Mechanization rice spreading device

An equipment and rice technology, applied in food preparation, food forming, food science, etc., can solve problems such as low production efficiency, rice spilling on the workbench, and loss of meal volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

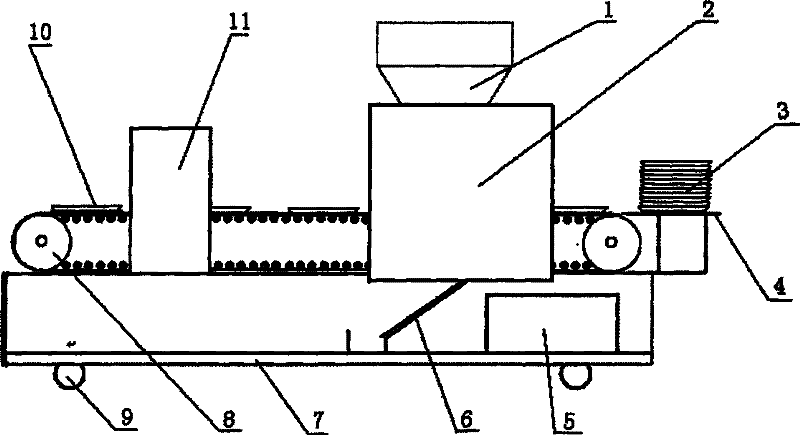

[0019] like figure 1 , figure 2 , image 3 , Figure 4 As shown, a kind of mechanized rice spreading equipment comprises frame 7, rice laying device 2, feeding table 4, driving mechanism 5, sprocket transmission mechanism 8 and electric control box 11, and feeding table 4 is positioned at the end of frame 7 The sprocket transmission mechanism 8 is horizontally placed on the upper part of the frame 7, the bottom of the frame 7 is equipped with a roller 9, the electric control box 11 and the driving mechanism 5 are arranged on the frame, and the rice spreading device 2 is arranged near the discharging platform. One side of 4, the below of rice laying device 2 has slope plate 6, and slope plate 6 bottom places have rice groove, is convenient to the rice that the rice spreading device 2 overflows is collected and reused.

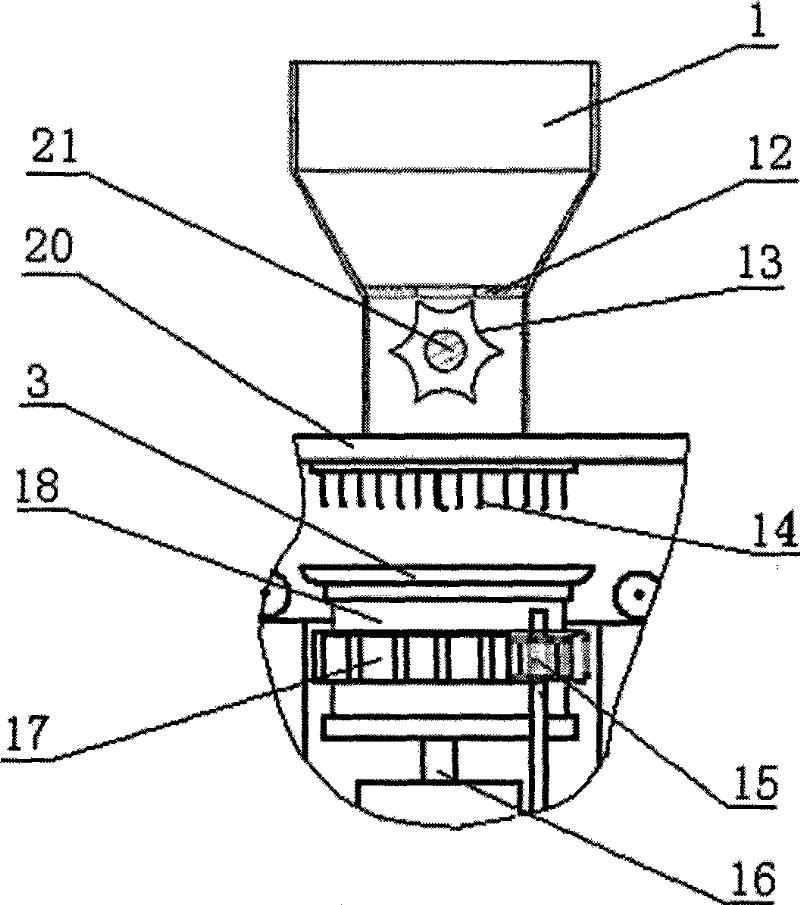

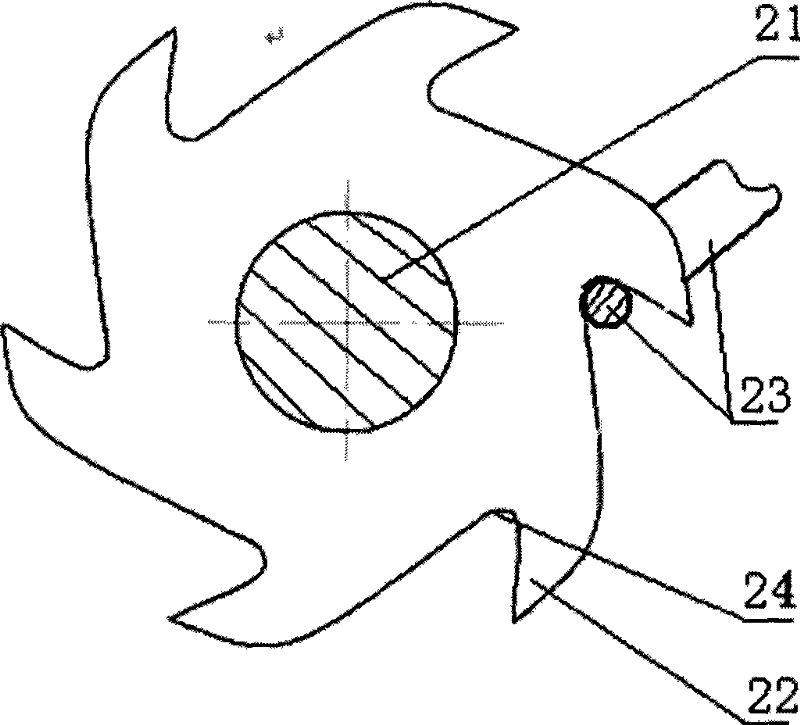

[0020] The rice spreading device 2 comprises a rice hopper mechanism and a spreading mechanism, and the rice hopper mechanism includes a rice hopper 1, a di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com