Workpiece inner hole processing equipment

A technology for processing equipment and workpieces, which is applied in the field of workpiece inner hole processing equipment, can solve problems such as difficulty in meeting high precision, lack of continuous tool feed, and low processing efficiency, and achieve the advantages of easy advance and retreat, high degree of automation, and high processing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

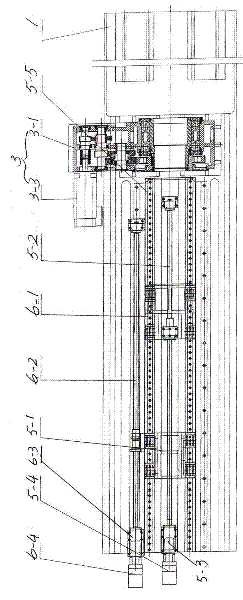

[0043] One of its specific implementation methods, as attached Figures 1~10 shown.

[0044] A workpiece inner hole processing equipment, comprising a bed 1, a workpiece support seat assembly 2, a main transmission box 3, a boring bar assembly device 4, a boring tool slider advance and retreat device 5, a boring bar assembly device advance and retreat device 6 and a boring bar front bay 7, which:

[0045] The workpiece supporting base assembly 2 includes two supporting bases 2-1 that can be slidably positioned along the length direction of the bed 1, a V-shaped block 2-2 fixed on the supporting base 2-1, and a flexible fastener chain 2-3; and the two V-shaped blocks 2-2 are on the same axis, one end of the flexible fastener chain 2-3 is fixedly connected to one side of the V-shaped block 2-2, and the other end is fastened by cladding The outer surface of the workpiece 12 is detachably fixedly connected with the other side of the V-shaped block 2-2 (as attached Figure 7 sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com