Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53results about How to "Cutting effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

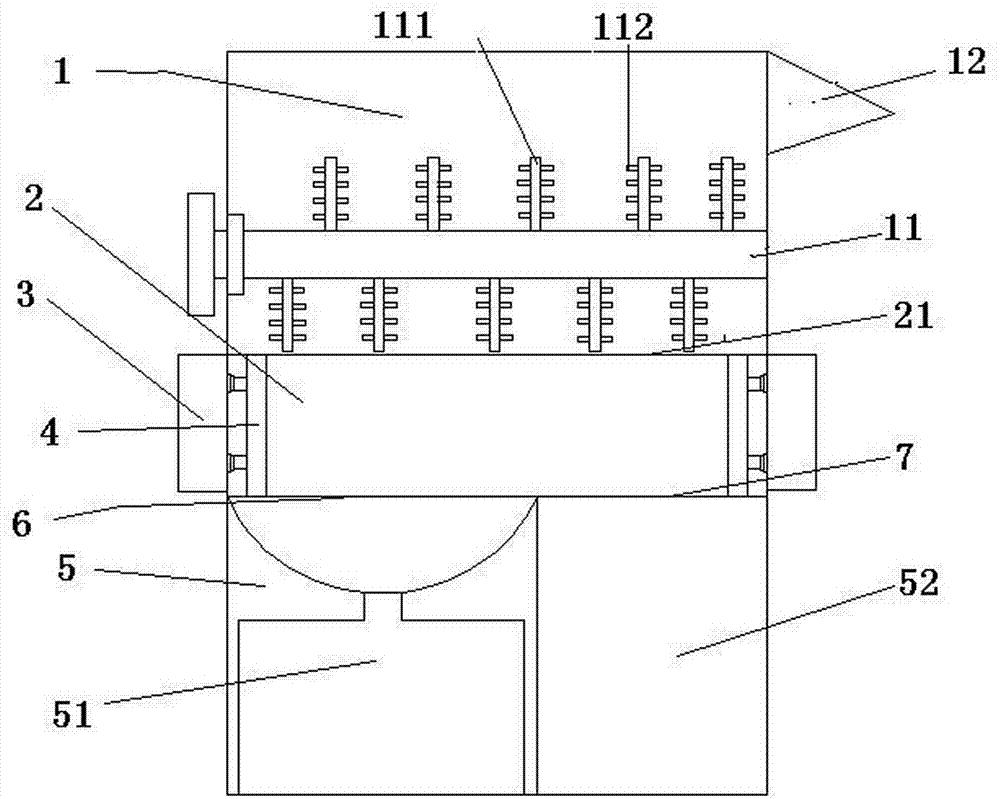

Household garbage treatment device

The invention discloses a household garbage treatment device, and relates to the technical field of garbage treatment. The household garbage treatment device provided by the invention comprises a cutting unit, a compression unit and a collecting unit, wherein one side of the cutting unit is provided with an opening; the cutting unit is internally provided with a knife frame, and the compression unit is correspondingly arranged below the cutting unit; the two ends of the compression unit are provided with compression motors, and the compression motors are internally provided with compression plates. The treatment device provided by the invention has the advantages that structure is simple and compact, solid waste and sewage in the household garbage are separated, part of household garbage (kitchen garbage) is recycled and reused, and the recovery value and the utilization value of the part of household garbage (kitchen garbage) are reflected.

Owner:LESHAN SHIFENG ENVIRONMENTAL PROTECTION TECH

Cutting thickness adjustable tablet cutting device

The invention relates to cutting devices, in particular to a cutting thickness adjustable tablet cutting device which is designed to achieve the technical effects of cutting a medicine material into tablets instead of manual operation, is convenient to operate and can also cut the medicine material into the tablets with the required thickness. The cutting thickness adjustable tablet cutting devicecomprises a rack. One side of the outer portion of the rack is fixedly connected with a supporting leg. At least two third connecting rods are obliquely mounted between the side, close to the supporting leg, of the outer portion of the rack and the side, far away from the rack, of the supporting leg. Through the cutting thickness adjustable tablet cutting device, the medicine material is placed into a containing tank to make contact with a baffle; a first motor is started and can drive a blade to move downwards to conveniently cut the medicine material into tablets instead of manual cutting;and moreover, a first wedge block is made to move left and right by pulling an elliptic nut to move left and right, that is, the cutting thickness adjustable tablet cutting device can be adjusted according to the required tablet thickness.

Owner:SHANDONG QINGDAO HOSPITAL OF INTEGRATED TRADITIONAL & WESTERN MEDICINE

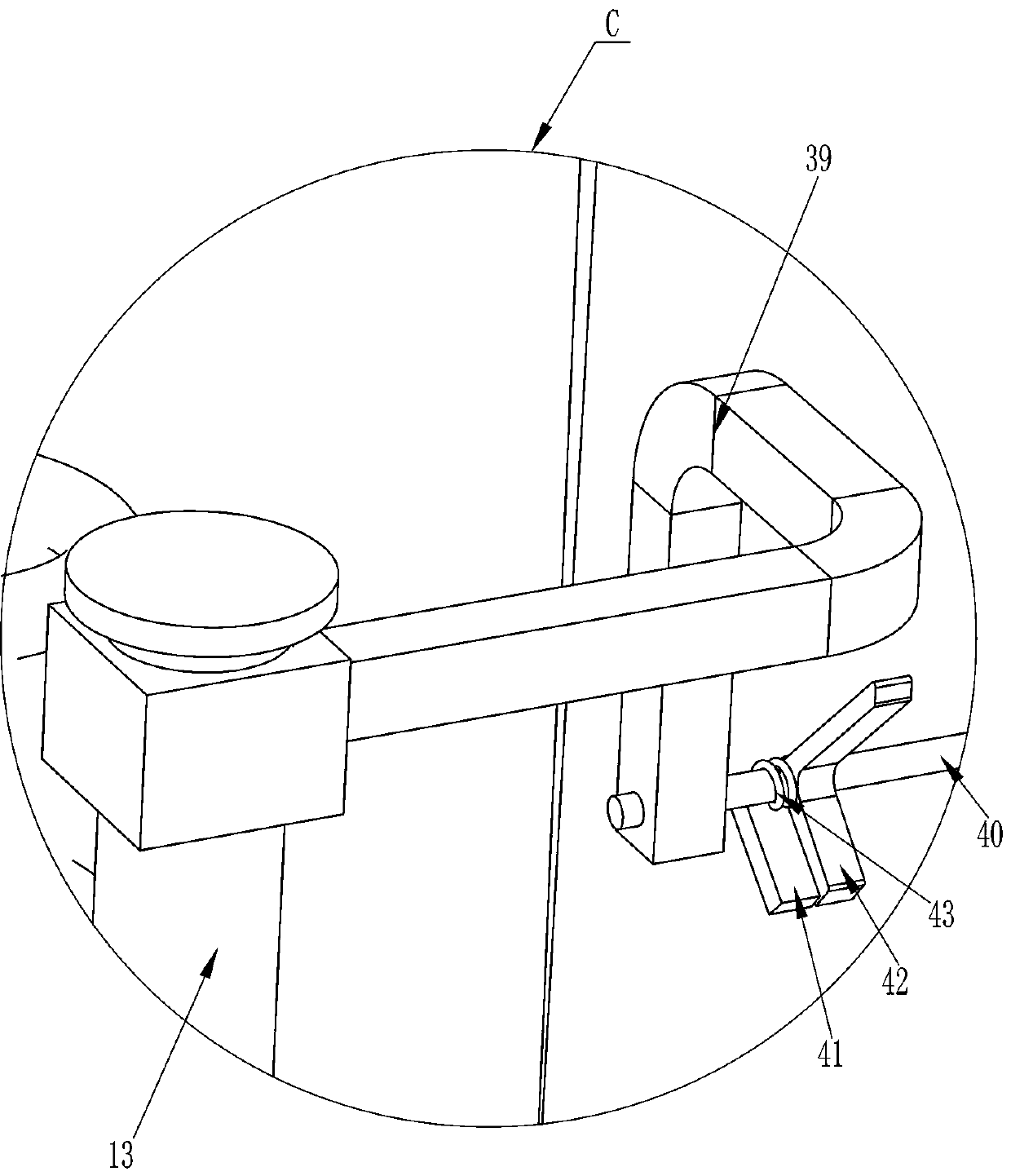

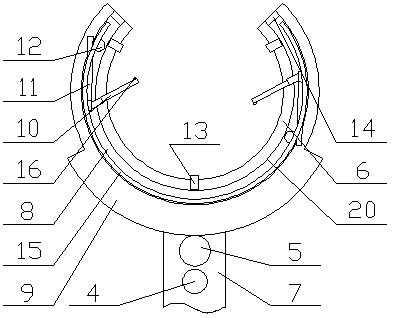

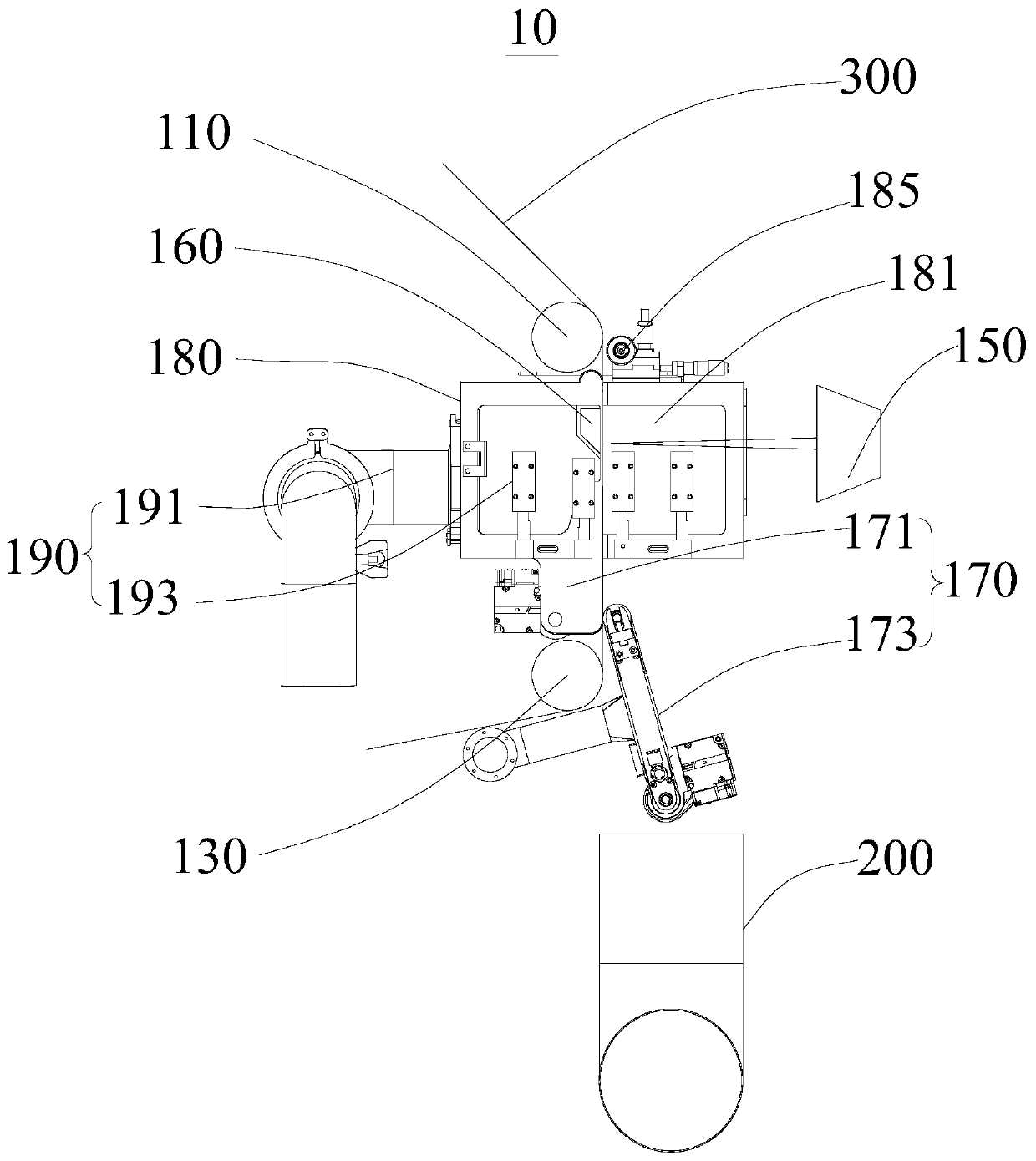

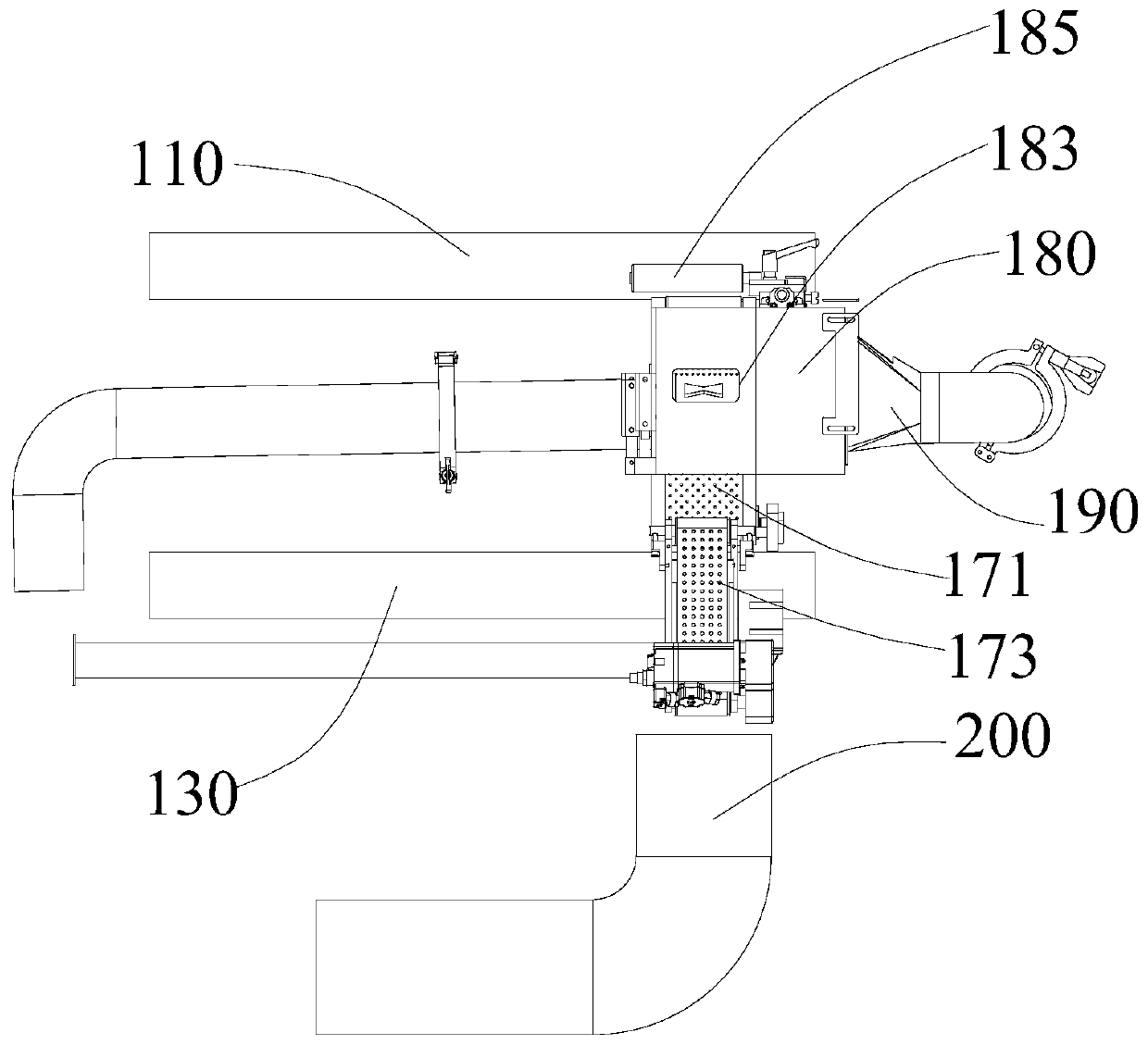

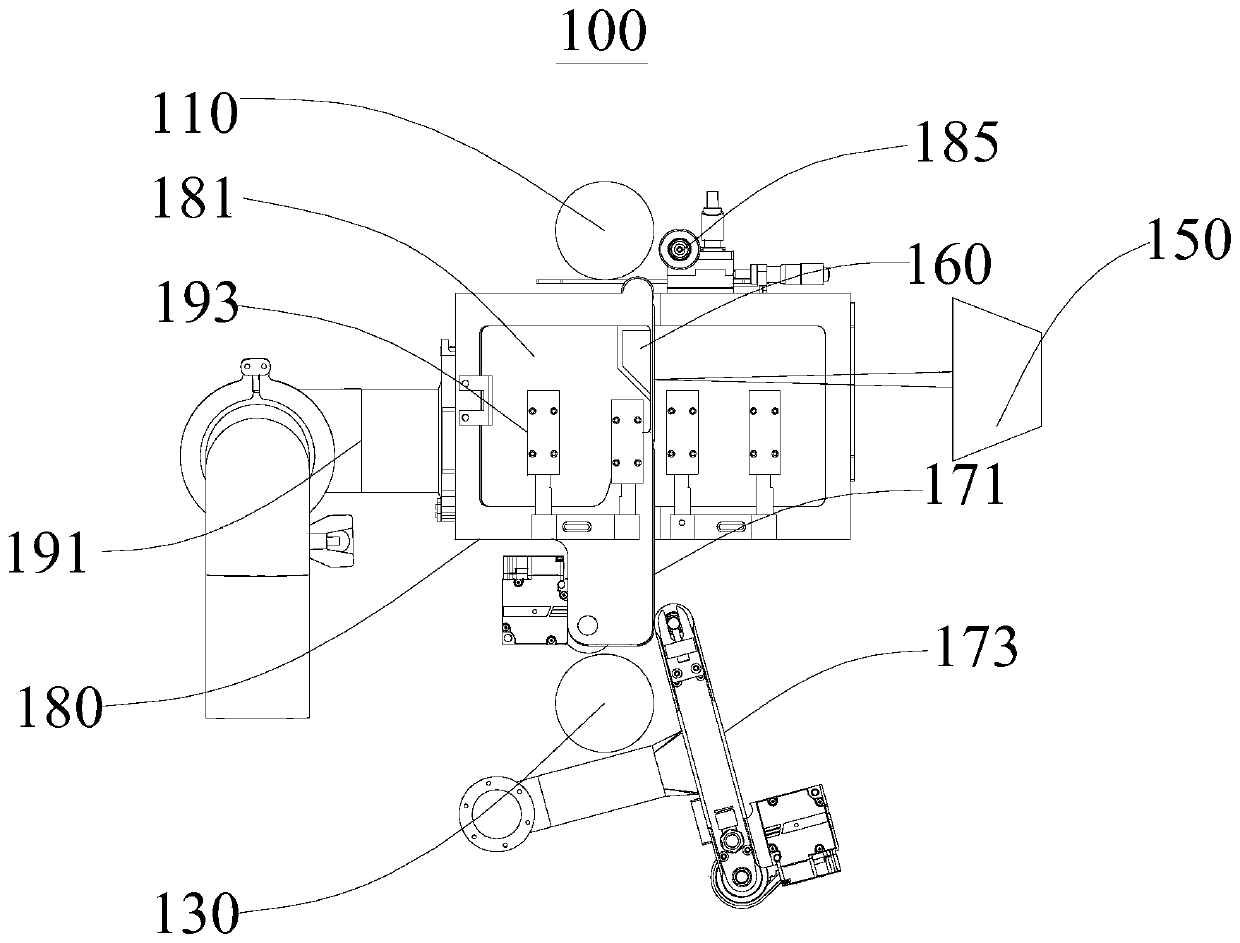

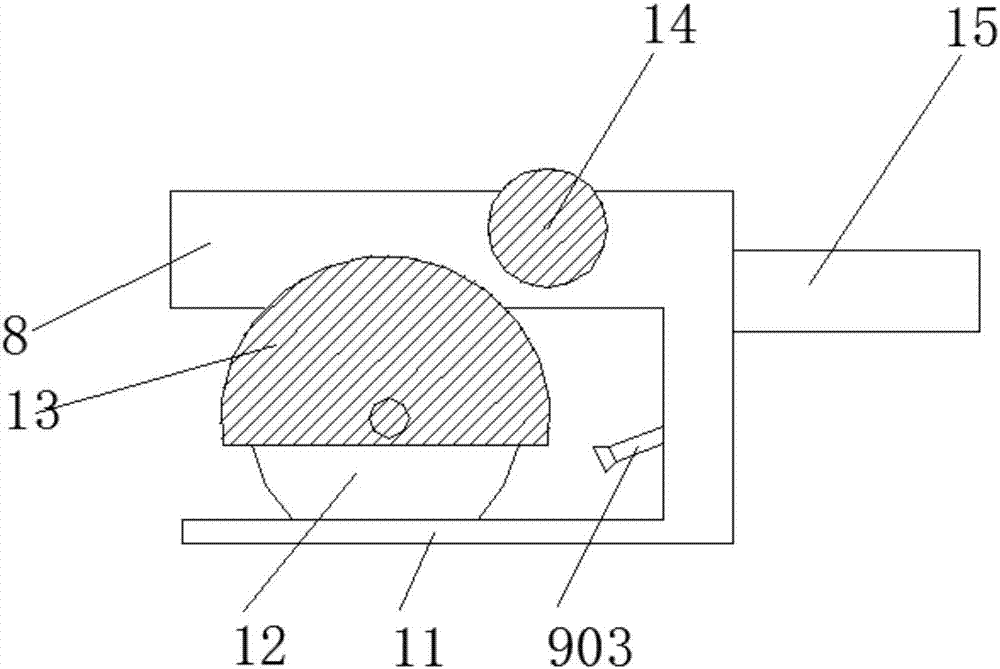

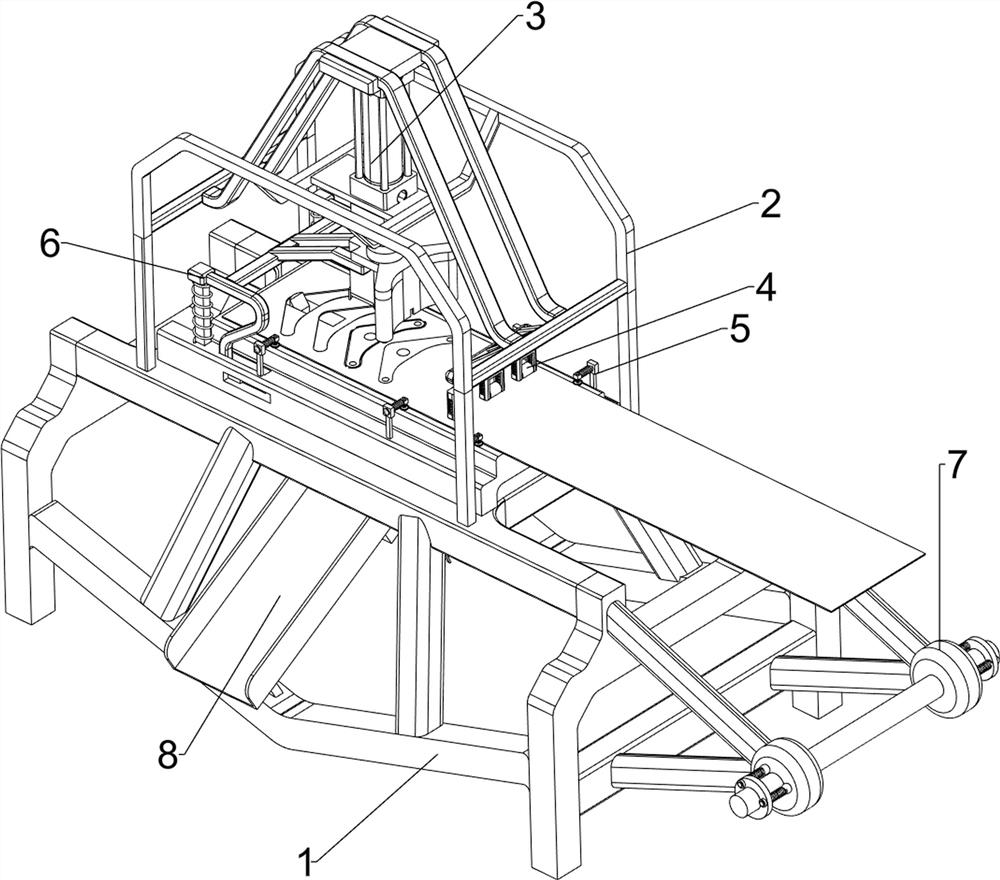

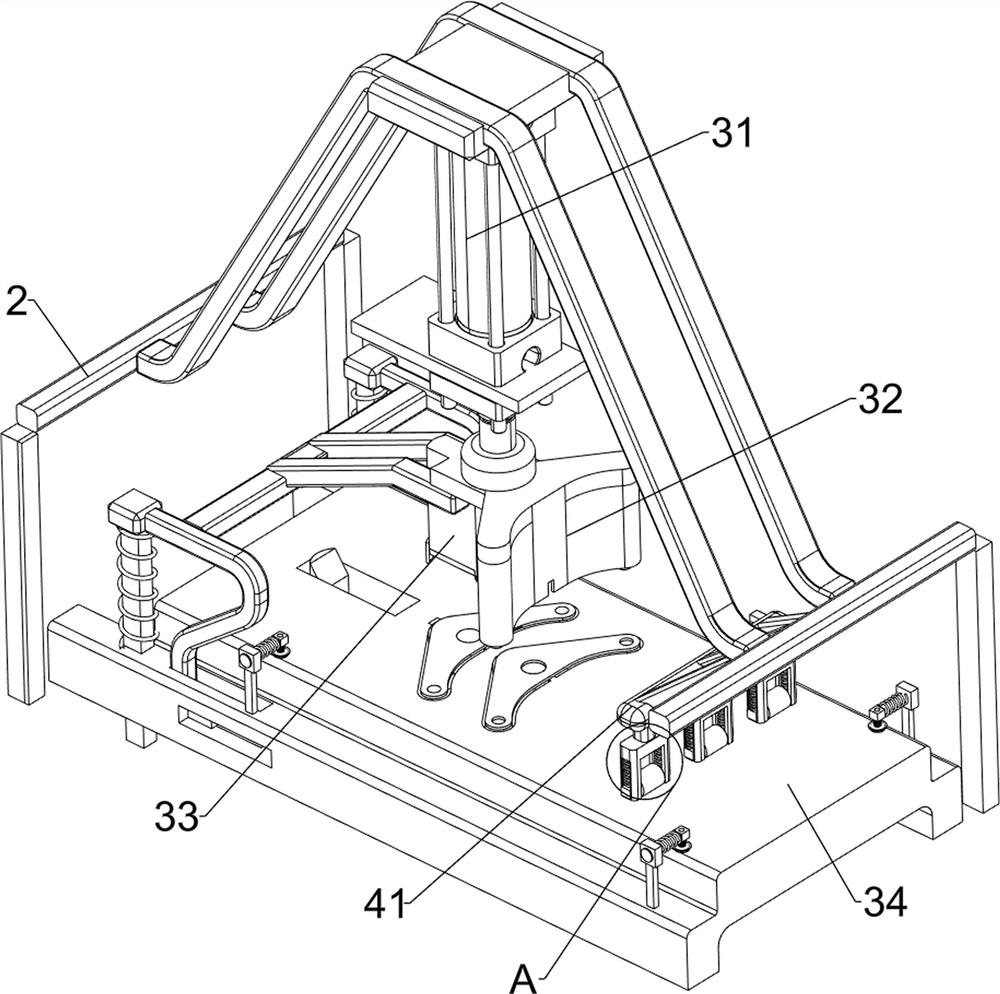

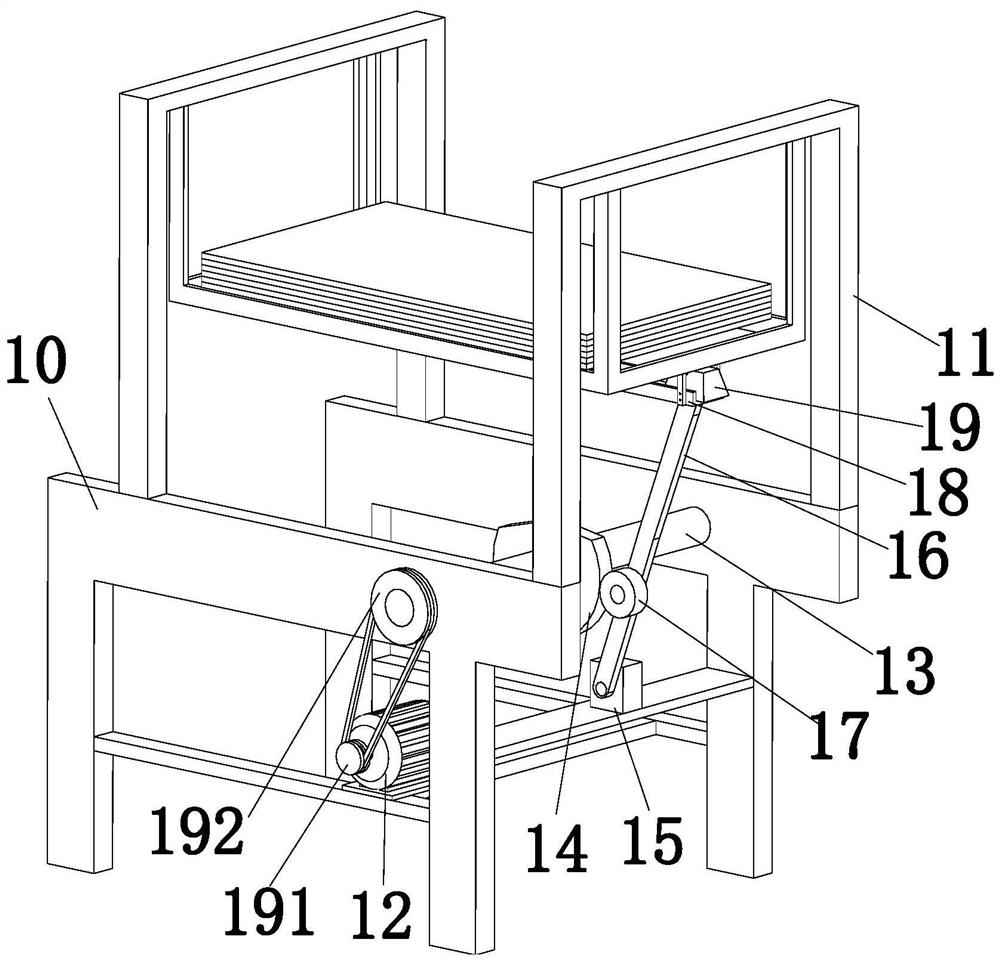

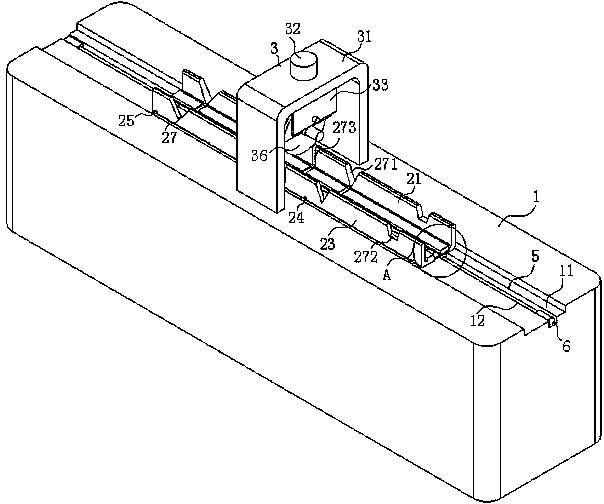

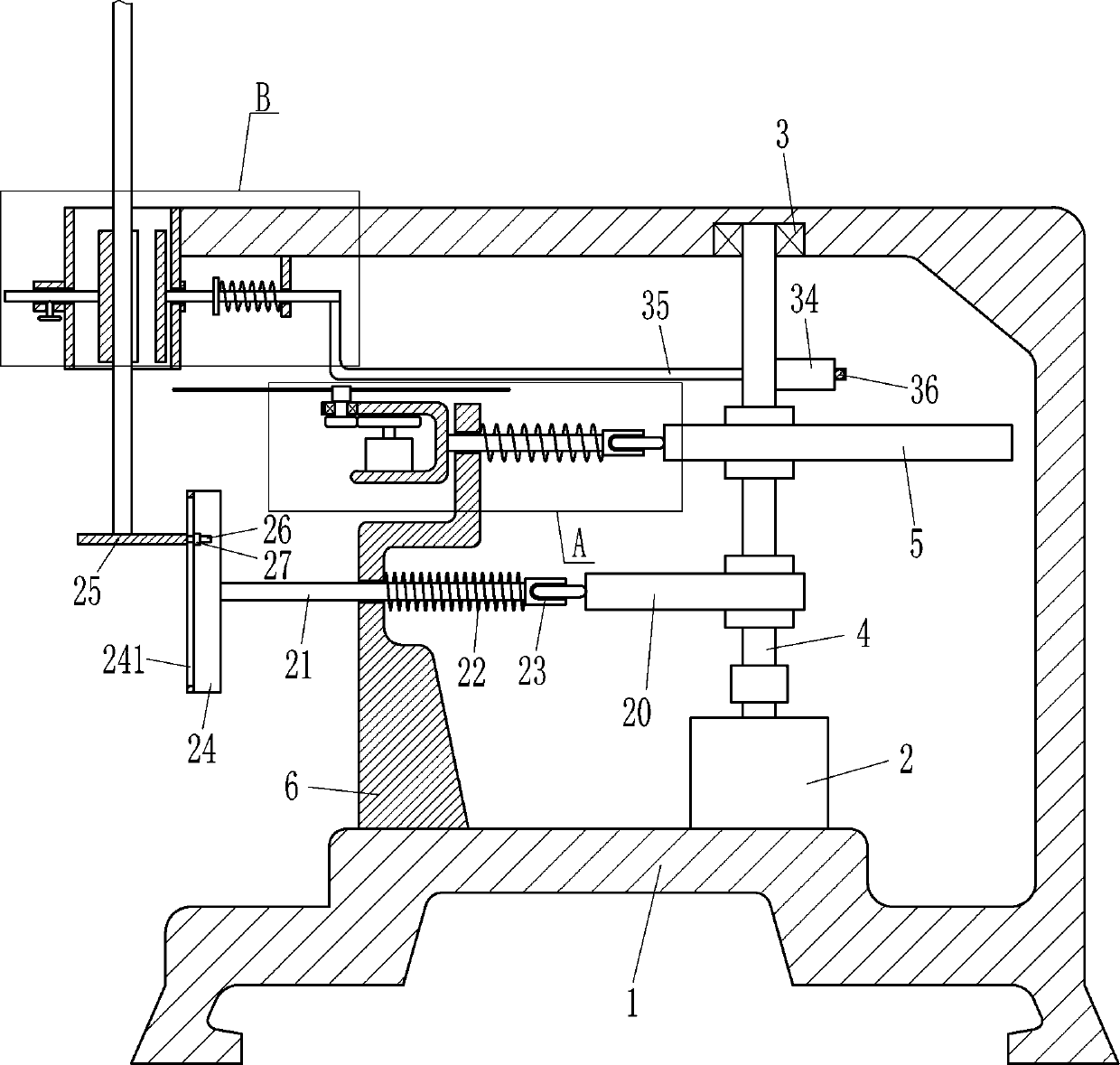

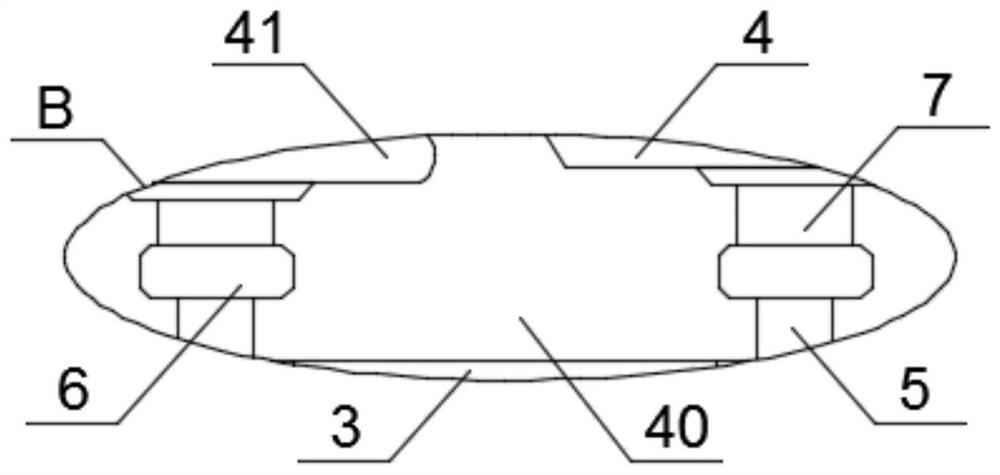

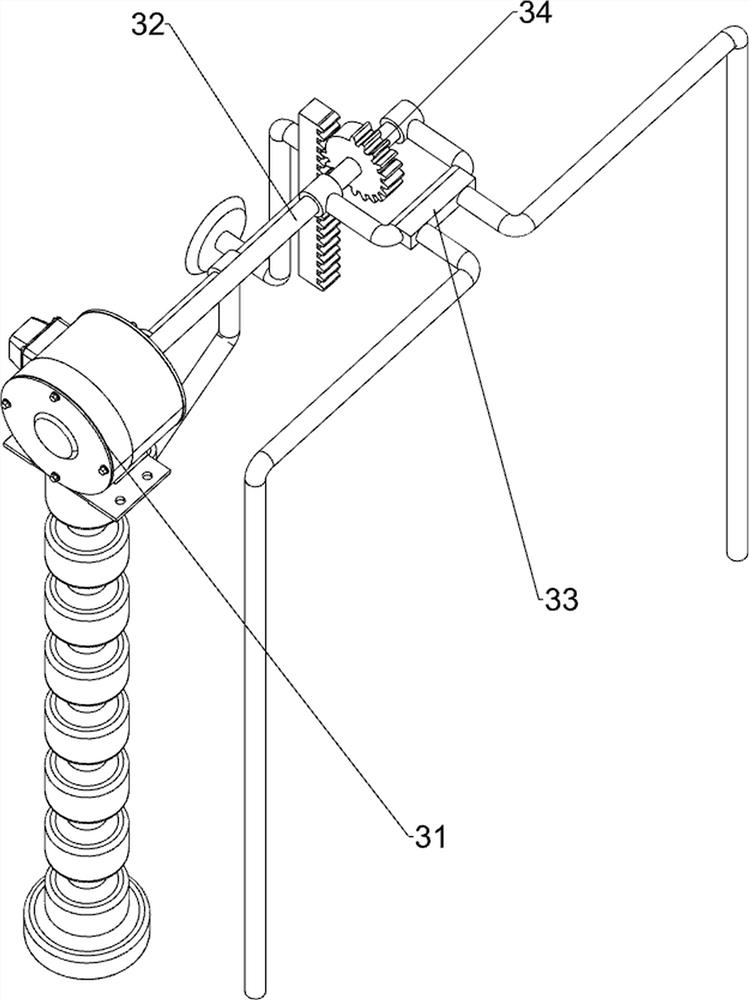

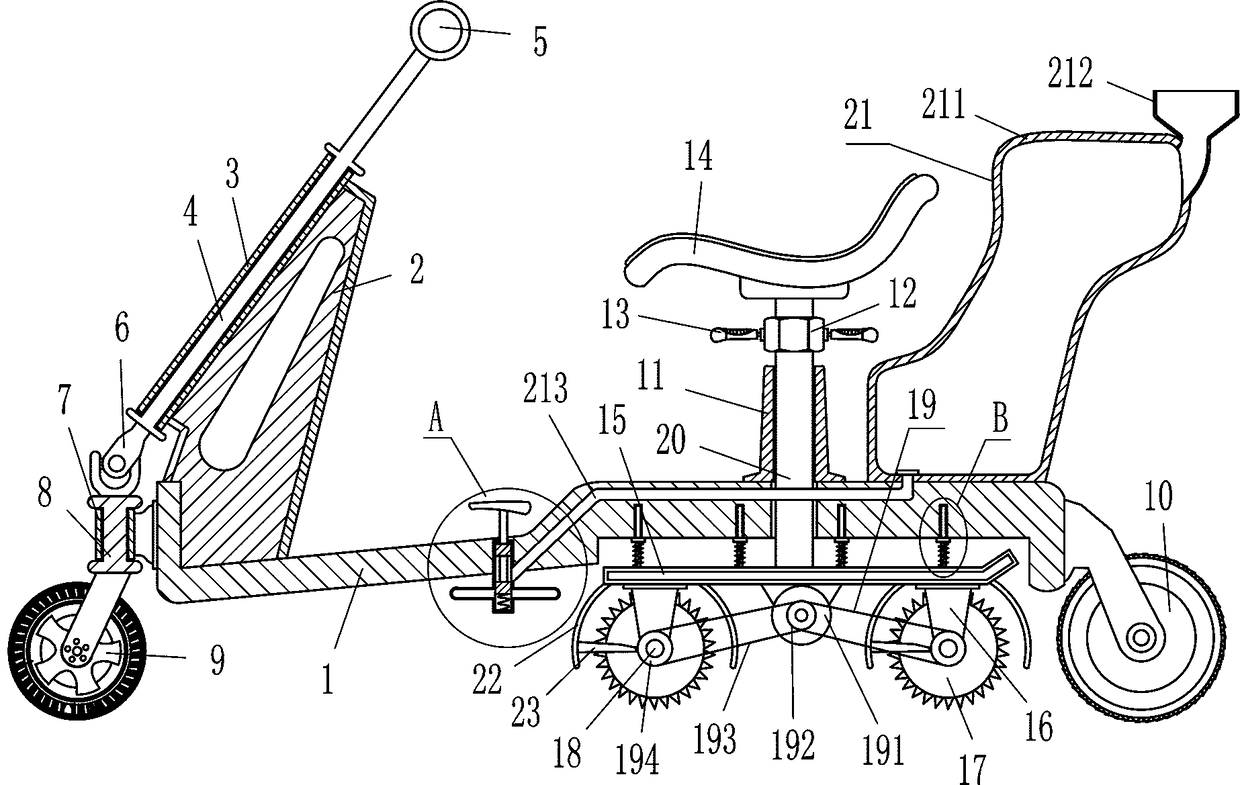

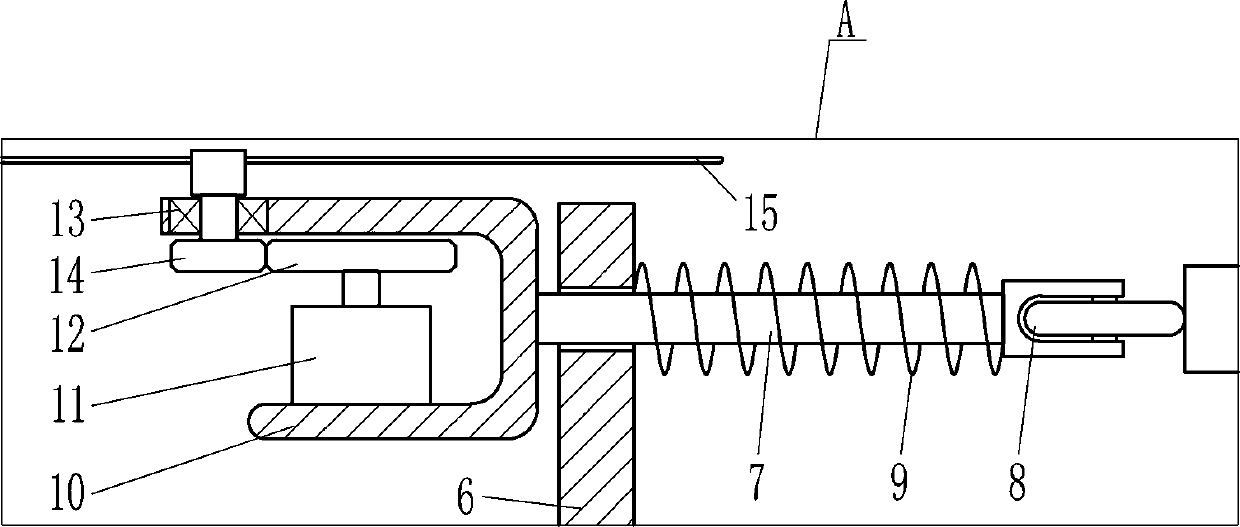

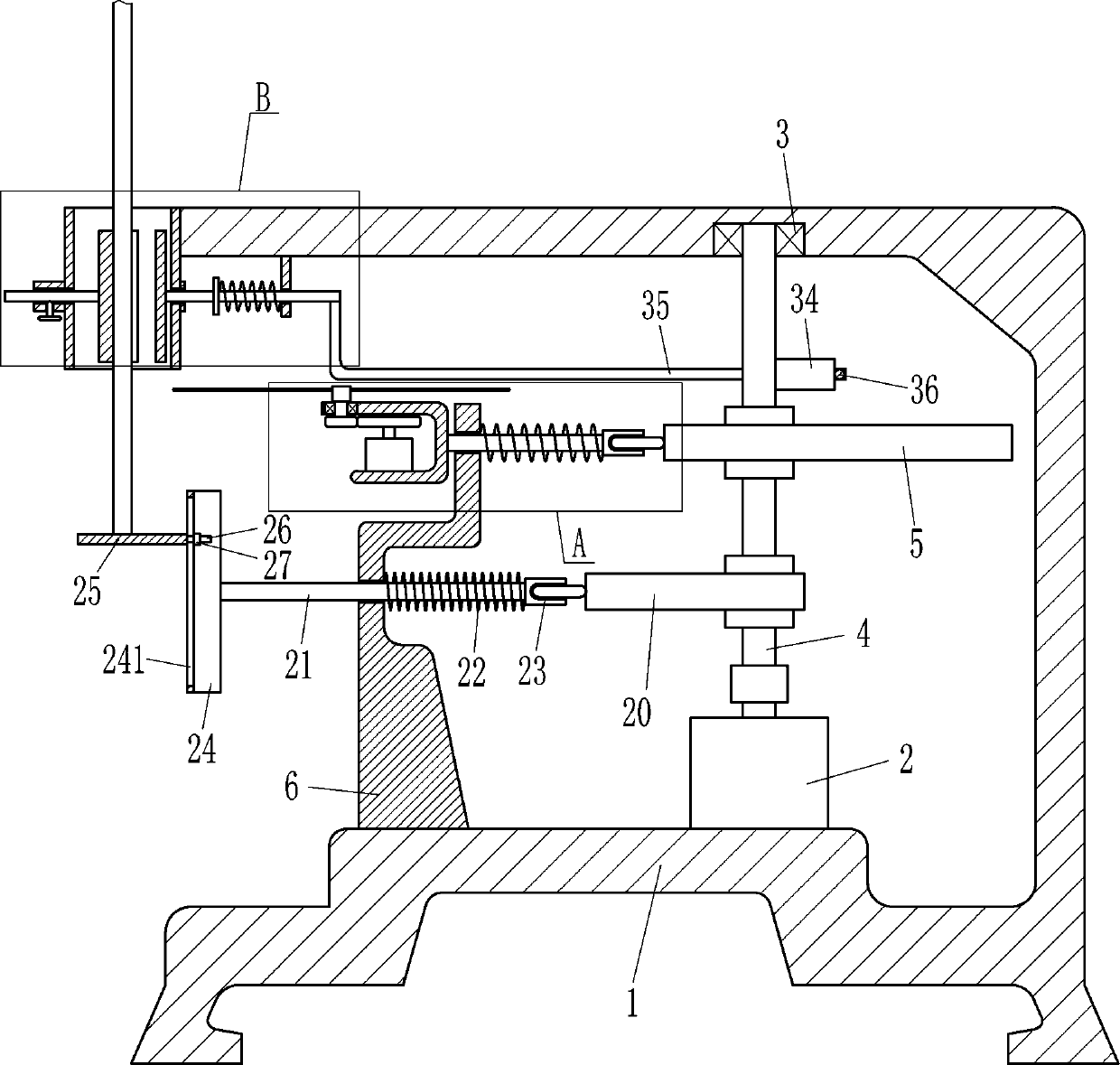

Harvester for leaves of agave sisalana

ActiveCN107926278AAchieve mechanized harvestingChanging the game for manual harvestingHarvestersEngineeringUltimate tensile strength

The invention discloses a harvester for leaves of agave sisalana. A lifting frame is movably connected up and down with the front end of a vehicle body, a piston is transversely fixed at the front endof the lifting frame, a piston rod of the piston extends towards one side of the vehicle body, and a harvesting device is fixed at the end part of the piston rod; and the harvesting device comprisesa ring sleeve, a hollow cavity is arranged in the ring sleeve, a groove opening is arranged in the middle of the top surface of the ring sleeve, an annular rod which is in slide connection along the ring sleeve is arranged in the ring sleeve, one side, far away from the piston, of the ring sleeve is provided with a gap A, the annular rod is provided with a gap B, the straight line distance of a gap with a smaller radian in the gap A and the gap B is greater than or equal to the diameter of the stem of the agave sisalana, the top, located at in the range of the groove opening, of the annular rod is inwards provided with cutting knives, and the distance between each cutting knife and the circle center of the annular rod is greater than the radius of the stem of the agave sisalana. Accordingto the above structure, the harvester for the leaves of the agave sisalana provided by the invention realizes mechanized harvesting of the leaves of the agave sisalana, thereby changing the industry rule that the agave sisalana can only be manually harvested, greatly reducing the labor intensity of harvesting of the leaves of the agave sisalana, and improving the harvesting efficiency of the leaves of the agave sisalana.

Owner:JIANGSU HIMALAYA NATURAL FIBER PROD

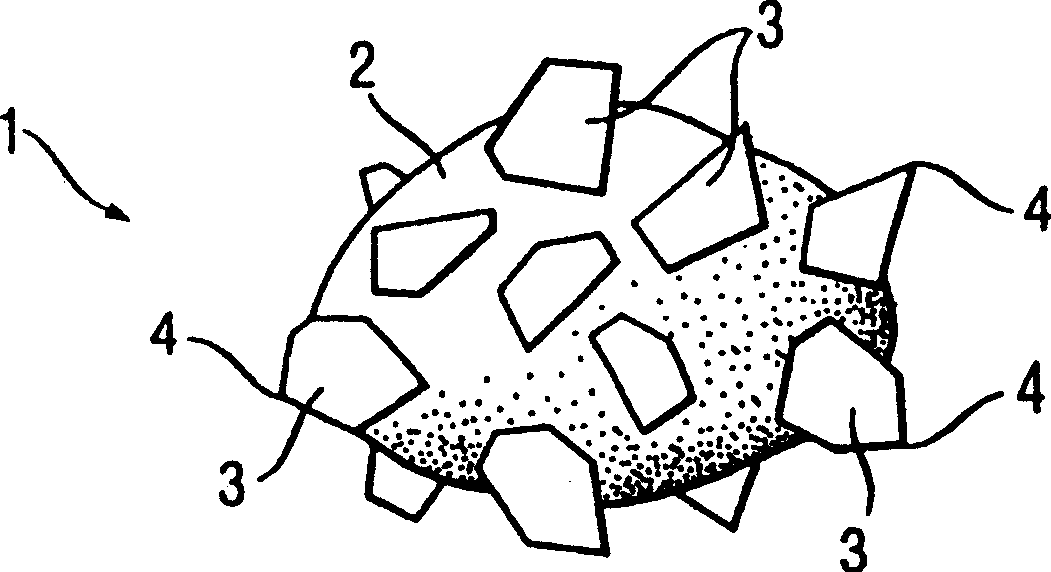

Diamond multicrystal group, segment block made of multicrystal group and their manufacturing method

A polycrystalline diamond assembly is proportionally prepared from the diamond particles (160-850 microns in diameter), the metal material as mother body and adhesive through mxing. A block for cutting purpose is prepared from said polycrystalline diamond assemblies, which are distributed in group mode, column mode or stack mode (1.21-8 mm in granularity). Its advantage is high cutting efficiency and antiwear performance.

Owner:曲云霄 +1

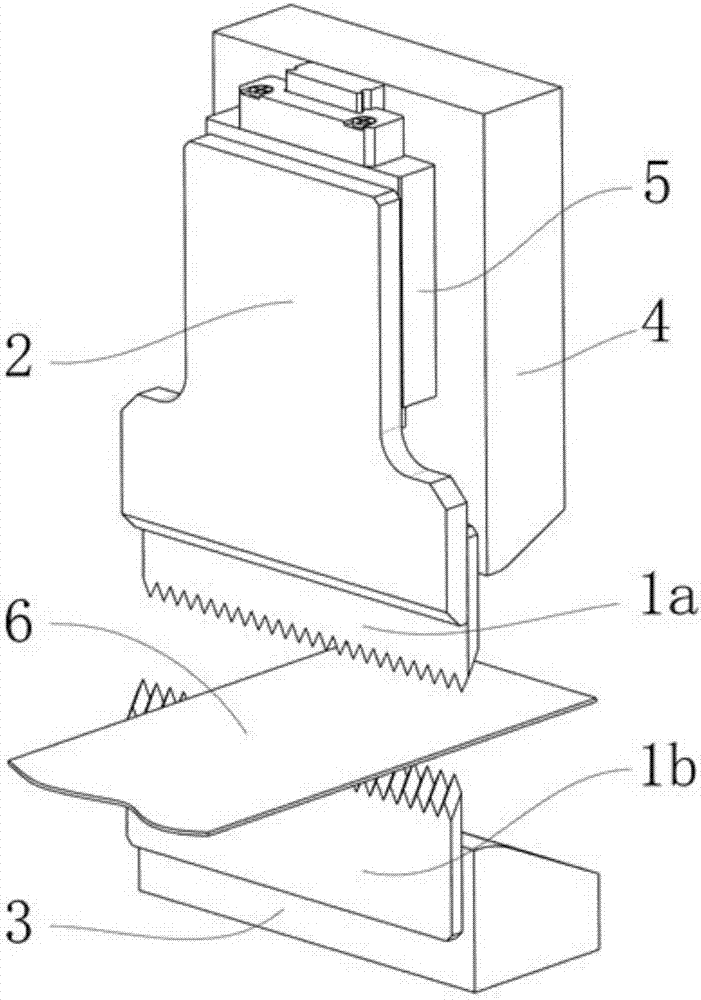

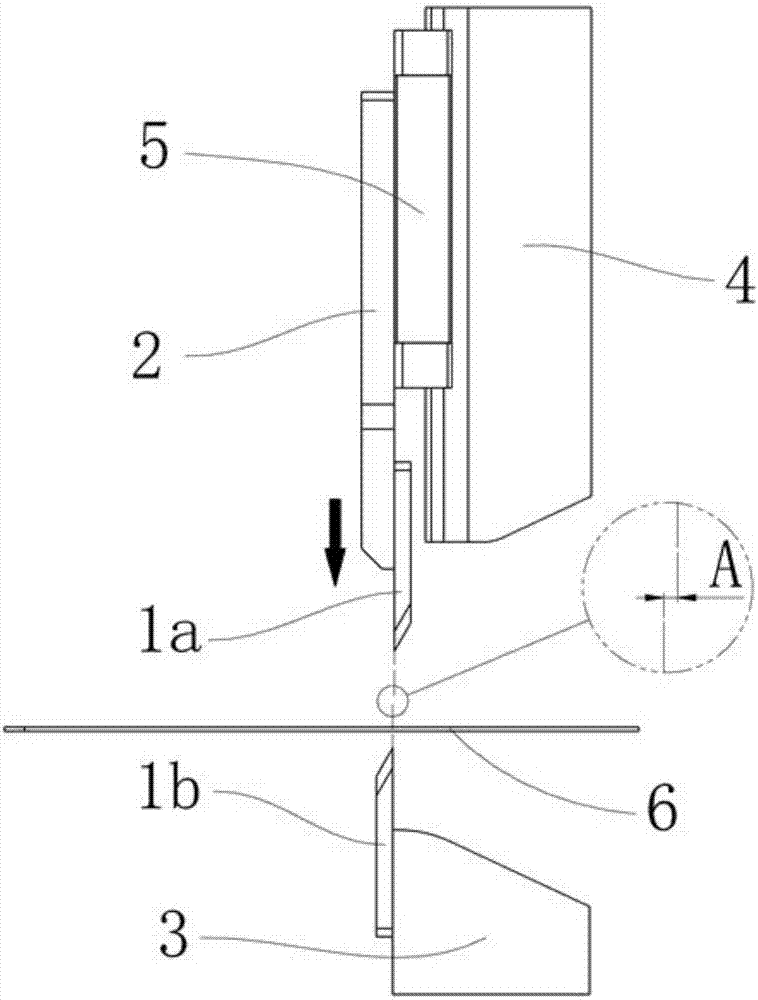

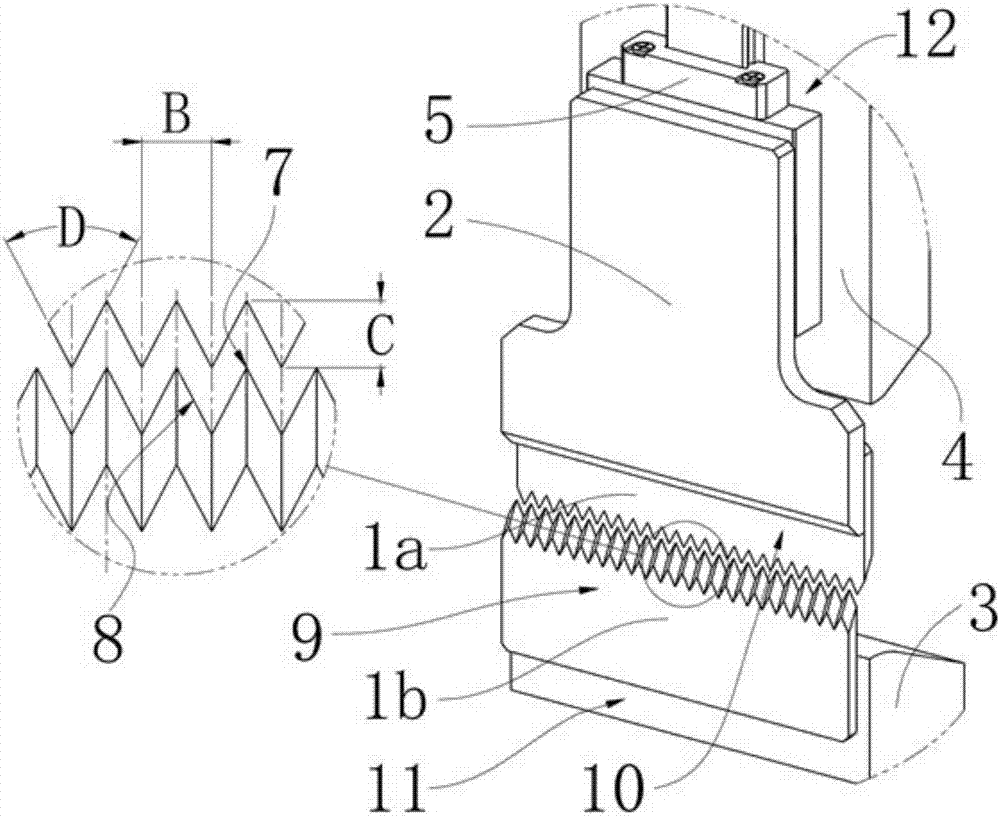

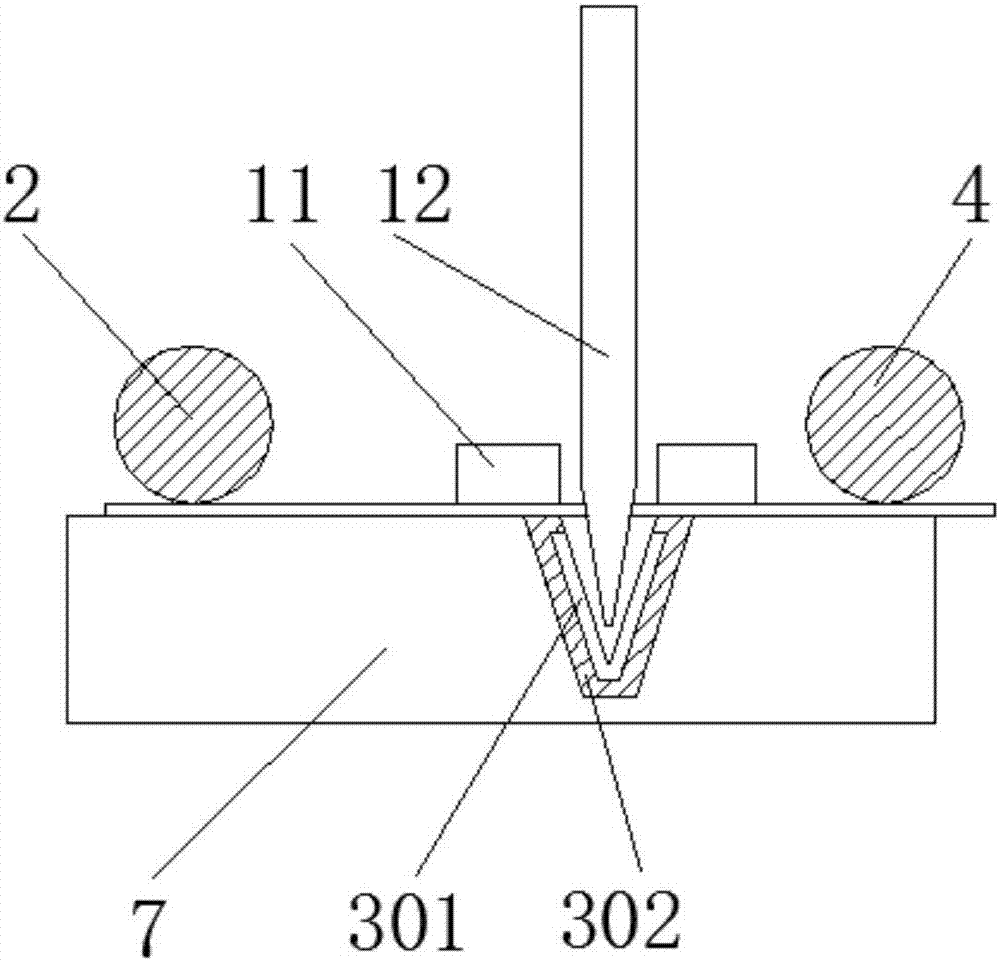

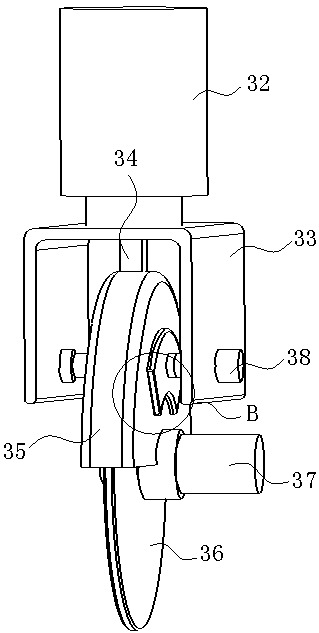

Adhesive tape cutting mechanism and method thereof

ActiveCN106876043ASolve wear and tearCutting effectManufacturing wire harnessesEngineeringMechanical engineering

The invention discloses an adhesive tape cutting mechanism and a method thereof, and belongs to the field of automatic devices. The cutting mechanism comprises an upper blade and a lower blade. Each of the edged part of the upper blade part and the lower blade part is in the shape of sawtooth. The sawteeth of the two blades are arranged on two sides where a to-be-cut adhesive tape in the cutting mechanism. A driving device is arranged on the upper blade and / or the lower blade and is used for driving the two blades to oppositely move and pierce the adhesive tape from opposite directions. Moving journeys of the sawtooth parts of the upper blade and the lower blade are overlapped to a certain degree in a position where the to-be-cut adhesive tape is arranged. In the overlapped journey, non-edged parts of the two blades get close to each but keep a certain distance. According to the invention, blades can be prevented from being abraded in actual application; the cutting mechanism and the method are quite suitable for all kinds of highly adhesive cloth-based adhesive tapes; and even if an inevitable adhesion phenomenon exists in a cutting process, cutting of the adhesive tape will not be affected.

Owner:ZHUJI CANU AUTOMATION EQUIP CO LTD

Plate cutting device

InactiveCN111251383ASimple structureEasy to operateProfiling/shaping machinesPhysicsElectric machinery

The invention discloses a plate cutting device. The device comprises a cutting machine, wherein a cutting cavity is arranged in the cutting machine, a lower side of the cutting cavity is communicatedwith a sliding cavity, the left side and the right side of the sliding cavity are communicated with the outside through a feed port and a discharge port, the lower side of the sliding cavity is communicated with a conveying cavity, the conveying cavity is internally provided with a conveying plate, the lower end of the conveying plate is fixed by two conveying assemblies which are the same on theleft and the right sides, a front end wall and a rear end wall of the lower side of the sliding cavity are respectively and fixedly provided with a sliding platform, the right side of the conveying cavity is provided with a blanking cavity communicated with the sliding cavity, a through hole matched with the blanking cavity is formed in the sliding platform, a supporting shaft is rotatably arranged on the upper end wall of the cutting cavity, the lower end of the supporting shaft is connected with a first spline shaft through a first spline sleeve, and a round disc is fixedly arranged at the lower end of a first reciprocating shaft. A motor drives a cutting knife to cut the plate by rotating a circle, and a pressing block presses the plate to prevent the plate from moving to influence thecutting, the manual cutting is not needed, and labor is saved.

Owner:宁波市萨哈机械科技有限公司

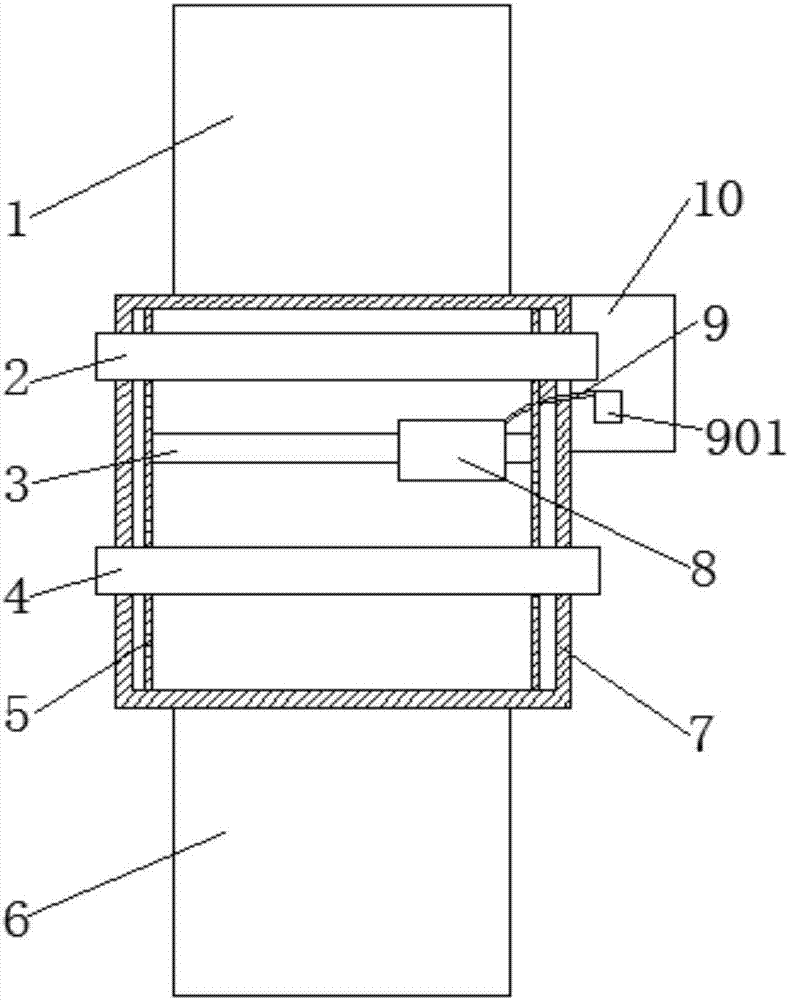

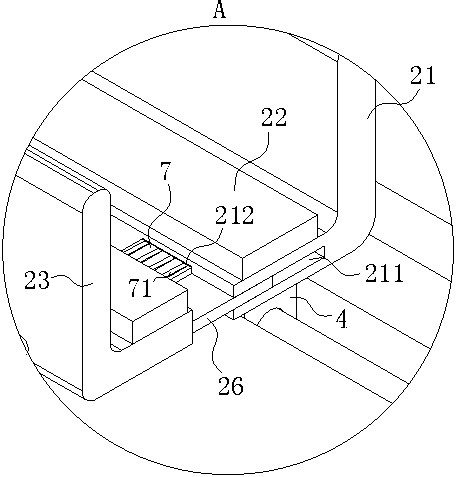

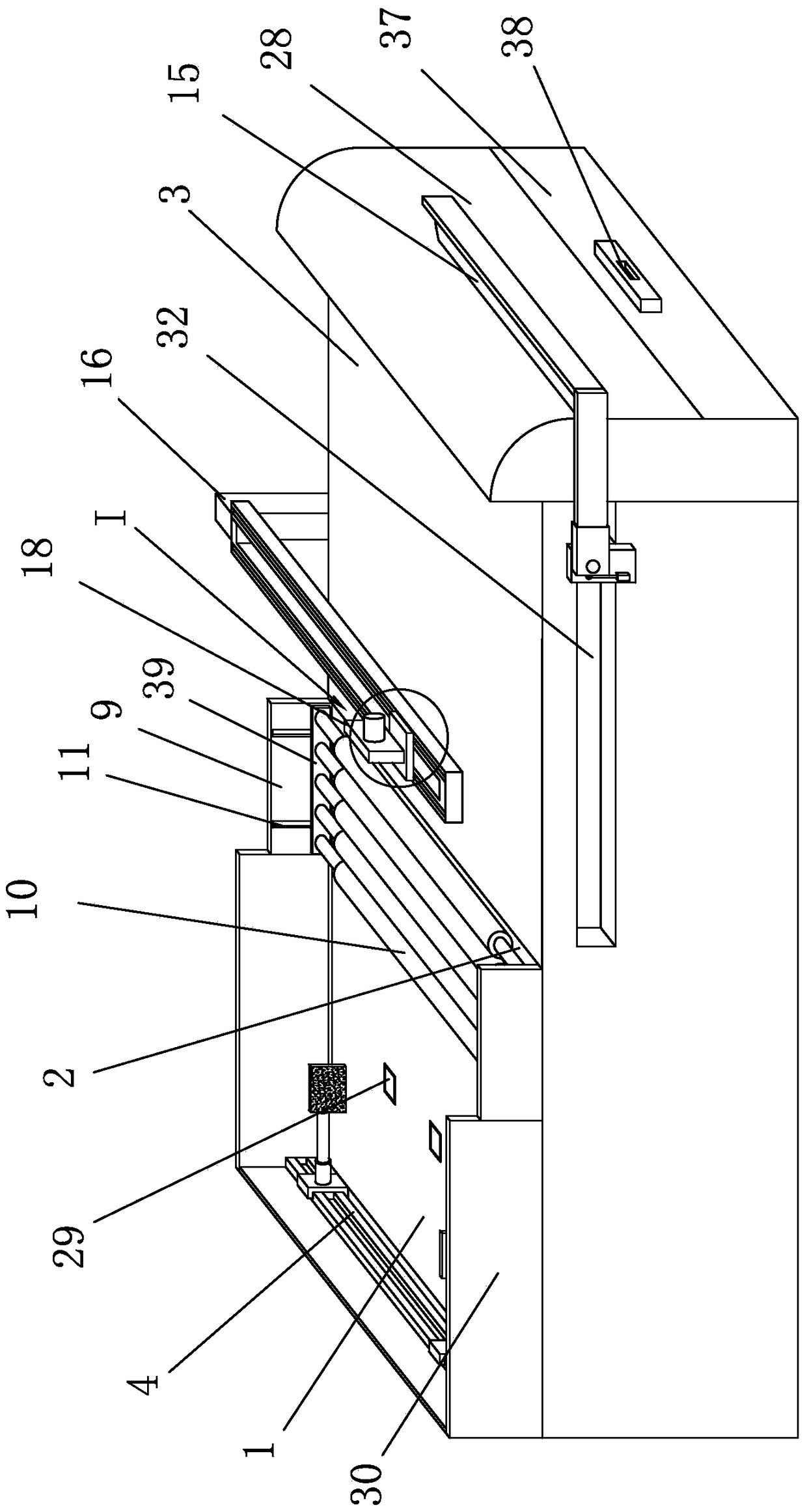

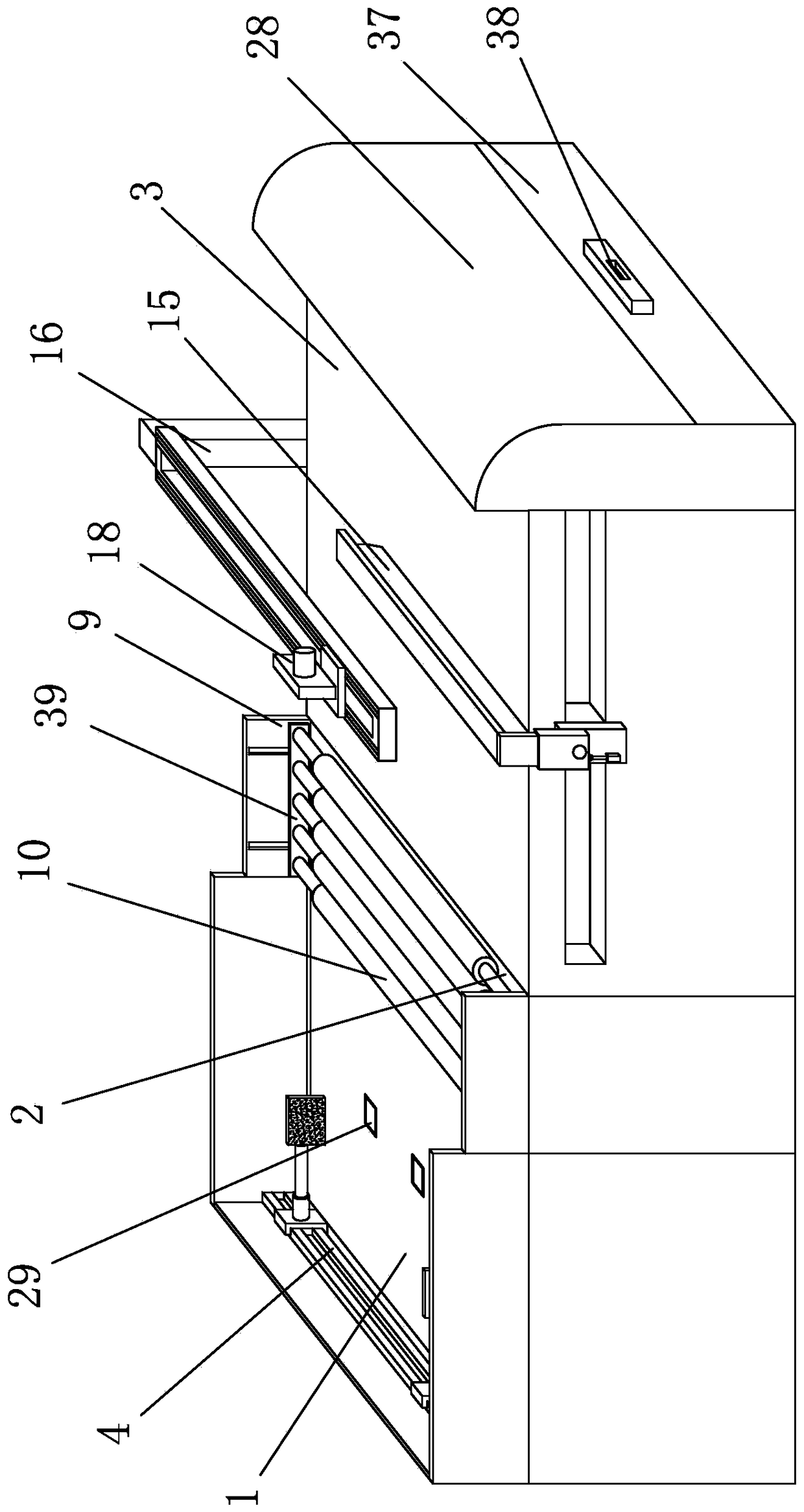

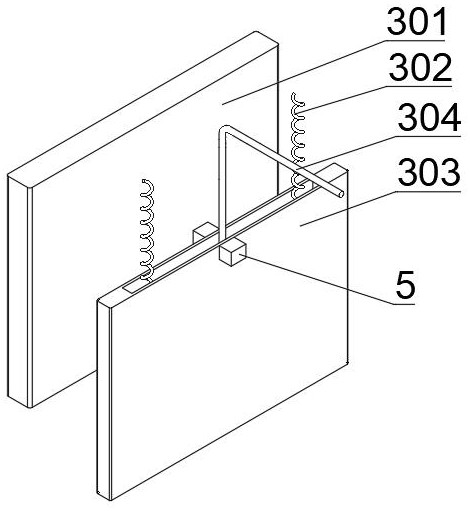

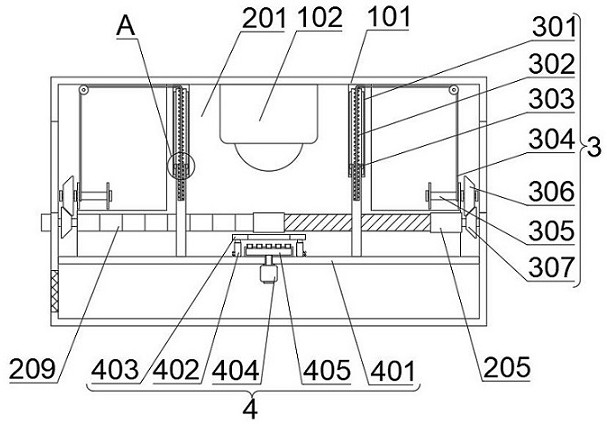

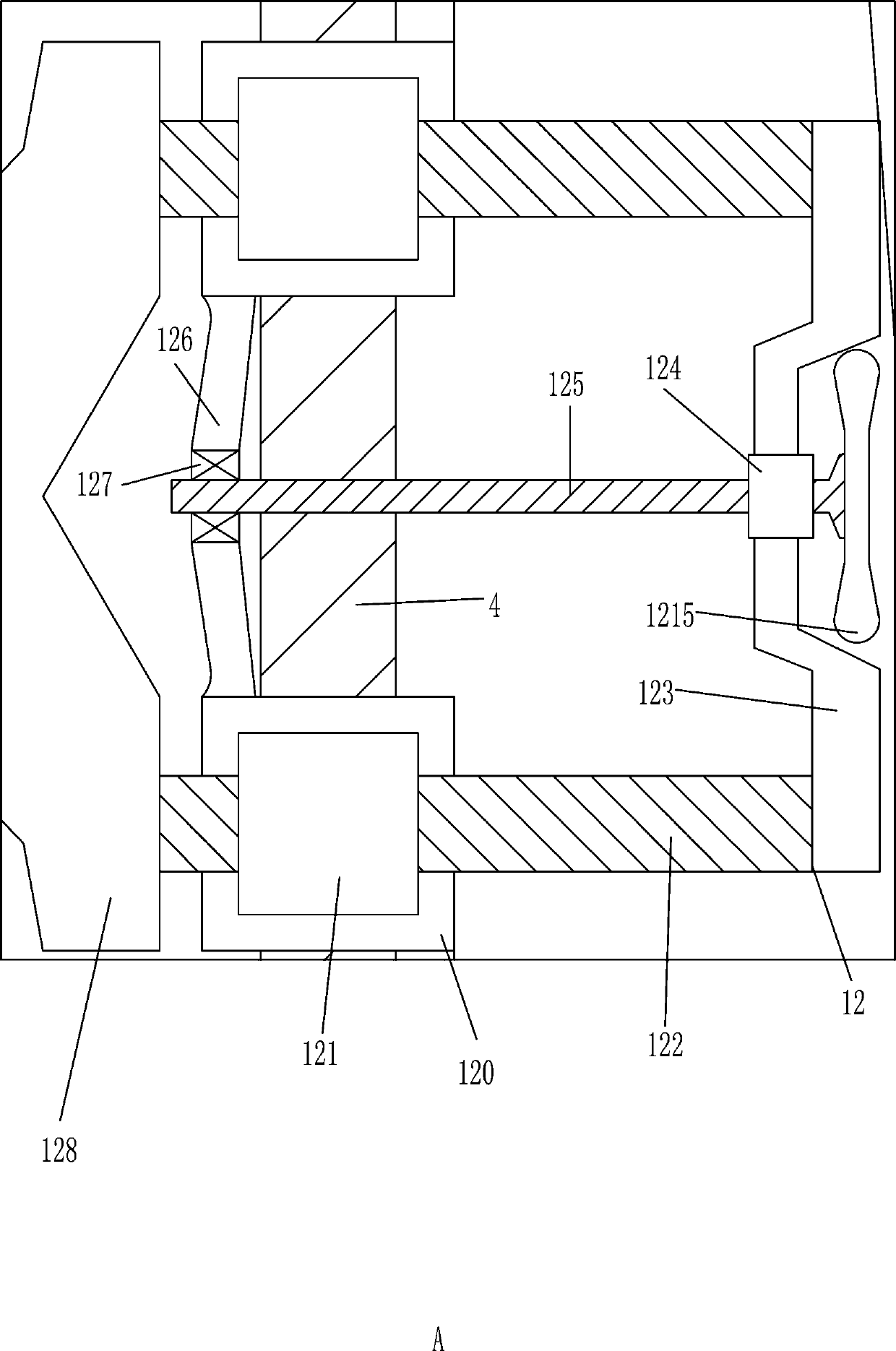

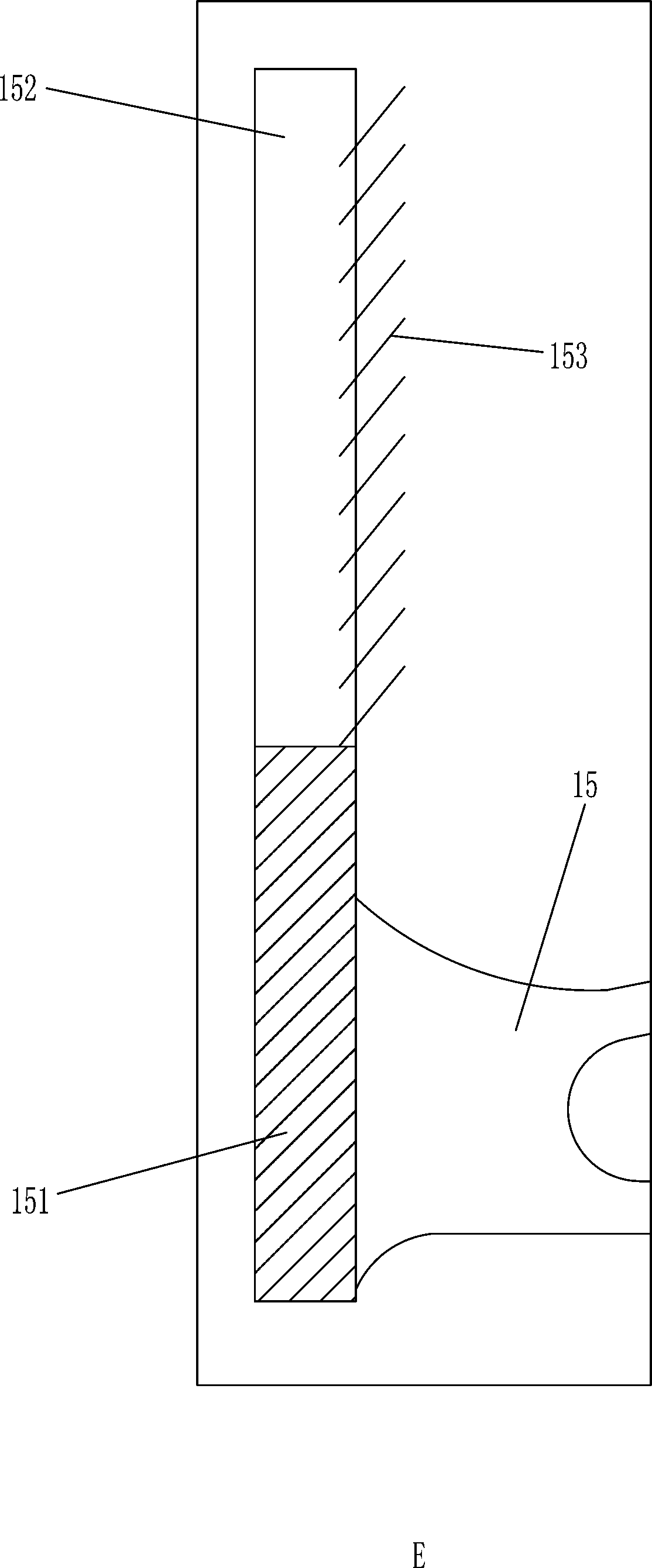

Pole lug cutting device and pole lug cutting system

PendingCN110560935AImprove stabilityCutting effectMetal working apparatusLaser beam welding apparatusPole pieceMechanical engineering

The invention provides a pole lug cutting device and a pole lug cutting system, and relates to the technical field of lithium battery manufacturing. The pole lug cutting device comprises a first supporting roller, a second supporting roller, a cutting bottom plate, a laser cutting part and a waste discharging mechanism. The first supporting roller and the second supporting roller are arranged in parallel in a spaced manner, the cutting bottom plate is arranged between the first supporting roller and the second supporting roller, the laser cutting part is opposite to the cutting bottom plate, the waste discharging mechanism comprises a negative pressure metal belt assembly and a negative pressure belt assembly, the negative pressure metal belt assembly is arranged between the second supporting roller and the cutting bottom plate, and the negative pressure belt assembly is arranged on the end, close to the second supporting roller, of the metal belt assembly. Compared with the prior art,the pole lug cutting device is long in service life, waste generated by cutting can be absorbed in time, stability of pole pieces in the cutting process is high, and cutting quality is ensured.

Owner:GEESUN AUTOMATION TECH

Garment fabric cutting machine

The invention provides a garment fabric cutting machine, and belongs to the technical field of garment processing equipment. The problem that existing cutting machines are relatively low in cutting accuracy is solved. The garment fabric cutting machine comprises a rack onto which a workbench plate is fixedly connected, and also comprises a driving wheel, a driven wheel, a tensioning wheel and a steel belt saw, wherein a connection base is connected onto the workbench plate in a sliding manner, the tensioning wheel is rotationally connected onto the connection base, a tensioning spring capable of allowing the tensioning wheel to tension the steel belt saw is arranged between the workbench plate and the connection base, a positioning base is connected onto the workbench plate in a sliding manner, a dust collection cavity is also formed on the lower surface of the positioning base, and the dust collection cavity is communicated with a through groove as well as an air pump. The garment fabric cutting machine can automatically cut garment fabric and is high in cutting accuracy.

Owner:HENAN INST OF ENG

Novel high-precision cloth cutting machine for preventing cloth from moving

ActiveCN107500008AAvoid dullingAvoid sticking to each otherArticle deliveryWebs handlingEngineeringControl switch

The invention discloses a novel high-precision cloth cutting machine for preventing cloth from moving. The novel high-precision cloth cutting machine comprises a feeding conveying belt, a front pressurizing roller, a cutting sliding rail, limiting blocking plates, a discharging conveying belt, a rack, a spray device, a cutting cutter blade, insulation balance iron, a control switch and an electromotor. The cutting sliding rail is arranged on the upper surface of a cutting platform and located between the front pressurizing roller and a back pressurizing roller. The limiting blocking plates are located on the two sides of the cutting platform. The insulation balance iron is located on the left side of the rack. The control switch is located at the tail end of the rack. The electromotor is located on the right side of the rack and connected with the cutting cutter blade. According to the novel high-precision cloth cutting machine for preventing the cloth from moving, the cutting sliding rail is arranged, the cutting sliding rail comprises a cutter grinding device and a sliding rail groove, arranging of the cutter grinding device can grind the cutting cutter blade while the cutting cutter cuts the cloth, and the fact that a cutter edge is blunt, and the cloth can not be effectively and fast cut due to the fact that the cutting cutter blade is not ground for a long time is prevented.

Owner:江苏优恩服饰辅料有限公司

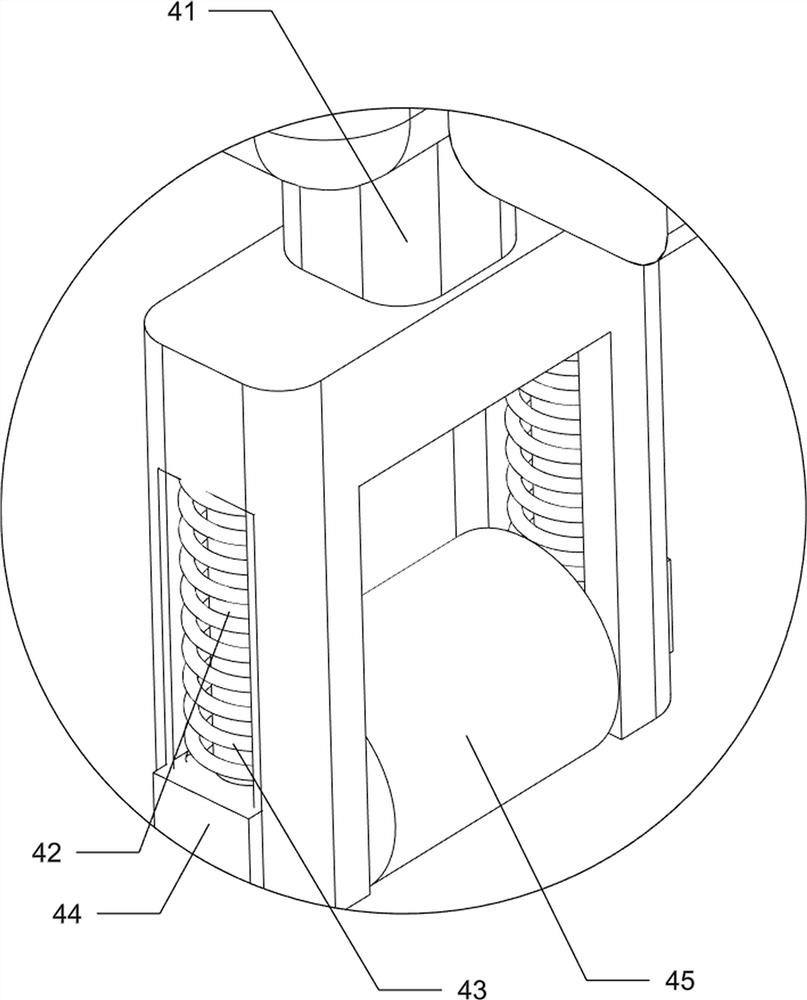

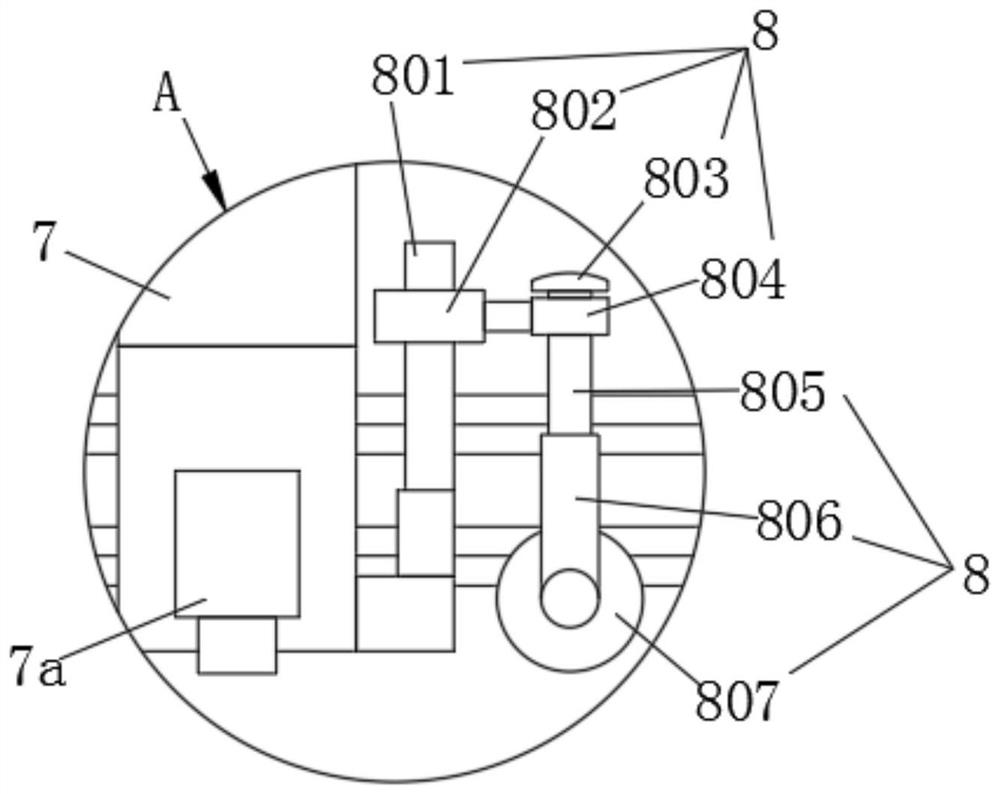

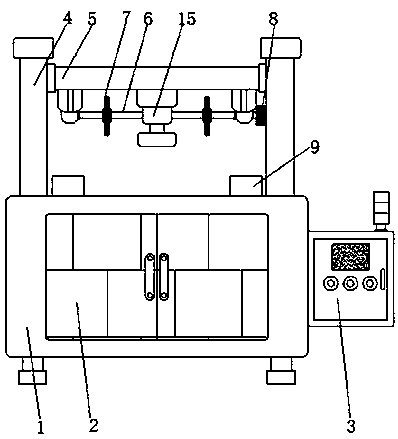

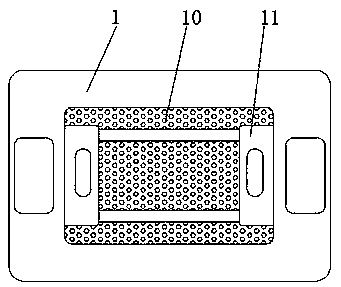

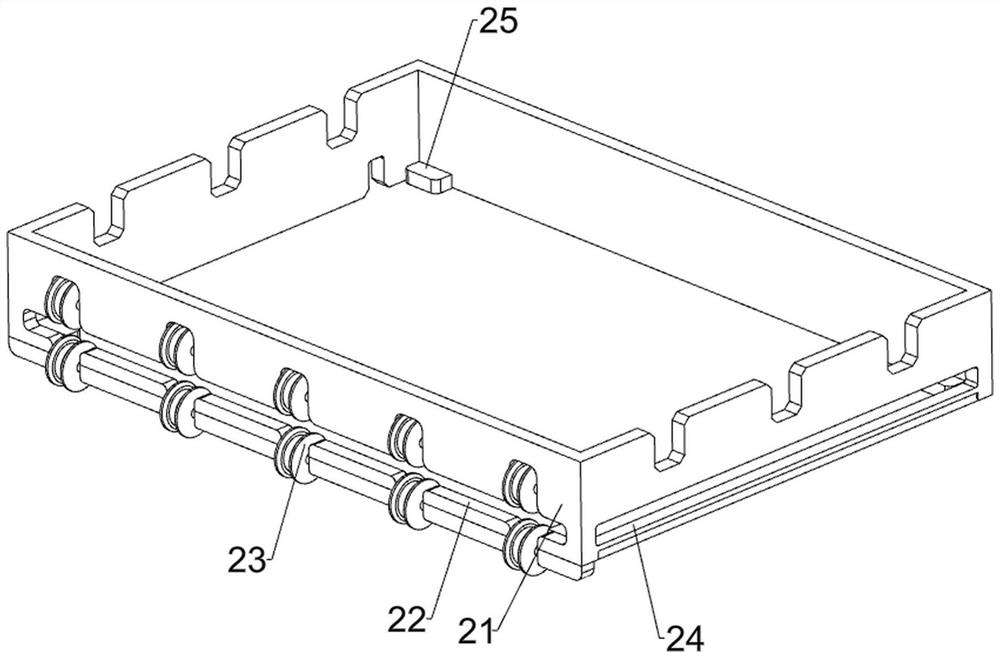

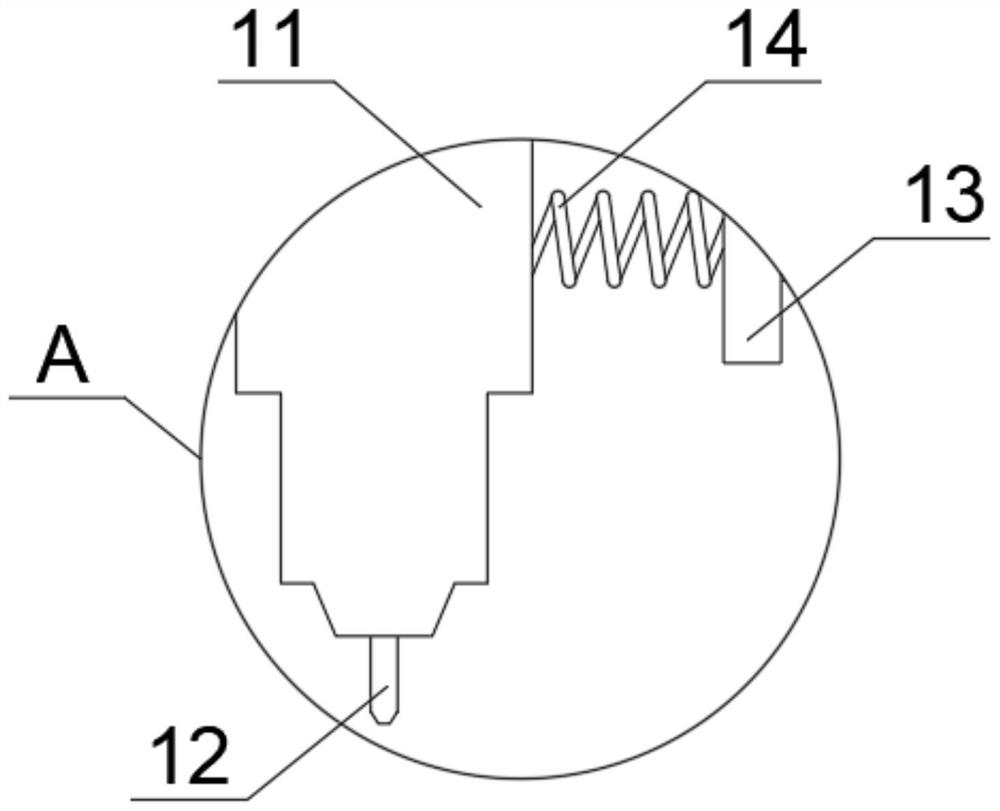

Rapid batch cutting equipment for perforated special-shaped metal pieces

PendingCN112719029AEasy Batch CuttingCutting effectMetal-working feeding devicesPositioning devicesMetal sheetFriction force

The invention relates to cutting equipment, in particular to rapid batch cutting equipment for perforated special-shaped metal sheets. According to the rapid batch cutting equipment for the perforated special-shaped metal sheets, iron sheets are easily fixed and limited from moving, the iron sheets are automatically conveyed, and metal sheets and waste materials are conveniently and uniformly collected. According to the technical scheme, the rapid batch cutting equipment for the perforated special-shaped metal pieces comprises a base, a cutting mechanism and a clamping mechanism; a top supporting frame is connected to the upper portion of the base; the cutting mechanism is arranged between the lower side of the middle of the top supporting frame and the upper portion of the base; and the clamping mechanism is arranged in the middle of one side of the top supporting frame. A spherical connecting rod is clamped into a dial, rotation of a rotating shaft is limited through friction force between the spherical connecting rod and the dial, the effect of limiting conveying of raw material iron sheets is achieved, the situation that the iron sheets cannot move to the accurate position due to inertia and other reasons is prevented, and accurate cutting of the metal pieces is guaranteed.

Owner:李昊儒

Film slitting system for film production and production process thereof

InactiveCN112357654ARealize mobile workImprove cutting efficiencyGrain treatmentsArticle deliveryEngineeringWaste material

The invention discloses a film slitting system for film production and a production process thereof, and belongs to the technical field of film production equipment. The film slitting system comprisesa film feeding system, a conveying frame, a first slitting system, a second slitting system, a film flattening system, a film discharging system and two film waste crushing systems, wherein the filmfeeding system is arranged beside the conveying frame; a horizontally-arranged conveying belt is arranged at the top of the conveying frame; the first slitting system comprises a slitting conveying part and a double-side slitting part; the slitting conveying part is arranged at the top of the conveying frame; the double-side slitting part is arranged at the top of the conveying frame; the second slitting system is arranged on the conveying frame; the film flattening system is arranged on the conveying frame; the two film waste crushing systems are symmetrically arranged at the top of the conveying frame; and the film discharging system is arranged beside the conveying frame. According to the film slitting system, films with different sizes can be cut.

Owner:邢付党

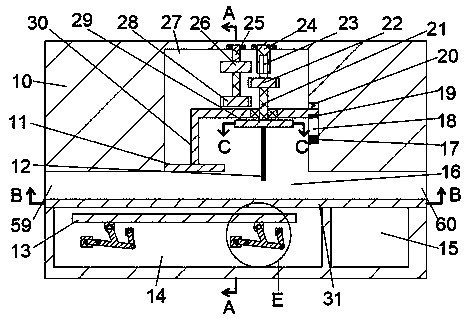

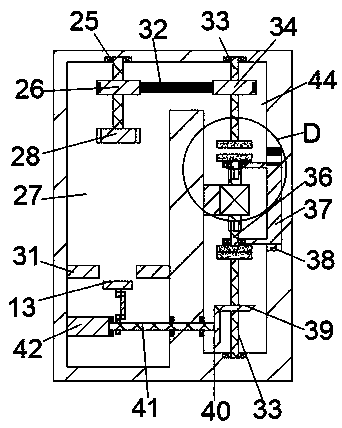

Stacked motor silicon steel sheet stamping device

ActiveCN113477785ACutting effectReal-time monitoring and control of punching forceManufacturing stator/rotor bodiesSortingConvertersElectric machine

The invention discloses a stacked motor silicon steel sheet stamping device. The stamping device comprises a fixing frame, a workbench is fixedly installed at the lower end of the fixing frame, a power frame is fixedly installed at the upper end of the fixing frame, and a lifting frame is movably installed at the middle position of the fixing frame. The lifting frame comprises a lifting frame body, a current processor, a first gas storage bottle, a second gas storage bottle and an upper mold, the first gas storage bottle and the second gas storage bottle are fixedly installed at the upper end in the lifting frame body, and the first gas storage bottle communicates with the second gas storage bottle through a pipeline. Stamping force generated by the stamping device is converted into power of a pressing plate so that the device can synchronously achieve the flattening function in the silicon steel sheet stamping process, meanwhile, the stamping force generated by the stamping device is converted into current magnitude capable of being monitored in real time through a converter, and then a worker can conveniently monitor and control the stamping force of the stamping device in the stamping process in real time.

Owner:南通双耀冲压有限公司

Special-shaped glass cutting machine for touch screen production

PendingCN113085028ACutting stabilityMaintain cleanlinessWorking accessoriesStone-like material working toolsEngineeringKnife cuts

The invention relates to the technical field of touch screen production, and provides a special-shaped glass cutting machine for touch screen production. The cutting machine comprises a supporting base, movable columns, fixing tables, a transmission platform, a transverse moving seat, a cutting seat and a positioning assembly, wherein the transmission platform is mounted at the top of the supporting base, the fixing tables are symmetrically fixed to the two sides, in the conveying direction, of the transmission platform, the movable columns sliding in the length direction of the fixing tables are mounted on the two fixed tables, the transverse moving seat is fixed between the top ends of the two movable columns, a guide rail strip is fixed on the vertical surface of the transverse moving seat, the cutting seat is mounted on the guide rail strip, the cutting seat moves along the guide of the guide rail strip, a cutting knife is fixed on one side of the cutting seat, the positioning assembly is fixedly mounted on one side of the cutting seat, and the positioning end of the positioning assembly is pressed on the screen surface of a touch screen on the transmission platform. According to the cutting machine, the positioning assembly is arranged to position the touch screen on the transmission platform, then the cutting knife cuts the touch screen, cutting is stable, and it is guaranteed that the touch screen cannot move in the cutting process.

Owner:湖北信永辉电子科技有限公司

Safe type aluminum alloy cutting equipment

ActiveCN110773814AImprove safe cutting operationsCutting effectPositioning apparatusMetal working apparatusElectric machineryAluminium alloy

The invention belongs to the technical field of aluminum alloy cutting equipment and particularly provides safe type aluminum alloy cutting equipment. The safe type aluminum alloy cutting equipment comprises a cutting platform; the upper end face of a positioning support plate is provided with a supporting block; the sidewall of the positioning support plate is provided with a sliding chute; a sliding support plate is slidably arranged on a guide sliding chute by virtue of a guide cylinder; the positioning support plate and the sliding support plate are both slidably arranged inside the guidesliding chute; a push cylinder is installed at the upper end of a supporting frame; the telescopic end of the push cylinder is connected with a U-shaped bracket after penetrating through the supporting frame; the inside of the U-shaped bracket is hinged with a mounting cover by virtue of a hinging block; a cutting blade is rotationally installed inside the mounting cover by virtue of a rotating column; a cutting motor is installed at the sidewall of the mounting cover; the output end of the cutting motor is connected with the rotating column; a limiting cylinder is installed at the two sides of the U-shaped bracket; and the telescopic end of the limiting cylinder is hinged to the mounting cover by virtue of the hinging block, thereby preventing the influences on safe and stable cutting ofa cutting worker to aluminum alloy as the aluminum alloy is relatively short when an operator cuts the aluminum alloy.

Owner:新沂天源节能材料有限公司

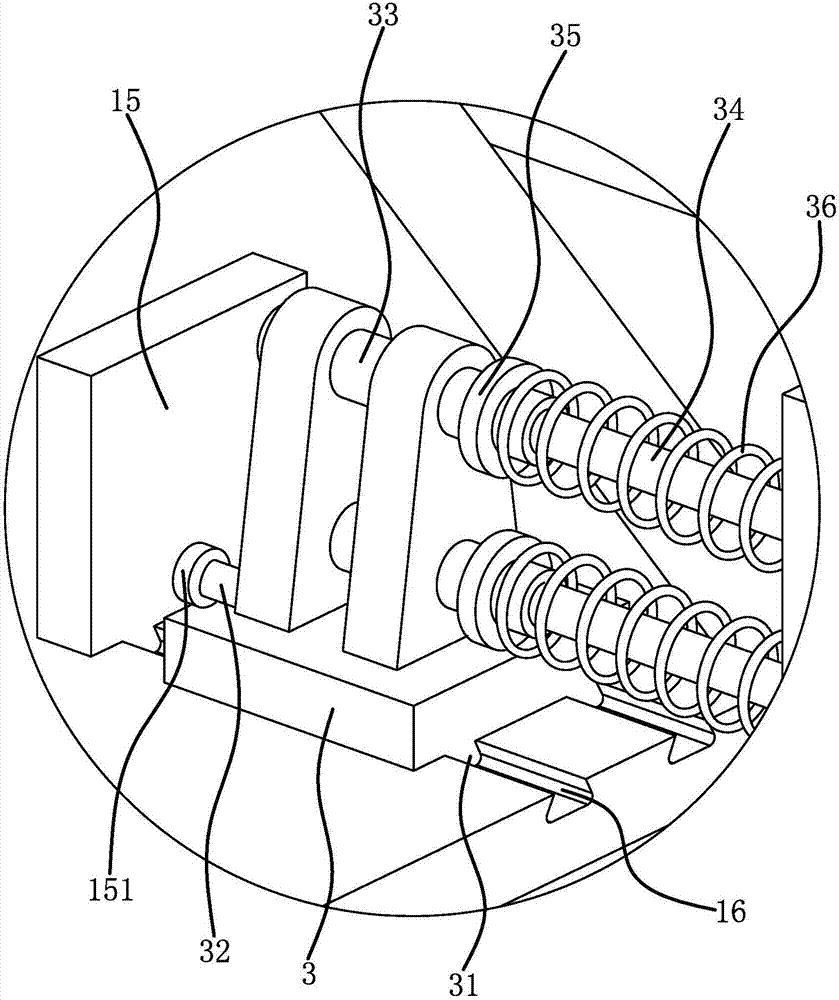

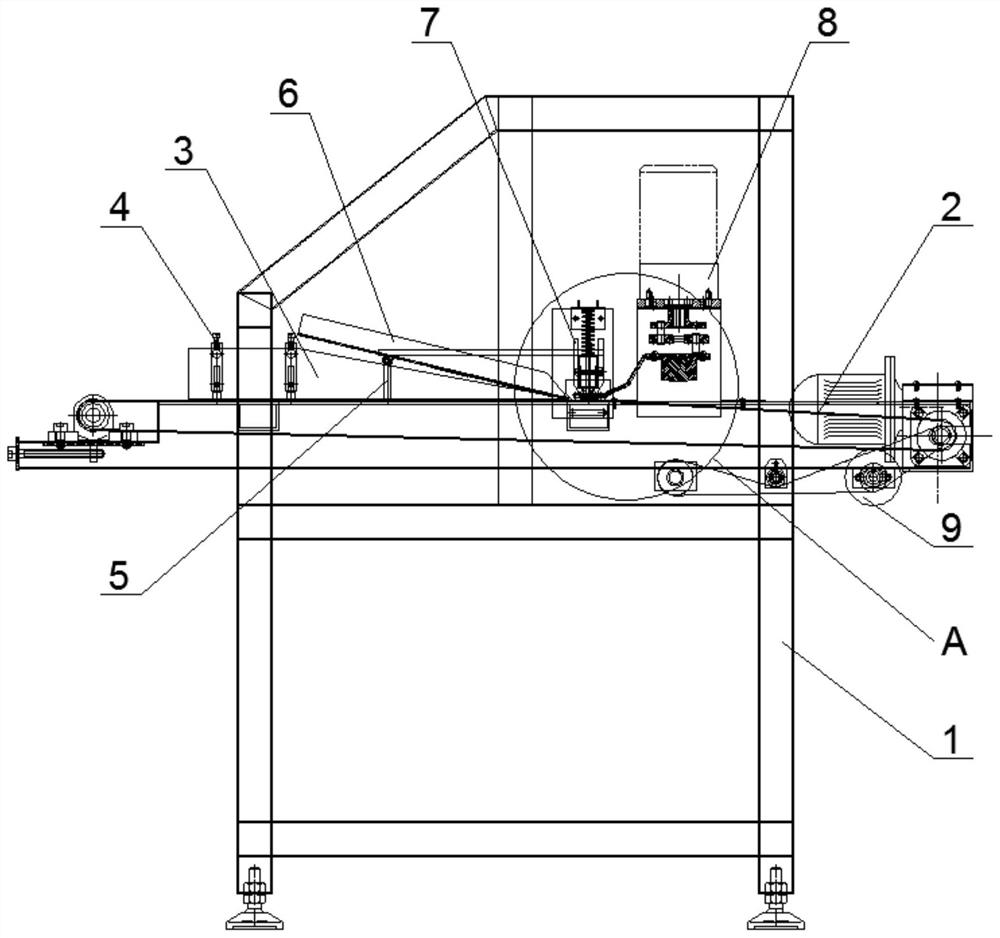

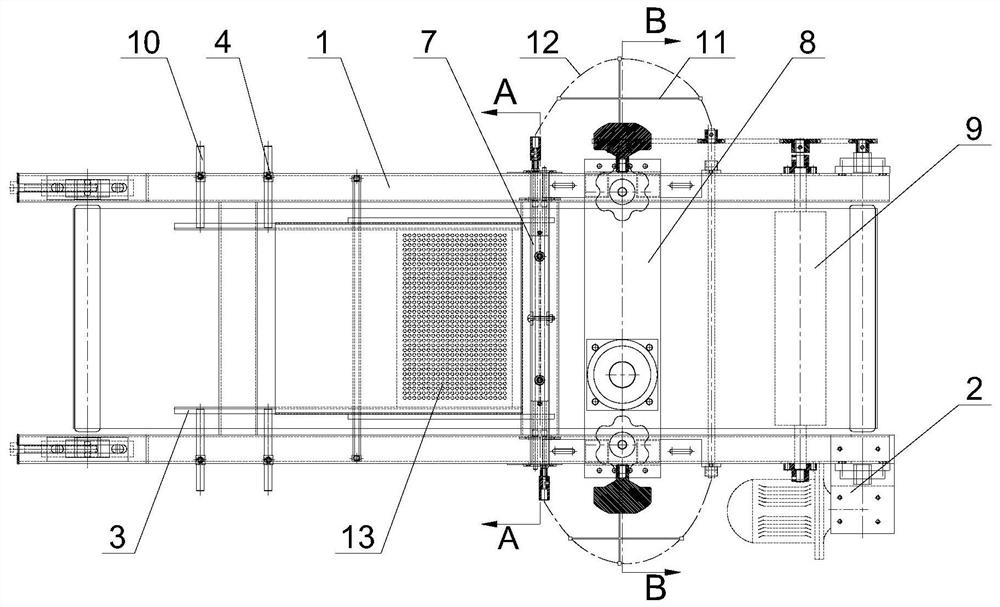

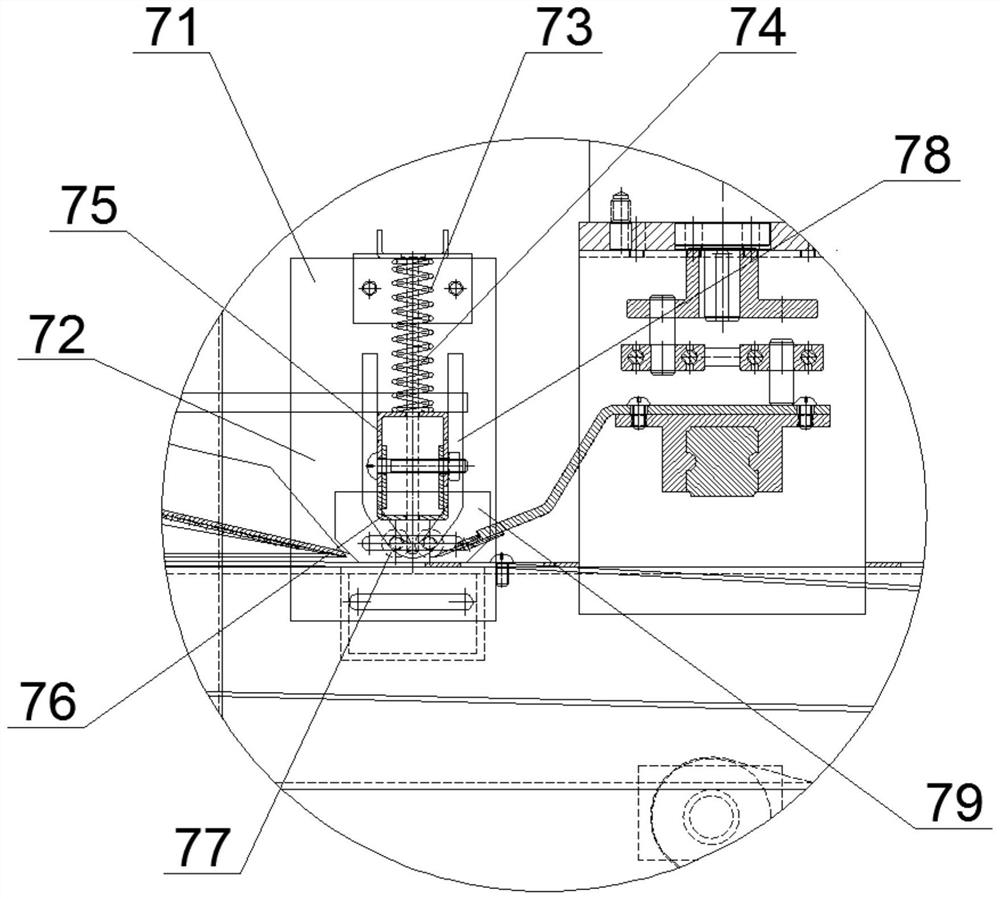

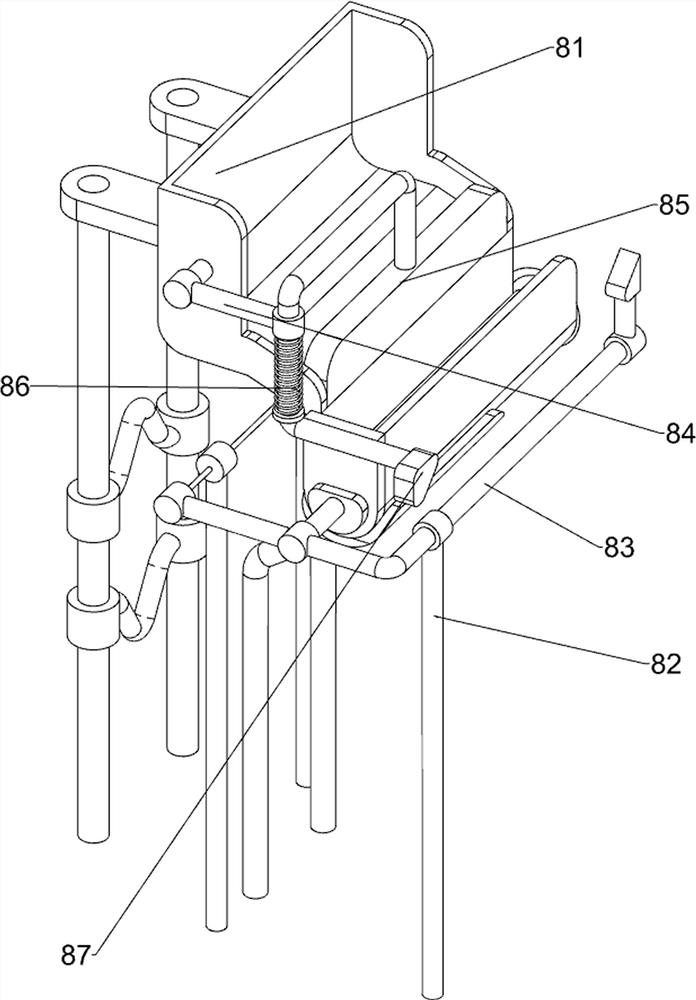

An improved automatic bamboo shoot slicer

ActiveCN110103270BLimit left and right positionAffect cutting qualityCleaning using toolsMetal working apparatusAgricultural engineeringStructural engineering

The invention discloses an improved automatic bamboo shoot slicing machine, which includes a frame and a belt transmission mechanism arranged on the upper surface of the frame. One end of the frame for feeding is provided with a side baffle for limiting the bamboo shoots. The frame is provided with a baffle fine-tuning mechanism for the side baffles. A bamboo shoot soft pressing mechanism and a blade swing mechanism for cutting bamboo shoots are installed in the middle of the frame. The bamboo shoot soft pressing mechanism is located between the blade swing mechanism and the side baffles. , and the bamboo shoot soft pressing mechanism is provided with a flat pressing mechanism on the side near the feed end to prevent the bamboo shoots from stacking. The invention can not only limit the bamboo shoots to ensure the regularity when feeding the bamboo shoots, but also ensure the stability when cutting the bamboo shoots, which greatly ensures the better appearance of the bamboo shoots after cutting. At the same time, the invention as a whole can The high degree of disassembly greatly facilitates disassembly and assembly operations, especially the difficulty of replacing the cutter, which saves time and labor costs for enterprises.

Owner:成都精钟满机械设备制造有限公司

Hardware pipe cutting device

InactiveCN110524043ACutting effectAvoid affecting cutting efficiencyTube shearing machinesShearing machine accessoriesEngineeringCam

The invention relates to a cutting device, in particular to a hardware pipe cutting device. The purpose of the invention is to provide the hardware pipe cutting device through which manual work can bereplaced for cutting hardware pipes, the situation that the cutting efficiency is affected by hand ache is avoided, and the cut lengths of the hardware pipes can be consistent. According to the technical scheme, the hardware pipe cutting device comprises a rack, a first motor, a first bearing, a shaft rod, a first cam, a first support, a first sliding rod and the like, wherein the first motor isarranged on the right side of the bottom in the rack, and the first bearing is embedded in the right side of the top in the rack. A hardware pipe is moved to a position between clamping plates on thefront side and the rear side, the cutting position is moved to the right left side of a cutting blade, and the first motor and the second motor are started, and therefore the cutting blade can move leftwards to cut the hardware pipe, a person does not need to hold a cutting tool to cut the hardware pipe, the situation that the cutting efficiency is affected by hand ache is avoided, and the lengthof the hardware pipe cut each time can be consistent through the effect of a supporting plate.

Owner:浙江年代建设工程有限公司

Edge cutting device for automobile casting machining

InactiveCN110977038AAvoid pollutionCutting effectPositioning apparatusMaintainance and safety accessoriesDrive shaftCoupling

The invention discloses an edge cutting device for automobile casting machining. The edge cutting device comprises a working table; mounting frames are fixed to the two sides of the outer wall of thetop of the working table through bolts, the inner walls of the two sides of the two mounting frames are in sliding connection with the same fixing frame, the same transmission shaft is fixed to the two sides of the outer wall of the bottom of the fixing frame through bearings, and the two ends of the transmission shaft are in sleeved connection with cutting blades; a motor is fixed to the outer wall of one side of the fixing frame through bolts, and an output shaft of the motor is connected to the transmission shaft through a coupler; and a rectangular opening is formed in the outer wall of the top of the working table, mesh plates are fixed to the inner walls of the two sides of the rectangular opening through bolts, and the two sides of the outer wall of the top of each mesh plate are provided with openings. According to the edge cutting device, two edges of a casting can be conveniently cut at the same time through the two cutting blades, and the casting is pressed through pressingmechanisms to avoid the situation that the casting moves in the cutting process, and consequently cutting is affected.

Owner:安徽永茂泰汽车零部件有限公司

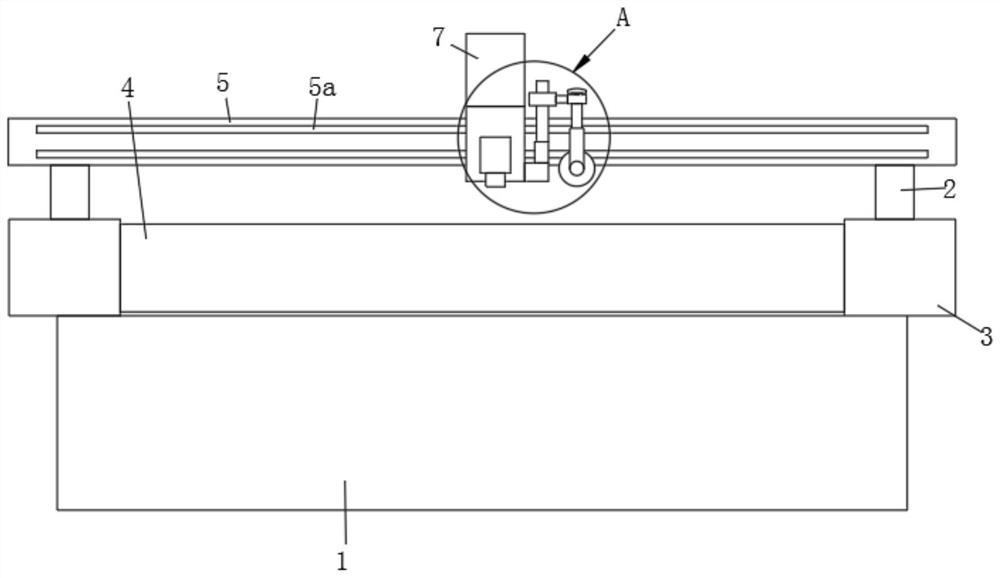

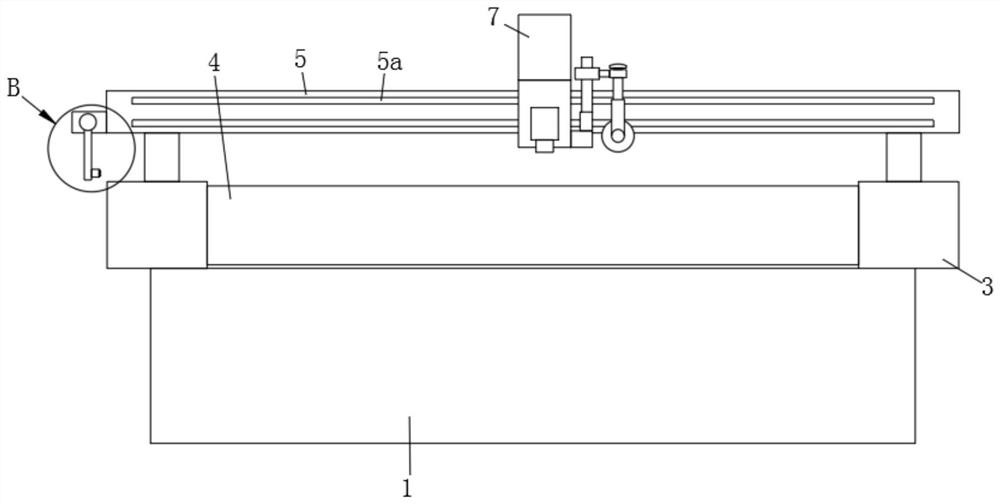

Novel plate laser cutting machine

ActiveCN112975175ACutting effectEasy to collectWelding/cutting auxillary devicesAuxillary welding devicesLaser cuttingMechanical engineering

The invention relates to a cutting machine, in particular to a novel plate laser cutting machine. The novel plate laser cutting machine aims to achieve the technical effects that automatic moving cutting is achieved, and plates are convenient to fix and take for use. The novel plate laser cutting machine comprises a rack; a feeding assembly which is mounted on the rack; a cutting assembly which is mounted on the feeding assembly; and a pushing assembly which is mounted between the feeding assembly and the cutting assembly. According to the novel plate laser cutting machine, the pushing assembly is arranged, so that cut plates can be pushed out of a discharging opening, and then workers can conveniently take out the cut plates; and a supporting assembly is arranged, so that the situation that cutting of the plates is affected due to midway falling of the plates during cutting can be effectively prevented.

Owner:赣州市恒邦金属制品有限公司

Elevator production metal plate machining equipment

PendingCN113084258ANo offsetHigh precisionFeeding apparatusPositioning apparatusGear wheelElectric machinery

The invention discloses elevator production metal plate machining equipment. The elevator production metal plate machining equipment comprises an outer frame, a machining table and a mounting plate, a fixing mechanism is arranged on the top wall of the machining table, a machining groove is formed in the outer frame, a connecting plate is fixedly mounted on the inner bottom wall of the machining groove, a mechanism groove is jointly formed between the connecting plate and the machining groove, and three first lead screws which are arranged in parallel are rotationally connected to the top wall of the connecting plate. According to the elevator production metal plate machining equipment, a driving motor drives a rotating rod to rotate, at the moment, a first bevel gear and a second bevel gear are meshed to rotate, then first lead screws are driven to rotate to be matched with first ball nuts, connecting rods are driven to move, the height of a machining table and the height of an air blower are adjusted at the same time, and it is guaranteed that metal plate cutting work is smoothly conducted; and the air blower generates flowing air from left to right, metal plate waste generated by cutting on the machining table is blown into a collecting box, and therefore centralized recycling of the metal plate waste is achieved, and centralized treatment of the metal plate waste is facilitated.

Owner:诸校军

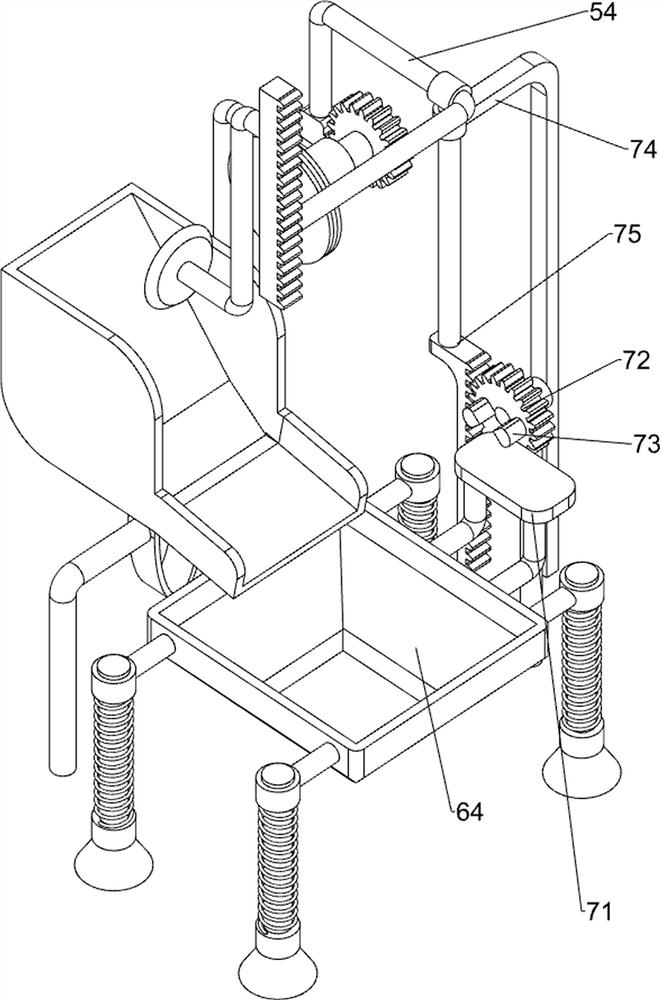

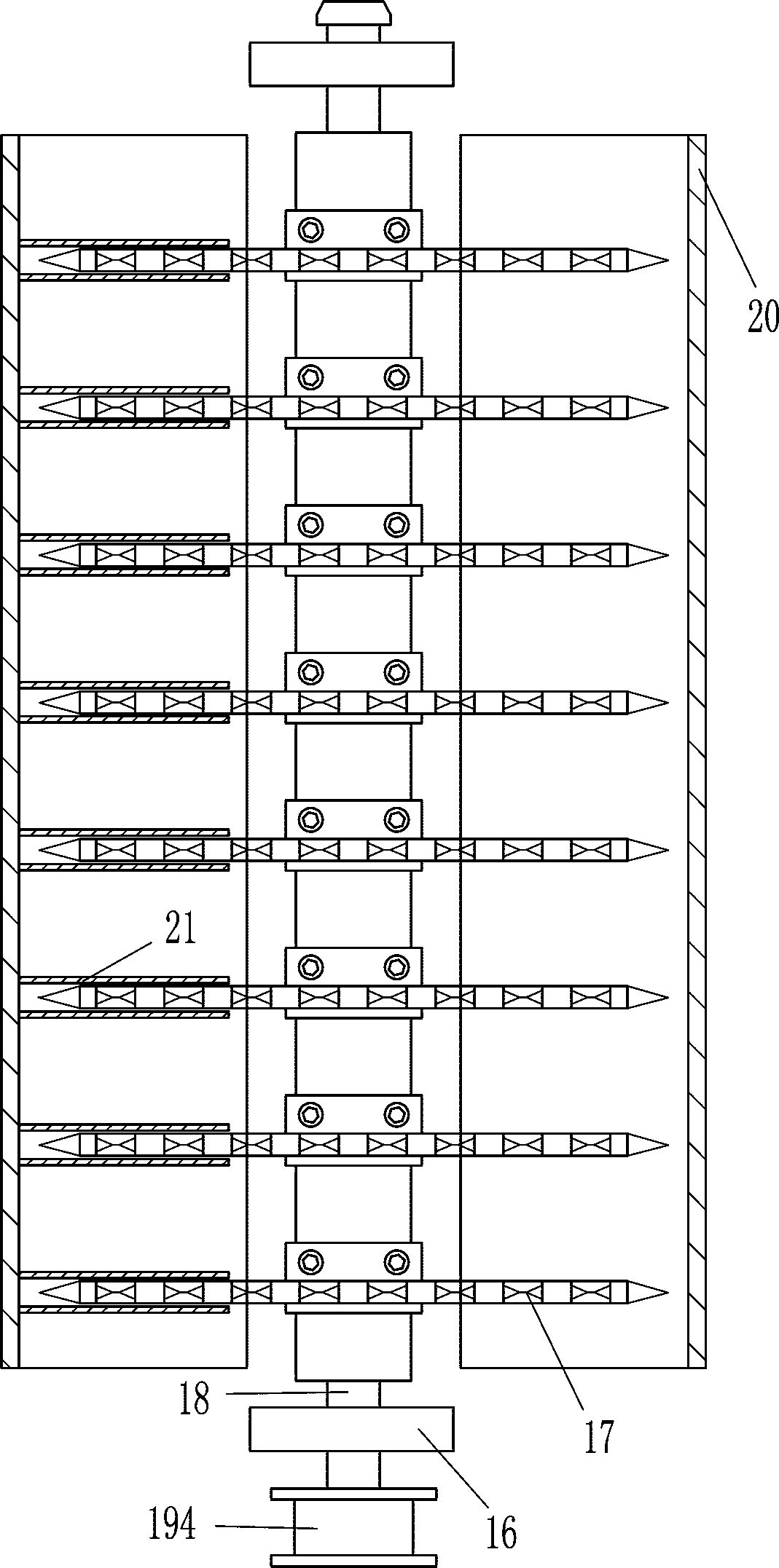

Salad making machine for food processing

PendingCN113103301ACutting effectReduce the burden onFood shapingMetal working apparatusProcess engineeringFood material

The invention relates to a salad making machine, in particular to a salad making machine for food processing. The technical problem to be solved is to provide the salad making machine for food processing. The salad making machine for food processing is efficient and can automatically cut food materials. The salad making machine for food processing comprises a bottom plate, a cutting mechanism mounted on the bottom plate and an automatic cutting mechanism mounted on the bottom plate. The device is provided with a cutting and material pressing mechanism, so that when the device cuts food materials, a sliding pressing plate can fix the food materials, and the situation that cutting of the food materials is affected due to movement of the food materials is prevented; the device is provided with an automatic intermittent pushing mechanism, so that the device can automatically push the food materials to move forwards, workers do not need to manually push the food materials to move, and the burden of the workers is reduced; and the device is provided with a collecting, shaking and stirring mechanism and an automatic material shaking mechanism, the cut food materials can be automatically and evenly mixed, and then the trouble that workers mix the food materials in the later period is reduced.

Owner:陈优娣

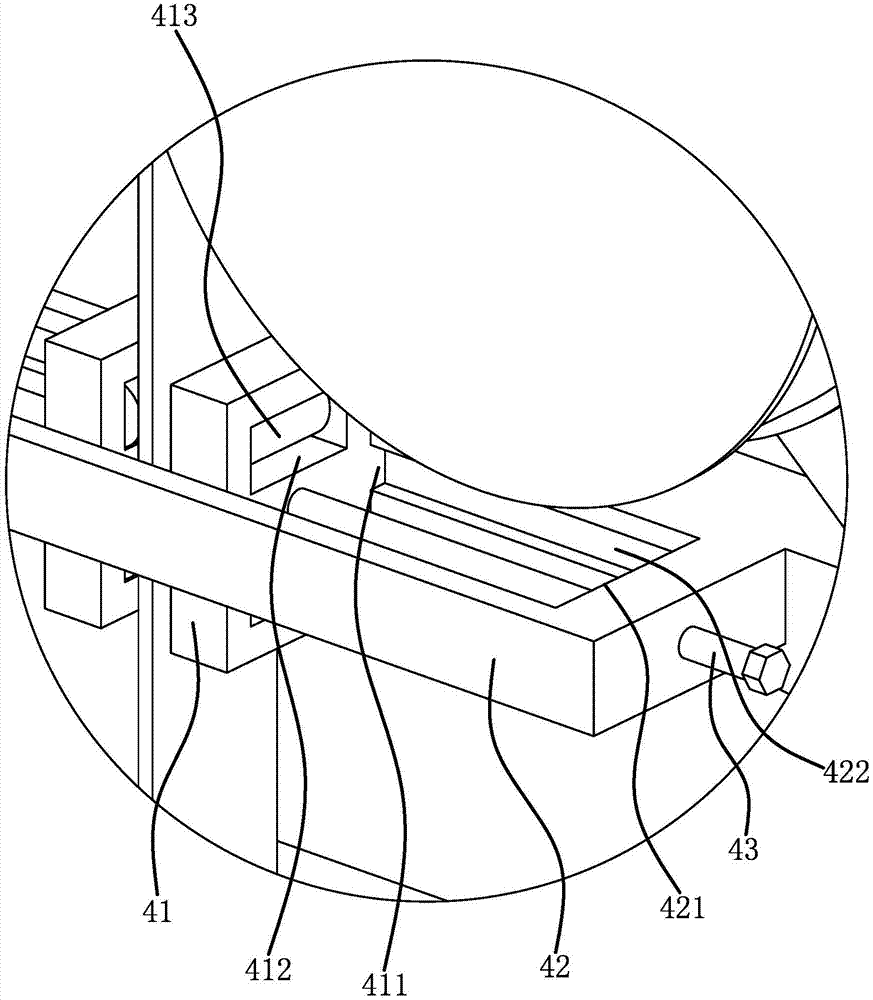

A cutting device used in aluminum processing and production

ActiveCN105436968BEasy to installEasy to fixFeeding apparatusOther manufacturing equipments/toolsPulp and paper industryProduct processing

The invention discloses a cutting device applied to aluminum product processing and production. The cutting device comprises a holding table, a flattening table and a cutting platform; a pushing unit is arranged on the holding table; a side plate and a pressing roller are arranged on the flattening table; a cutting mechanism and a sweeping unit are arranged on the cutting platform; the cutting mechanism comprises a lifting column, a cutting plate and a cutting tool; the sweeping device comprises a slider, a telescopic plate and a fixed plate; a brush is arranged on a bottom surface of the fixed plate; and a waste collecting box is arranged on a right side of the cutting platform. The cutting device applied to aluminum product processing and production is simple in structure and high in practicability; with the design of the pushing unit, aluminum products can be conveyed more conveniently and simply; with the design of the pressing roller, surfaces of aluminum products can be pressed and flattened by heating, thereby facilitating processing on the aluminum products in next step, and therefore, the quality of the cut aluminum products is improved; and with the design of the sweeping unit, the cutting platform can be cleaned to avoid the influence of accumulated waste materials on subsequent cutting of aluminum products; in short, the cutting device is more convenient and simpler to use, and the comprehensive utilization efficiency is improved.

Owner:台山市里程金属制品有限公司

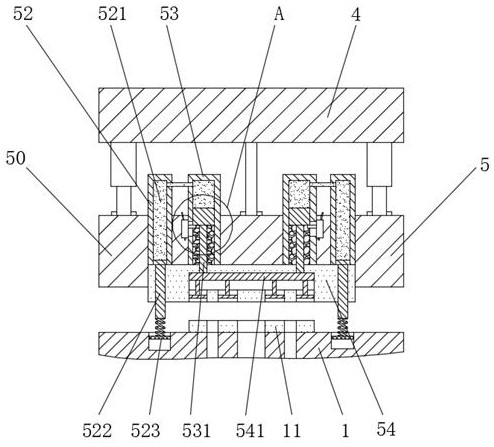

Stepping motor gear and one-time precision cutting die thereof

InactiveCN113102651AQuality improvementNo warpingBelt grinding machinesGear wheelsHydraulic cylinderGear wheel

The invention discloses a stepping motor gear and a one-time precision cutting die thereof, and relates to the technical field of stepping motor gear machining. The stepping motor gear comprises a stepping motor gear body and the one-time precision cutting die; the one-time precision cutting die comprises a machining support and a pressure plate, the machining support is used for placing a to-be-machined stainless steel plate material; the pressure plate is fixedly arranged at the bottom end of a hydraulic cylinder; a one-time precision cutting structure comprises a pre-pressing cylinder piece, a first supporting rod, and a second supporting rod, the bottom end of the second supporting rod is fixedly connected with an inner circle fine cutting piece through a bolt. According to the stepping motor gear and the one-time precision cutting die thereof, the flatness of the surface of a stainless steel plate can be detected before precision cutting, the uneven surface of the stainless steel plate is prevented from being machined, the surface of the stainless steel plate is pressed and clamped during precision cutting, and the condition that the finish-cut part on the surface of the stainless steel plate is tilted or the finish-cut surface is not flat is avoided, so that the quality of the machined stepping motor gear is improved.

Owner:苏州市鼎泰精密机械有限公司

Integrated feeding and discharging cutting device for metal material machining

InactiveCN114643489APrevent splashReduce security risksMaintainance and safety accessoriesMetallic materialsStructural engineering

The invention discloses an integrated feeding and discharging cutting device for metal material machining, and relates to the technical field of metal material machining equipment. The device comprises a cutting module, the cutting module comprises a box body, cutting equipment is arranged in the middle of the inner top wall of the box body, a shielding mechanism is arranged in the box body, the shielding mechanism comprises first mounting plates, and reset springs are arranged on the inner top walls of the two first mounting plates; a first shielding plate is arranged at the lower ends of every two reset springs, when the feeding mechanism conveys metal materials, the winding roller can be driven to rotate to unwind the connecting rope, the first shielding plates can be driven to move in the first mounting plate through the elastic force of the reset springs, the shielding plates seal the cutting area in the box body, and the cutting efficiency is improved. When the cutting equipment cuts a metal material, sparks and chippings generated during cutting of the metal material can be prevented from splashing, and therefore potential safety hazards of workers are reduced.

Owner:HANGZHOU GONGCHENG AUTOMATION EQUIP

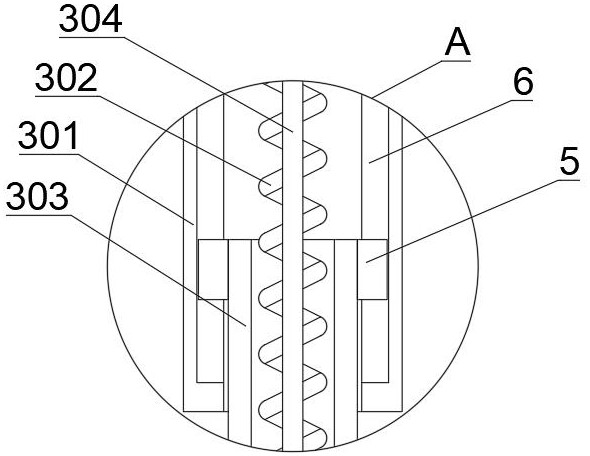

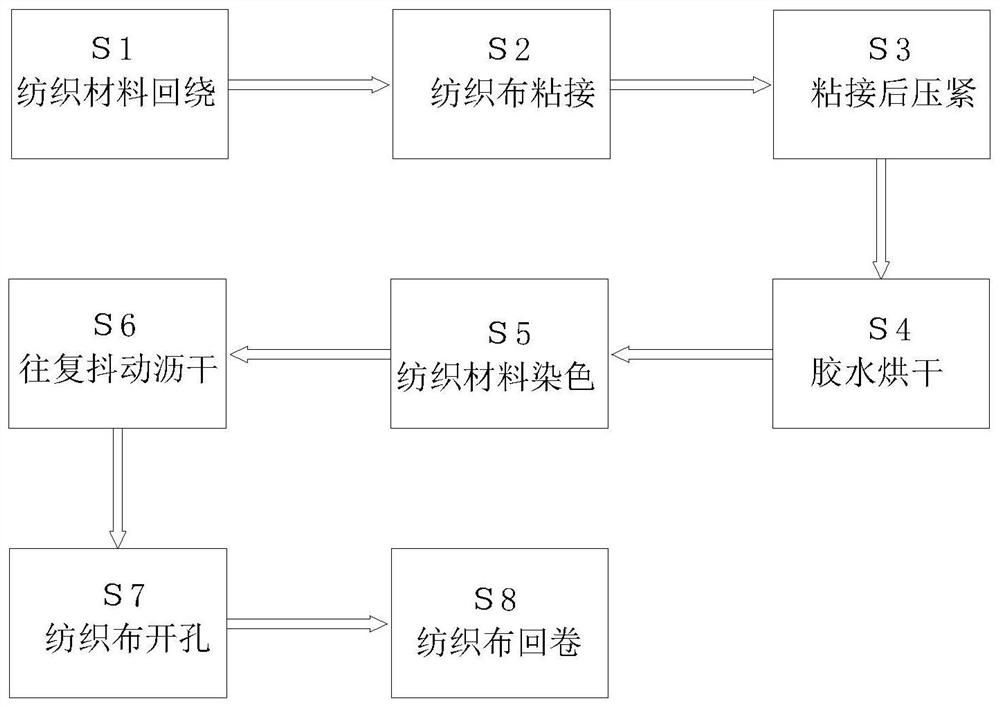

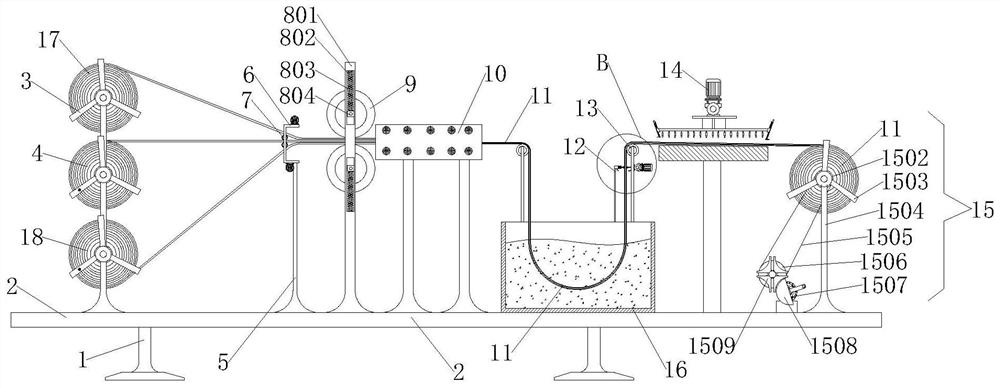

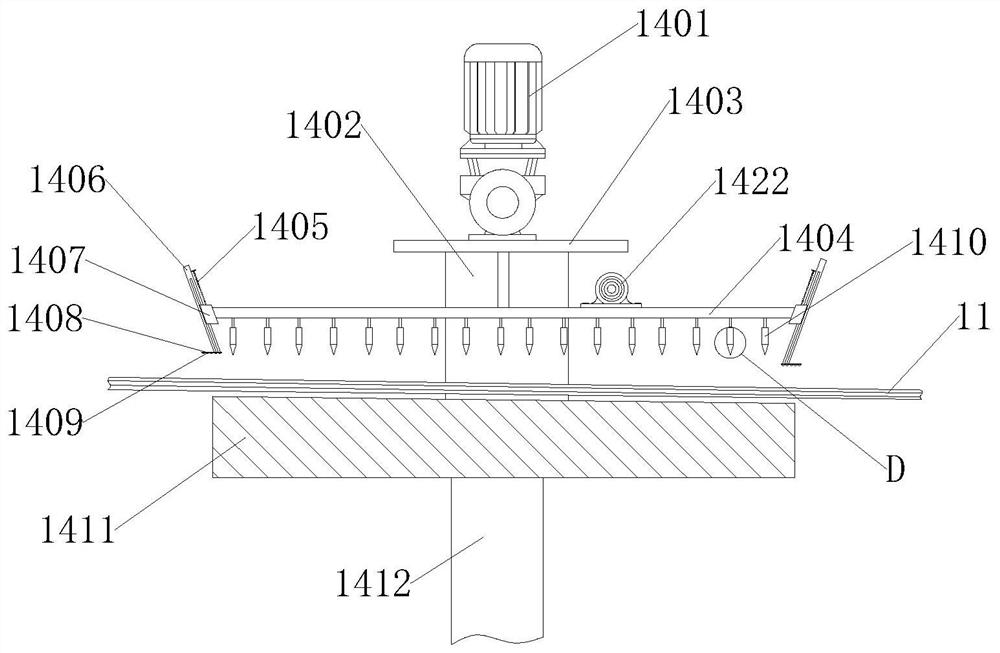

High-elasticity breathable textile material and production and preparation process thereof

PendingCN113774599AReduce the number of workersReduce work loadLiquid surface applicatorsLamination ancillary operationsPolymer chemistryDyeing

The invention provides a high-elasticity breathable textile material and a production and preparation process thereof, and relates to the technical field of textile materials. The production and preparation process of the high-elasticity breathable textile material comprises the following steps that S1, the textile material is rewound, specifically, the textile cloth made of different materials and wound into the cylinder shape extends in the same direction at the same time; and S2, bonding of the textile cloth is carried out, specifically, the multiple layers of textile materials in the step S1 are bonded in an attached mode, and the different materials are wound into the cylindrical textile cloth to be bonded and fastened in an interlayer mode. According to the production and preparation process of the high-elasticity breathable textile material, whole-course unattended automatic production and processing are carried out through whole-course automatic production and processing, and the process steps of automatic uniform gluing and bonding, uniform dyeing, rapid shaking and draining, automatic trepanning and the like are carried out on the multi-layer textile fabric.

Owner:颜丽菊

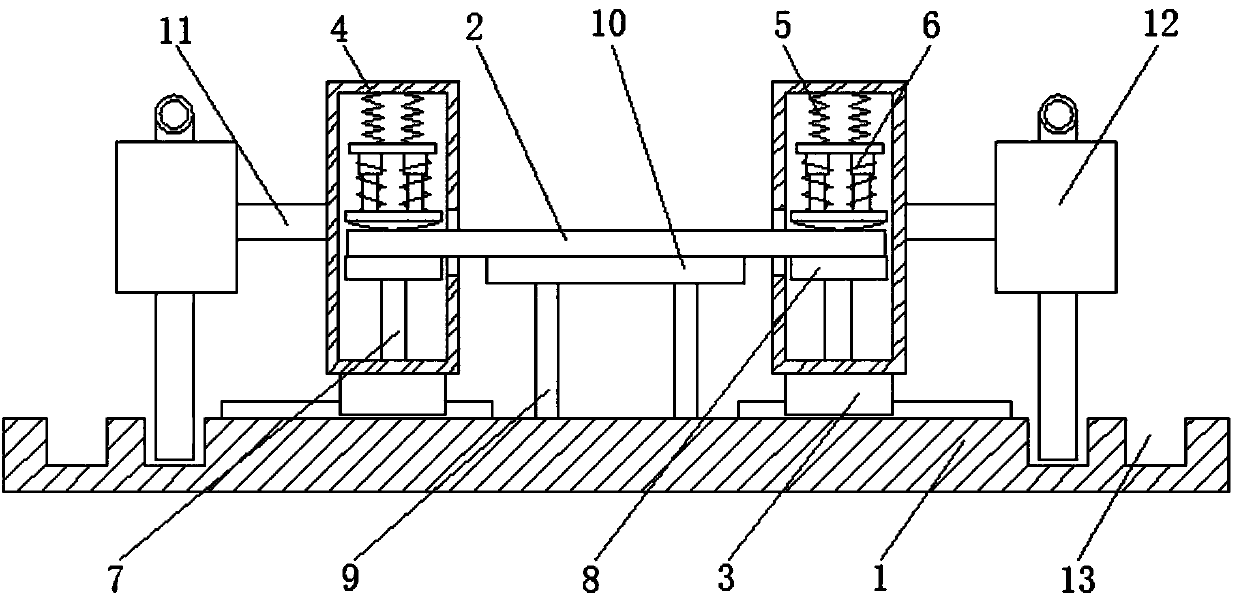

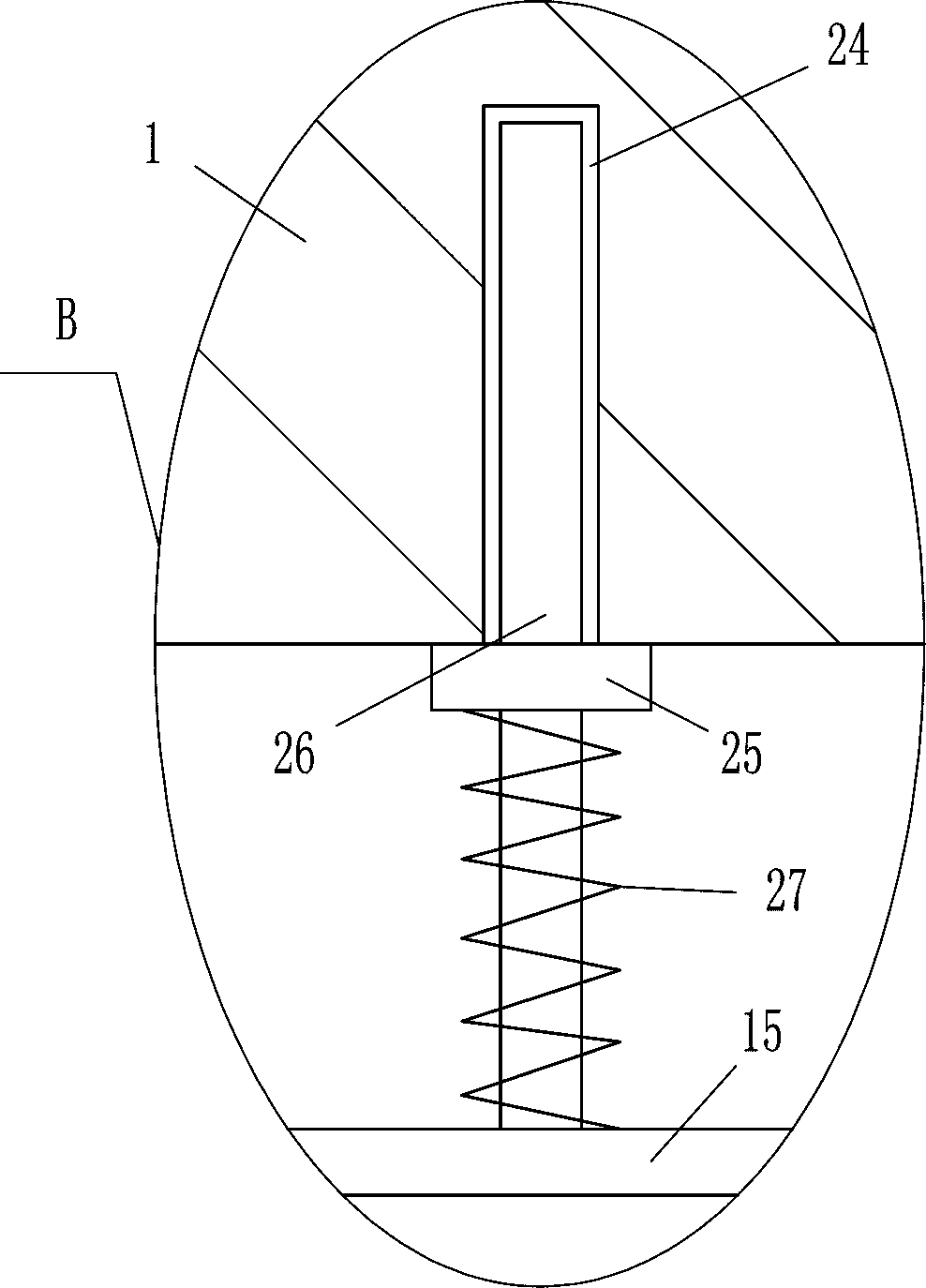

Fixing device for automobile glass cutting

The invention discloses a fixing device for automobile glass cutting, which comprises a base plate and a glass body, sliders are slidably connected to both sides of the top of the base plate through slide rails, moreover, fixed boxes are fixedly connected to the tops of the sliders, pressing springs are fixedly connected to the tops of the inner walls of the fixed boxes, pinch devices are fixedlyconnected to the bottom ends of the pressing springs, vertical rods are fixedly connected to the bottoms of the inner walls of the fixed boxes, supporting plates are fixedly connected to the top endsof the vertical rods, the tops of the supporting plates are in contact with the bottom of the glass body, and supporting rods which are located between the two sliders are fixedly connected to both sides of the top of the base plate. The invention relates to the technical field of automobile parts. The fixing device for automobile glass cutting can carry out fixing in the process of automobile glass cutting, the burden of workers and the difficulty of cutting are decreased, the efficiency of cutting is increased, and moreover, automobile glass can be prevented from shifting to affect cutting,so that unnecessary economic loss can be prevented.

Owner:合肥市春华起重机械有限公司

Garden turf shaving device

ActiveCN109197400ACutting effectPrevent splashHops/wine cultivationTurf growingDrive wheelUniversal joint

The invention relates to a shaving device and particularly relates to a garden turf shaving device. Therefore, the technical problem of the present invention is to provide a garden turf shaving devicecapable of cutting a turf into pieces, the removal of the turf by people is facilitated, the labor intensity is small, and water can be sprayed to reduce dust and avoid the influence on a surroundingenvironment. The technical solution of the invention is that the garden turf shaving device comprises a base, a support plate, a first shaft sleeve, a first rotating shaft, a fixed rod, a universal joint, a second shaft sleeve, a second rotating shaft, a driven wheel, an electric roller and a third shaft sleeve, the top of the base is fixedly connected to the support plate capable of installing the first shaft sleeve, the first shaft sleeve is fixedly connected to the upper part of a left side face of the support plate, and the first shaft sleeve is inclined. According to the shaving device,planing wheels are driven to rotate by starting a driving motor, the planing wheels are rotated to cut the turf, the planing wheels cut the turf into pieces through the electric roller, so the removalof the turf by people is facilitated, continuously waving a hoe is not needed, and time and labor are saved.

Owner:温州宇岚科技有限公司

Machine for cleaning residual vines on vigna unguiculata vine pole

The invention relates to a cleaning machine, in particular to a machine for cleaning residual vines on a vigna unguiculata vine pole. The machine used for cleaning the residual vines on the vigna unguiculata vine pole and capable of increasing the cleaning speed and reducing shaking amplitude of the vine pole is provided for solving the technical problems. According to the technical scheme, the machine used for cleaning the residual vines on the vigna unguiculata vine pole comprises a mounting plate, first rotating shafts, wheels, a guide rod and a guide roller, wherein the first rotating shafts are rotationally arranged on the left side and the right side of the lower part of the mounting plate, and the wheels are arranged at the outer ends of the first rotating shafts. Vines on the vinepole can be cleaned by a cutting device, the vine pole is enable to be recovered to the initial state, manual cleaning is not needed, preparation is made for next use, and the cleaning speed is higherthan the speed of manual cleaning, and the efficiency is higher; the position of the machine can be fixed by a toothed plate and a gear, then the machine is kept stable when the vines are cut, and adverse effects on vine cutting because of shaking of the whole machine due to the fact that the wheels are not fixed are avoided.

Owner:罗煊

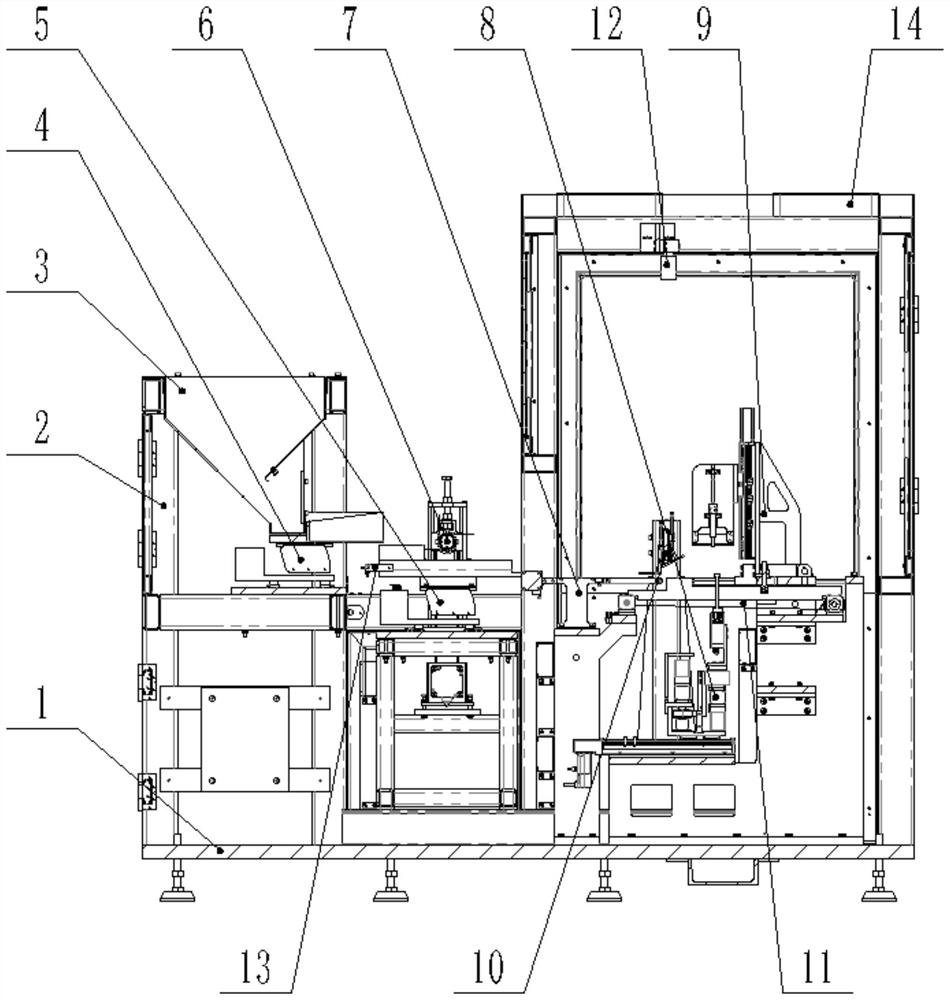

Novel automatic intelligent food slicing machine

ActiveCN113843845AHigh quality cuttingImprove pass rateMetal working apparatusControl engineeringProcess engineering

The invention discloses a novel automatic intelligent food slicing machine which comprises a machine base, a machine frame arranged on the machine base and at least one feeding unit arranged on the machine frame. Each feeding unit comprises a storage bin mechanism, a first-stage feeding mechanism, a second-stage feeding mechanism and an anti-overlapping mechanism. The novel automatic intelligent food slicing machine further comprises feeding mechanisms, a clamping translation and rotation mechanism, a slicing mechanism, a posture adjustment and discharging mechanism and a discharging belt conveyor, and the feeding mechanisms correspond to the feeding units respectively. Food to be cut in storage bins enter the feeding mechanisms after sequentially passing through the first-stage feeding mechanisms, the second-stage feeding mechanisms and the anti-overlapping mechanisms, the food is subjected to position adjustment by the clamping translation and rotation mechanism after posture adjustment, and the food is sliced by the slicing mechanism and then is conveyed out by the discharging belt conveyor. According to the novel automatic intelligent food slicing machine, the clamped food is subjected to proper translation and rotation, so that the ideal cutting joint position is overlapped with a cutter, high-quality cutting of the food is realized, and the qualification rate and grade of food slicing, especially cutting of areca nuts, are improved.

Owner:湖南会当智能科技有限公司

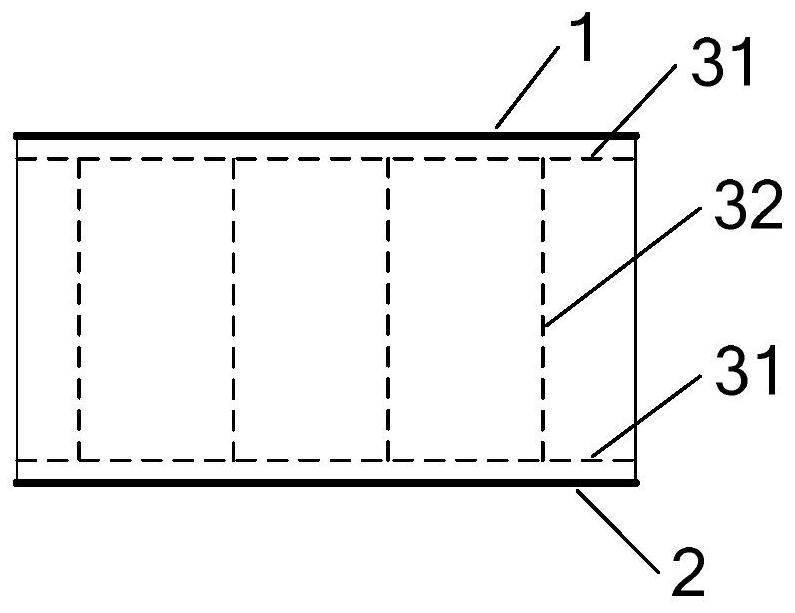

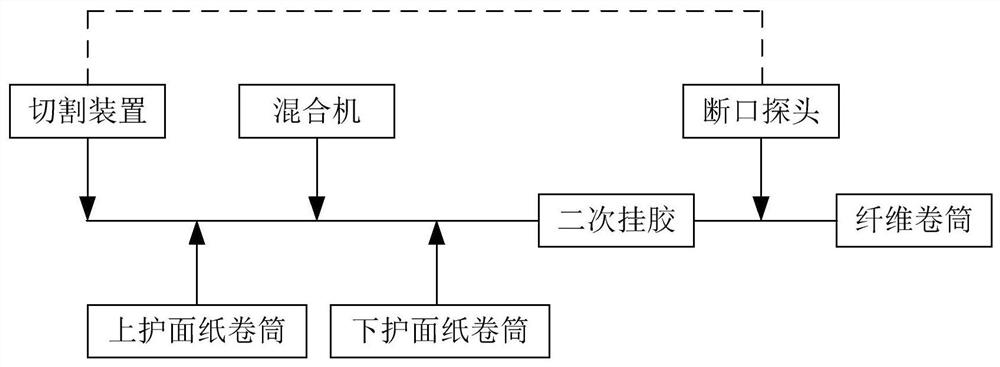

Reinforced gypsum board and production system and production method thereof

PendingCN113733704AHigh strengthLow production costPaper/cardboard layered productsSurface layering apparatusFiber structureMineralogy

The invention discloses a reinforced gypsum board as well as a production system and a production method thereof. The reinforced gypsum board comprises upper surface protection paper, lower surface protection paper and at least two fiber layers arranged between the upper surface protection paper and the lower surface protection paper; every two adjacent fiber layers are connected through vertical yarns to form a three-dimensional fiber structure; and the three-dimensional fiber structure is filled with a plate core.

Owner:BEIJING NEW BUILDING MATERIAL +1

A hardware pipe cutting device

InactiveCN110524043BCutting effectAvoid affecting cutting efficiencyTube shearing machinesShearing machine accessoriesElectric machineryEngineering

The invention relates to a cutting device, in particular to a hardware pipe cutting device. The purpose of the invention is to provide the hardware pipe cutting device through which manual work can bereplaced for cutting hardware pipes, the situation that the cutting efficiency is affected by hand ache is avoided, and the cut lengths of the hardware pipes can be consistent. According to the technical scheme, the hardware pipe cutting device comprises a rack, a first motor, a first bearing, a shaft rod, a first cam, a first support, a first sliding rod and the like, wherein the first motor isarranged on the right side of the bottom in the rack, and the first bearing is embedded in the right side of the top in the rack. A hardware pipe is moved to a position between clamping plates on thefront side and the rear side, the cutting position is moved to the right left side of a cutting blade, and the first motor and the second motor are started, and therefore the cutting blade can move leftwards to cut the hardware pipe, a person does not need to hold a cutting tool to cut the hardware pipe, the situation that the cutting efficiency is affected by hand ache is avoided, and the lengthof the hardware pipe cut each time can be consistent through the effect of a supporting plate.

Owner:浙江年代建设工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com