Machine tool laser compensation device for slender shaft machining and compensation method conducted though machine tool laser compensation device

A compensation device, slender shaft technology, applied in metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of reduced accuracy, bending deformation, poor rigidity of the slender shaft, etc. Large deformation, the effect of preventing workpiece deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

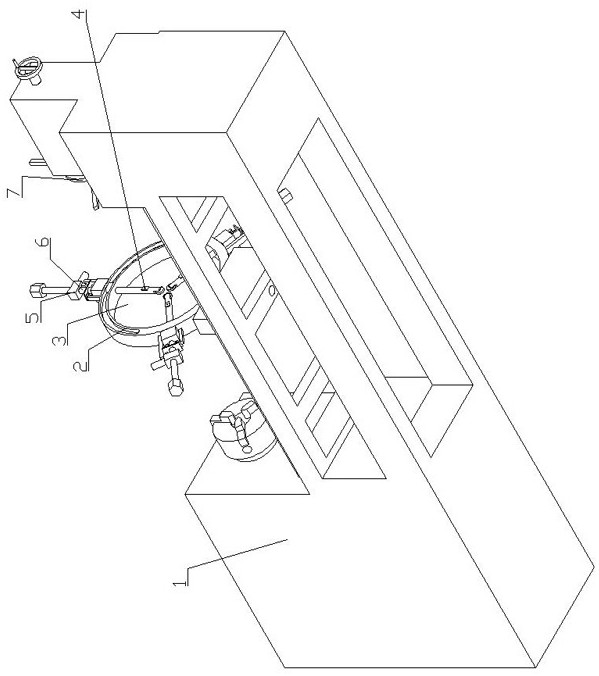

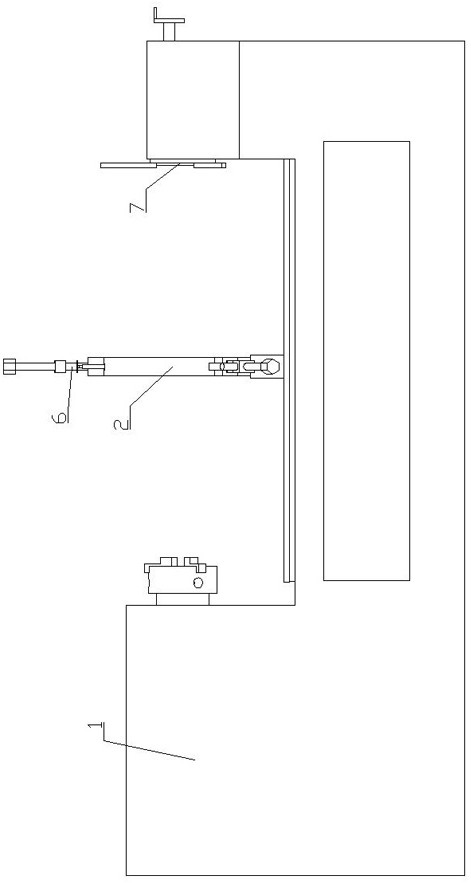

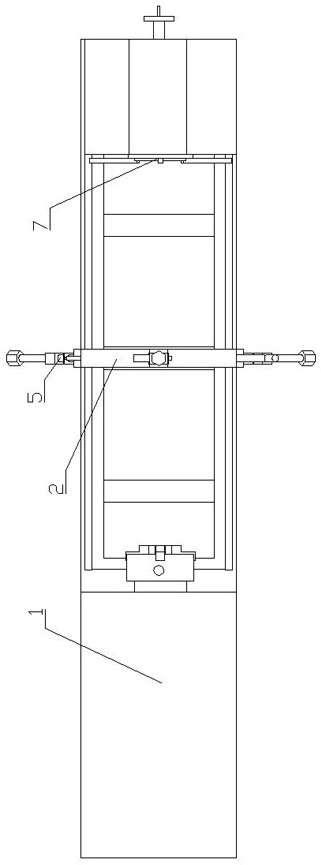

[0043] Machine tool laser compensation device for slender shaft processing, such as Figure 1-7 As shown, the self-compensating steady rest 2 is included, and the self-compensating steady rest 2 is fixedly arranged on the machine tool 1 . The fixed position of the self-compensating steady rest 2 on the machine tool 1 is: located at the center of the longitudinal direction of the machine tool 1 to ensure that the workpiece can pass through the self-compensating steady rest 2 when it is on the machine tool 1 .

[0044] The cross-section of the self-compensating center frame 2 is circular. On the self-compensating center frame 2, a tank body 3 is arranged along the thickness direction of the self-compensating center frame 2. The tank body 3 is circular, and the dots of the tank body 3 are aligned with the self-compensating center frame. The dots of the center frame 2 coincide.

[0045] A support rod 8 is slidably arranged on the self-compensating center frame 2, and the support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com