Special mechanical equipment for machining fan shaft sleeve

A fan shaft and mechanical technology, which is applied to metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problem of low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] specific implementation

[0040] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

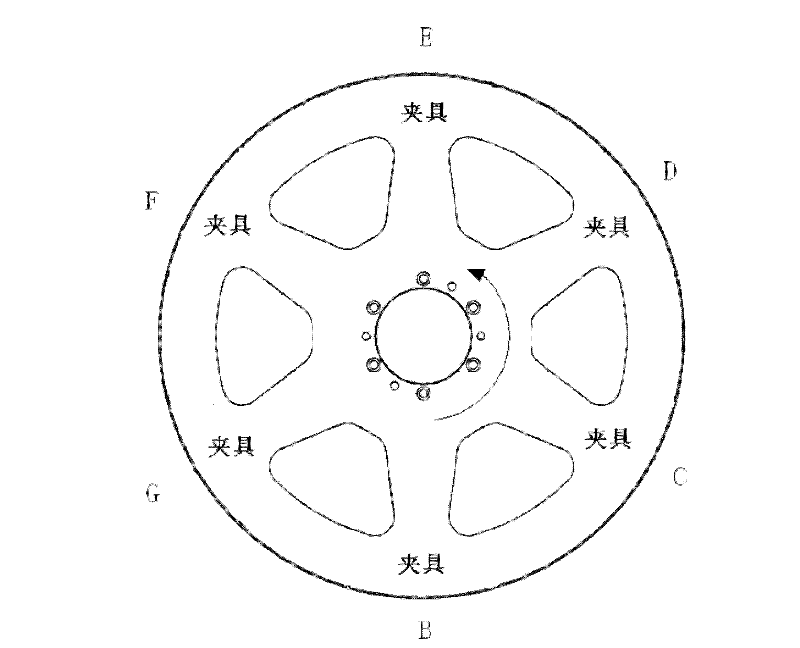

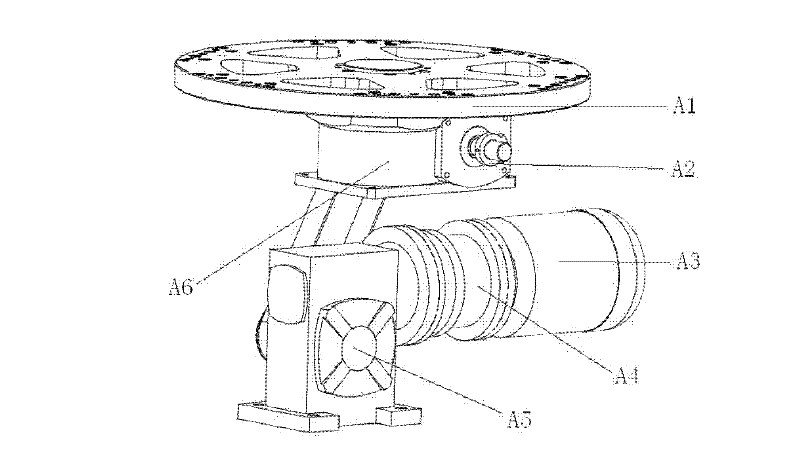

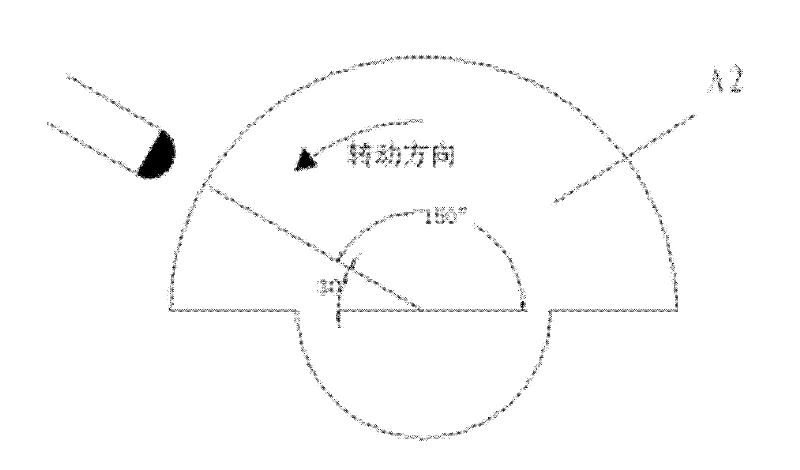

[0041] as attached figure 1 As shown, the special mechanical equipment for fan shaft sleeve processing includes splitter mechanism A, feeding mechanism B, drilling mechanism C, tapping mechanism D, plane milling mechanism E, chamfering and reaming mechanism F, discharging mechanism G, controller , the controller controls the work of other various institutions. What adopt in the present invention is the controller with PLC as the core, and its specific model is Omron CP1E type PLC, CP1W expansion unit.

[0042] Six stations are designed on the workbench of the whole machine, which can process workpieces at the same time. The six stations are distributed counterclockwise as feeding station, drilling station, tapping station, plane millin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com