Three-dimensional fine electric spark servo scanning rough and finish machining combined process

An electric spark and rough machining technology, which is applied in the field of three-dimensional micro EDM servo scanning rough and fine machining combined process, can solve the problems of small discharge area at the end of the micro electrode, increase the discharge energy, and process failure, etc., to solve the problem of efficiency and precision. Contradictory problems, the effect of improving forming accuracy and surface accuracy, and improving finishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention provides a three-dimensional fine EDM servo scanning combined process for rough and fine machining. The present invention will be further described below in conjunction with the accompanying drawings and specific implementation methods.

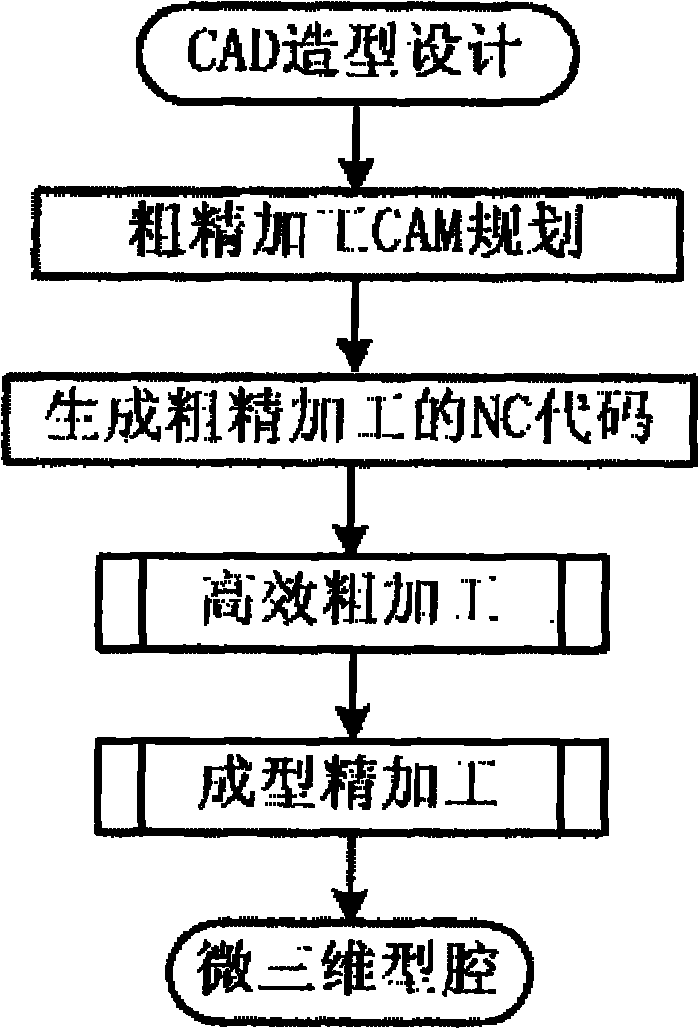

[0031] figure 1 It is a three-dimensional micro-EDM servo scanning roughing and finishing process, which mainly includes CAD modeling design, roughing and finishing CAM planning, roughing and finishing NC code generation, high-efficiency roughing, forming and finishing and other processes.

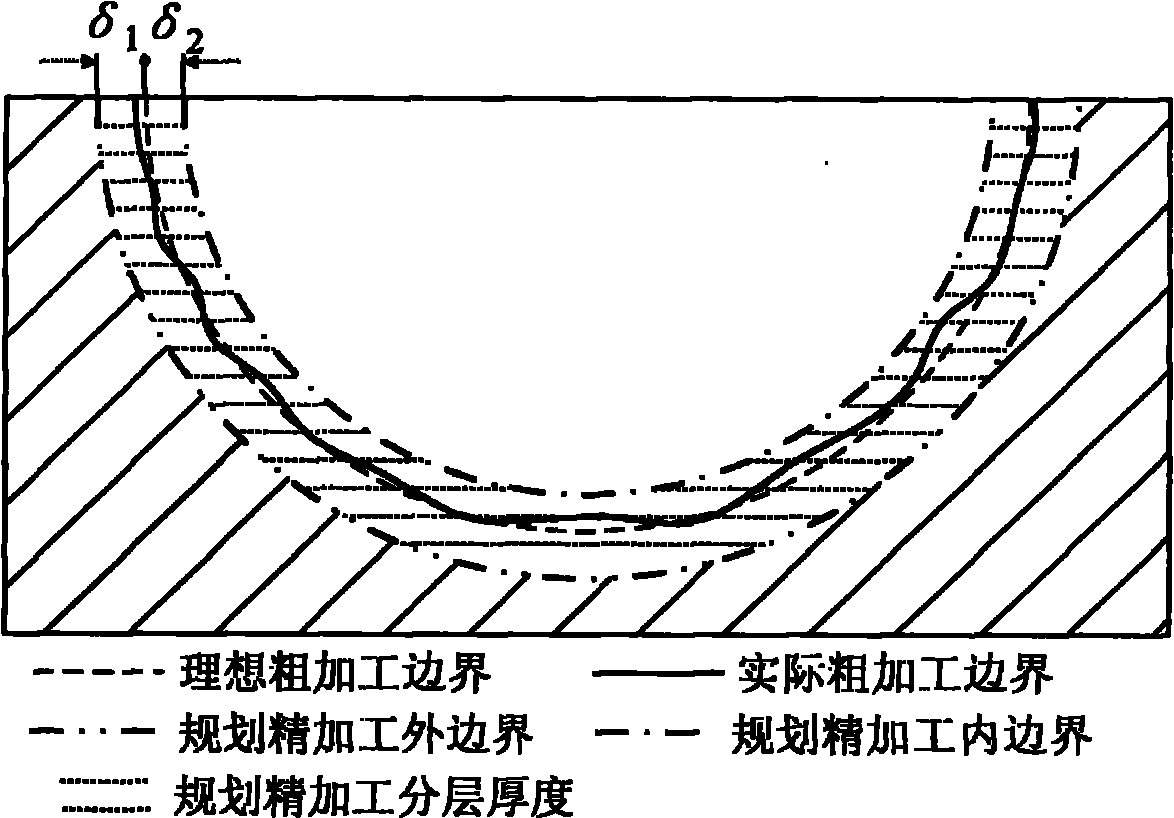

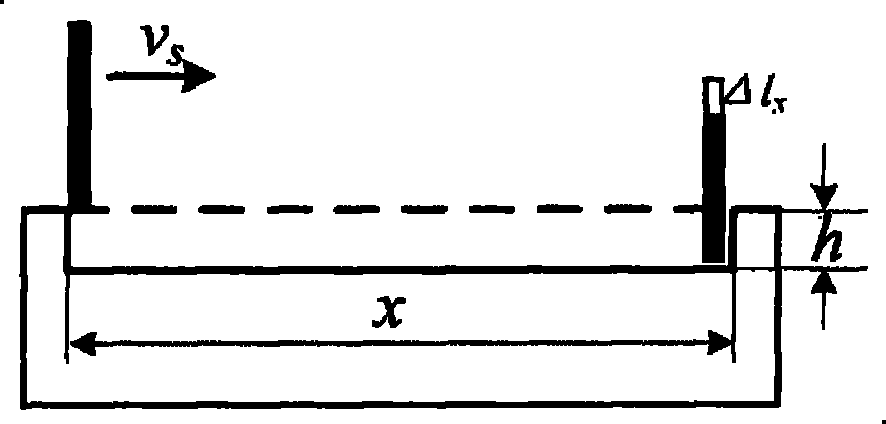

[0032] In order to illustrate the superiority and implementation of the processing technology of the present invention, the three-dimensional servo scanning processing method adopted is firstly described. Then, it focuses on the method of determining the boundary of rough and fine machining, the method of scanning the maximum value of the servo feed depth of the tool electrode at each point proposed in the finishing machining,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com