Five-axis NC machine tool calibration device and operation method

A technology of CNC machine tools and calibration devices, which is applied to metal processing machinery parts, large fixed members, measuring/indicating equipment, etc., and can solve the problems of inaccurate calibration and affecting the machining accuracy of CNC machine tools.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

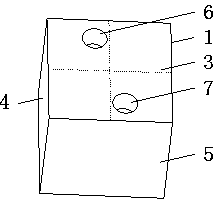

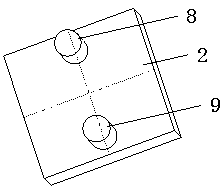

[0028] A five-axis CNC machine tool calibration device, including a first calibration block 1 and a second calibration block 2, the surface of the first calibration block 1 is provided with a first calibration surface 3, a second calibration surface 4 and a third calibration surface 5, the first The first calibration surface 3 of a calibration block 1 is provided with a first circular hole 6 and a second circular hole 7, and the surface of the second calibration block 2 is provided with a first positioning pin 8 and a second positioning pin 9, and the second calibration block 2. The first positioning pin 8 and the second positioning pin 9 adopt an integrated design.

[0029] Operation method:

[0030] Linear motion axis zero return calibration: install the first calibration block 1 on a fixed position on the workbench, its center point is the zero point of the machine tool, and then calibrate with the X-axis zero point, first input the size of the first calibration block 1 in ...

Embodiment 2

[0033] A five-axis CNC machine tool calibration device, including a first calibration block 1 and a second calibration block 2, the surface of the first calibration block 1 is provided with a first calibration surface 3, a second calibration surface 4 and a third calibration surface 5, the first The first calibration surface 3 of a calibration block 1 is provided with a first circular hole 6 and a second circular hole 7, and the surface of the second calibration block 2 is provided with a first positioning pin 8 and a second positioning pin 9, and the second calibration block 2. The first positioning pin 8 and the second positioning pin 9 adopt an integrated design. The first calibration block 1 is a rectangular block with a symmetrical structure. The first calibration surface 3, the second calibration surface 4 and the third calibration surface 5 are mutually mutually Vertical, the angle between the center line of the first circular hole 6 and the second circular hole 7 and th...

Embodiment 3

[0038]A five-axis CNC machine tool calibration device, including a first calibration block 1 and a second calibration block 2, the surface of the first calibration block 1 is provided with a first calibration surface 3, a second calibration surface 4 and a third calibration surface 5, the first The first calibration surface 3 of a calibration block 1 is provided with a first circular hole 6 and a second circular hole 7, and the surface of the second calibration block 2 is provided with a first positioning pin 8 and a second positioning pin 9, and the second calibration block 2. The first positioning pin 8 and the second positioning pin 9 adopt an integrated design. The first calibration block 1 is a rectangular block with a symmetrical structure. The first calibration surface 3, the second calibration surface 4 and the third calibration surface 5 are mutually mutually Vertical, the angle between the center line of the first circular hole 6 and the second circular hole 7 and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com