An improved automatic bamboo shoot slicer

An improved, slicer technology, used in cleaning methods and utensils, cleaning methods using tools, chemical instruments and methods, etc. The effect of high disassembly degree, increased stability, and convenient disassembly and assembly operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

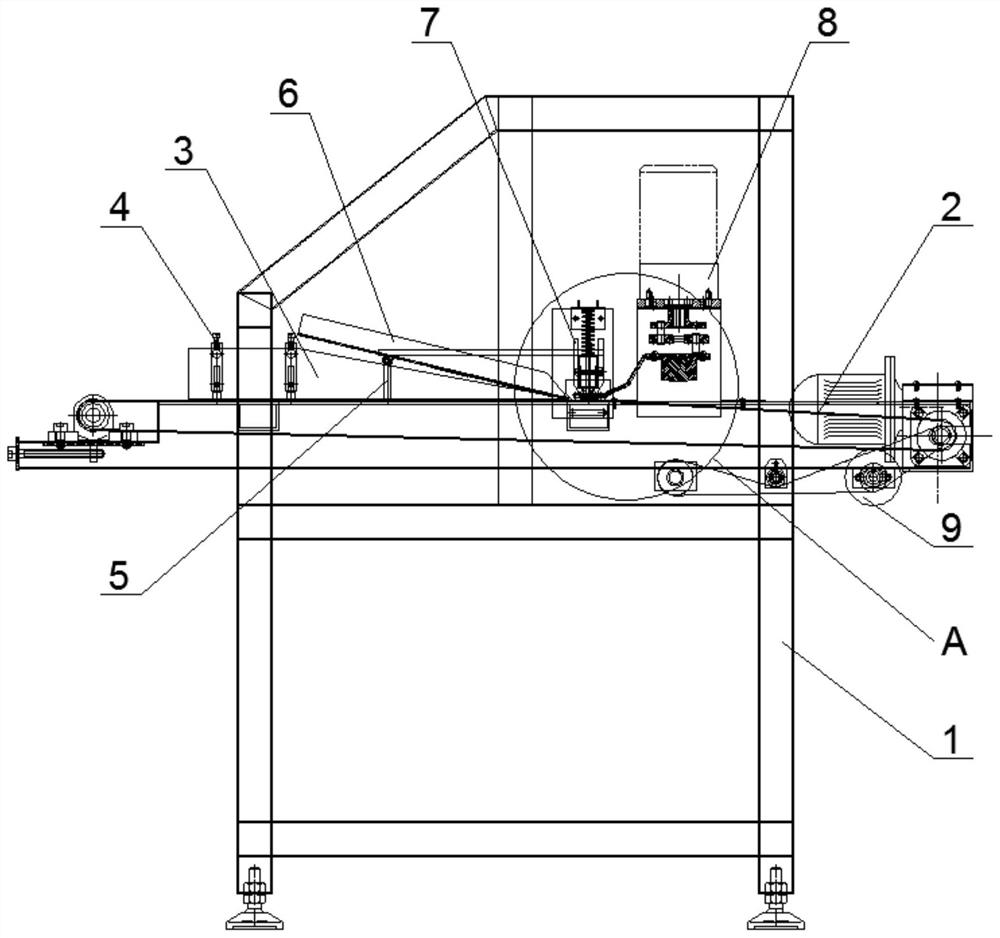

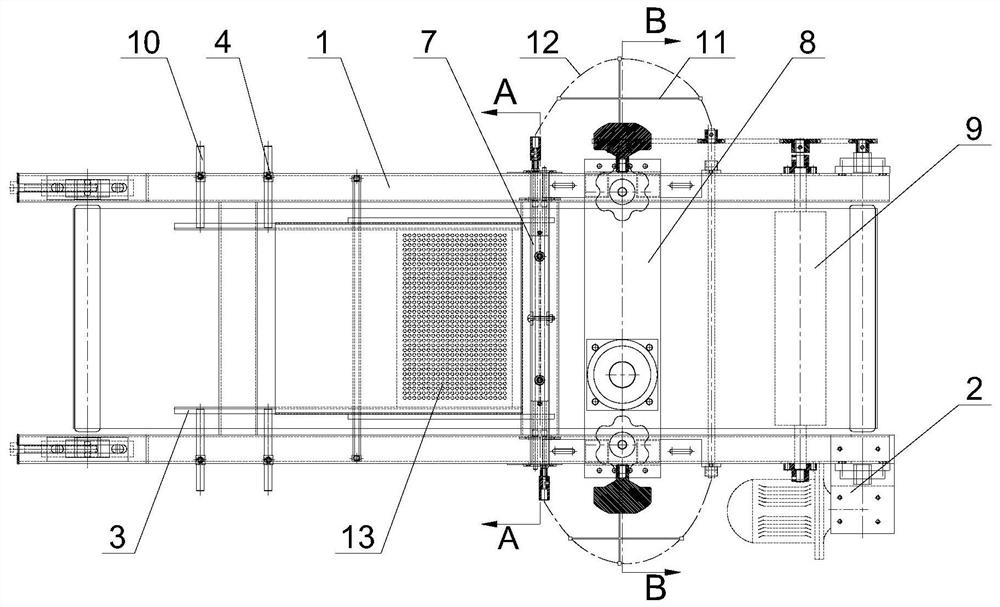

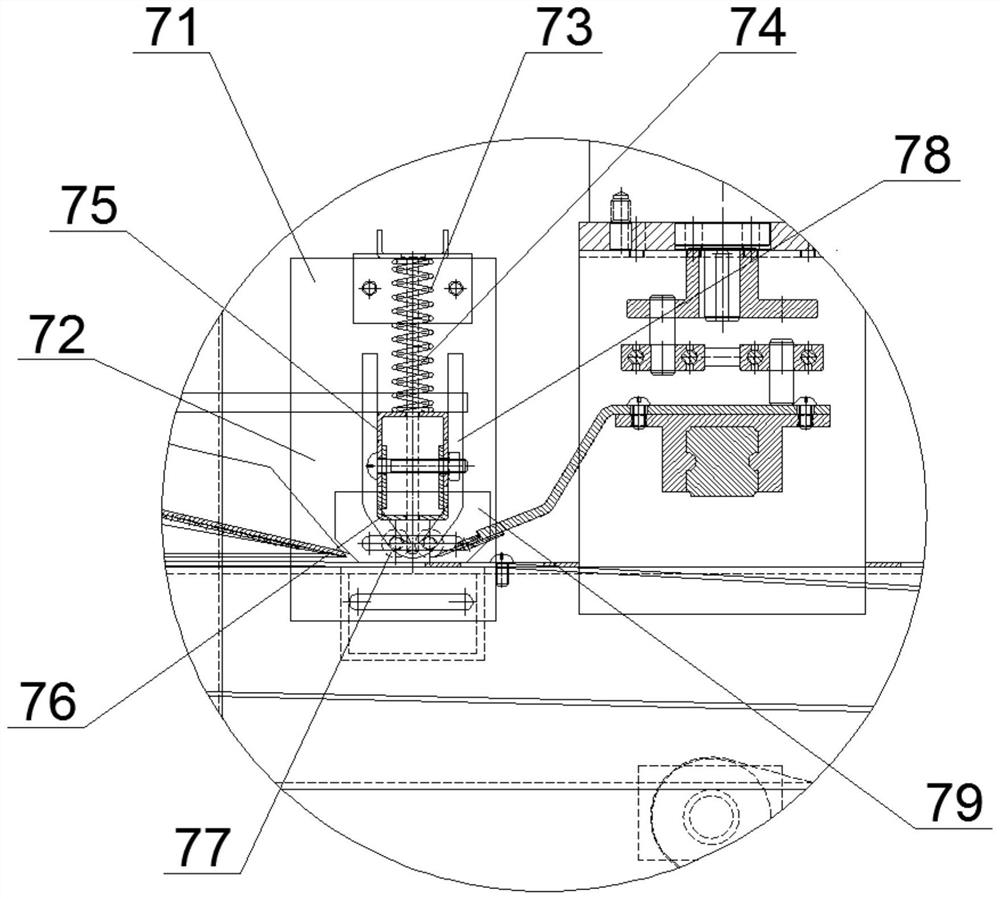

[0029] like Figure 1 to Figure 6 As shown, the improved automatic bamboo shoot slicer provided in this embodiment includes a frame and a belt transmission mechanism 2 arranged on the upper surface of the frame 1. In order to ensure the cleanliness of the transmission belt in the belt transmission mechanism 2, the frame 1 is provided with There is a slag cleaning mechanism 9 for cleaning the conveyor belt in the belt conveyor mechanism 2 . The slag removal mechanism 9 includes a drum and a sleeve sleeve mounted on the drum with bristles. The drum is rotatably arranged on the frame 1 through bearings. In order to save electricity costs, the power of the drum and the belt transmission mechanism 2 adopt the same The motor is used as a drive, specifically, the roller is installed on the frame 1 below the belt transmission mechanism 2, and the roller rotates synchronously with the driving roller at the middle end of the belt transmission mechanism 2 through a chain, and the bristle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com