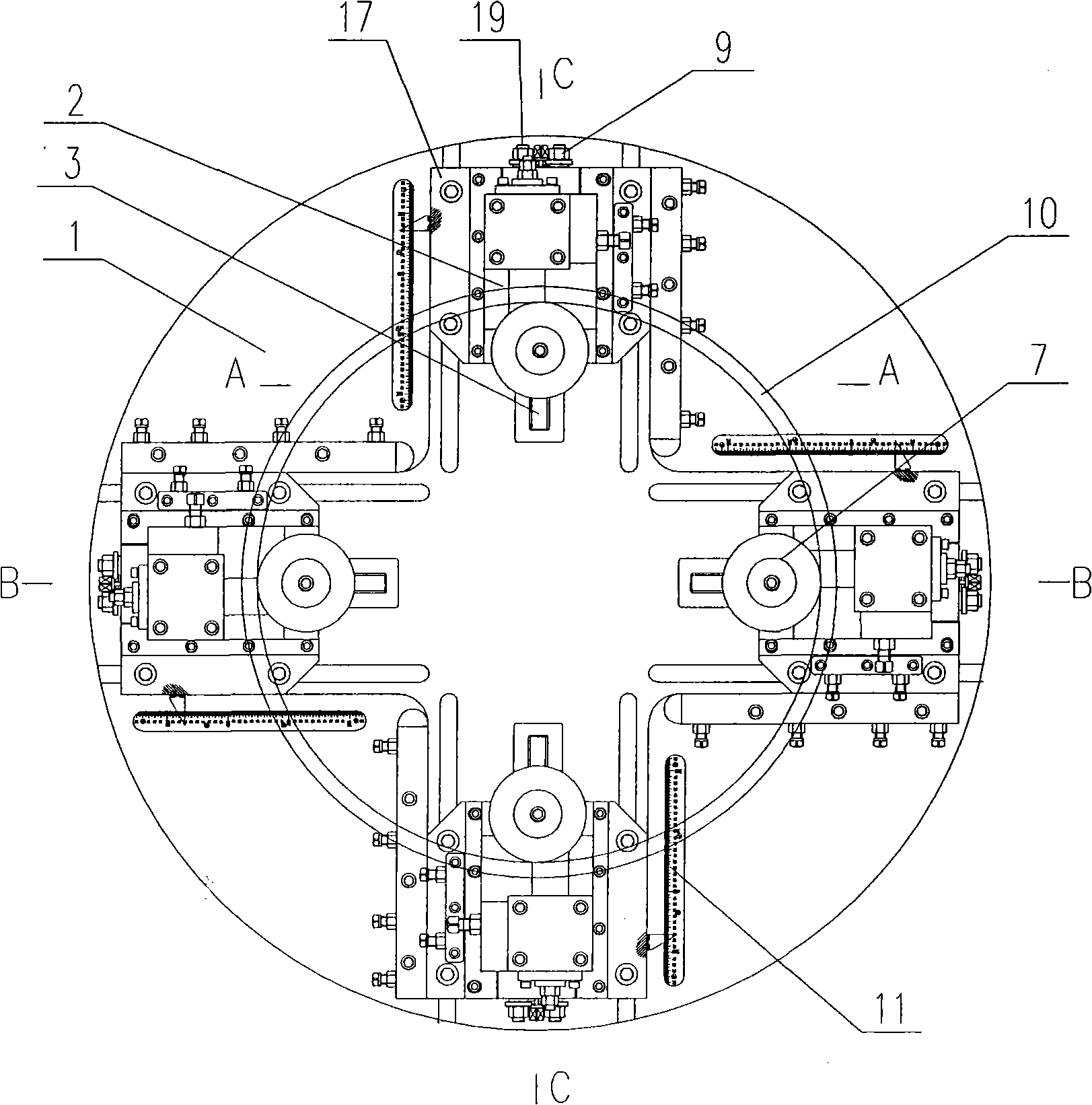

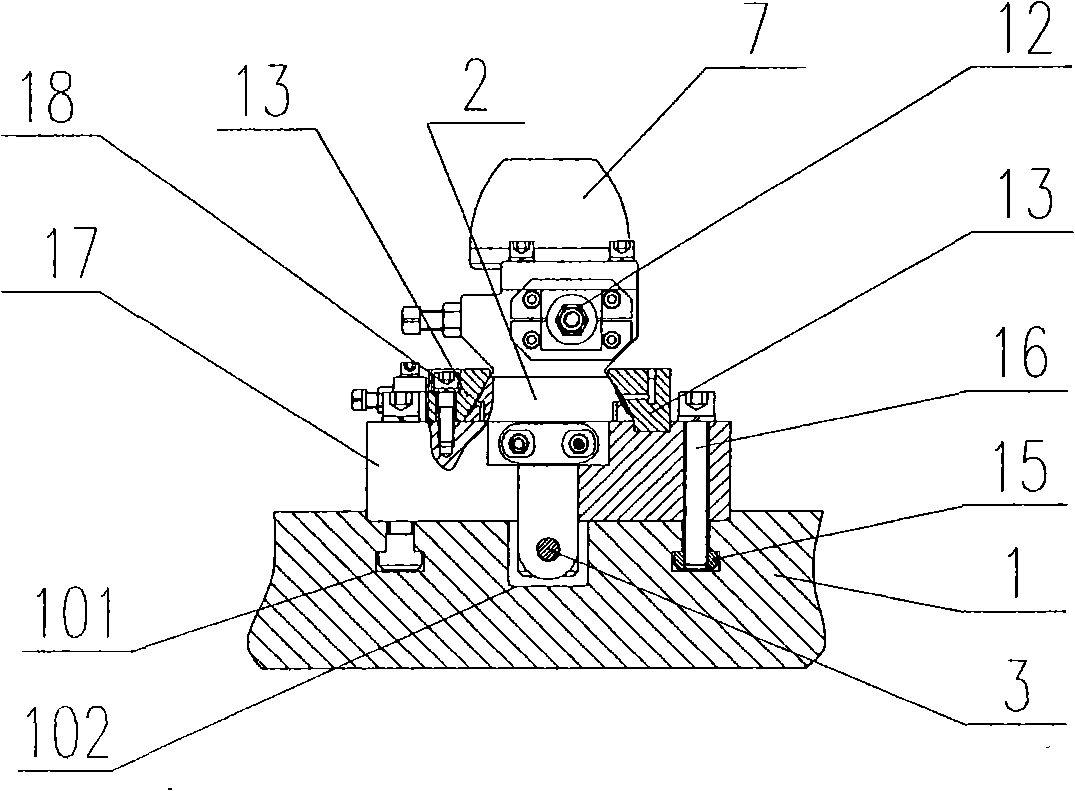

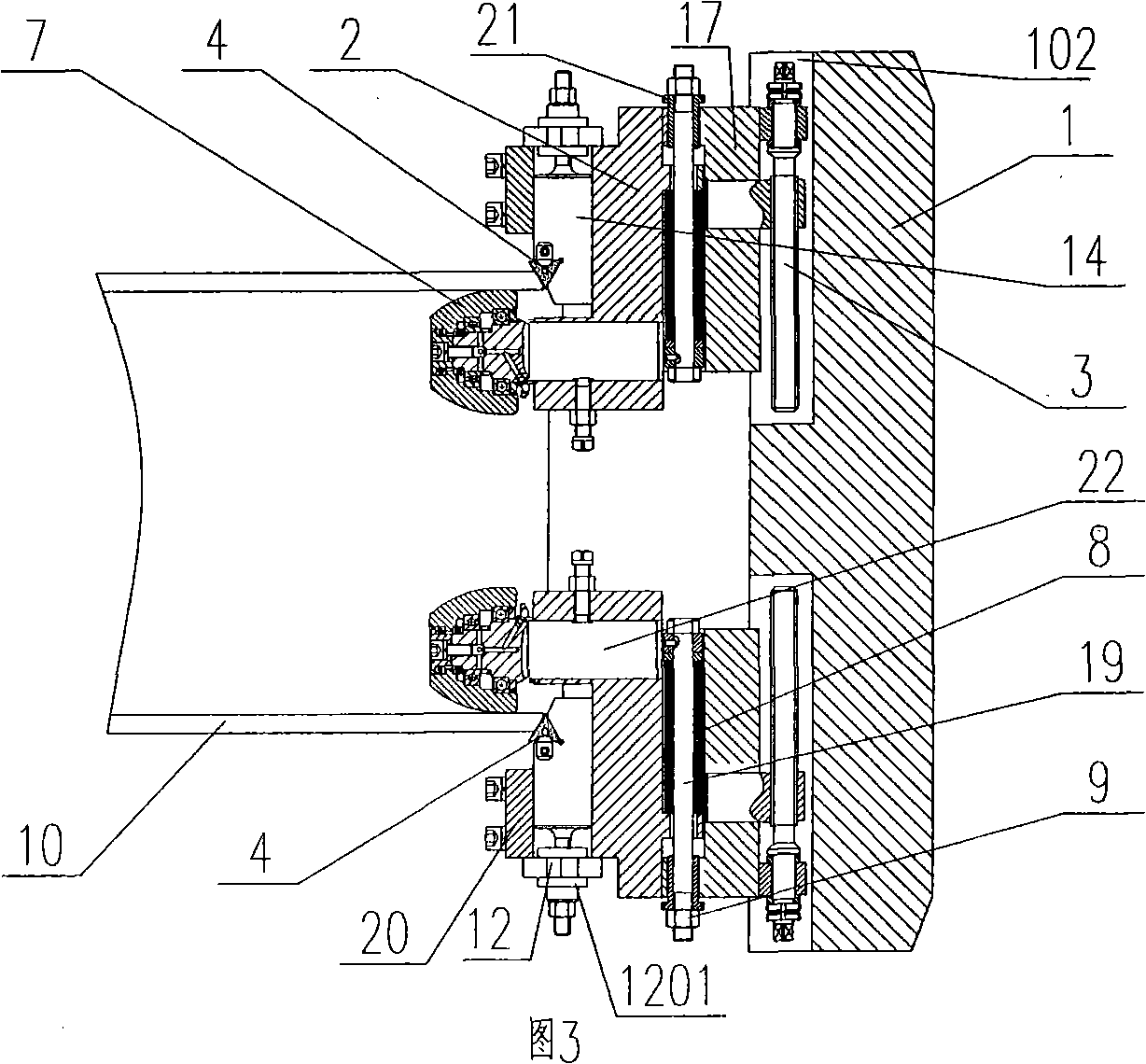

Adjustment method of inner-profile radial floating tool rest and tool

InactiveCN101357404AEat evenlyUniform turningAuxillary equipmentCopying process control systemsProduction lineEngineering

The invention relates to an internal profile modeling tool apron which is used in a steel pipe flat-end-face chamfering device in a large-dimensional and straightly welded seam pipe production line and floats along the radial direction; the tool apron comprises a cutter head, of which the end face are symmetrically provided with four sliding base bodies along the radial direction; each sliding base body is provided with a floating tool apron by a connecting screw rod; a cutter is vertical to the side wall of a steel pipe and arranged on the outer end of the floating tool apron, namely, the end far from an axis; the rear part of the cutter is provided with screw threads which are connected with a cutter adjusting mechanism; the end faces and the middle part of the sliding base bodies are provided with a spring slots; a plurality of dish-shape springs are sheathed on the connecting screw rod and arranged in the spring slots; the outer end of the connecting screw rod is provided with a spring adjusting nut; floating stroke adjusting nuts are arranged on the connecting screw rod and at the inner end of the spring adjusting nut; a profile modeling rolling is arranged at the inner end of the floating tool apron and rolls against the interior wall of the steel pipe; the position of the cutter and the steel pipe wall are relatively fixed, thereby simultaneous penetration of four cutters on the cutter head, even turning, no easy collision of the cutters and high production efficiency are ensured. The invention also relates to an adjusting method of the cutters.

Owner:TIANSHUI METALFORMING MACHINE TOOL GROUP

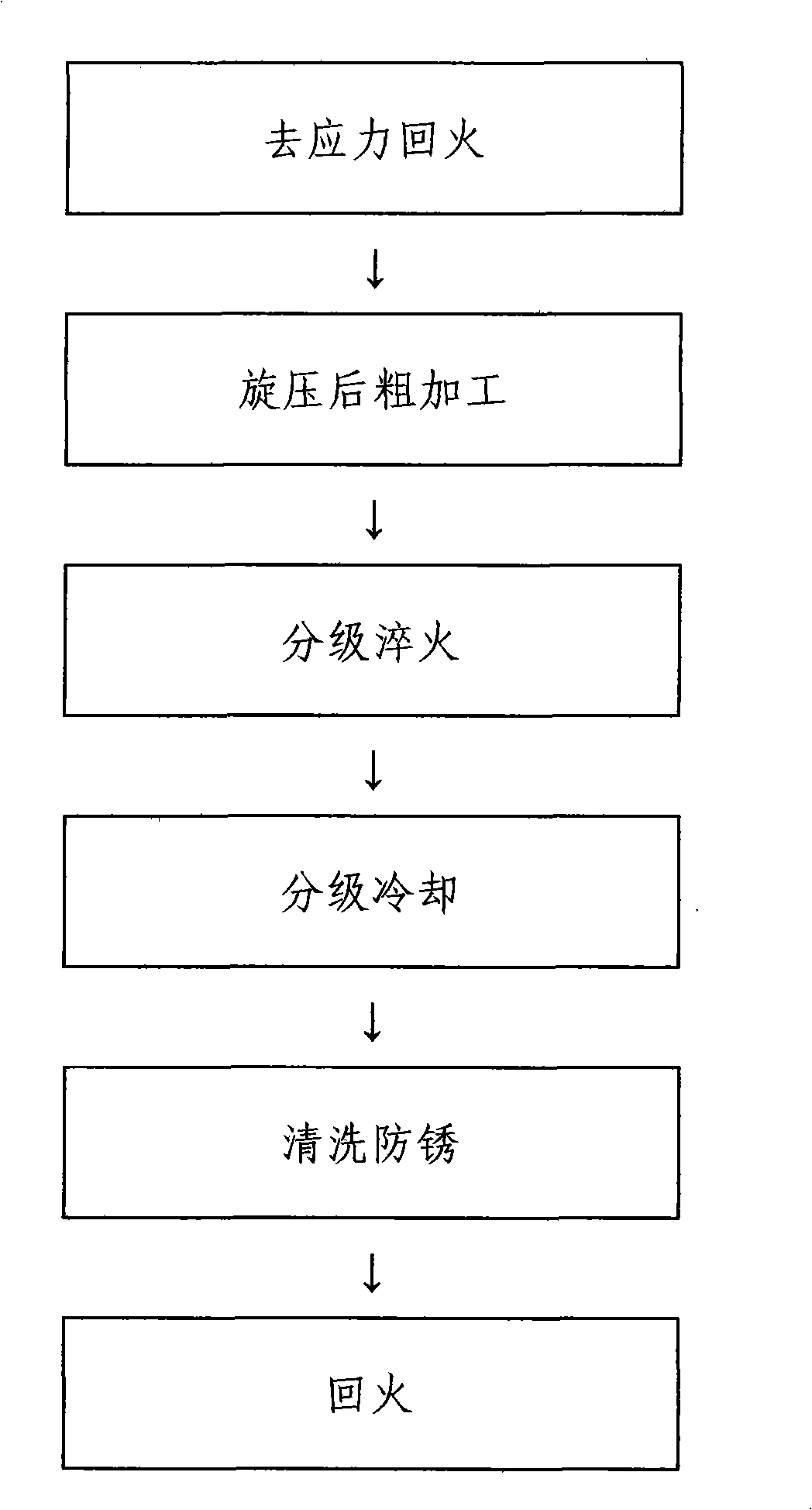

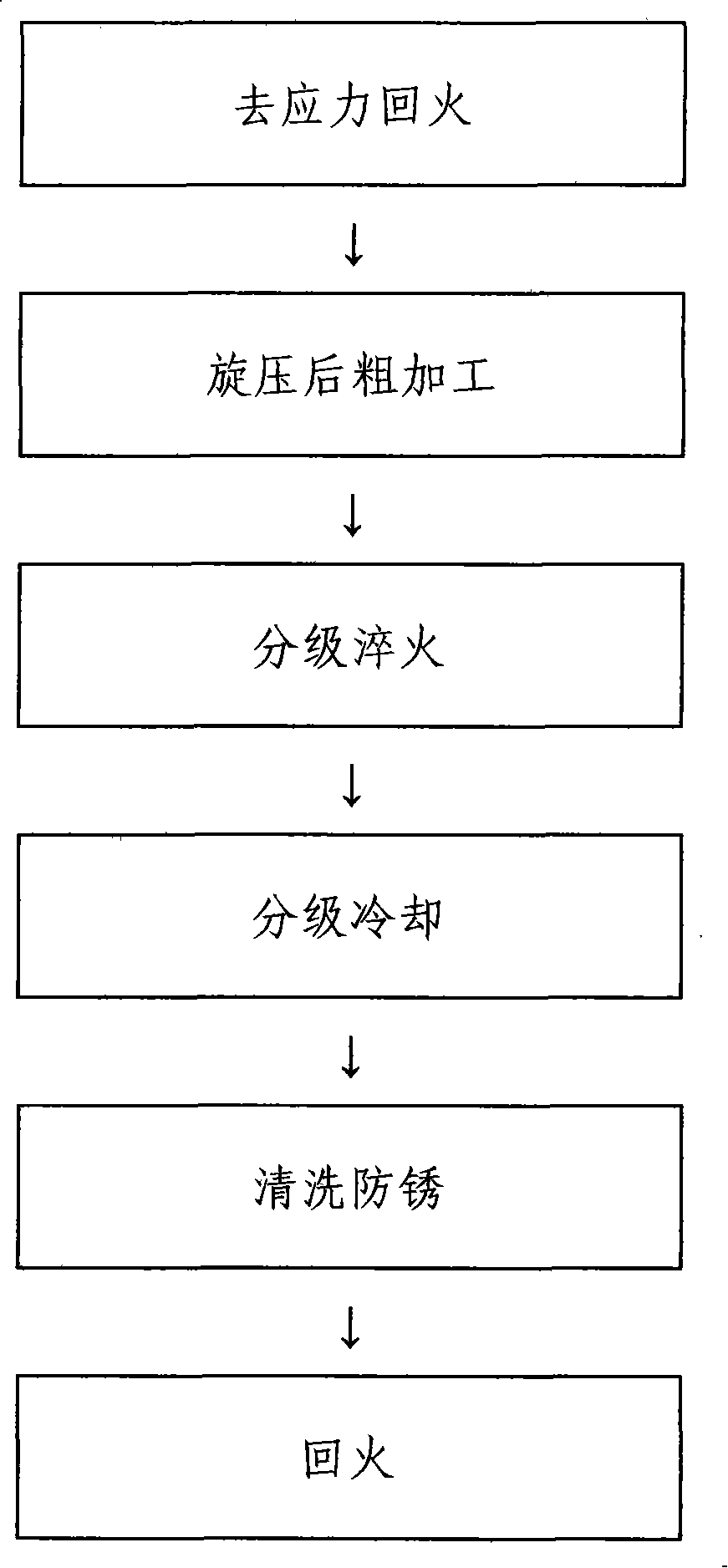

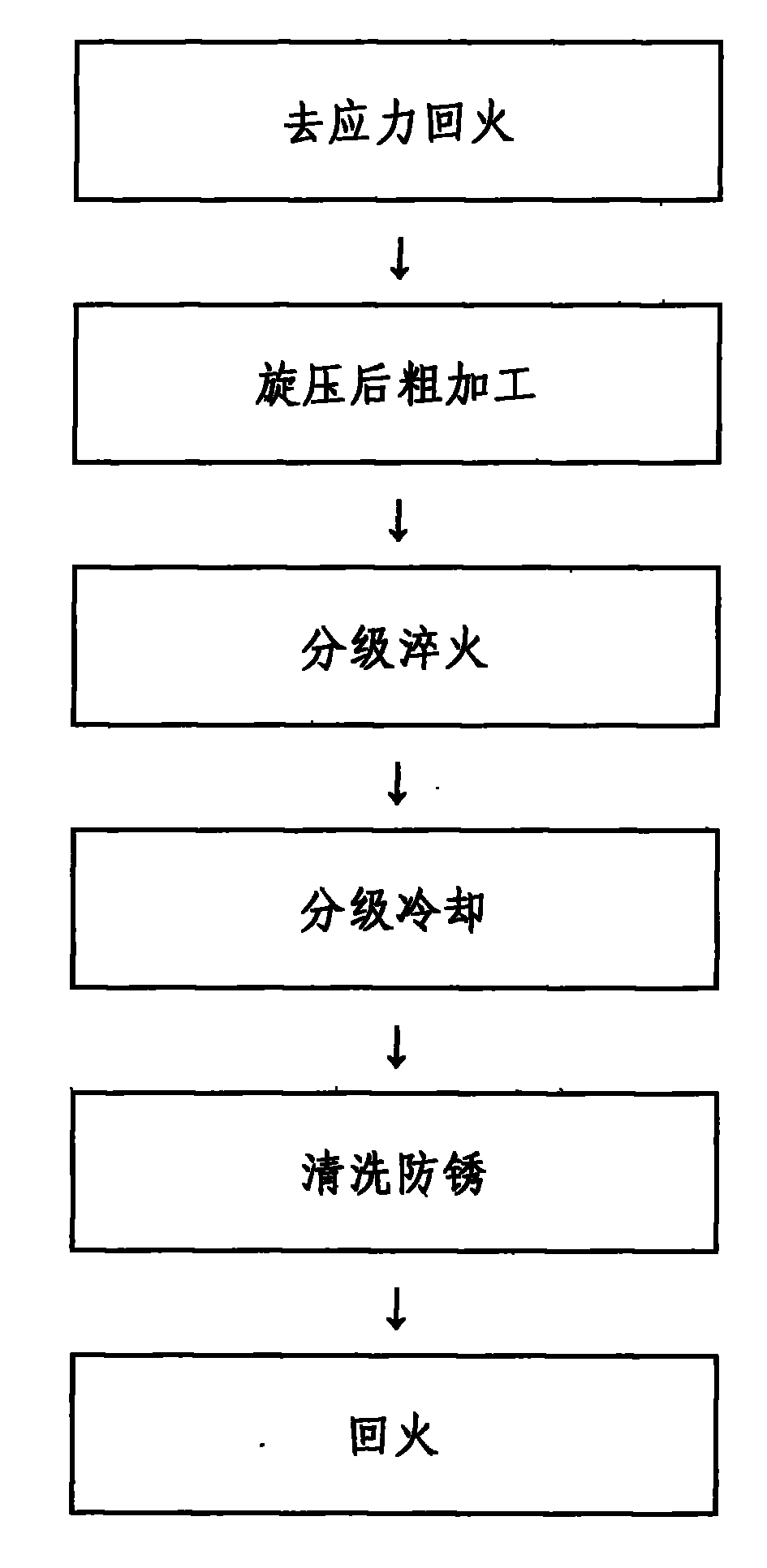

Composite heat treatment method for 30CrMnSiA steel thin wall spinning cylinder-shape element

InactiveCN101265514AImprove organizational stabilityEasy to processFurnace typesQuenching agentsQuenchingMachining

A compound heat treatment method of 30CrMnSiA steel to thin wall cylindrical shaped element with large diameter and thin wall thickness by spinning is characterized in that the method comprises a preferable 'stress tempering-interrupted quenching-tempering' heat treatment combination. The method comprises the steps of: stress tempering a workpiece while releasing the residual stress of the workpiece to a certain extent by controlling the tempering temperature and temperature holding time; conducting interrupted quenching by preheating, heating with a salt-bath furnace, cooling with a nitrate thermostatic bath and air cooling, washing to remove residual salt or alkaline liquid on the surface of the workpiece, and performing passivation and anti-corrosive treatment; and placing the workpiece into a well type tempering furnace or a special tempering furnace to conduct tempering treatment. The workpiece subjected to compound heat treatment has the advantages of high processing precision, high hydraulic pressure test strength, and low deformation liability of the following machining operation.

Owner:江南工业集团有限公司

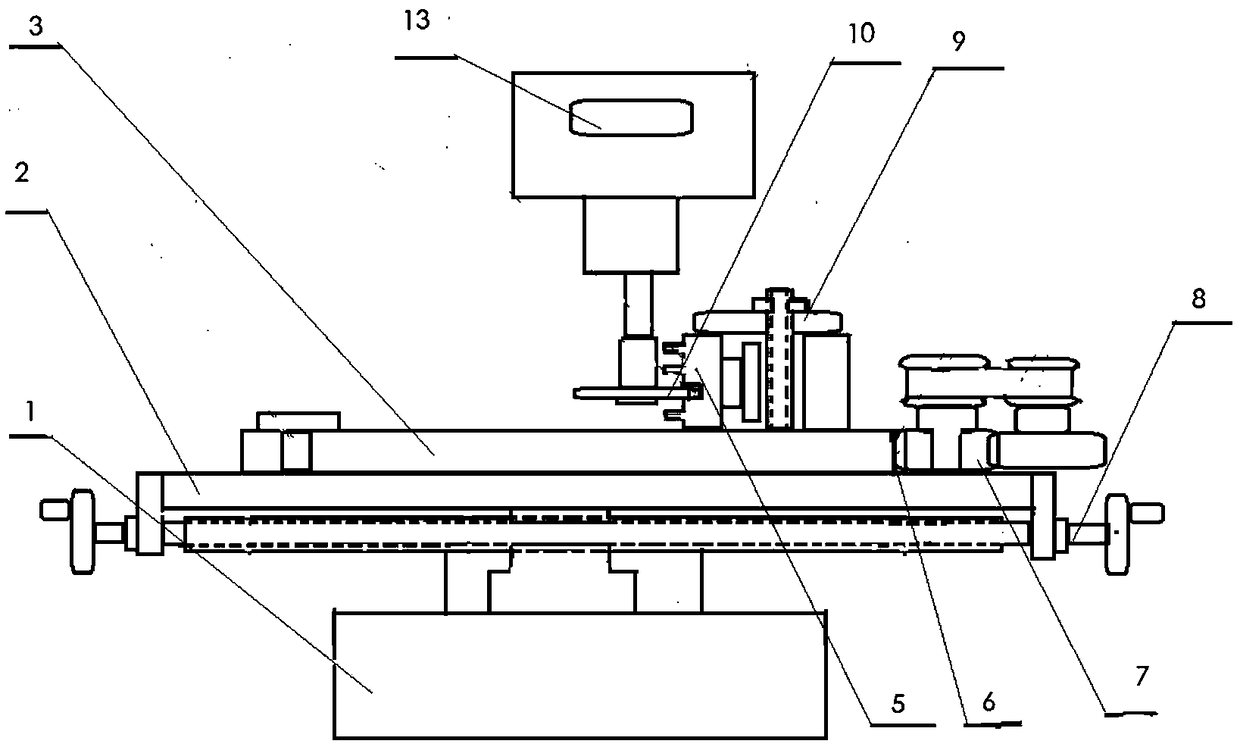

Relief angle adjustable device for automatic grinding of arc-edge diamond lathe tool

InactiveCN102248451AImproving the manufacturing accuracy of blade shapeImprove production efficiencyPlaning/slotting toolsTurning toolsEngineeringDiamond

The invention discloses a relief angle adjustable device for the automatic grinding of an arc-edge diamond lathe tool, comprising a base, wherein a driving device, a grinding disc and a photographing device are sequentially installed on the table board of the base; the driving device comprises a transverse feed device and a longitudinal feed working table connected with the transverse feed device; a longitudinal feed device is arranged on the longitudinal feed worktable; a swing device is connected with the longitudinal feed device; a relief angle adjustable fixture comprises a cantilever part connected with the swing device; the center of one side of an angle adjusting part and the center of the front end of the cantilever part are connected through a shaft and can rotate around the shaft at a certain rotation angle; the rotation angle can be displayed through a reading device; a lathe tool clamping part on which a groove is arranged is connected with one side of the angle adjusting part; and the diamond lathe tool arranged on a tool holder is inserted in and connected with the groove. By utilizing the device provided by the invention, the relief angle of the lathe tool can be accurately adjusted when the arc-edge diamond lathe tool is ground.

Owner:TIANJIN UNIV

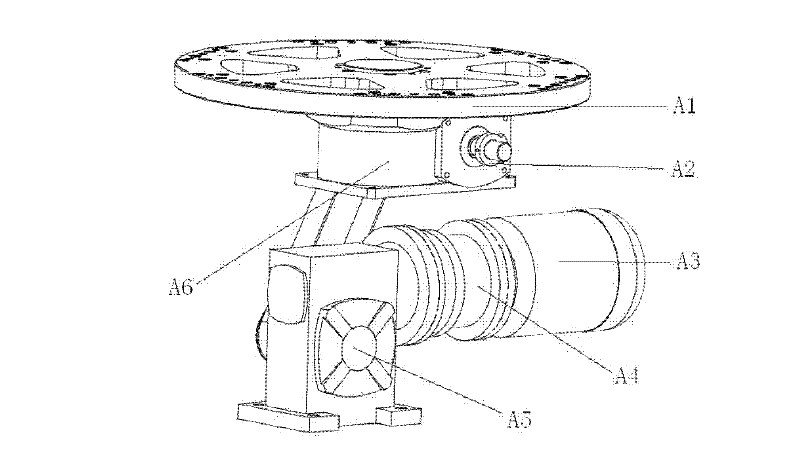

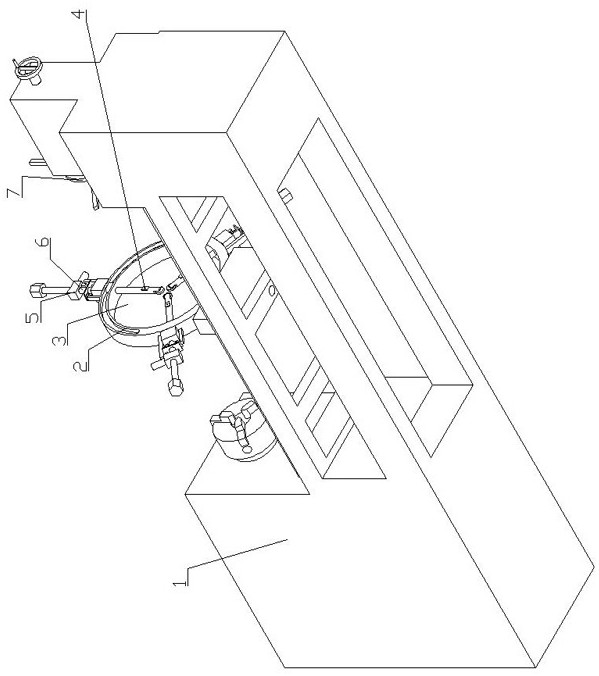

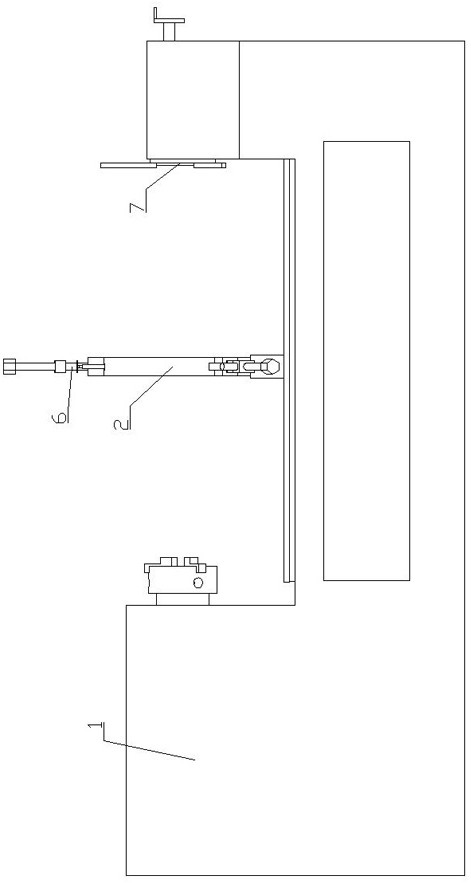

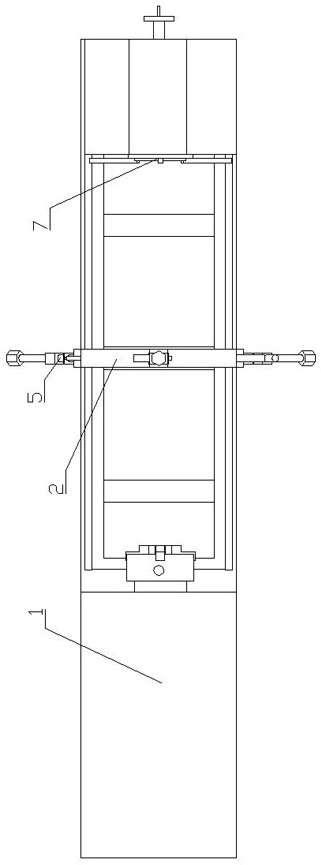

Workpiece inner hole processing equipment

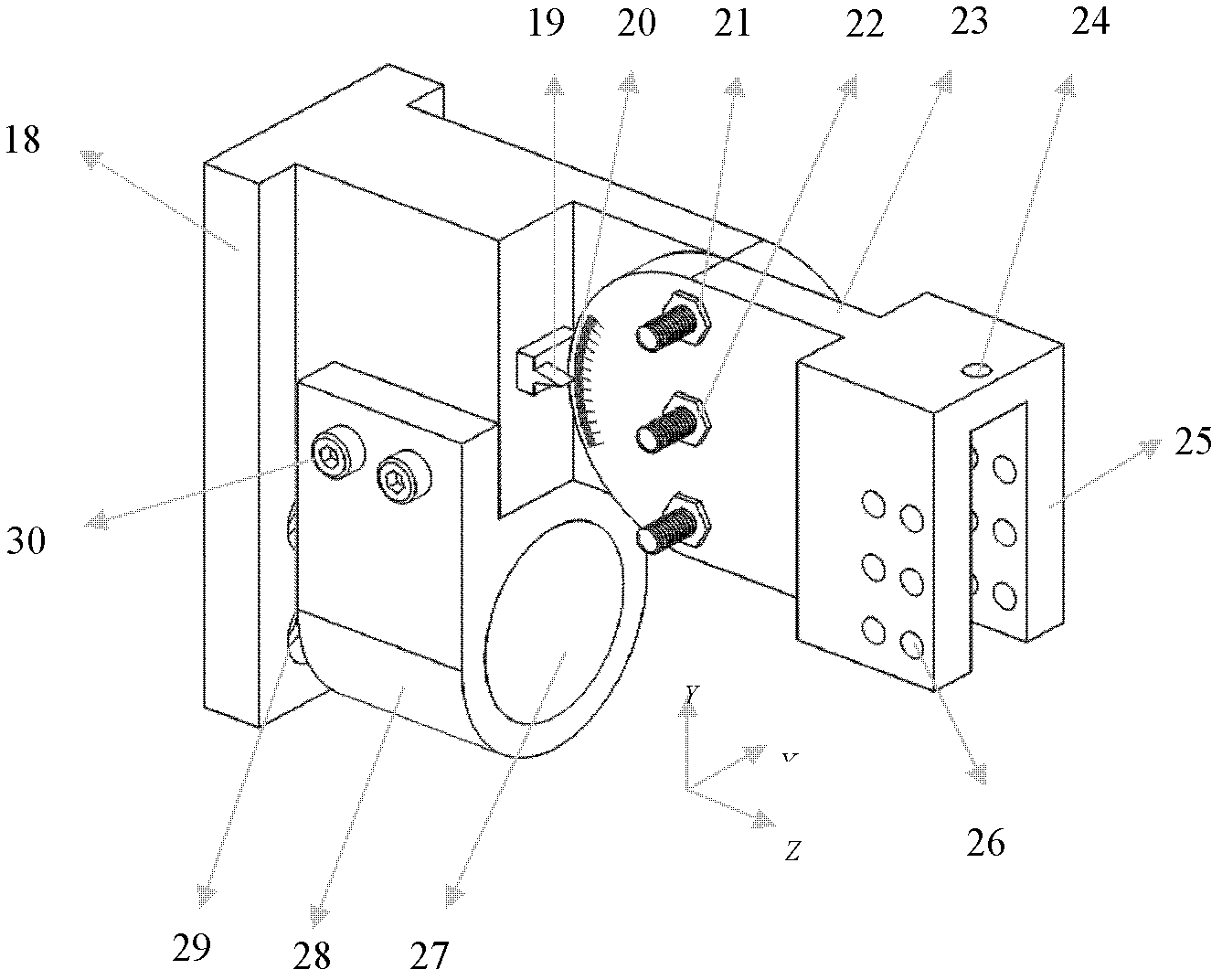

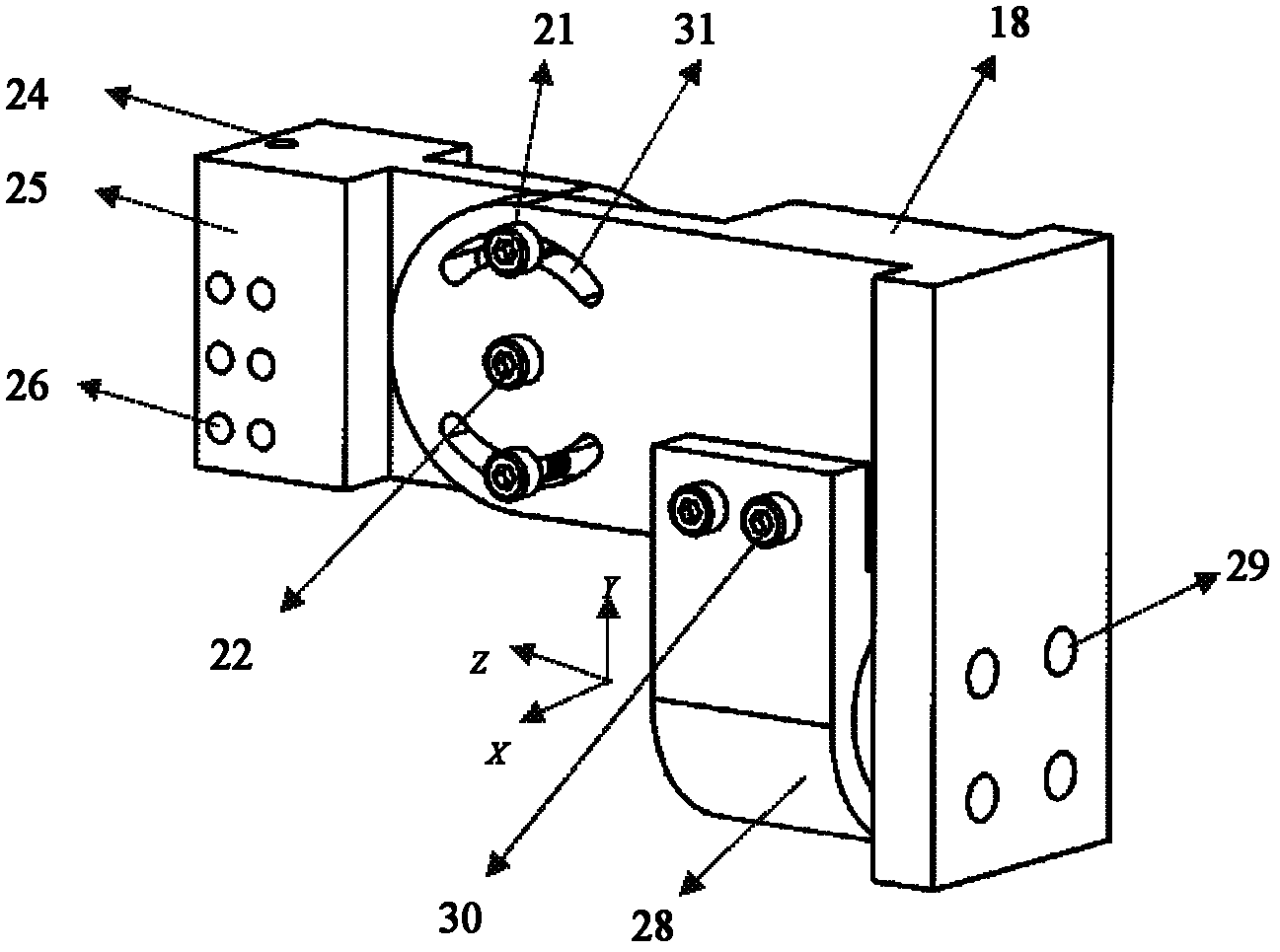

InactiveCN102284719ALarge shifting rangeSolve the machining accuracyBoring barsPositioning apparatusSet screwGear wheel

The invention discloses workpiece inner hole processing equipment. The workpiece inner hole processing equipment is mainly characterized in that: a workpiece supporting component is flexibly clamped and fastened; a main transmission box adopts multi-stage gear pair transmission controlled by a numerical controller and driven by a first speed-changing motor; a boring cutter combined device is thata boring cutter driving disk is matched with a boring bar double key groove pair and a boring cutter fixed block is slidingly matched with a boring cutter sliding block movement guide rail base; the boring cutter sliding block and the boring bar combined device are driven by a second speed-changing motor and a third speed-changing motor which are controlled by the numerical controller; and a boring bar front bracket and a boring bar are connected by one fastening screw axially. The workpiece inner hole processing equipment has the characteristics of advanced structure, simpleness and convenience for operation, high processing precision, high automation degree, high processing efficiency, multiple functions of turning, boring and grinding and the like.

Owner:CHANGZHOU BAOLING HEAVY IND MACHINERY

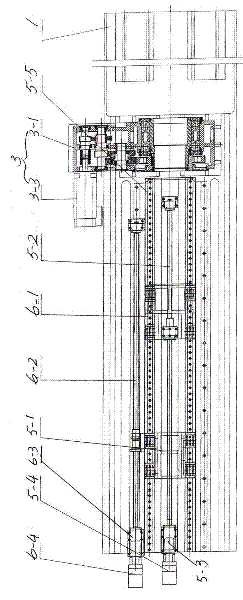

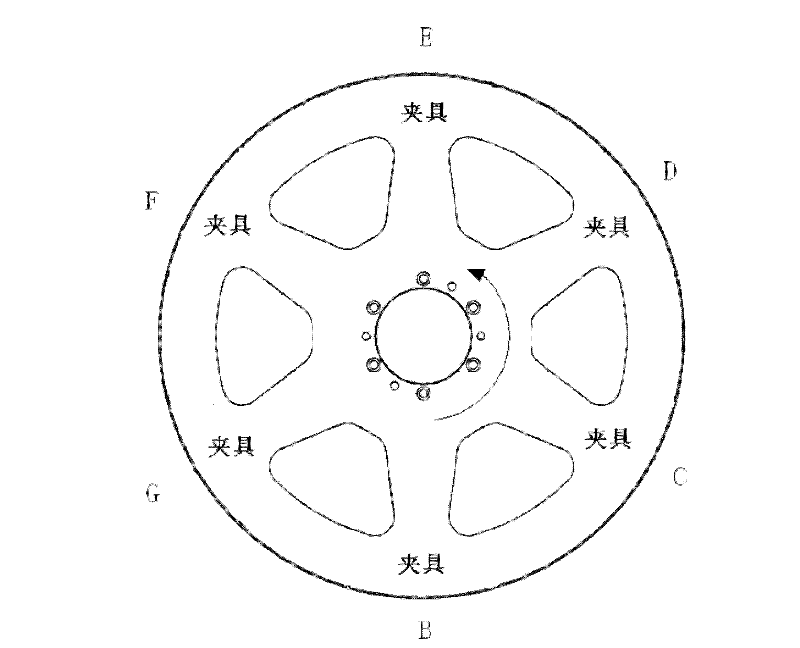

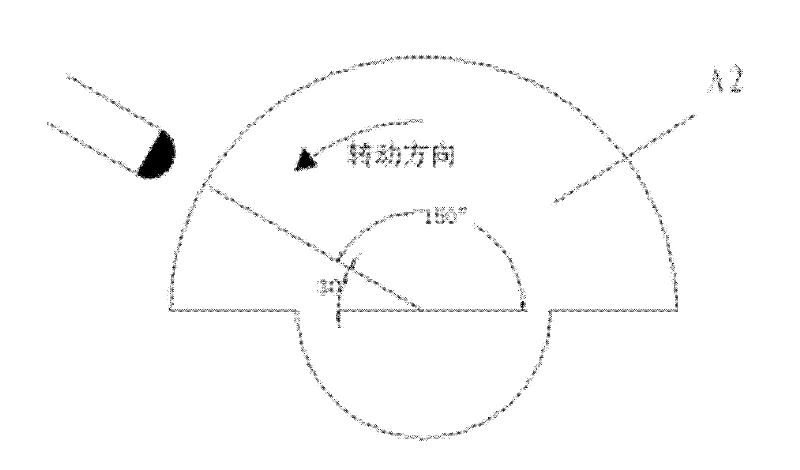

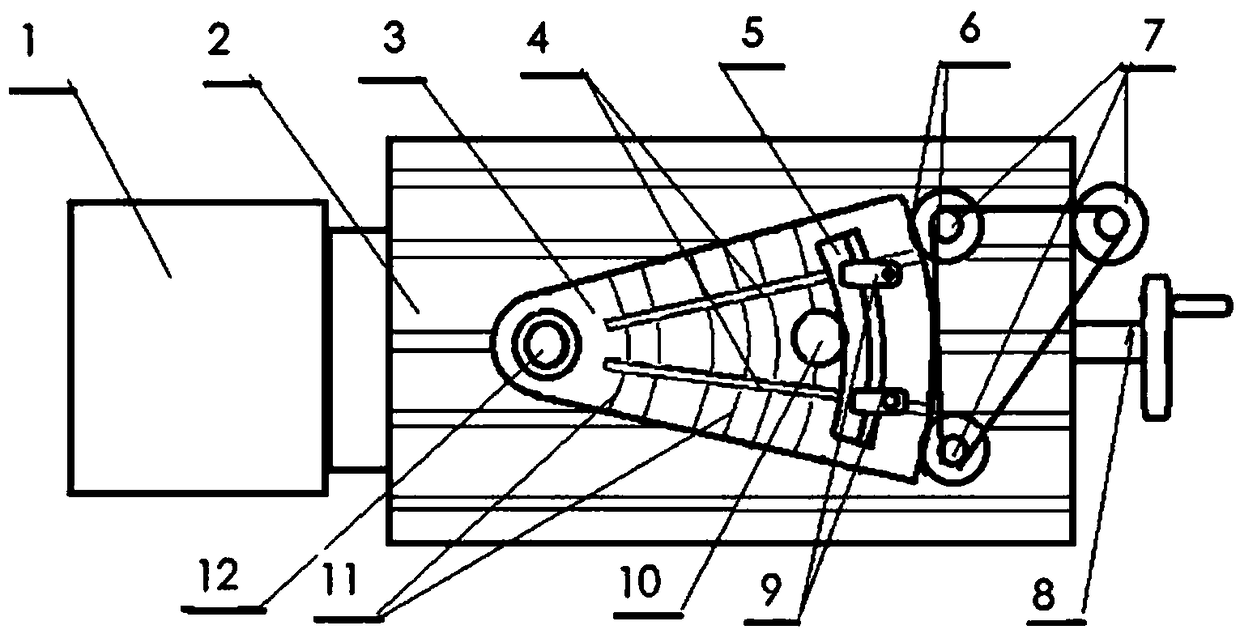

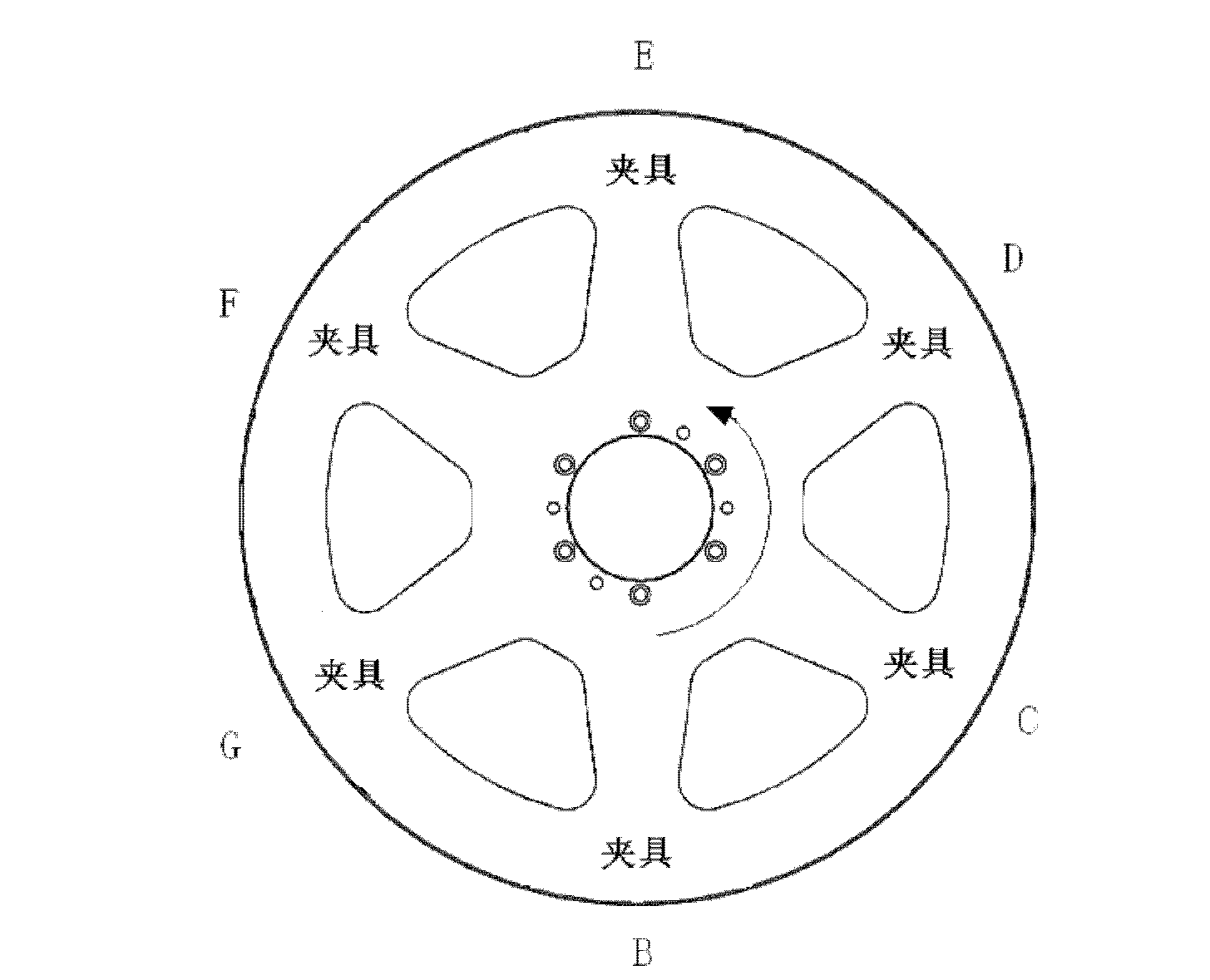

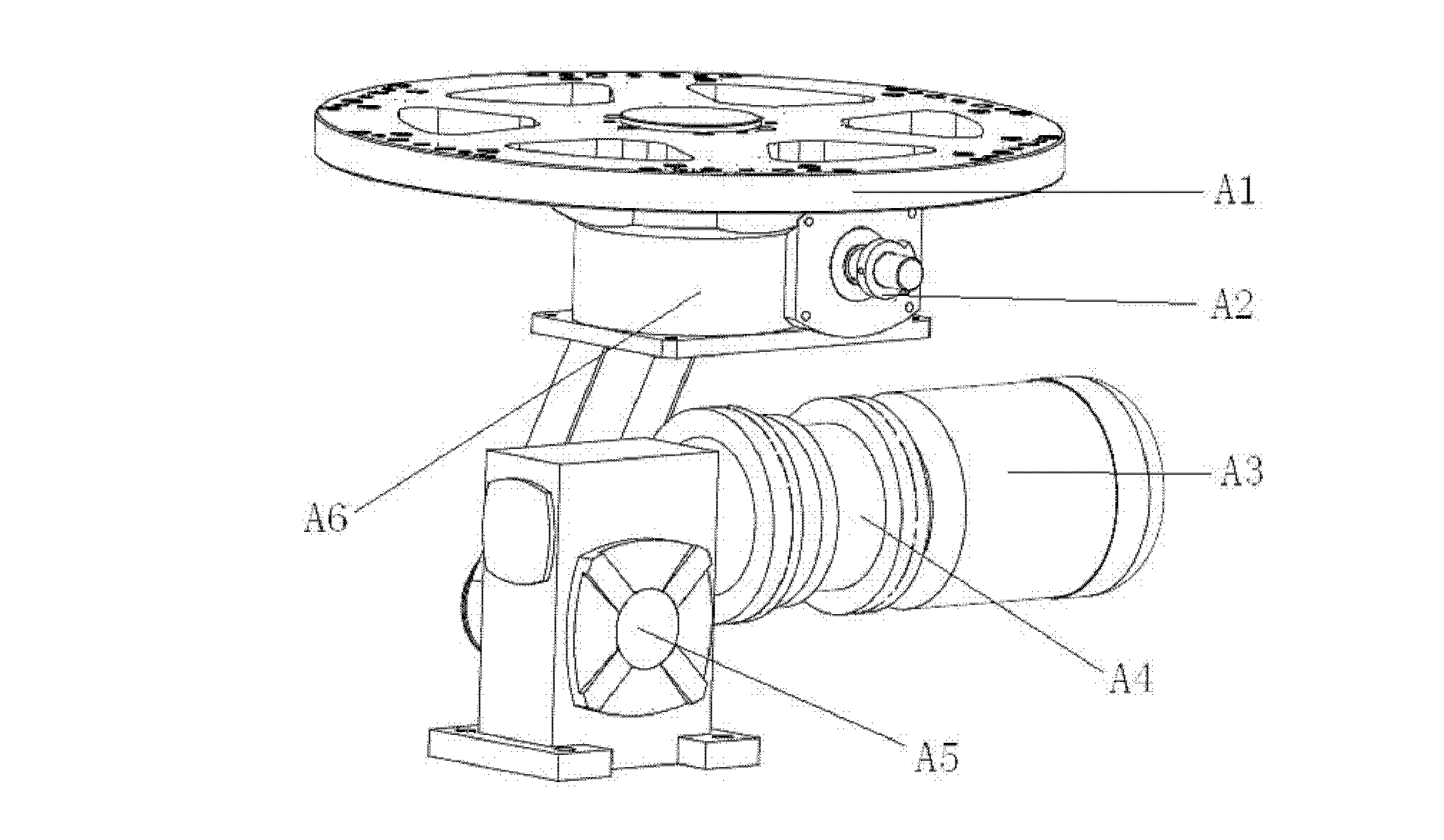

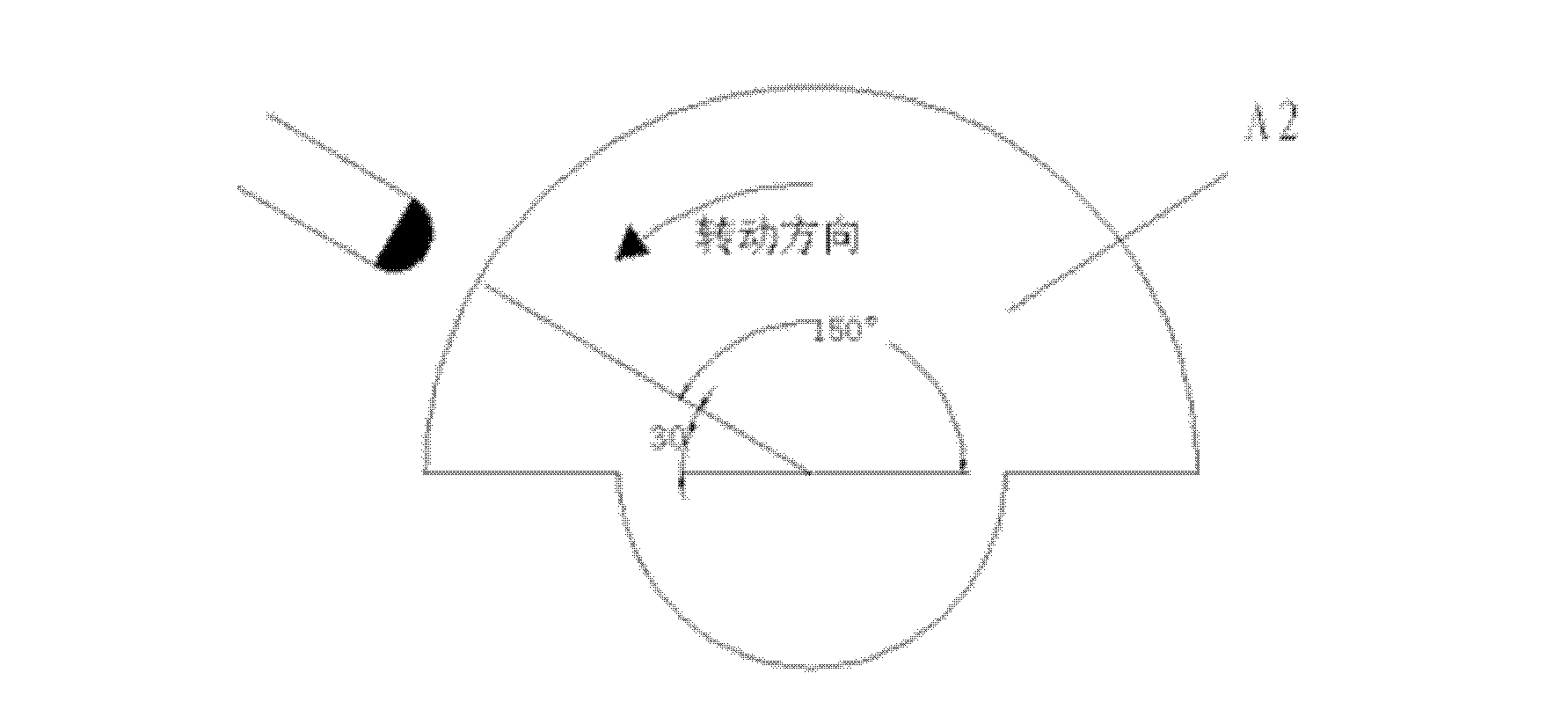

Special mechanical equipment for machining fan shaft sleeve

InactiveCN102363264ASolve processing efficiencySolve the machining accuracyPrecision positioning equipmentOther manufacturing equipments/toolsElectromagnetic clutchMechanical equipment

The invention discloses special mechanical equipment for machining a fan shaft sleeve. The mechanical equipment comprises a divider mechanism, a feeding mechanism, a drilling mechanism, a tapping mechanism, a plane milling mechanism, a chamfering and reaming mechanism, a discharge mechanism and a controller. The feeding mechanism, the drilling mechanism, the tapping mechanism, the plane milling mechanism, the chamfering and reaming mechanism and the discharge mechanism are uniformly distributed around the divider mechanism in included angles of 60 degrees; the divider mechanism consists of anindexing disc, a cam, a three-phase motor, an electromagnetic clutch, a reduction box and a high-speed precision intermittent divider; chamfering and reaming in the chamfering and reaming mechanism are implemented on the same station; and the controller is used for controlling the motion of each mechanism. By using the special mechanical equipment for machining the fan shaft sleeve, the production efficiency is greatly improved, the precision of a product is ensured, the defective rate is greatly reduced relative to other machining modes, and the requirement of industrial production is met.

Owner:SOUTH CHINA UNIV OF TECH +1

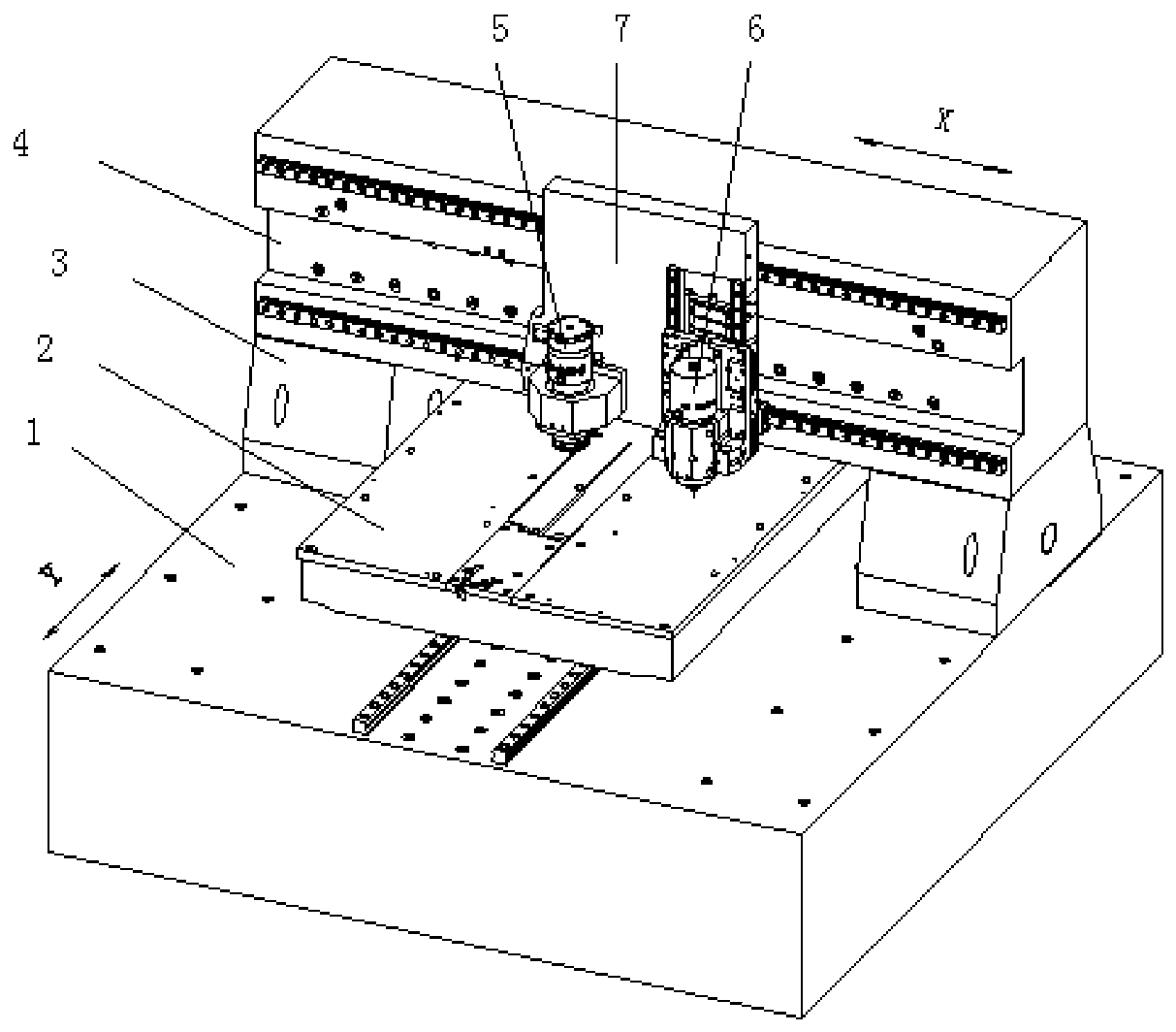

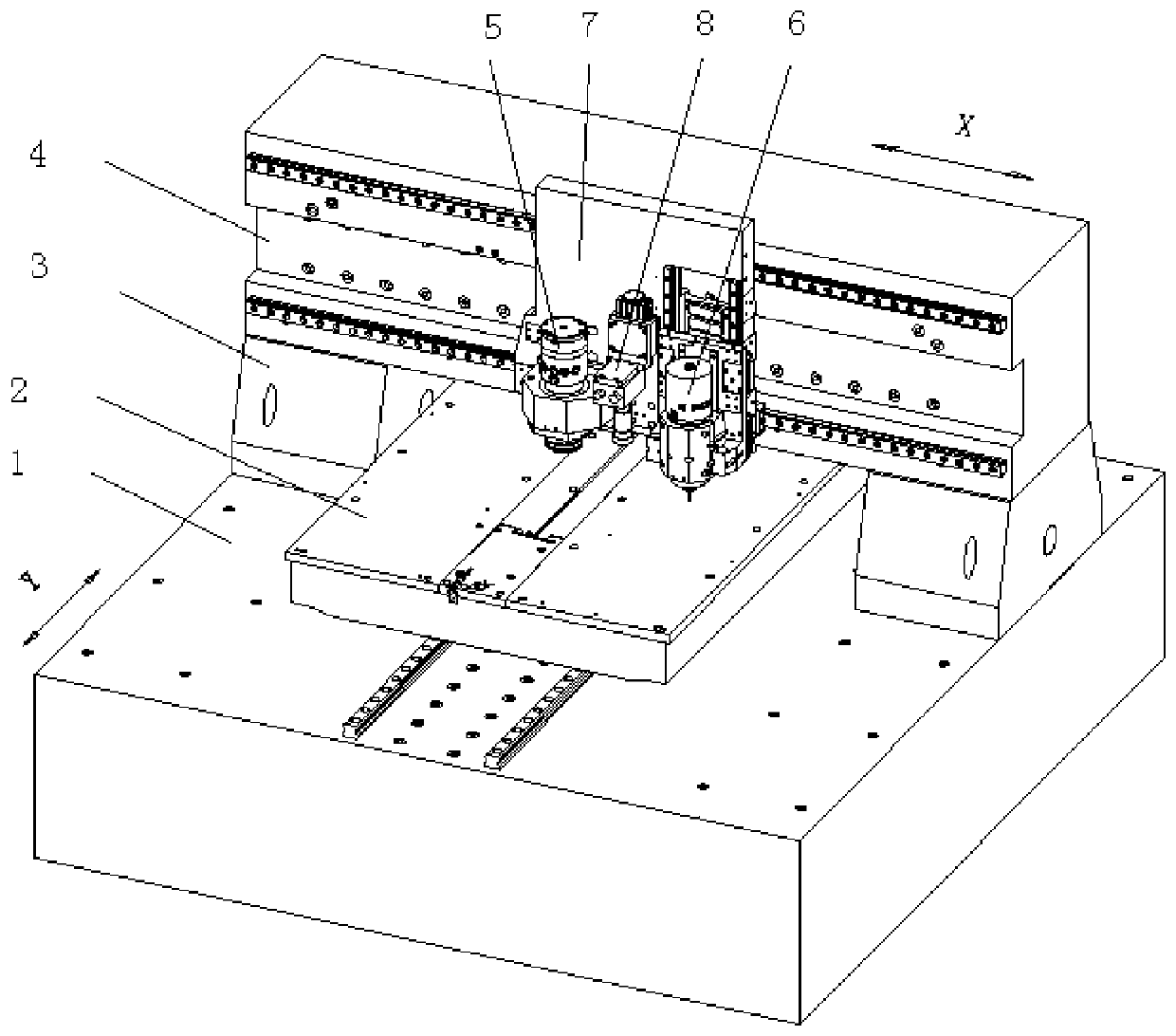

Turning integrated turning plate numerical control machining center

InactiveCN108857582ASolve the machining accuracySolve processing efficiencyFeeding apparatusDriving apparatusNumerical controlEngineering

The invention provides a turning integrated turning plate numerical control machining center composed of four-axis transmission mechanisms, a double-layer tool rest, a main shaft tool magazine and a lathe tool magazine. The four-axis transmission mechanisms include a Z axis responsible for lifting, an X axis, a Y axis, a rotation mechanism for rotating chucks and a rotating shaft of an automatic switching mechanism correspondingly, wherein the X axis and the Y axis are responsible for feeding and moving of the tool rest, and the rotating shaft is used when the turning integrated turning platenumerical control machining center is used for turning. The double-layer tool rest mechanism comprises a main shaft feeding mechanism on the upper layer and the tool automatic switching mechanism on the lower layer. The main shaft tool magazine mainly conducts automatic tool changing for the main shaft feeding mechanism on the upper layer. The lathe tool magazine mainly conducts automatic tool switching for the tool automatic switching mechanism on the lower layer during rotating turning. The chucks are fixedly connected with the rotation mechanism. The rotation mechanism is fixedly connectedwith a lifting mechanism. By means of rotating and lifting, the workpiece position of the turning integrated turning plate numerical control machining center is adjusted through numerical control, andthe cutting requirement of full-function numerical control machining is met through cooperation with an X-axis and Y-axis feeding mechanism, the tool automatic switching mechanism and the tool magazine mechanism; and the turning integrated turning plate numerical control machining center can be widely used for various types of machining occasions.

Owner:湖南鈊耐自动工装系统发展有限公司

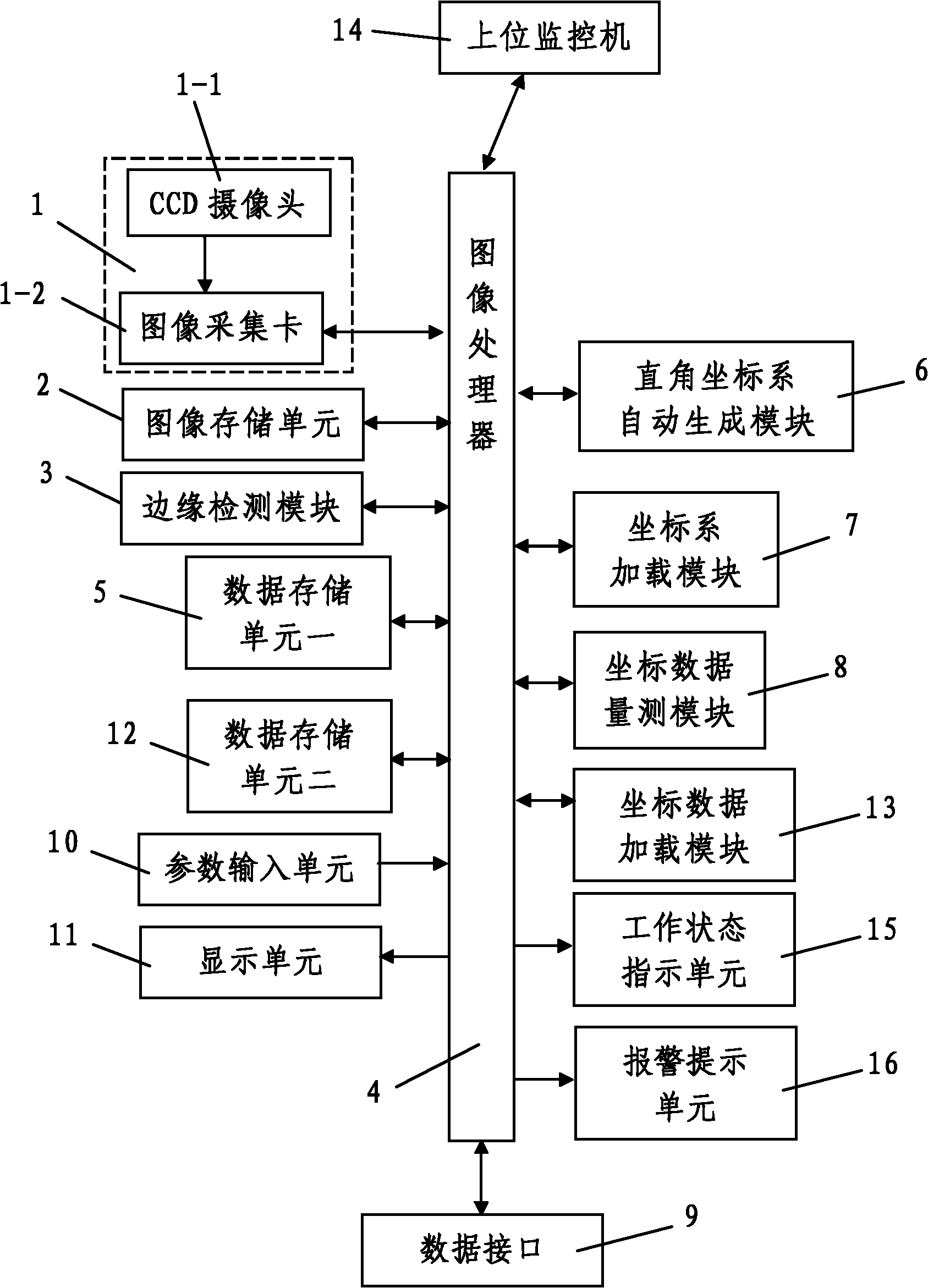

Automatic generation system of numerical control machine tool working diagram

InactiveCN103163835AReasonable designLow costProgramme controlComputer controlNumerical controlData synchronization

The invention discloses an automatic generation system of a numerical control machine tool working diagram. The automatic generation system of the numerical control machine tool working diagram comprises an image capture device, an image storage unit, an edge detection module, an image processor, a first data storage unit, a rectangular coordinate system automatic generation module, a coordinate system loading module, a coordinate data measurement module, a second data storage unit, a coordinate data loading module, a data interface, a parameter input unit and a display unit, wherein the image capture device is used for shooting molding product images, the edge detection module detects edges of the molding product images, the image processor extracts contour lines of molding products according to detection results of the edge detection module, the coordinate system loading module is used for loading measured coordinate data to the contour lines of the molding products synchronously, and the data interface, the parameter input unit and the display unit are respectively connected with the image processor. The automatic generation system of the numerical control machine tool working diagram is reasonable in design, simple and convenient to use and operate, good in using effects, high in intelligent degree and good in production processing images, can generate working diagrams for the numerical control machine tool automatically and quickly, and man-made design error does not exist.

Owner:XIAN KUOLI MACHANICAL & ELECTRICAL TECH

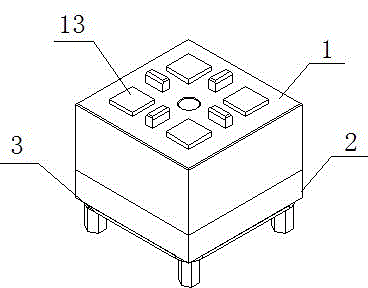

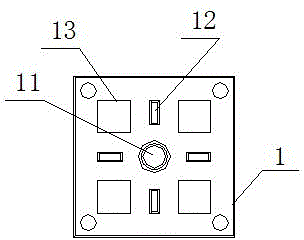

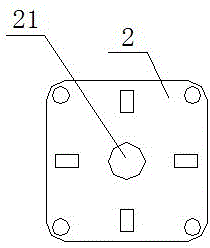

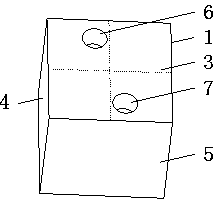

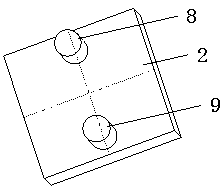

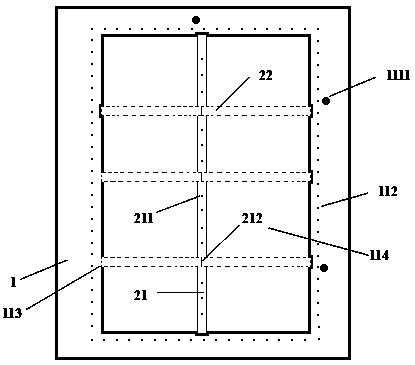

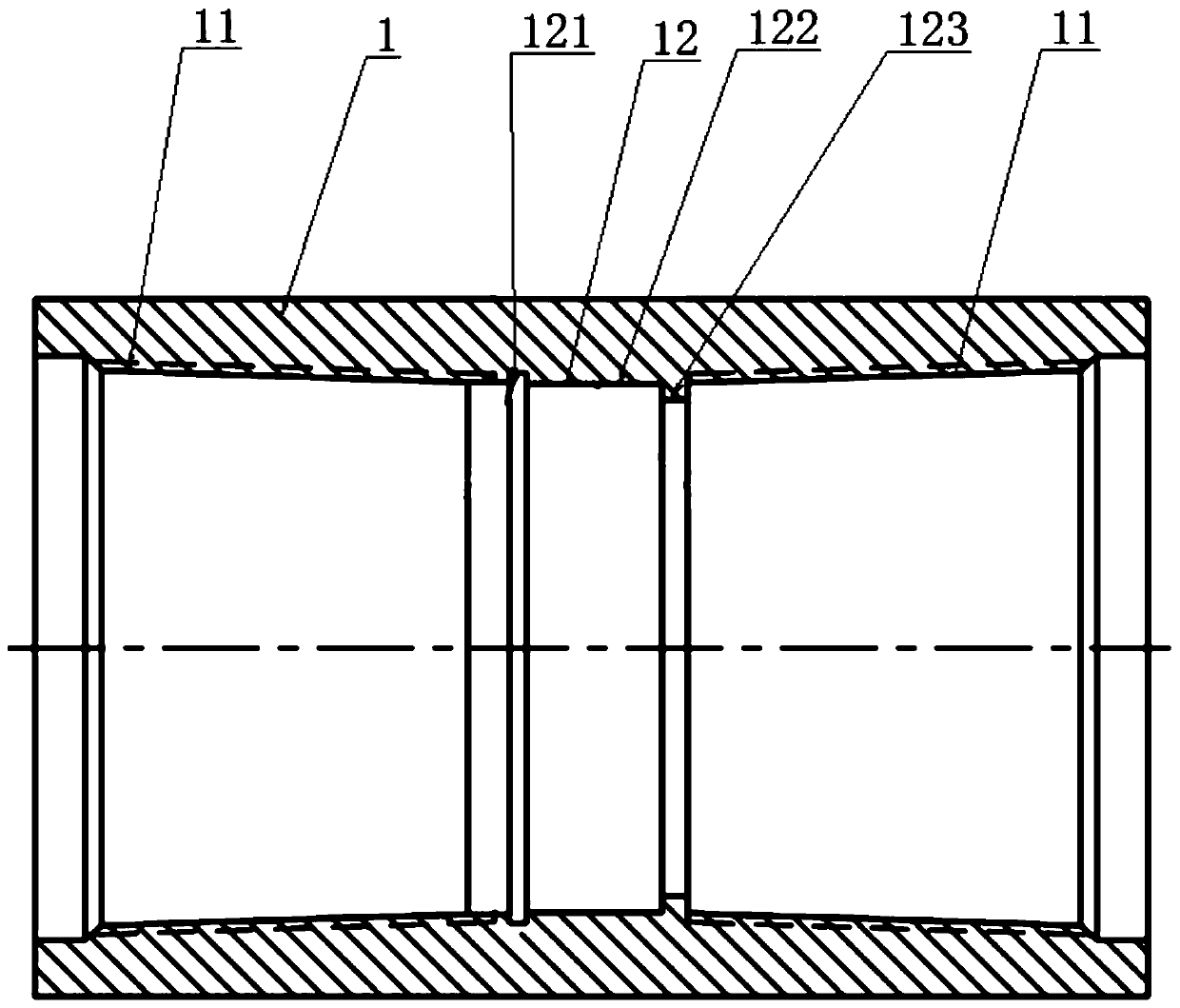

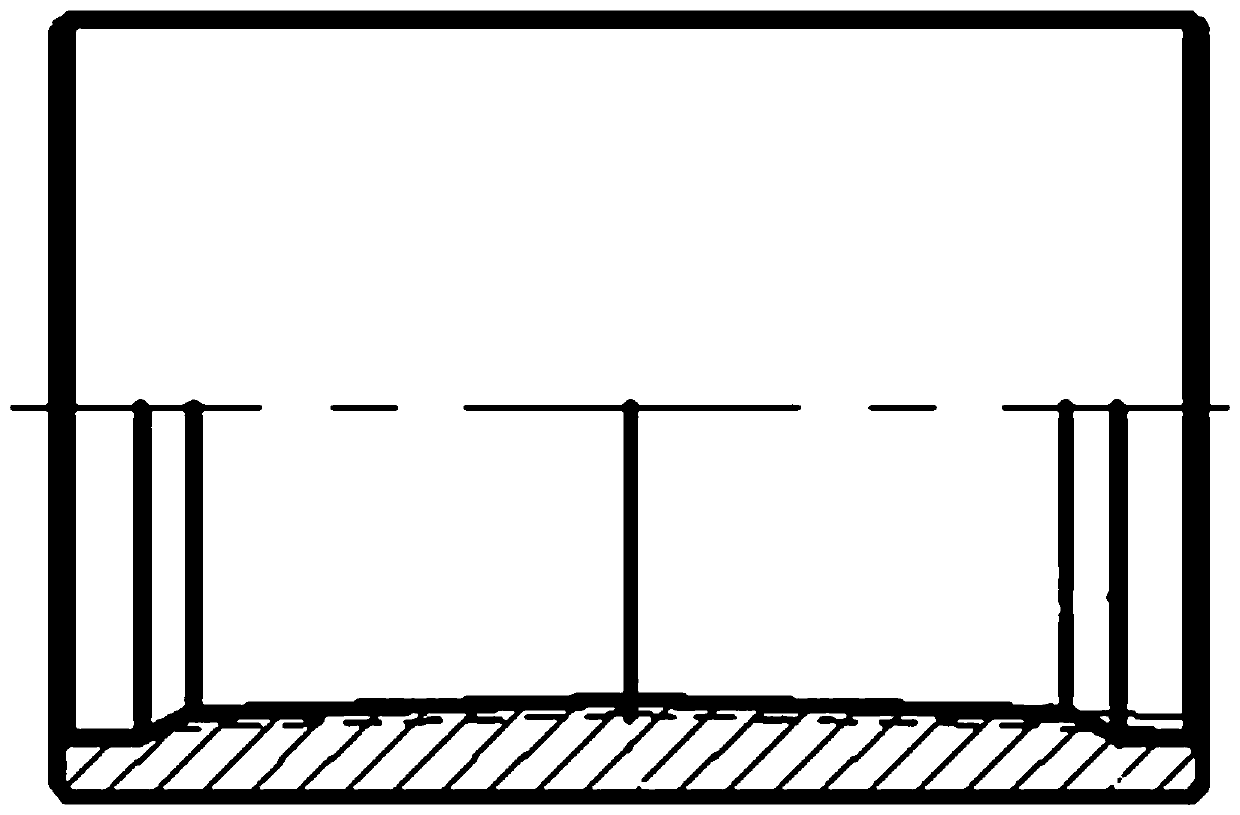

Fixing device for electrode batch processing

InactiveCN103331627AReduce processing costsSolve the machining accuracyPositioning apparatusMetal-working holdersBatch processingEngineering

The invention relates to a fixing device for electrode batch processing. The fixing device for electrode batch processing comprises a jig plate, a base plate and locating blocks, wherein the base plate is fixed on the lower portion of the jig plate through a screw, the locating blocks are fixed on the lower portion of the base plate through screws, a screw hole is formed in the center of the jig plate, two sets of rectangular bosses are symmetrically distributed on the periphery of the screw hole, two sets of square bosses are symmetrically distributed among the rectangular bosses, and a screw through hole is formed in the center of the base plate. A step is formed on the surface, opposite to the inner side of one rectangular boss, of the inner side of one square boss. The fixing device for electrode batch processing has the advantages of being ingenious in design, stable in work, simple in structure, convenient to process, easy to assemble and disassemble, and capable of reducing the processing cost of a die, solving the problems of the processing precision of electrodes and the processing speed of the electrodes fundamentally and ensuring that the tolerance precision is below 0.005mm.

Owner:TIANJIN ZHONGHUAN SANFENG ELECTRONICS

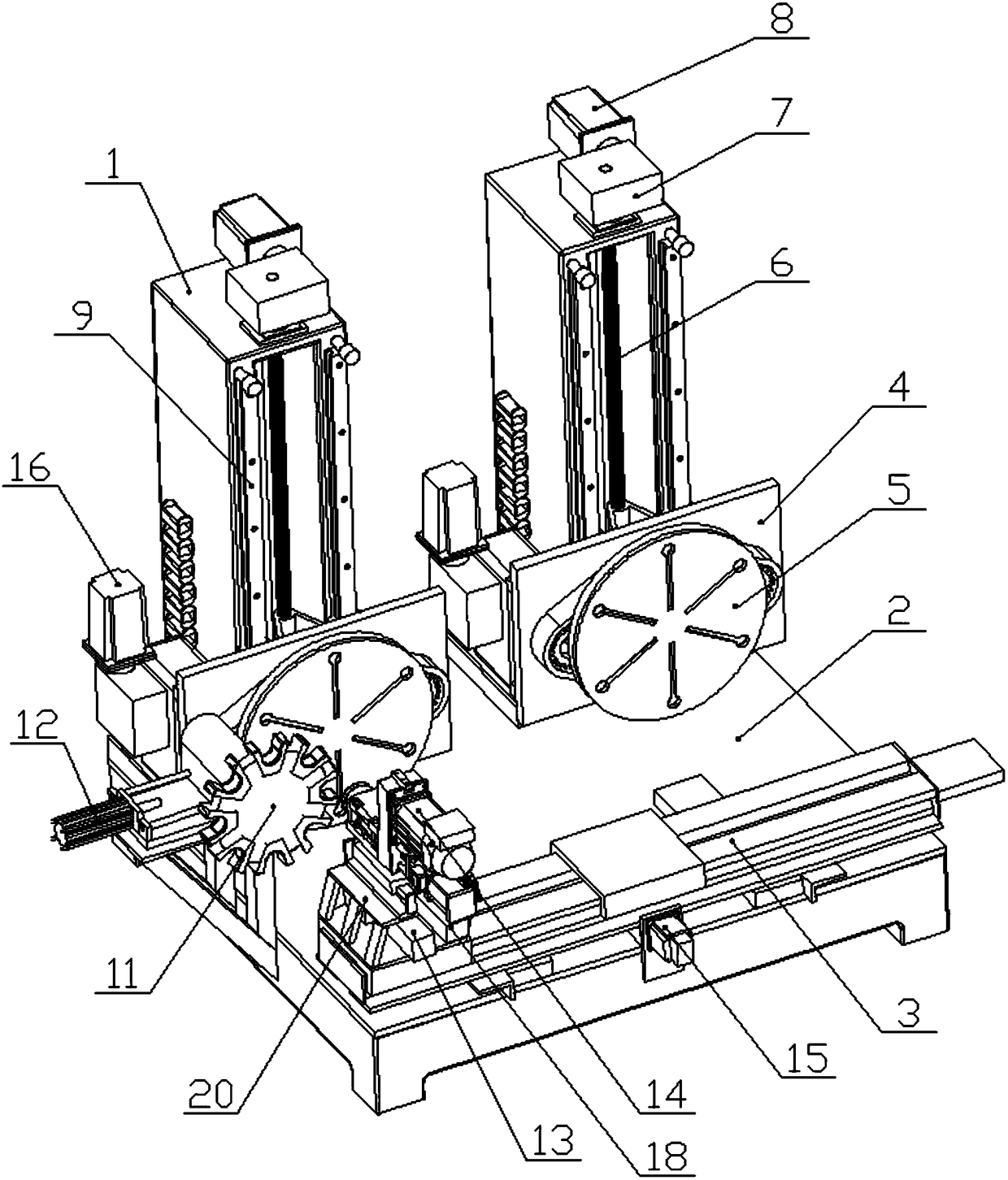

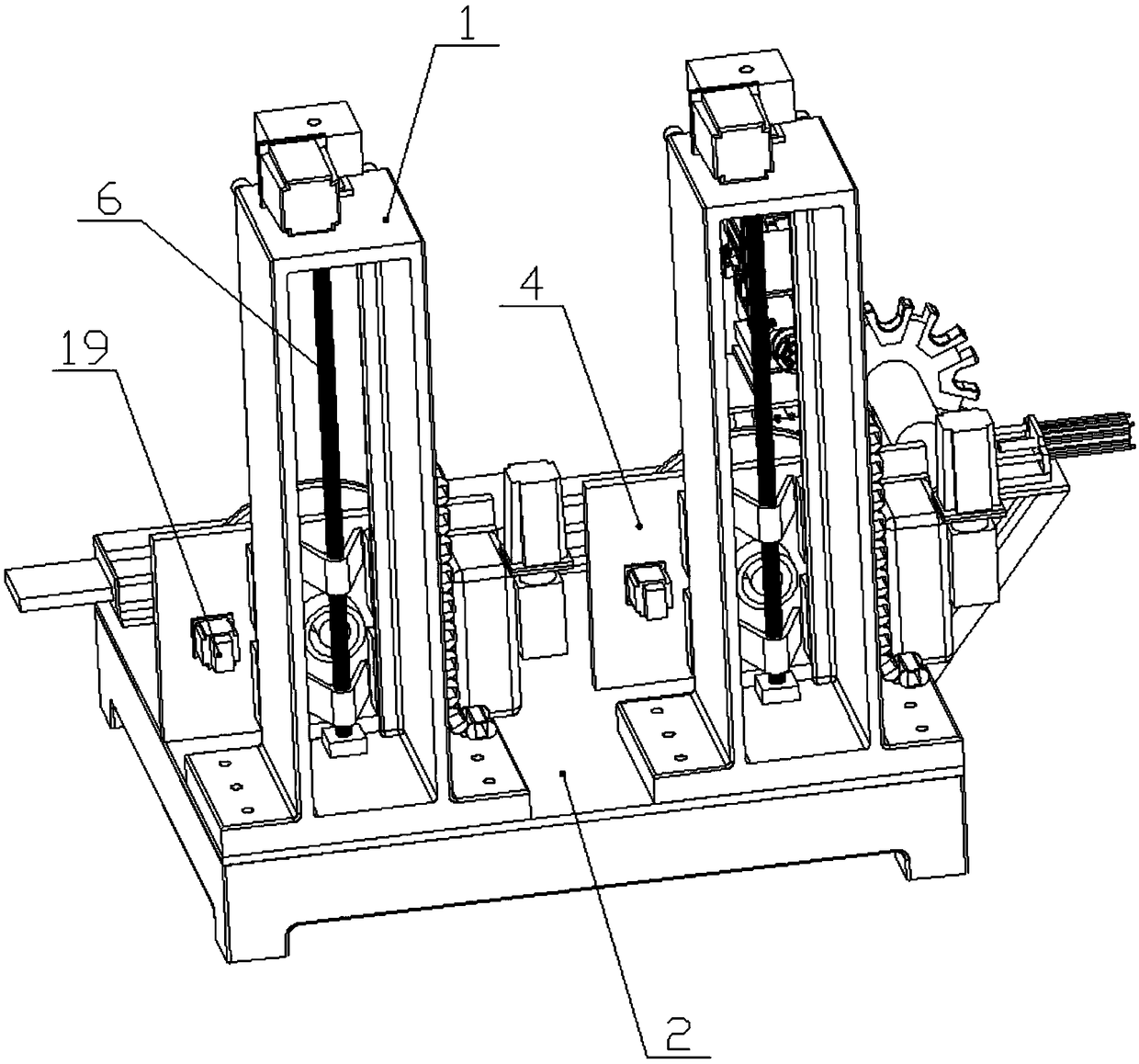

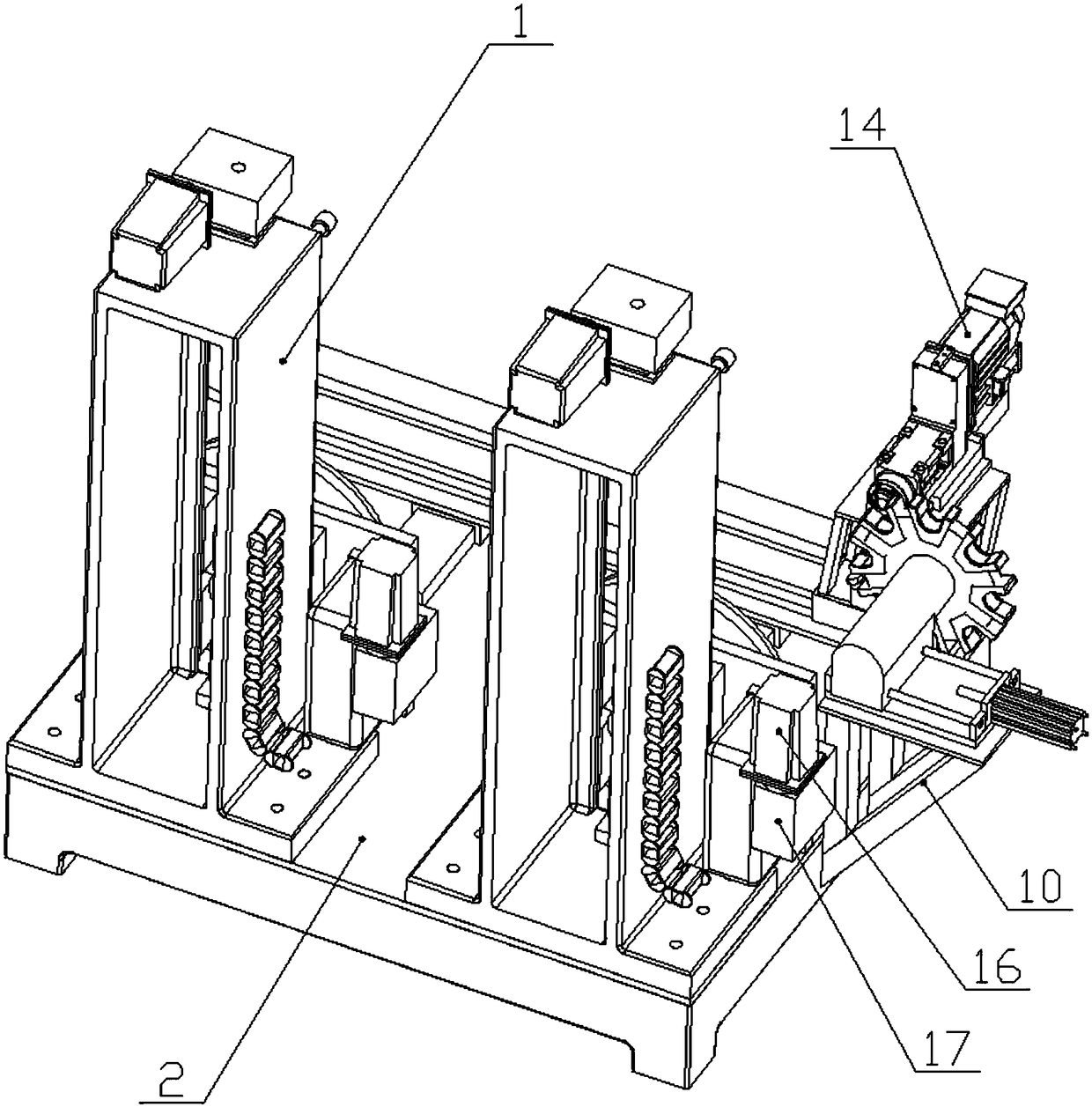

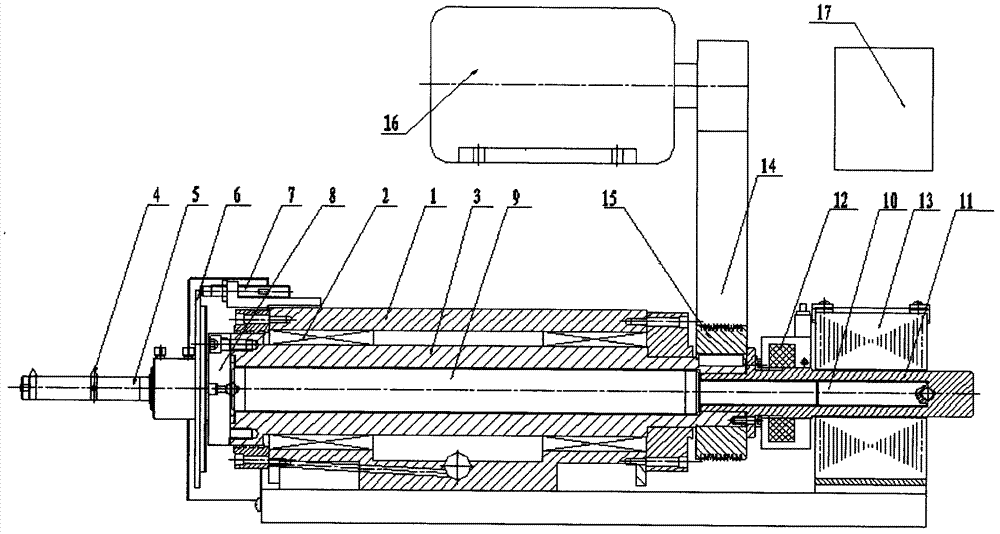

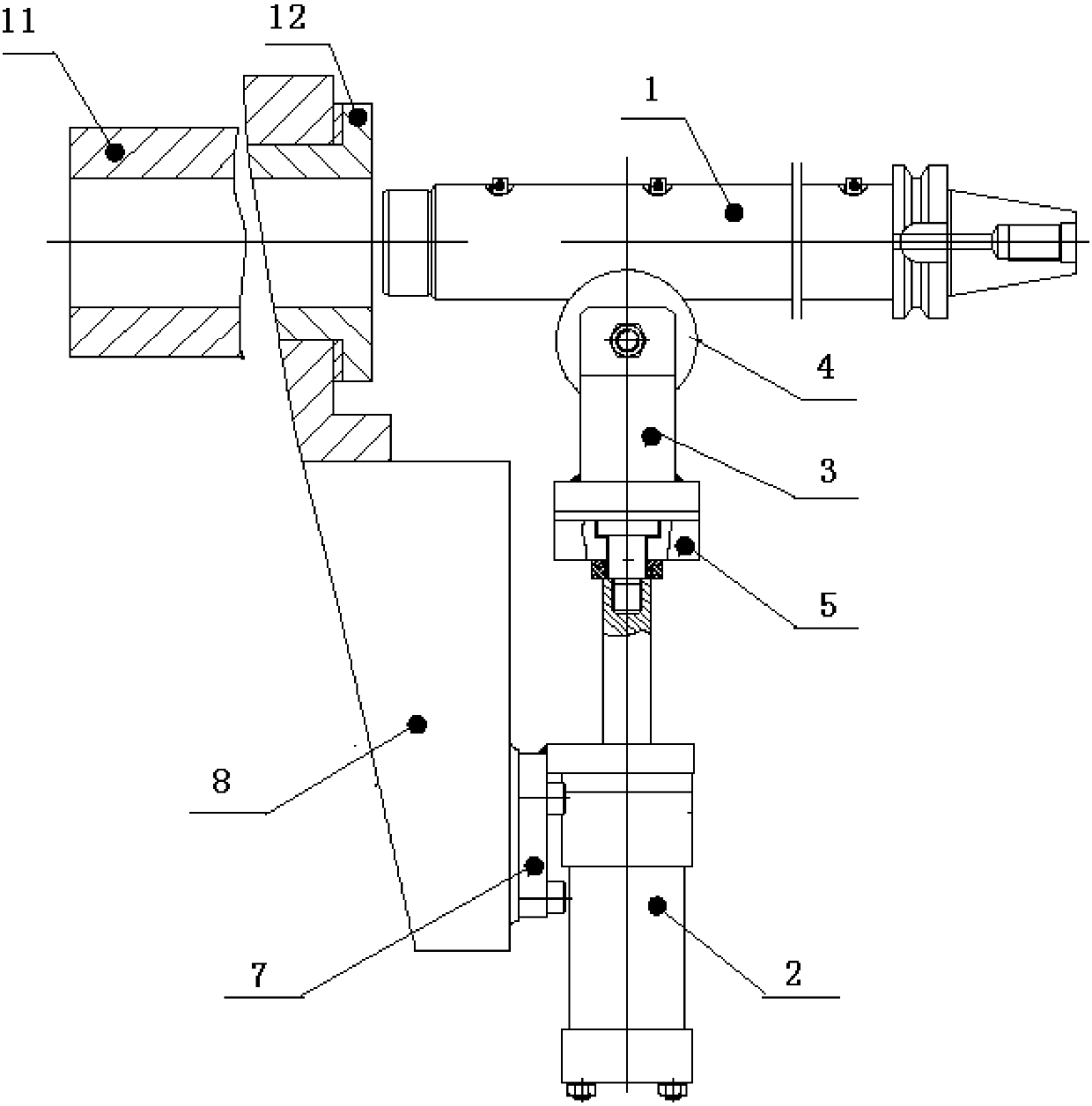

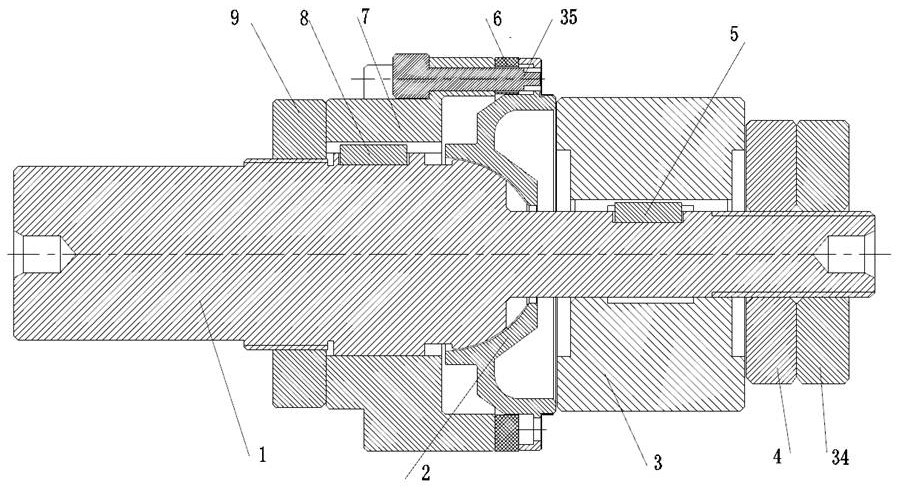

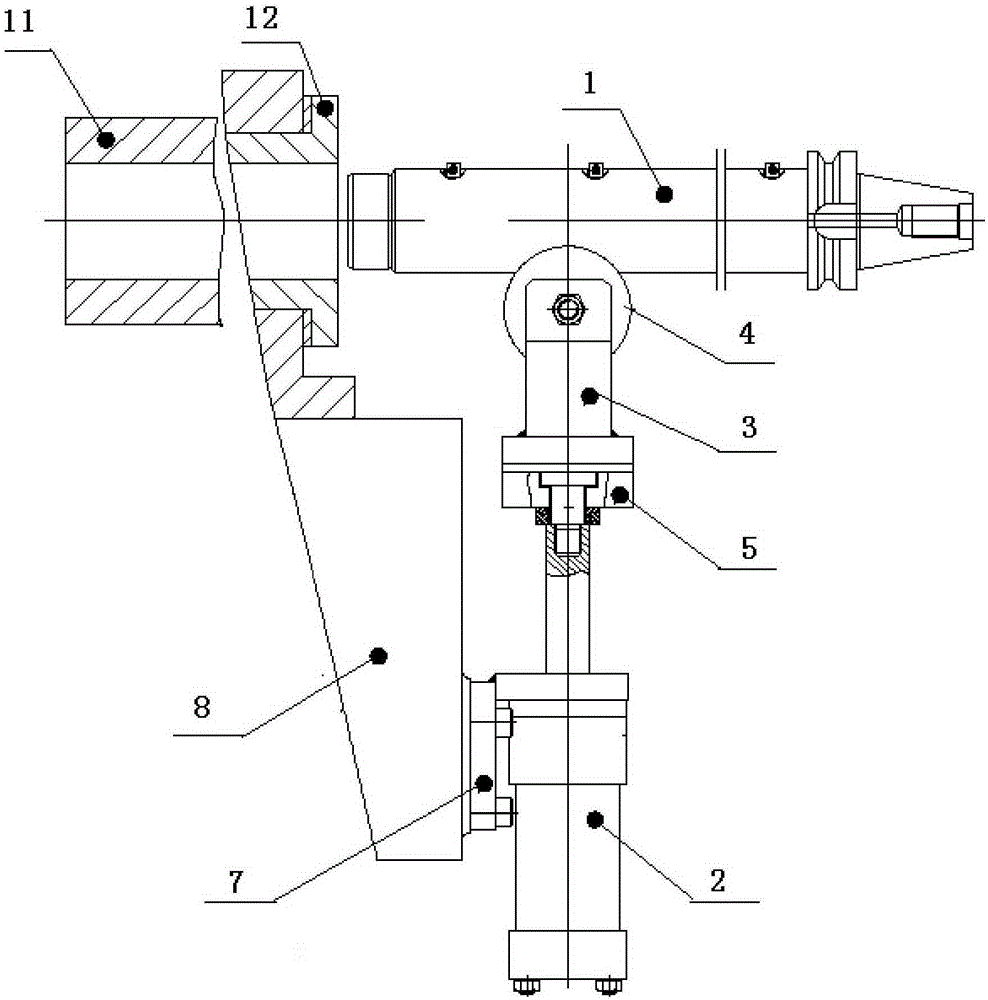

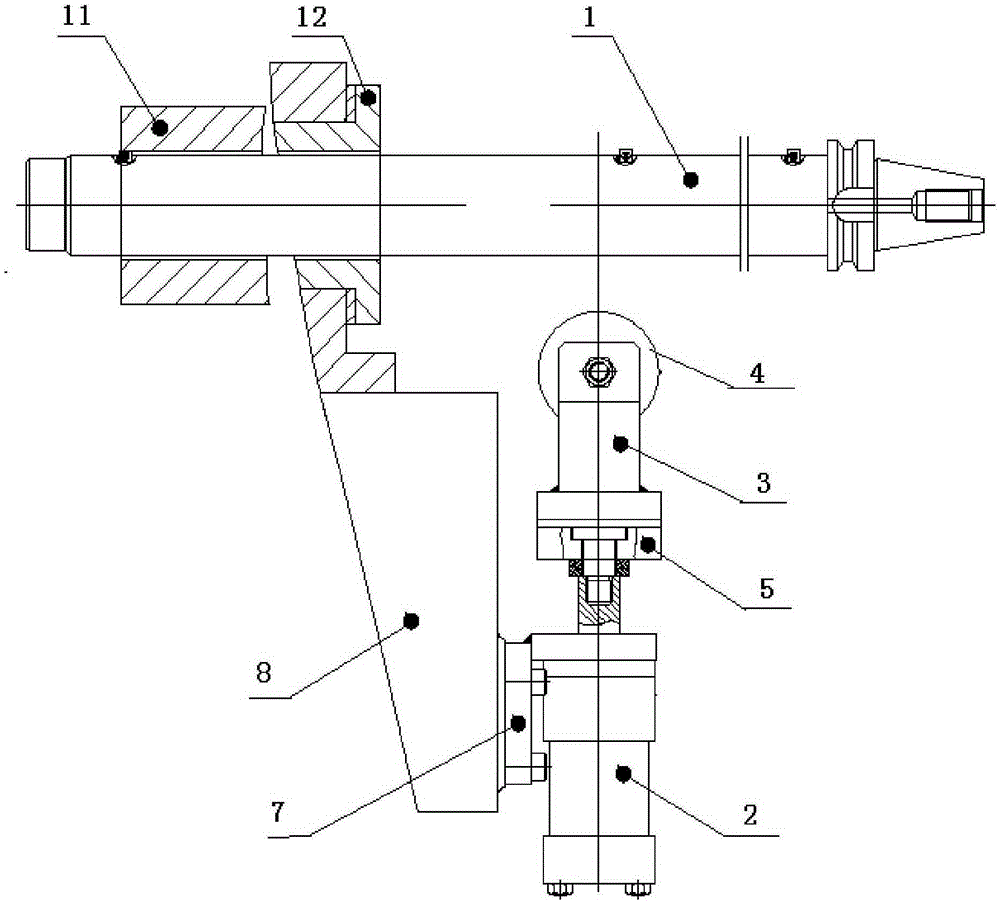

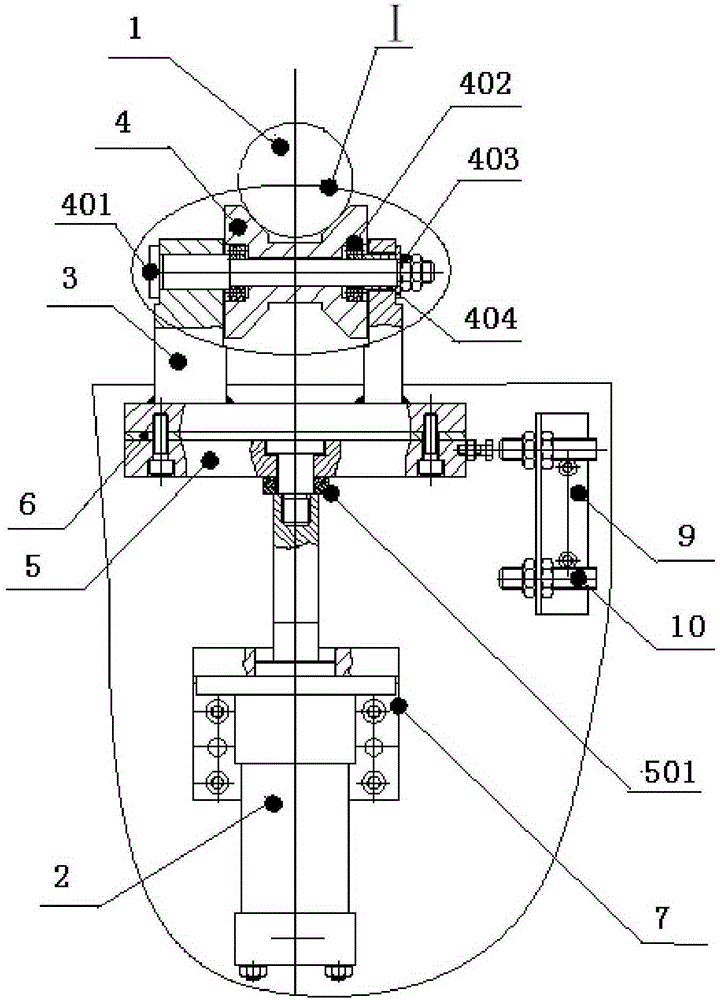

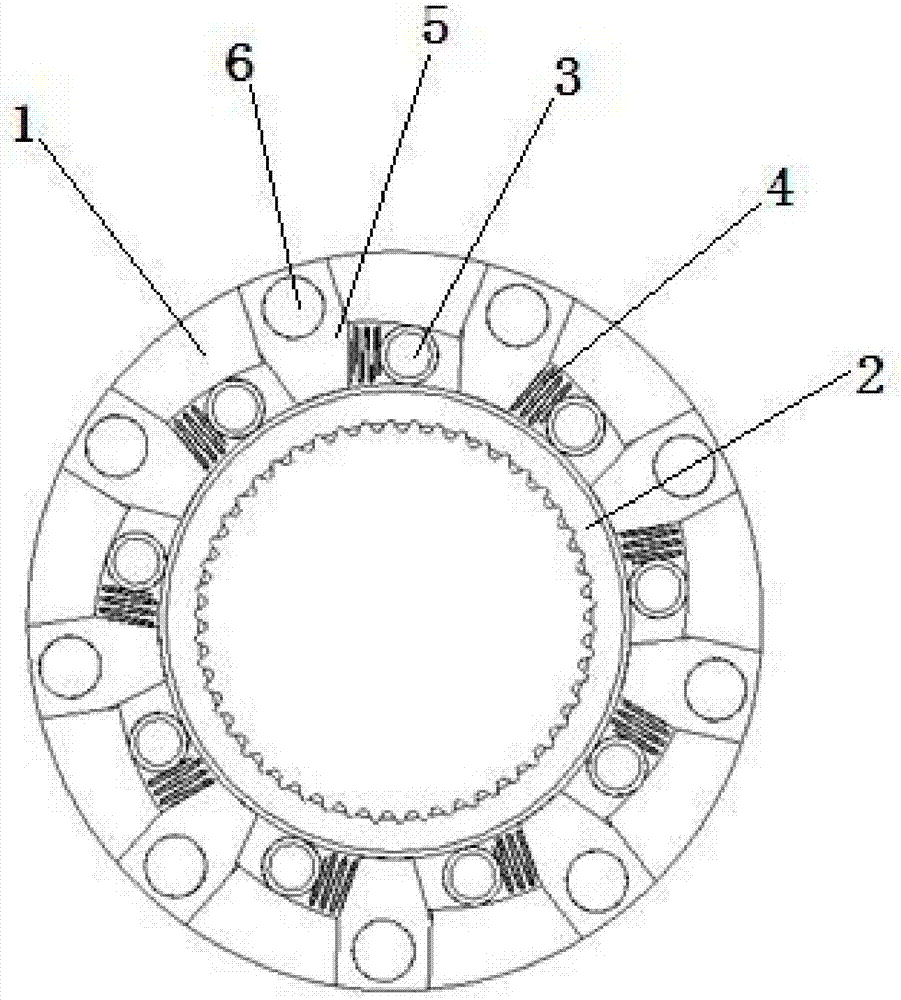

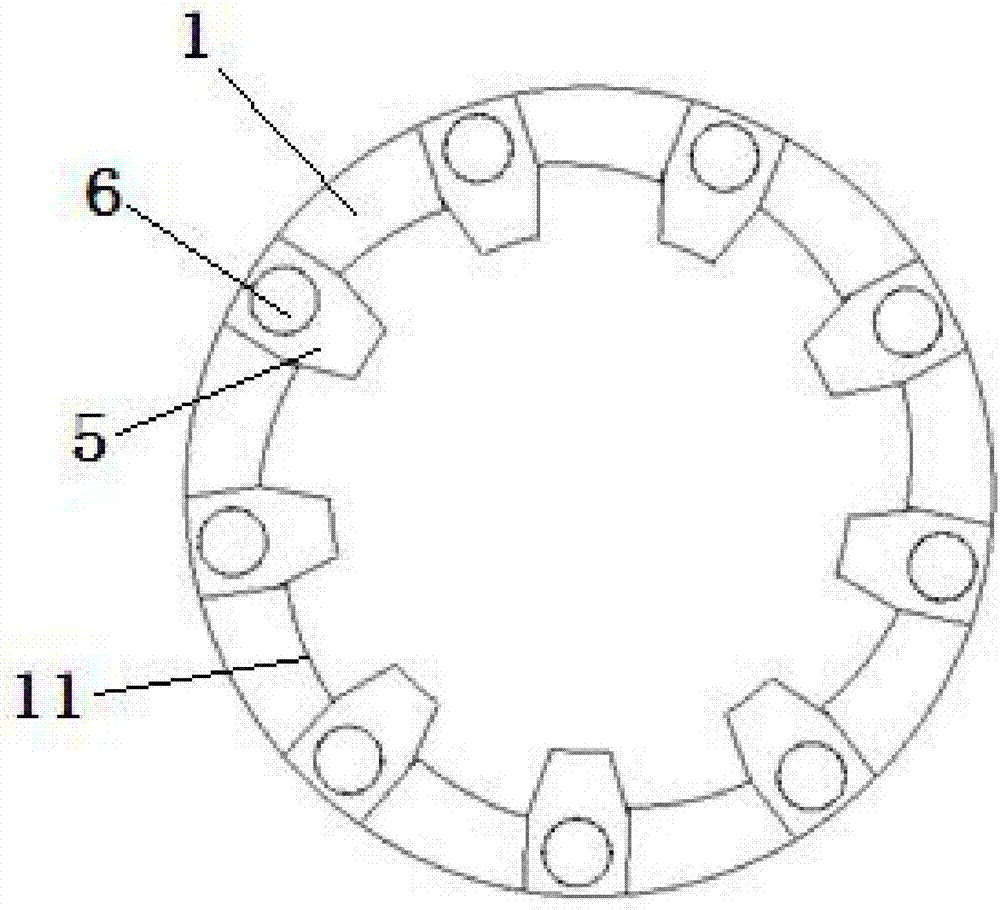

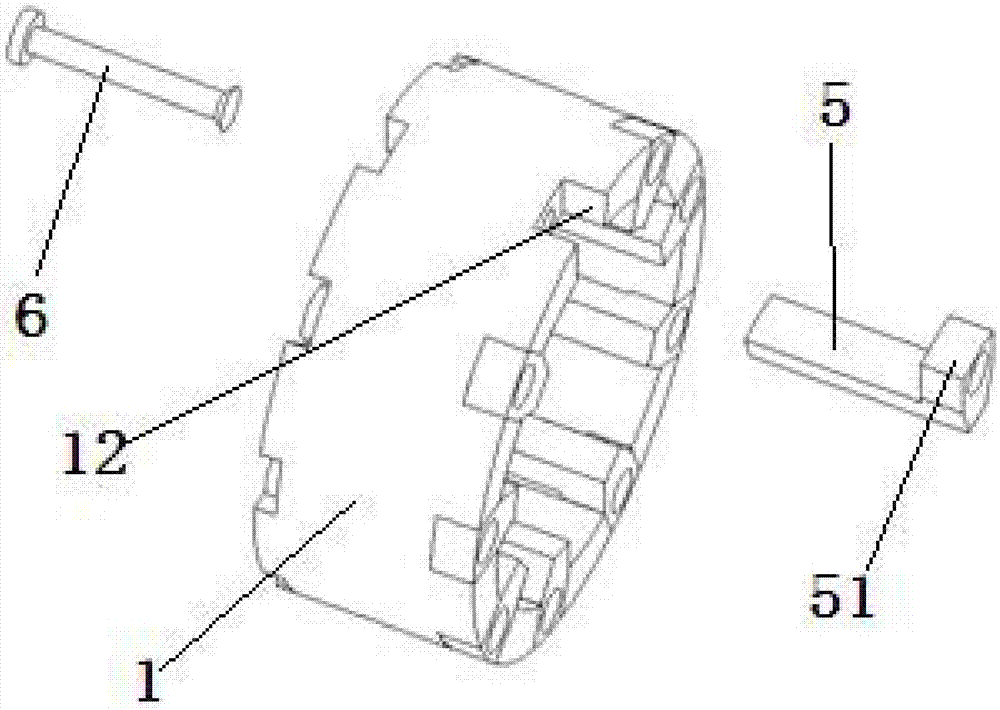

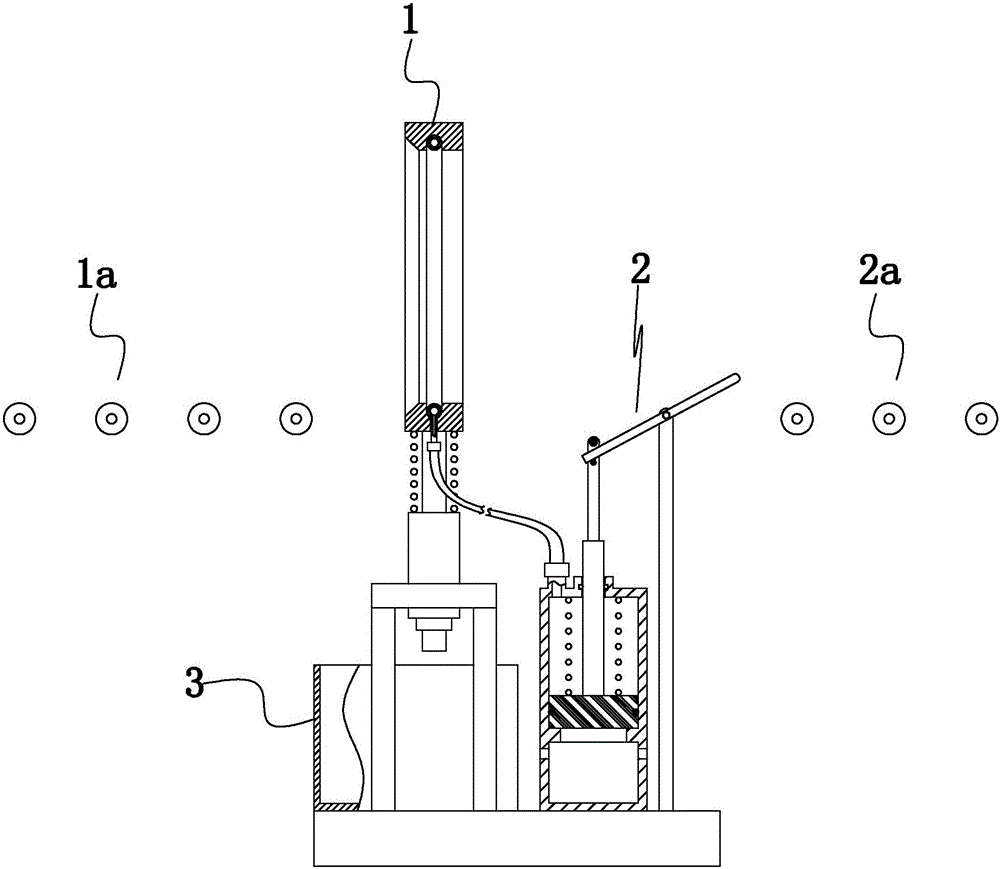

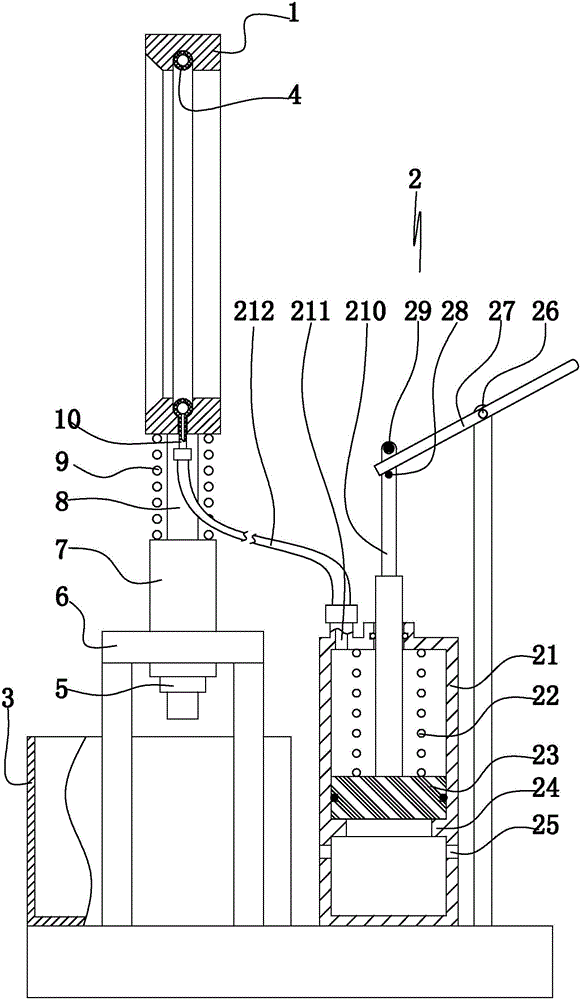

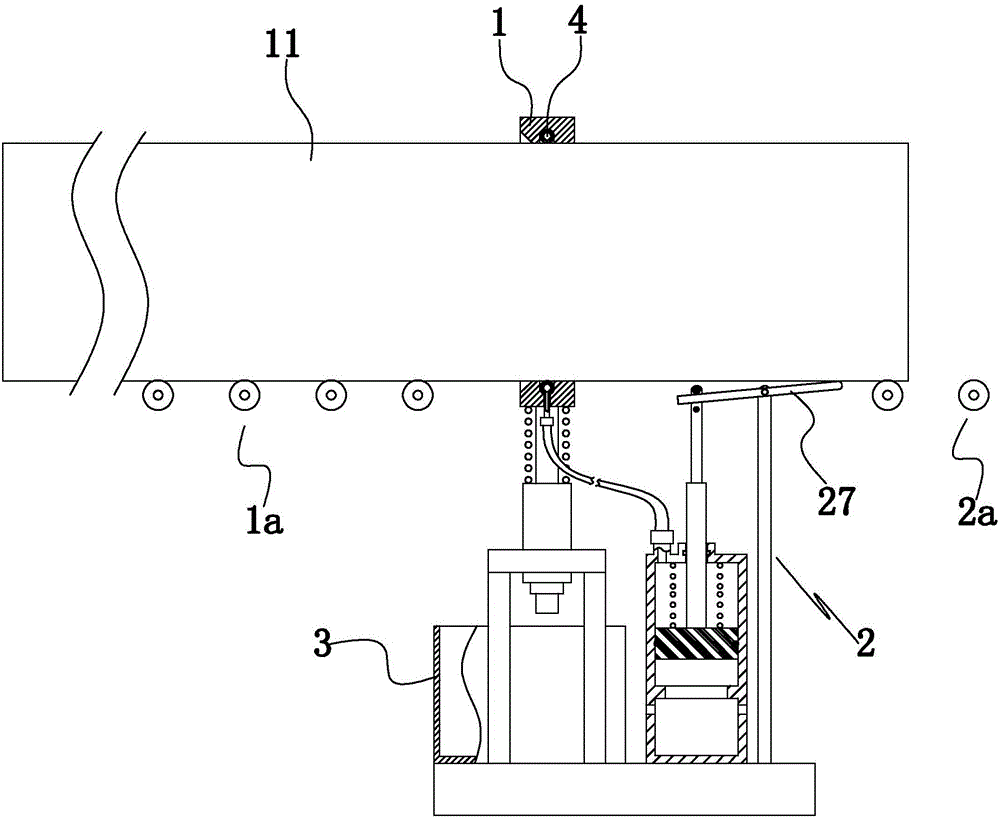

Boring head for boring non-circular holes

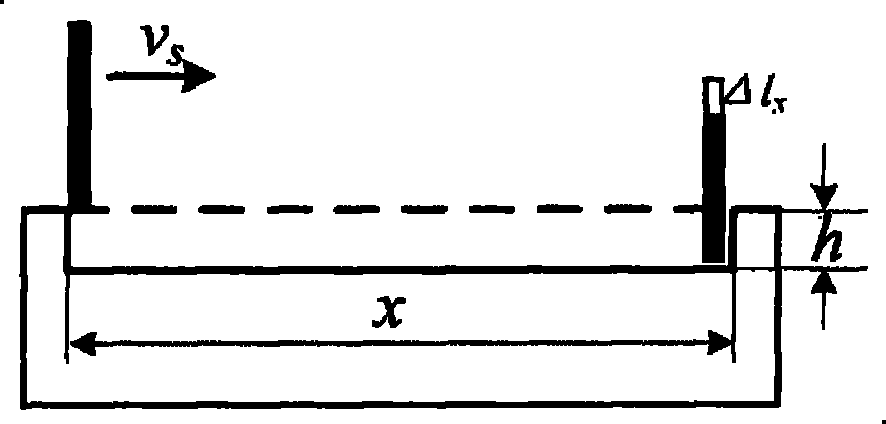

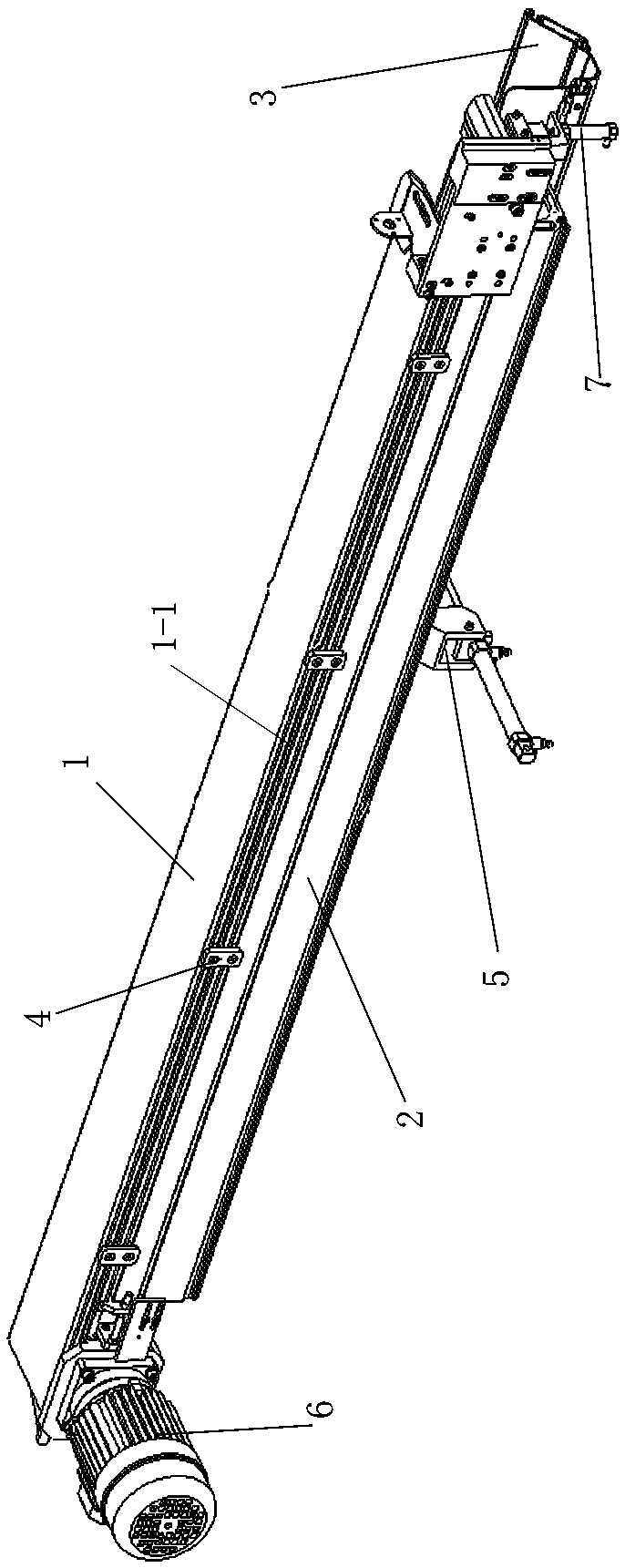

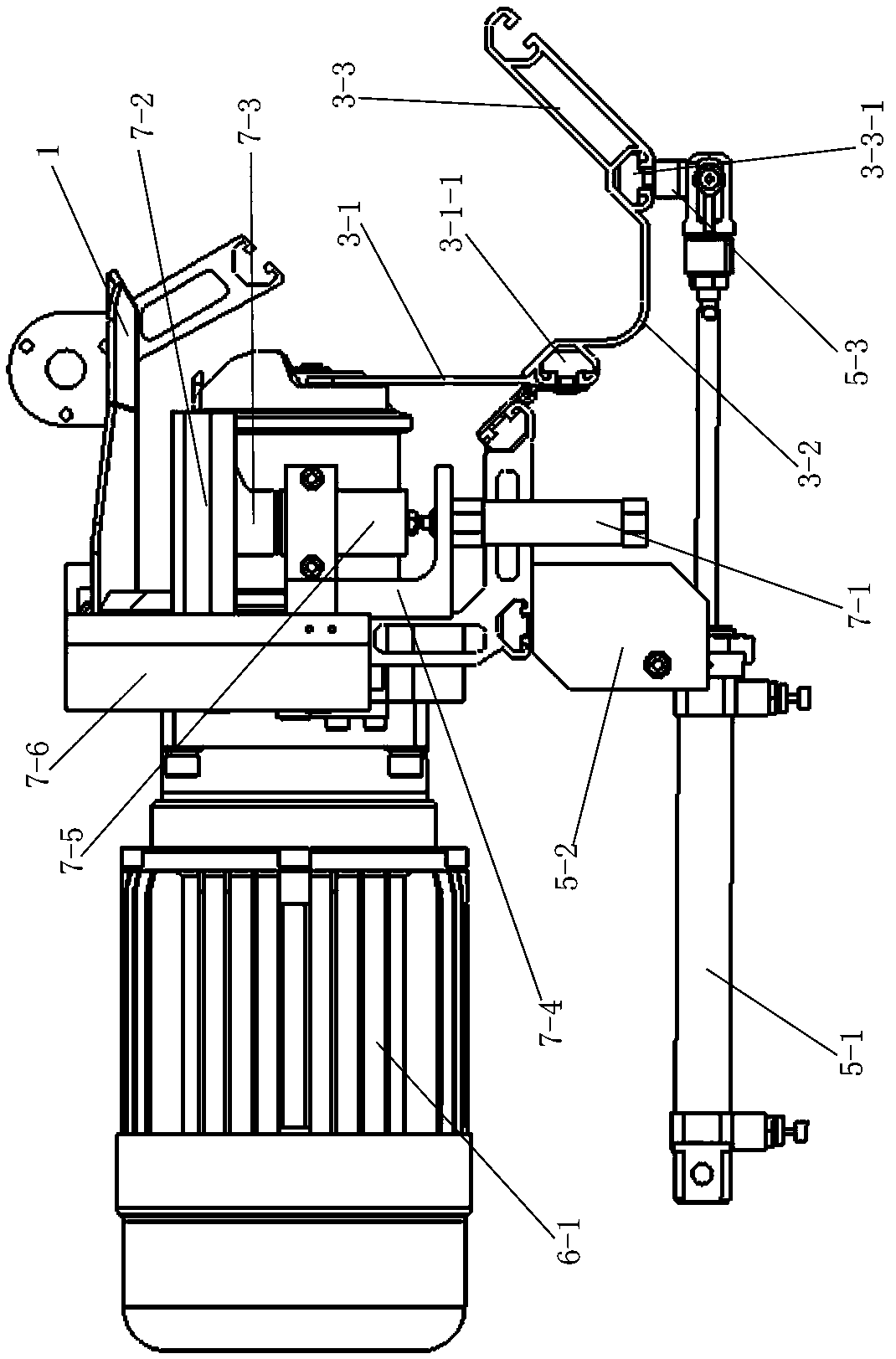

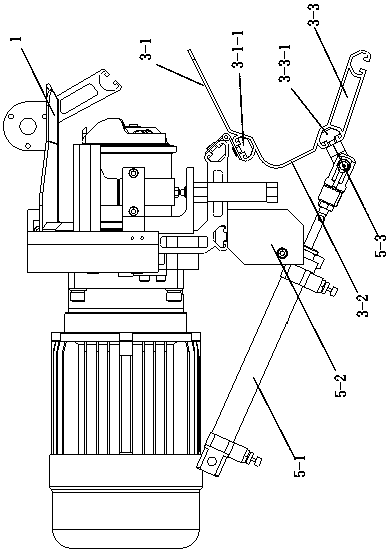

InactiveCN102814516ASolve the machining accuracySolve processing efficiencyBoring headsBoring/drilling machinesRotary encoderRadial position

A boring head for boring non-circular holes mainly comprises a casing (1), a boring head bearing (2), a hollow shaft (3), a boring tool (4), a boring bar (5), a displacement measuring panel (6), a displacement sensor (7), a spring plate (8), a transitional bar (9), a magnetostrictive rod (10), a non-magnetic material tube (11), a rotary encoder (12), a coil (13), a belt (14), a belt pulley (15), a spindle motor (16), a driver (17) and the like. The driver (17) controls magnitude of field current in the coil (13) to drive the magnetostrictive rod (10) to constrict, and elastic deformation of the spring (8) is changed by the aid of the transitional bar (9), so that the radial position of the boring tool (4) is changed, and the non-circular holes can be bored accurately according to feedbacks of the displacement sensor (7) and the rotary encoder (12).

Owner:周众

Five-axis NC machine tool calibration device and operation method

InactiveCN110340730APrecise processingSolve the machining accuracyMeasurement/indication equipmentsLarge fixed membersLinear motionNumerical control

The invention discloses a five-axis NC machine tool calibration device and an operation method. The five-axis NC machine tool calibration device comprises a first calibration block and a second calibration block. The surfaces of the first calibration block are provided with a first calibration surface, a second calibration surface and a third calibration surface; the first calibration surface of the first calibration block is provided with a first round hole and a second round hole. The surface of the second calibration block is provided with a second locating pin and a second locating pin. The second calibration block, the first locating pin and the second locating pin are integrally designed. The five-axis NC machine tool calibration device conducts calibration on the zero point of a linear motion axis in the X-axis direction through the first calibration block and the second calibration block, conducts calibration on the zero point in the Y-axis direction and the zero point in the Z-axis direction through the same method and conducts calibration on the zero point of the rotation axis. Through accurate calibration, an NC machine tool can conduct machining more accurately. The problem that an existing machine tool calibration technology is not enough accurate in calibration and the machining precision of the NC machine tool is affected is solved.

Owner:SHANDONG POLYTECHNIC

Supporting mechanism for machine tool cutter

ActiveCN102990410ASolve the machining accuracyAvoid deformationPositioning apparatusMetal-working holdersHorizontal axisEngineering

The invention discloses a supporting mechanism for a machine tool cutter and relates to the field of machine tool machining. The supporting mechanism comprises a movable base and a supporting part, wherein the movable base is arranged on the bottom side of the cutter and makes flexible motion towards the cutter, and the supporting part is arranged on the movable base; and particularly in the period of reloading a workpiece or in the machine tool stopping period and the cutter returns to a normal position in the machining process, the movable base is extended out to reach the highest position, the cutter is supported on a horizontal axis by the supporting part, and thus the problem that the machining accuracy of the cutter is affected due to the deflection deformation caused by the long-time suspension of the cutter is avoided.

Owner:HANGZHOU BRANCH ZHEJIANG GEELY AUTOMOBILE RES INST +2

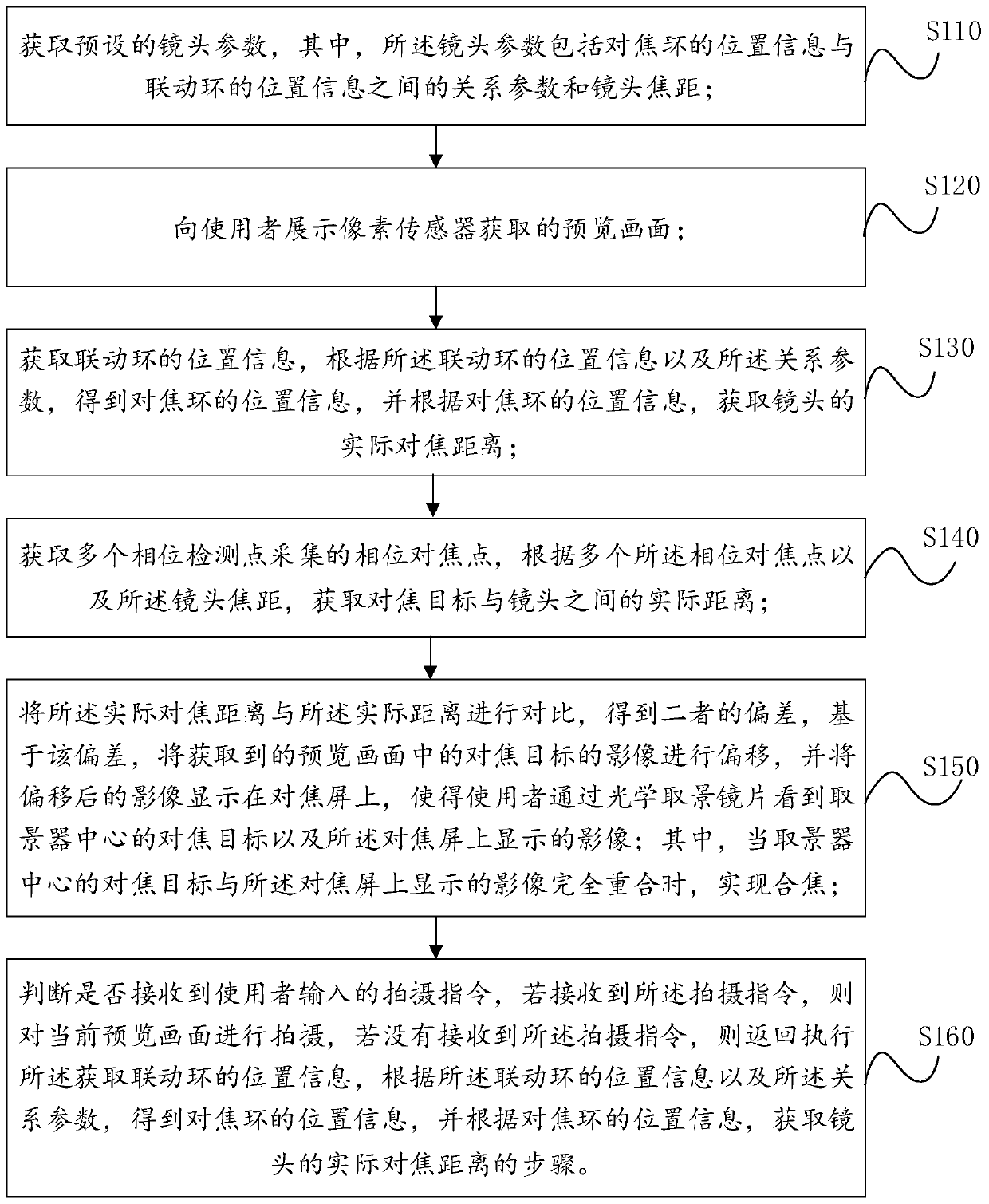

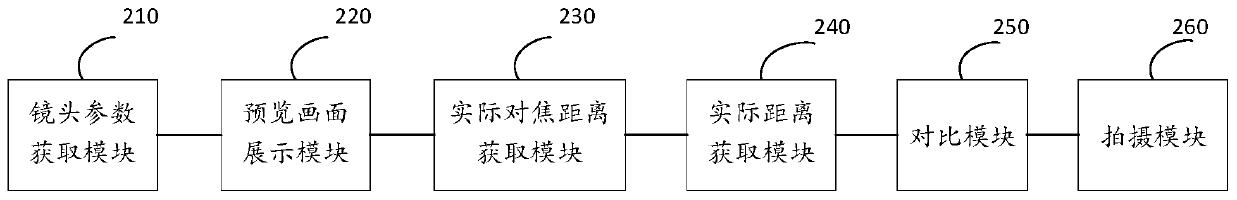

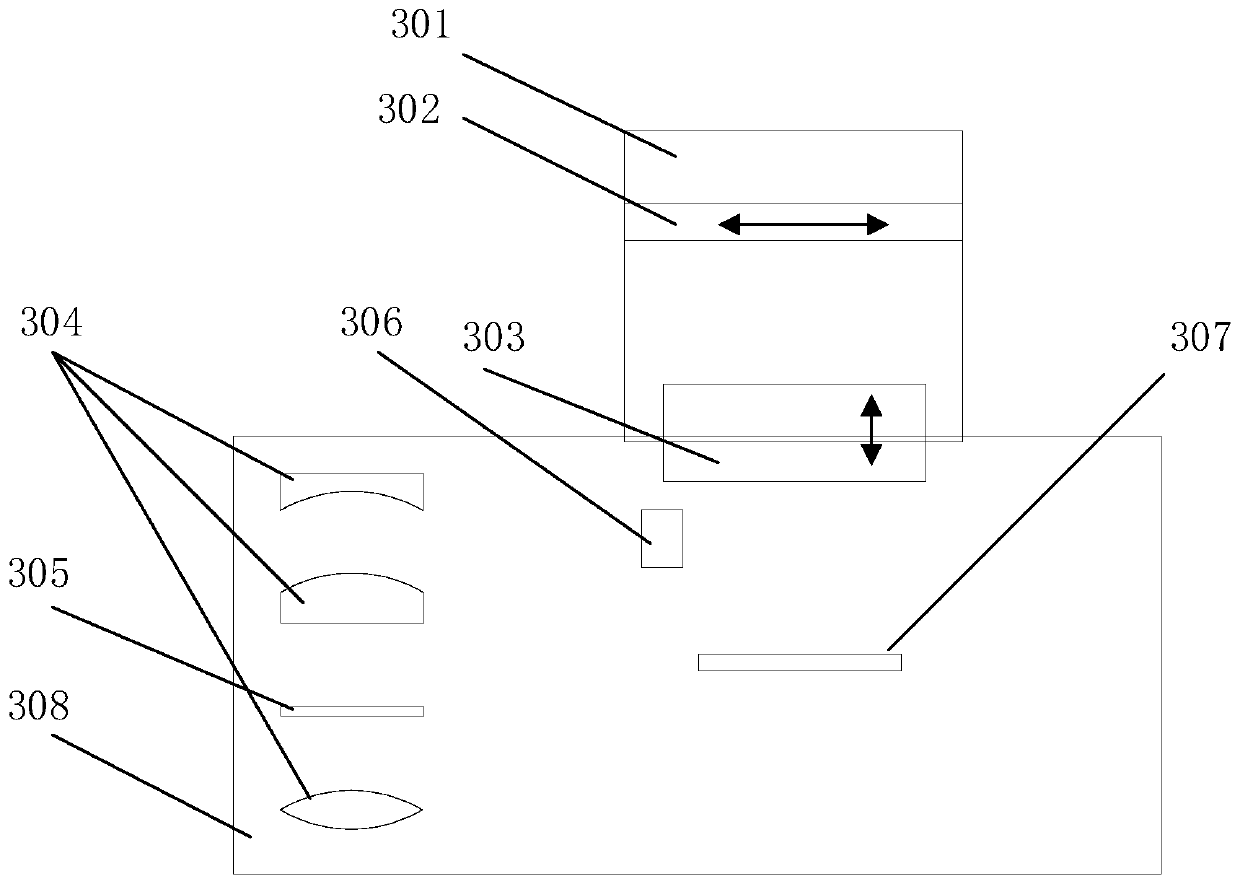

Manual focusing shooting method and device of exchangeable lens paraxial camera

ActiveCN111263059AEasy to operateResolve mismatchTelevision system detailsColor television detailsOphthalmologyComputer science

The embodiment of the invention discloses a manual focusing shooting method and device of an exchangeable lens paraxial camera. The method comprises the steps of acquiring preset lens parameters; displaying a preview image acquired by a pixel sensor to a user; obtaining the actual focusing distance of the lens according to the position information of a linkage ring and the lens parameters; obtaining the actual distance between a focusing target and the lens according to the phase focusing point and the lens focal length; according to the deviation between the actual focusing distance and the actual distance, deviating the image of the focusing target in a preview image and displaying on a focusing screen; judging whether a shooting instruction is received or not ; if the shooting instruction is received, shooting the current preview image ; and if the shooting instruction is not received, executing the step of obtaining the actual focusing distance of the lens according to the positioninformation of the linkage ring and the lens parameters again.

Owner:SHANGHAI SEAGULL DIGITAL CAMERA

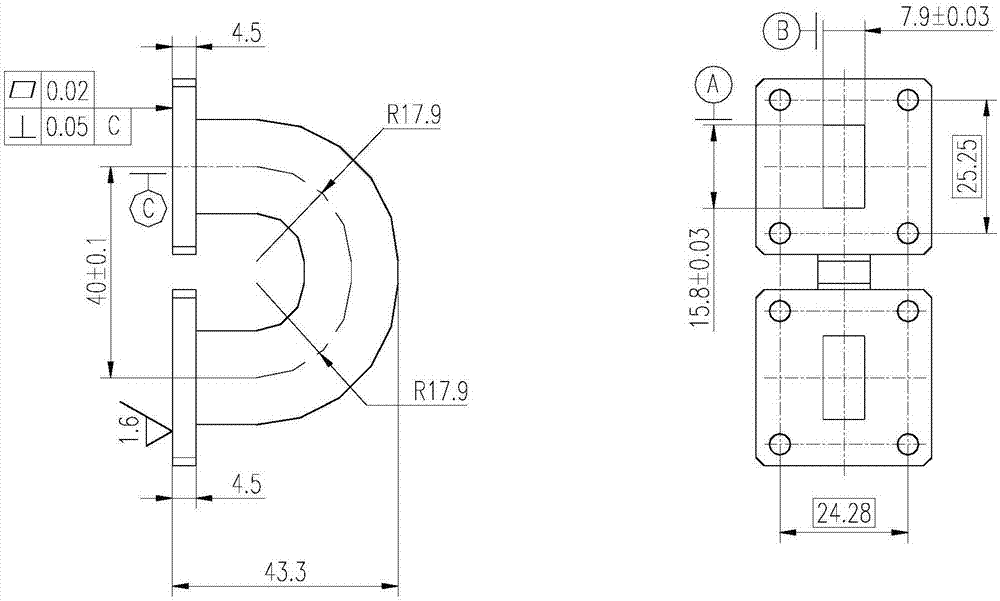

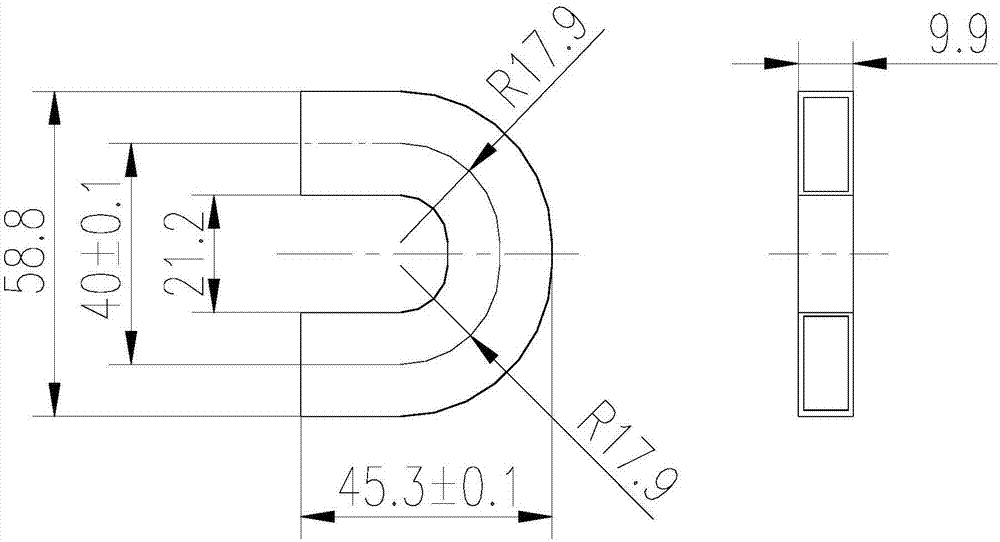

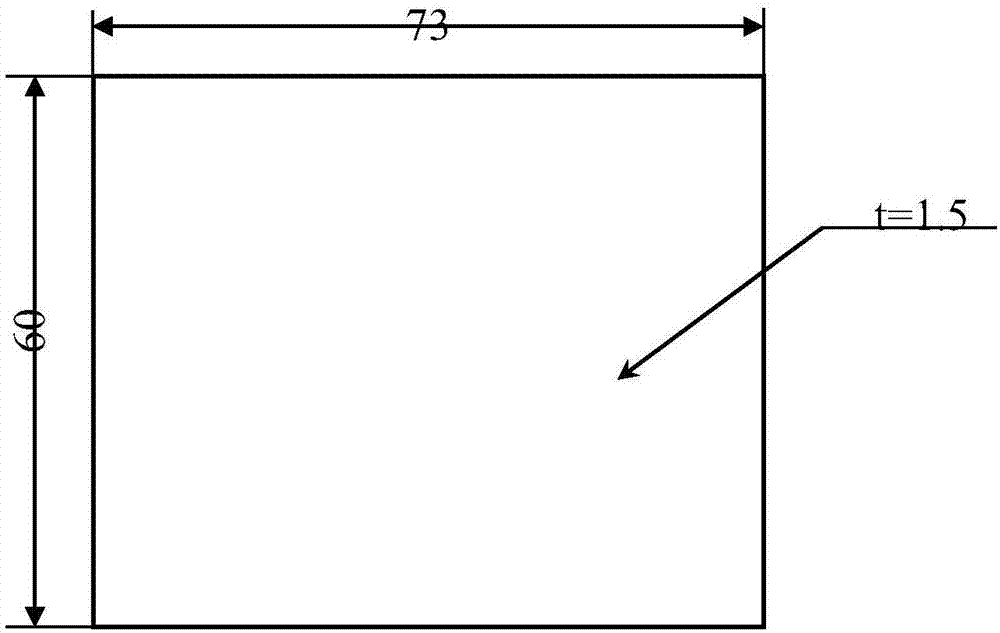

U-shaped bent waveguide processing method

ActiveCN107570965AImprove processing efficiencyReduced processing performanceMilling equipment detailsWaveguideFlange

The invention relates to a U-shaped bent waveguide processing method which comprises the following steps: at first, processing a tool of a U-shaped groove in a milled part, then, milling a U-shaped cavity, brazing a cover plate on the U-shaped cavity, placing the U-shaped cavity welded with the cover plate in the U-shaped groove of the tool, milling the cover plate with the size consistent with the boundary dimension of the U-shaped bent waveguide, and finally, welding flanges at two ends of the U-shaped cavity.

Owner:CNGC INST NO 206 OF CHINA ARMS IND GRP

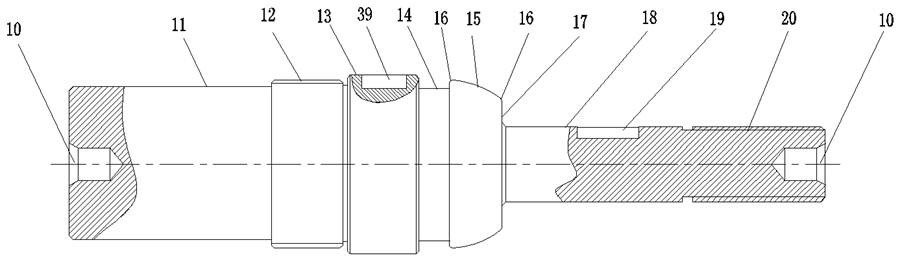

Positioning clamp and machining method for rotor cover of dynamic pressure air bearing of gyro motor

ActiveCN114589520APrecise positioningRestricted freedom of movementWork clamping meansPositioning apparatusAir bearingGyroscope

The invention relates to a thin-wall part precision turning machining method and a positioning clamp, in particular to a positioning clamp and a machining method of a gyroscope motor dynamic pressure air bearing rotor cover. The positioning clamp comprises a spherical surface positioning mandrel, a positioning lantern ring, an anti-vibration pad and a back supporting seat. The spherical positioning mandrel is a step shaft with center holes formed in the two end faces, and comprises a clamping section, a large thread section, a second guide cylindrical section, a spherical positioning section, a spherical table end face, a first guide cylindrical section and a small thread section from left to right in sequence. The machining method comprises the steps of first-step machining of the rotor cover, machining of a series of spherical positioning mandrels, machining of a positioning lantern ring and a back supporting seat, selection of a proper spherical positioning mandrel, turning of the rotor cover and the like. The problems that an existing machining method is poor in positioning precision and low in machining efficiency, and the concave spherical surface is crushed are solved, damage to the concave spherical surface is avoided by limiting six degrees of freedom, and the machining precision of the rotor cover is guaranteed.

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

Gland segment grooving device

PendingCN108971587ASimple structureReduce volumeMeasurement/indication equipmentsMilling equipment detailsFixed bearingEngineering

The invention provides a gland segment grooving device. An existing milling and drilling machine is taken as the basis, and a fan-shaped plate is arranged on a working table; the circle center position at the head part of the fan-shaped plate is provided with a circle center hole, and a fixed bearing is embedded in the hole; the fixed bearing takes the bearing hole in the inner side as the circlecenter, and concentric circle arc lines which are densely arranged every 1-2mm on the fan-shaped plate; dovetail-shaped pressing plate grooves are symmetrically and vertically arranged on the left andright of the fan face of the fan-shaped plate; the pressing plate grooves extend to the tail part of the fan-shaped plate, and gland sealing pressing plates capable of moving along the groove channels are arranged in the grooves; and teeth are designed at the arc-shaped outer edge of the fan-shaped plate, and the teeth are identical with a driving gear. The gland segment grooving device is simplein structure, small and exquisite in size, easy and convenient to operate, large-scale vertical lathe equipment can be replaced, the problems that both time and labor are consumed and the difficultyis large in the processing process of a steam seal ring can be effectively solved, the working efficiency can be remarkably improved, the machining precision problem can be solved, and the machining error is controlled within 0.02mm.

Owner:江苏透平电力技术有限公司

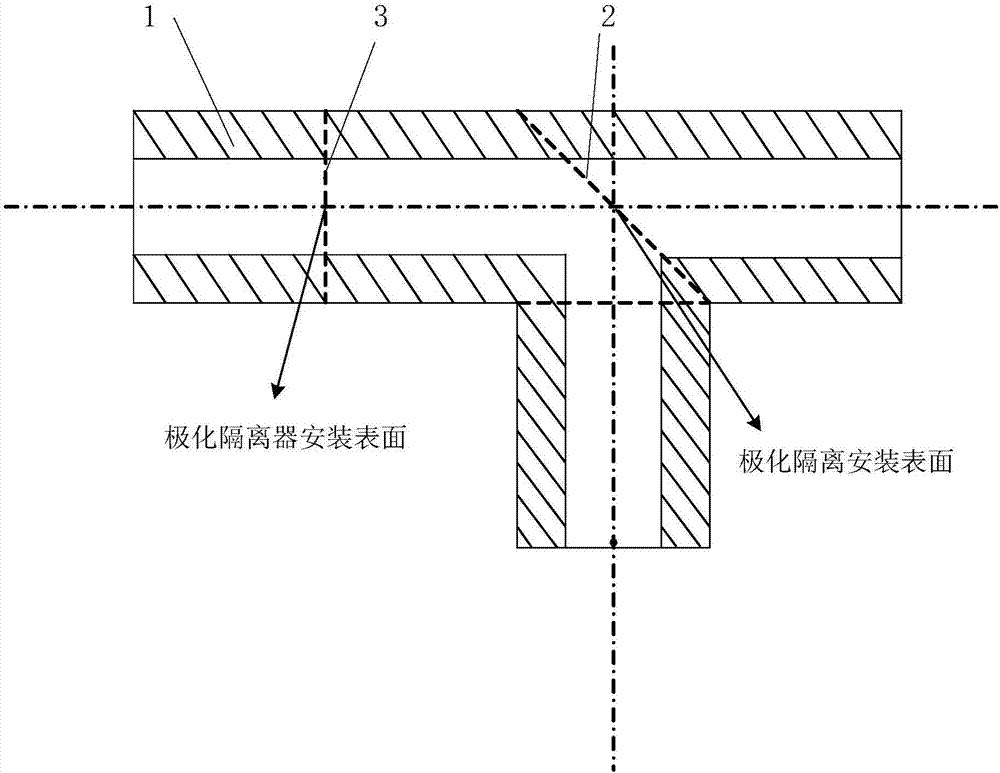

340-GHz thin-film type transmission polarized converter

InactiveCN107257029AImprove robustnessAvoid the problem of processing precision of simple metal gridAntennasFrequency bandLinear polarization

The invention discloses a 340-GHz thin-film type transmission polarized converter, so that the transmission type polarized converter based on a double-layer-array-structure metamaterial is realized. The 340-GHz thin-film type transmission polarized converter is suitable for a frequency band of 340GHz+ / - 15GHz to realize mutual conversion between a linear polarization wave and circular polarized wave. The polarized converter is a circular metal gasket; thin films are pasted at the surfaces of the two sides of the metal gasket; an array formed by periodic metal units is arranged at the outer surface of each thin film; and each periodic metal unit is formed by a rectangular metal piece penetrating the thin film and one row of square metal pieces with one sides arranged uniformly along the length direction of the rectangular metal piece, wherein a gap is formed between the rectangular metal piece and the one row of square metal pieces.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

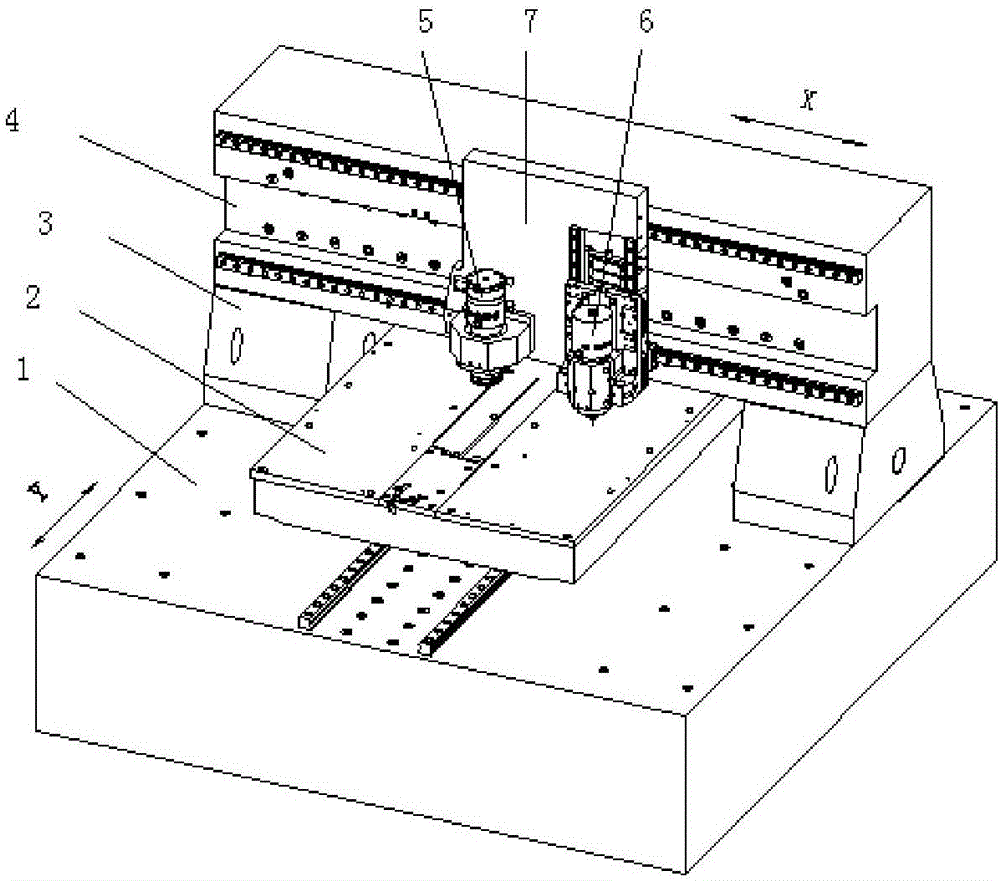

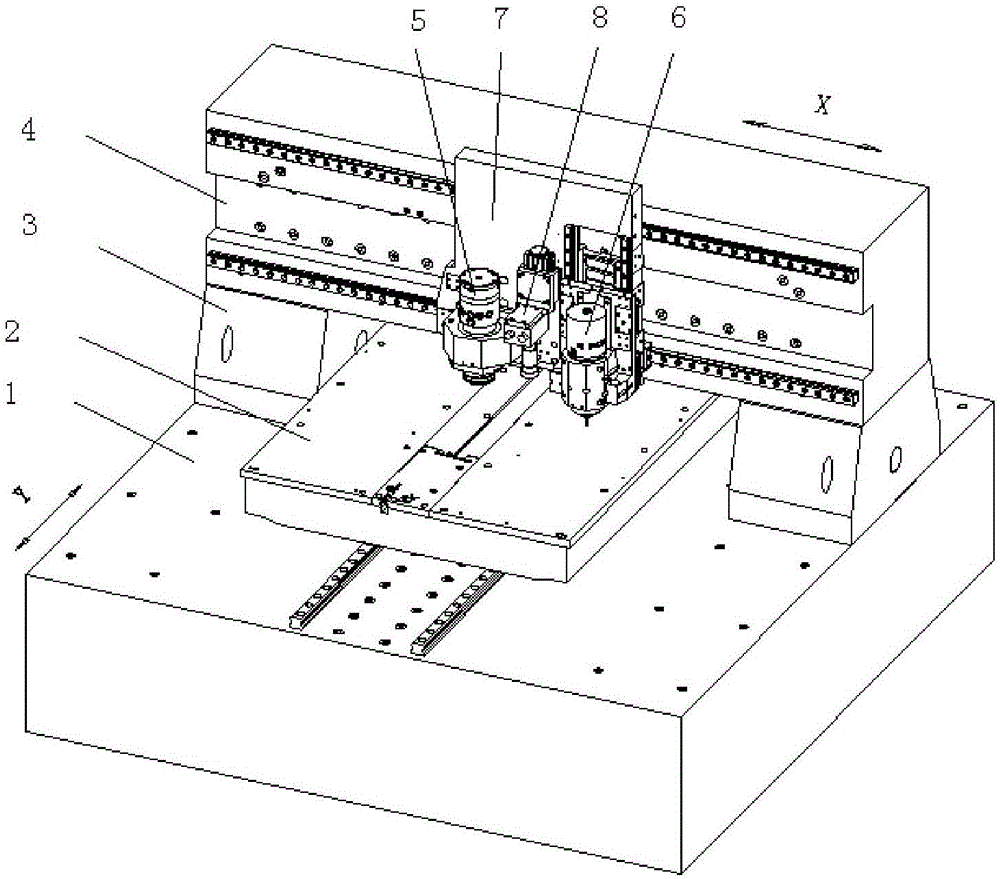

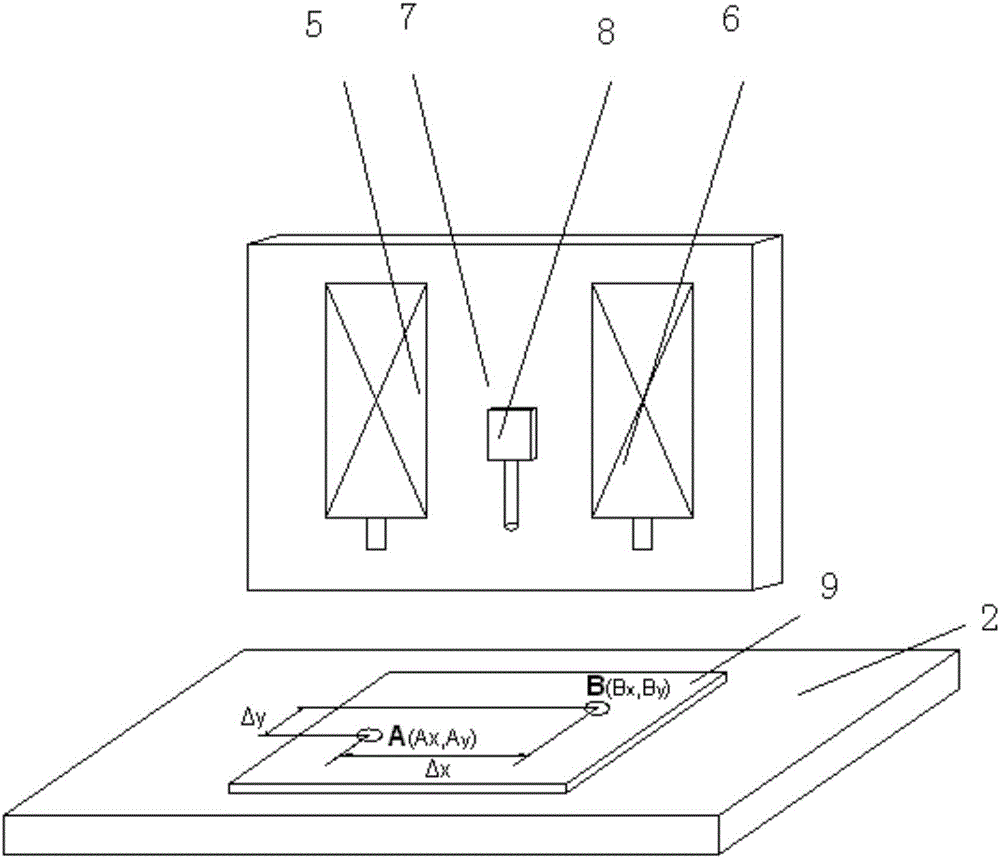

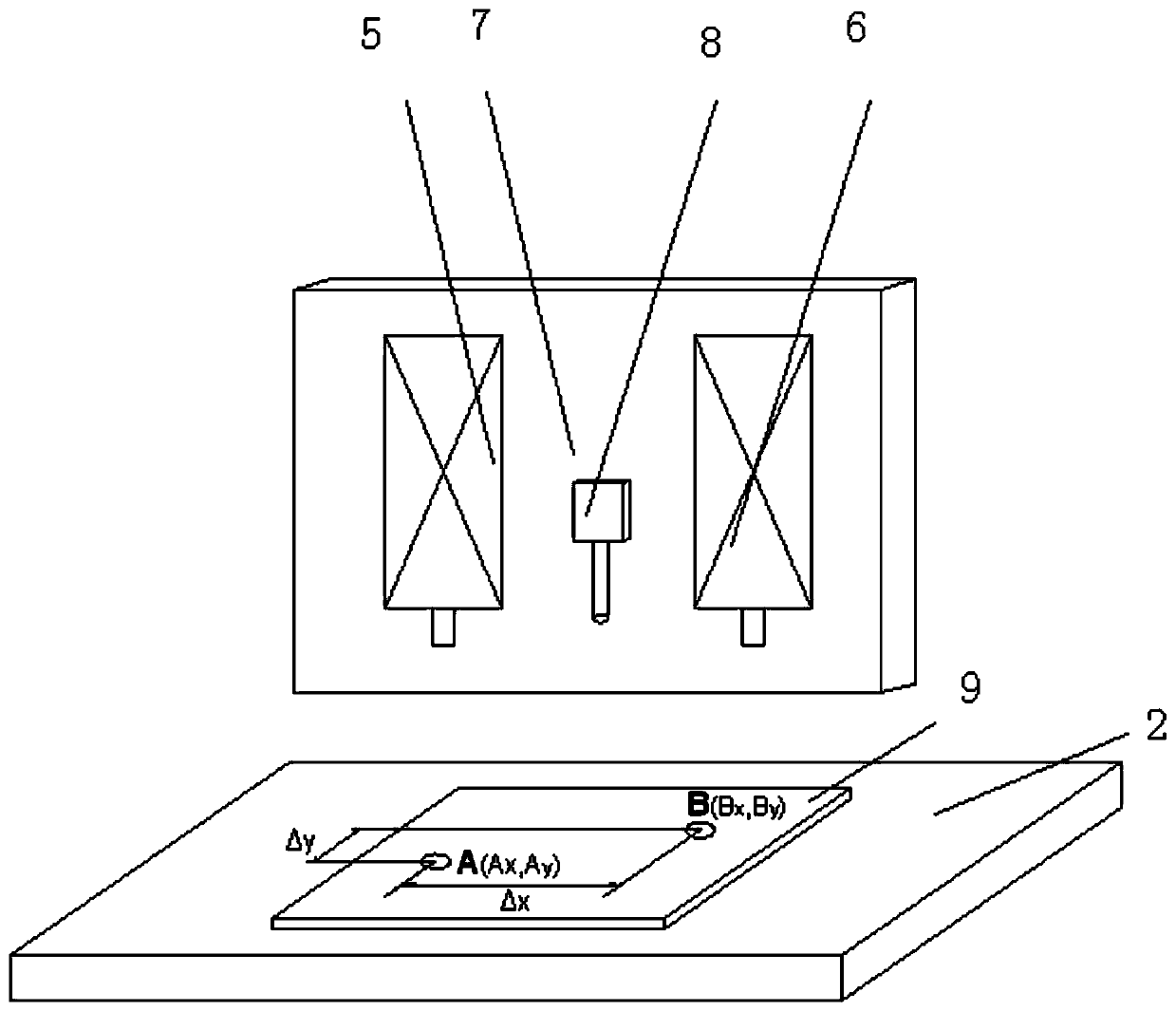

Drilling and milling dual-purpose machine and method for calibrating distances between shafts of drilling and milling dual-purpose machine

ActiveCN106793502ASimplified calibration stepsSolve the problem of machining accuracyOther manufacturing equipments/toolsPrinted circuit manufactureEngineeringDual purpose

The invention relates to the field of machinery, in particular to a drilling and milling dual-purpose machine and a method for calibrating distances between shafts of the drilling and milling dual-purpose machine. The drilling and milling dual-purpose machine comprises a bed body, a beam arranged on the bed body, a work bench, a drilling shaft, a milling shaft and a vision system, wherein the drilling shaft and the milling shaft are located on a bottom plate; and the vision system is located on the bottom plate. The method for calibrating the distances between the shafts of the drilling and milling dual-purpose machine comprises the following steps of (a) drilling holes on a circuit board by adopting the drilling shaft and the milling shaft of the drilling and milling dual-purpose machine respectively; (b) locating the two holes by using the vision system to obtain machine coordinates of the two holes; and (c) calculating the distances between physical positions, in X and Y coordinate directions, of the milling shaft and the drilling shaft, namely the distances between the two shafts according to machine coordinate values of the two holes. According to the method for calibrating the distances between the shafts, the problem of machining precision caused by deformation due to thermal expansion of a mechanical structure and a workpiece is solved and the machining property of equipment is improved.

Owner:HANS CNC SCI & TECH

A machine tool tool support mechanism

ActiveCN102990410BSolve the machining accuracyAvoid deformationPositioning apparatusMetal-working holdersHorizontal axisEngineering

The invention discloses a supporting mechanism for a machine tool cutter and relates to the field of machine tool machining. The supporting mechanism comprises a movable base and a supporting part, wherein the movable base is arranged on the bottom side of the cutter and makes flexible motion towards the cutter, and the supporting part is arranged on the movable base; and particularly in the period of reloading a workpiece or in the machine tool stopping period and the cutter returns to a normal position in the machining process, the movable base is extended out to reach the highest position, the cutter is supported on a horizontal axis by the supporting part, and thus the problem that the machining accuracy of the cutter is affected due to the deflection deformation caused by the long-time suspension of the cutter is avoided.

Owner:HANGZHOU BRANCH ZHEJIANG GEELY AUTOMOBILE RES INST +2

External star wheel type one-way clutch

ActiveCN107956817ASolve the machining accuracySolve the processing qualityFreewheel clutchesPulp and paper industryClutch

The invention relates to an external star wheel type one-way clutch. The external star wheel type one-way clutch aims to solve the problem that an existing roller column type one-way clutch is high inmachining cost and low in machining efficiency. The external star wheel type one-way clutch is provided, the clutch comprises an external star wheel assembly, roller columns, folding springs and an inner ring; the device is characterized in that the external star wheel assembly is of a split structure and comprises an external star wheel and baffles; a plurality of equally spaced raceway surfacesare arranged on the inner side surface of the external star wheel; the baffles are arranged between every two adjacent raceway surfaces; a mounting part with a radial protrusion is arranged at one end of the baffles; mounting grooves are formed in the end surface of the external star wheel; the mounting parts are arranged in the mounting grooves and are fixedly connected with the external star wheel through fasteners; the inner ring and the external star wheel are coaxially installed; the roller columns are arranged between each raceway surface and the inner ring; the folding springs are arranged between each roller columns and the baffles at the large end of the adjacent raceway surfaces. The external star wheel type one-way clutch is easy to machine and low in machining cost.

Owner:GUANGXI LIUGONG MASCH CO LTD

Machine tool laser compensation device for slender shaft machining and compensation method conducted though machine tool laser compensation device

InactiveCN112719951ASolve the machining accuracyEasy to useMeasurement/indication equipmentsLarge fixed membersElectric machineryStructural engineering

The invention discloses a machine tool laser compensation device for slender shaft machining and a compensation method conducted though the machine tool laser compensation device. The device comprises a self-compensation center frame, springs, supporting rods, lead screws and motors. The self-compensation center frame is provided with a groove body which is formed in the thickness direction of the self-compensation center frame in a penetrating manner, and the groove body is round. The springs are arranged on the supporting rods in a sleeving manner and located on the outer side of the self-compensation center frame, one end of each spring is connected with the corresponding supporting rod, the other ends of the springs are connected to the self-compensation center frame, and the supporting rods are arranged on the self-compensation center frame in a sliding manner and arranged in the axial direction of the groove body. The first ends of the supporting rods face the center of the groove body, the second ends of the supporting rods are connected with nuts, the nuts are in threaded connection to the lead screws, and the lead screws are in transmission connection with the motors. According to the machine tool laser compensation device for slender shaft machining, the problem that when a slender shaft is turned and machined, machining precision is affected due to bending deformation of a workpiece can be solved, the response speed is high, and accurate compensation resetting can be conducted through a reverse compensation method.

Owner:PINGDINGSHAN UNIVERSITY

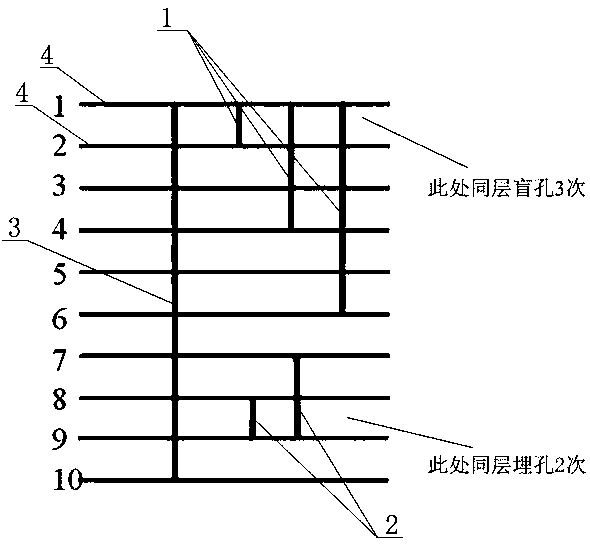

Machining process for local electroplating of blind buried holes

ActiveCN111343800ASolve the machining accuracyReduce line width/spacing out-of-tolerance issuesPrinted element electric connection formationCopper platingEngineering

The invention discloses a machining process for local electroplating of blind buried holes, which comprises the following steps: S2, for two times of blind buried hole forming in the same layer, basematerials are stacked and pressed, and then blind buried hole drilling treatment, copper deposition treatment, full-board copper plating treatment, inner-layer circuit manufacturing, full-board thickened copper plating treatment, base material outer surface film stripping treatment, inner-layer circuit manufacturing, inner-layer etching treatment and browning treatment are sequentially carried out; and S3, for three times of blind buried hole forming in the same layer, the base materials are stacked and pressed, and then blind buried hole drilling treatment, copper deposition treatment, full-board copper plating treatment, inner-layer circuit manufacturing, full-board thickened copper plating treatment, base material outer surface film stripping treatment, inner-layer circuit manufacturing, inner-layer etching treatment and browning treatment are conducted in sequence. The method has the beneficial effects that when the process is applied to the forming of blind buried holes twice in the same layer, copper plating of the holes can be effectively guaranteed, and meanwhile, the problem of machining precision of small line width and small spacing is solved, and the yield is increased.

Owner:四川英创力电子科技股份有限公司

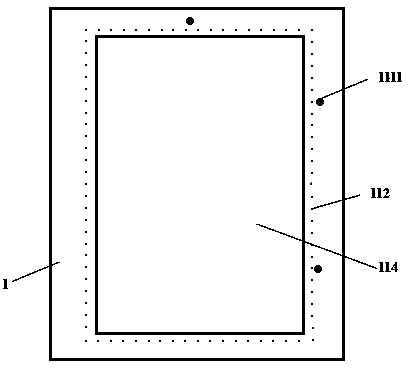

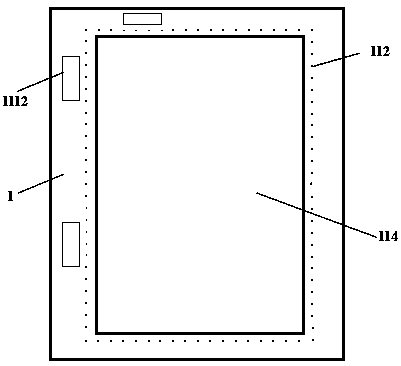

Support mechanism for machining double-sided ITO (Indium Tin Oxide) glass

InactiveCN103663994AGuaranteed positioning accuracyGuaranteed fixed effectIndium tin oxideEngineering

The invention discloses a support mechanism for machining double-sided ITO (Indium Tin Oxide) glass, and ensures the surface flatness of the double-sided ITO glass within a certain area. The support mechanism comprises a positioning mechanism and a support mechanism, wherein the positioning mechanism is used for limiting the position of the double-sided ITO glass; the support mechanism is used for supporting the double-sided ITO glass, used for reducing the droop of the double-sided ITO glass, and used for ensuring the machining precision. Because of the large size and small thickness, a small allowable support area is available when ITO glass is machined, and because of the self-gravity, great droop can be resulted, and as a laser process requires that the flatness of the glass surface shall be within a certain range, such as being less than 0.1mm, when the glass is etched by using laser, a support device is essential for ensuring the flatness of the glass when being machined. By adopting the support mechanism of the double-sided ITO glass disclosed by the invention, the problem that the double-sided ITO glass drops down because of the self-gravity in the machining process is well solved, the machining precision is ensured, and the production efficiency and the yield are improved.

Owner:KUNSHAN THETA MICRO

Welding machining technology of swinging frame

InactiveCN109570803ASolve welding qualitySolve the machining accuracyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMachining process

The invention discloses a welding machining technology of a swinging frame. The welding machining technology of the swinging frame is characterized in that a single piece required for parts is taken for assembling welding, the assembling welding is characterized in that uniform welding is carried out at two side symmetric positions, vibration aging is carried out after welding to remove welding stress, and then, the single piece is switched to a numerical control horizontal type machining center to be machined to reach required sizes. According to the welding machining technology of the swinging frame, the welding quality and machining precision of the swinging frame are effectively improved, welding deformation of the parts can be effectively reduced in the welding and machining process of tool positioning, meanwhile, the technology application of the vibration aging can effectively reduce the welding stress, numerical control machining can further guarantee the machining precision and improve the machining efficiency, ensure the safe using performance of the whole manufacturing process of the swinging frame, and guarantee the safety of the engineer operation.

Owner:江苏智博工程机械科技有限公司

Degreasing device for steel pipes

ActiveCN105127217AGood degreasing effectSolve the machining accuracyWork treatment devicesMetal rolling arrangementsPistonSteel tube

The invention discloses a degreasing device for steel pipes, and aims to provide the degreasing device for the steel pipes which is high-efficient, fast and good in degreasing effect and can effectively solve the problem that the degreasing effect is not good caused by the problems that the processing precision of the cold rolling steel pipes is not high and the processing precision of a degreasing device is not high. The degreasing device comprises a rack, a first degreasing guide sleeve arranged on the rack, a first mounting groove formed in the inner side surface of the first degreasing guide sleeve, an inflation sealing ring arranged in the first mounting groove and a self-adaption inflation-exhaust conversion device arranged on the rack, wherein the self-adaption inflation-exhaust conversion device comprises a triggering lever which is arranged on the rack in a rotary manner through a horizontal shaft lever, a vertical cylinder body which is vertically arranged on the rack, a piston body arranged in the vertical cylinder body and a first limiting block which is arranged on the inner side surface of the vertical cylinder body and is located under the piston body.

Owner:ZHEJIANG ZHONGWU STEEL TUBE MFG CO LTD

Special coupling with sealing and positioning structure

PendingCN111502557AReserve connection methodIncrease the lengthDrilling rodsDrilling casingsCouplingEngineering

The invention discloses a special coupling with a sealing and positioning structure, and relates to the technical field of thermal fluid and petroleum collecting and conveying equipment. The special coupling is provided with a coupling main body mounted on a pipeline, pipeline connecting parts of the coupling main body, an extending part between two pipeline connecting parts on the inner wall of the coupling main body, a positioning groove formed in the extending part and used for fixing an inner core tube; and a sealing surface used for sealing the end part of the inner core tube. The specialcoupling can be used for solving the problems of sealing and positioning when an 'inner heat preservation pipe 'is used in the thermal fluid collection process, a connecting method of a common coupling is reserved, an original operation method of an oil well operation method is still maintained, the field construction quality is ensured, and the special coupling can be used for transformation andconnection of old oil pipes and can also be used for connection of newly designed oil pipes, so that the dimensional accuracy, roughness and the like of the coupling main body are easy to control, and the special coupling is very convenient to replace and repair even if problems exist.

Owner:江苏联冠兆星石化科技有限公司

A method for calibrating the axis distance of a drilling and gong dual-purpose machine

ActiveCN106793502BSimplify the calibration stepsSolve the machining accuracyOther manufacturing equipments/toolsPrinted circuit manufactureEngineeringMachine

The invention relates to the field of machinery, in particular to a drilling and milling dual-purpose machine and a method for calibrating distances between shafts of the drilling and milling dual-purpose machine. The drilling and milling dual-purpose machine comprises a bed body, a beam arranged on the bed body, a work bench, a drilling shaft, a milling shaft and a vision system, wherein the drilling shaft and the milling shaft are located on a bottom plate; and the vision system is located on the bottom plate. The method for calibrating the distances between the shafts of the drilling and milling dual-purpose machine comprises the following steps of (a) drilling holes on a circuit board by adopting the drilling shaft and the milling shaft of the drilling and milling dual-purpose machine respectively; (b) locating the two holes by using the vision system to obtain machine coordinates of the two holes; and (c) calculating the distances between physical positions, in X and Y coordinate directions, of the milling shaft and the drilling shaft, namely the distances between the two shafts according to machine coordinate values of the two holes. According to the method for calibrating the distances between the shafts, the problem of machining precision caused by deformation due to thermal expansion of a mechanical structure and a workpiece is solved and the machining property of equipment is improved.

Owner:HANS CNC SCI & TECH

Special mechanical equipment for machining fan shaft sleeve

InactiveCN102363264BSolve processing efficiencySolve the machining accuracyPrecision positioning equipmentOther manufacturing equipments/toolsElectromagnetic clutchMechanical equipment

The invention discloses special mechanical equipment for machining a fan shaft sleeve. The mechanical equipment comprises a divider mechanism, a feeding mechanism, a drilling mechanism, a tapping mechanism, a plane milling mechanism, a chamfering and reaming mechanism, a discharge mechanism and a controller. The feeding mechanism, the drilling mechanism, the tapping mechanism, the plane milling mechanism, the chamfering and reaming mechanism and the discharge mechanism are uniformly distributed around the divider mechanism in included angles of 60 degrees; the divider mechanism consists of anindexing disc, a cam, a three-phase motor, an electromagnetic clutch, a reduction box and a high-speed precision intermittent divider; chamfering and reaming in the chamfering and reaming mechanism are implemented on the same station; and the controller is used for controlling the motion of each mechanism. By using the special mechanical equipment for machining the fan shaft sleeve, the production efficiency is greatly improved, the precision of a product is ensured, the defective rate is greatly reduced relative to other machining modes, and the requirement of industrial production is met.

Owner:SOUTH CHINA UNIV OF TECH +1

Composite heat treatment method for 30CrMnSiA steel thin wall spinning cylinder-shape element

InactiveCN101265514BImprove organizational stabilityEasy to processFurnace typesQuenching agentsQuenchingMachining

A compound heat treatment method of 30CrMnSiA steel to thin wall cylindrical shaped element with large diameter and thin wall thickness by spinning is characterized in that the method comprises a preferable 'stress tempering-interrupted quenching-tempering' heat treatment combination. The method comprises the steps of: stress tempering a workpiece while releasing the residual stress of the workpiece to a certain extent by controlling the tempering temperature and temperature holding time; conducting interrupted quenching by preheating, heating with a salt-bath furnace, cooling with a nitrate thermostatic bath and air cooling, washing to remove residual salt or alkaline liquid on the surface of the workpiece, and performing passivation and anti-corrosive treatment; and placing the workpiece into a well type tempering furnace or a special tempering furnace to conduct tempering treatment. The workpiece subjected to compound heat treatment has the advantages of high processing precision, high hydraulic pressure test strength, and low deformation liability of the following machining operation.

Owner:江南工业集团有限公司

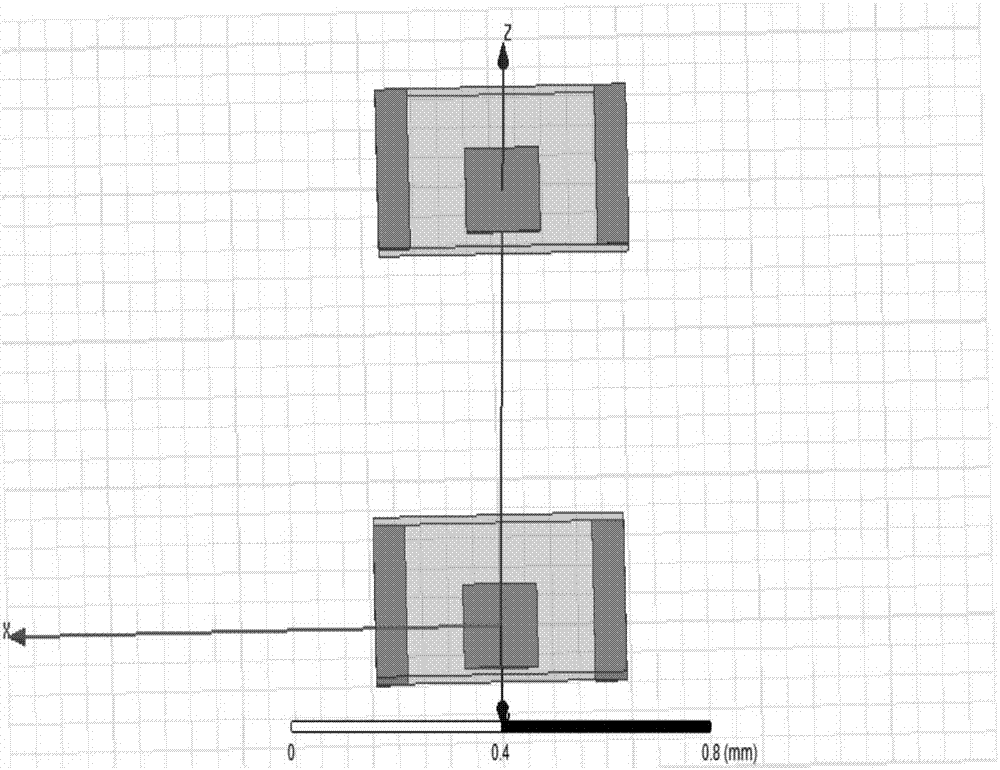

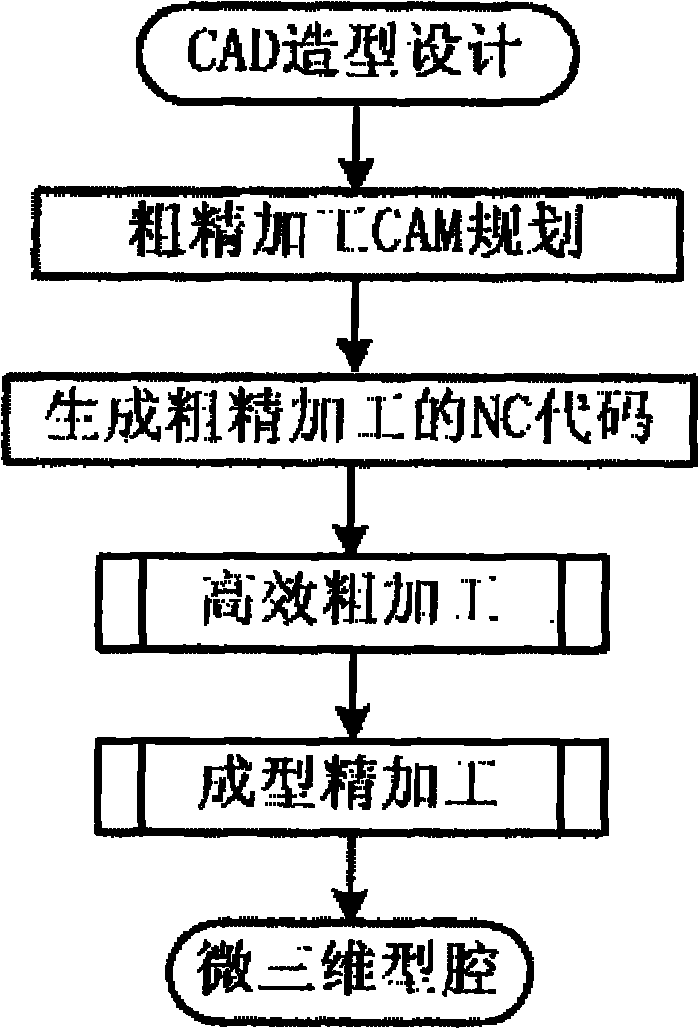

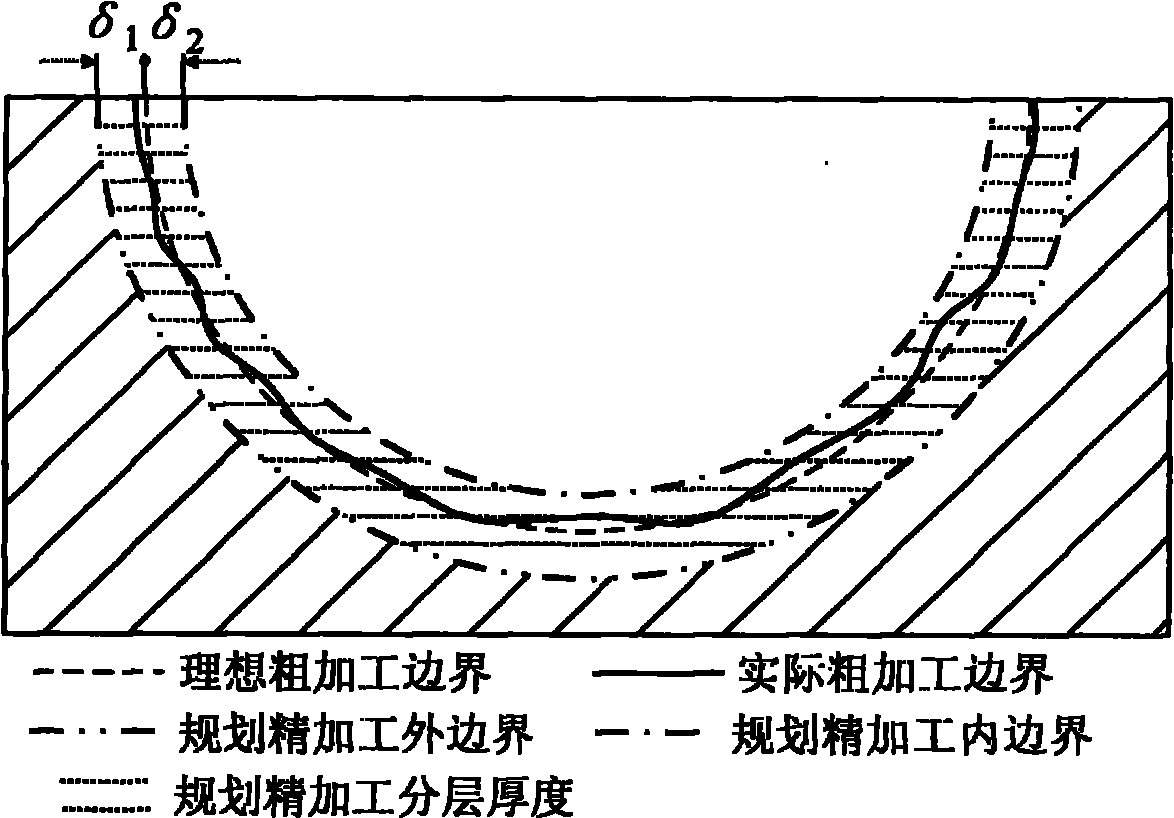

Three-dimensional fine electric spark servo scanning rough and finish machining combined process

A three-dimensional fine electric spark servo scanning rough and finish machining combined process belongs to the technical field of special micro machining. The process which is adaptive to machining of micro three-dimensional cavities with millimeter-sized and utilizes a servo control discharge clearance to realize real-time on-line compensation of axial consumption of an electrode includes removing a large quantity of cavity materials rapidly when in rough machining, applying a maximum method of servo feed depth of an tool electrode of each scanning point to avoid and reduce lack of machining and over-cutting machining and guarantee consistency of processed depths of different layers when in finish machining, further, feeding back processed depth of each layer by combing with tool electrode low-voltage electric contact in a closed loop form, then applying a variable velocity servo scanning method to compensate depth error, and finally completing molding process with high surface precision and high size precision by adopting low discharge energy and thin dividing thickness. The combined process resolves the problem of precision limitation of processed depth of three-dimensional servo scanning, eliminates contradiction between high precision and high efficiency, and can be applied to high-precision and high-efficiency machining of micro three-dimensional cavities made of metal alloy and conductive silica-based materials.

Owner:TSINGHUA UNIV

Cable collecting device

ActiveCN107618807ASimplified installation procedurePracticalConveyorsConveyor partsSlide plateCable harness

The invention discloses a cable collecting device which comprises a cover plate, a support, a cable collecting groove plate, a connecting plate, an overturning assembly, a driving assembly and a cablesupporting assembly. The cover plate is fixedly connected with the support through the connecting plate, and an interval is formed between the cover plate and the upper end surface of the support; the cable collecting groove plate is movably connected to the lower end of the support, and the side end of the cable collecting groove plate is connected with a piston rod of an overturning air cylinder inside the overturning assembly which is mounted at the lower end of the support; and the driving assembly is mounted inside the support and located below the cover plate, the cable supporting assembly is vertically mounted at the front end of the support, and a guiding plate of the cable supporting assembly corresponds to a belt of the driving assembly. According to the cable collecting device,cable harnesses are conveyed through the driving assembly, the cable collecting groove plate is driven by the overturning assembly to vertically overturn, and when overturning upwards, the cable collecting groove plate makes contact with a rubber buffer strip to achieve buffering; and when the cable collecting groove plate overturns downwards under the effect of the overturning air cylinder, thebelt can be completely exposed, a cable supporting plate and a sliding plate are dismounted, an adjusting lead screw is loosened, and then the belt can be quickly dismounted.

Owner:HEBI HAICHANG SPECIAL EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com