Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Affect cutting quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

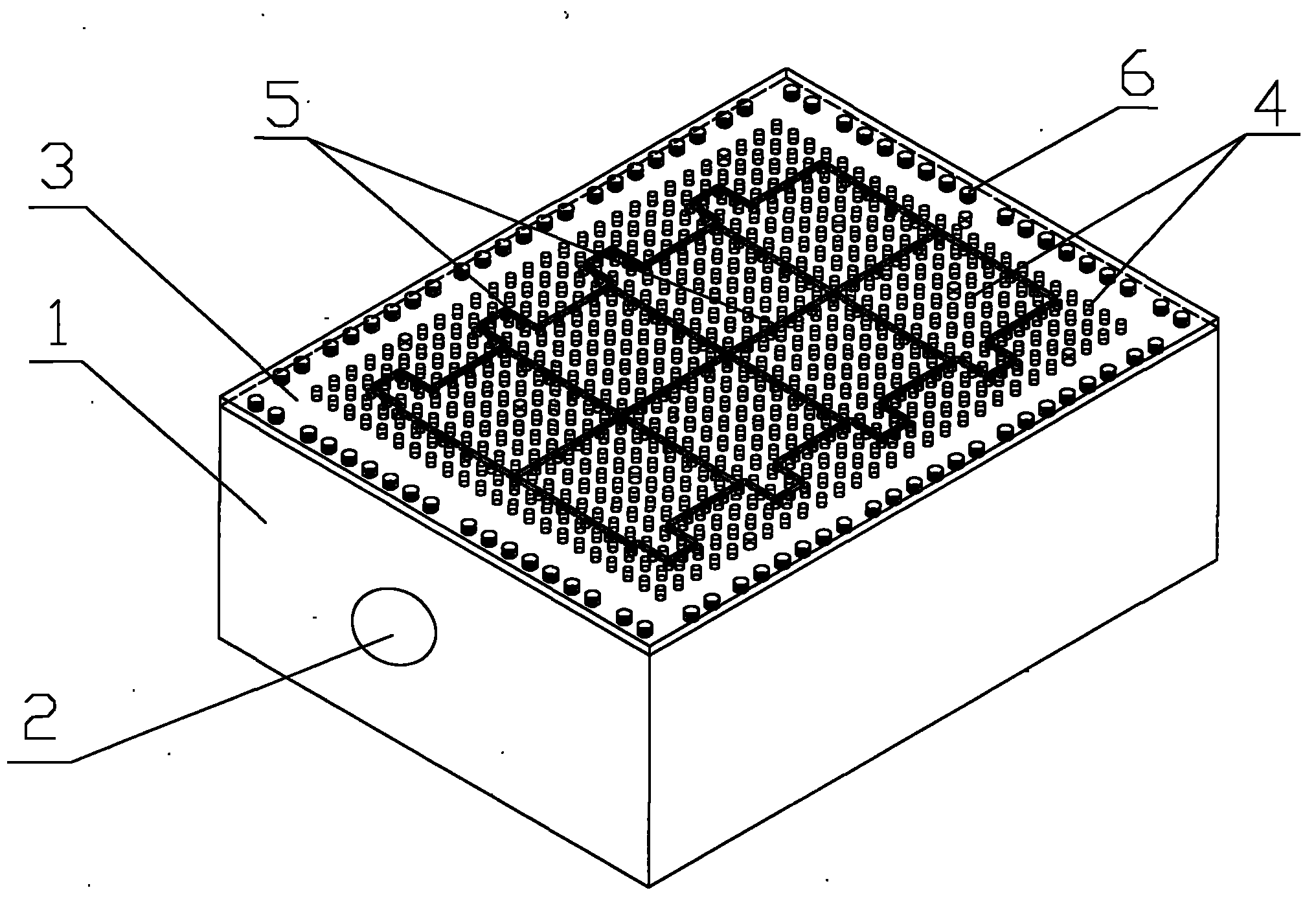

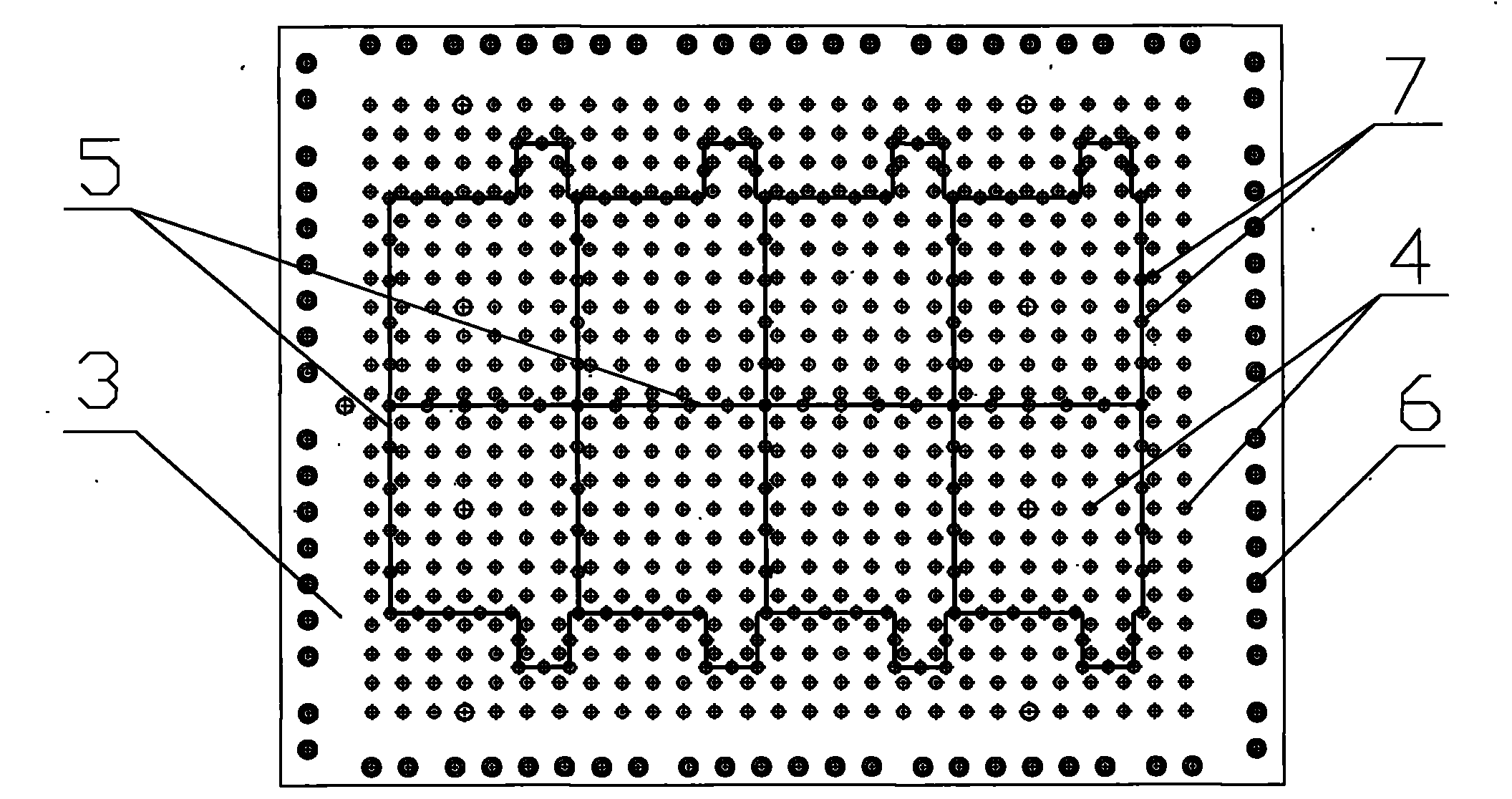

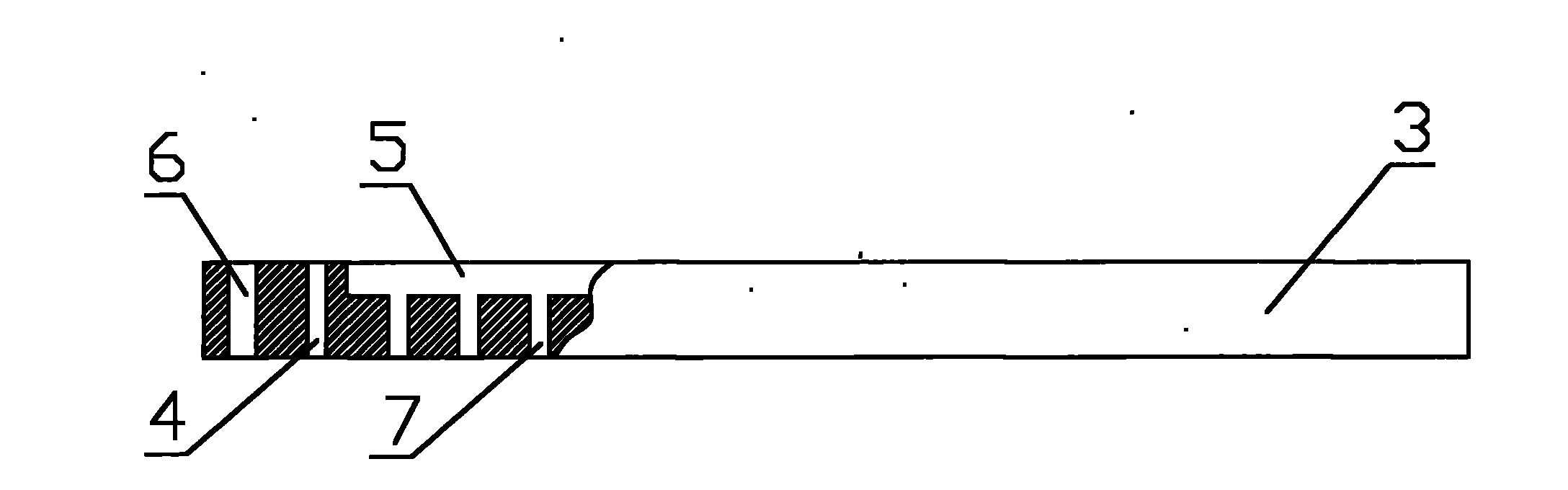

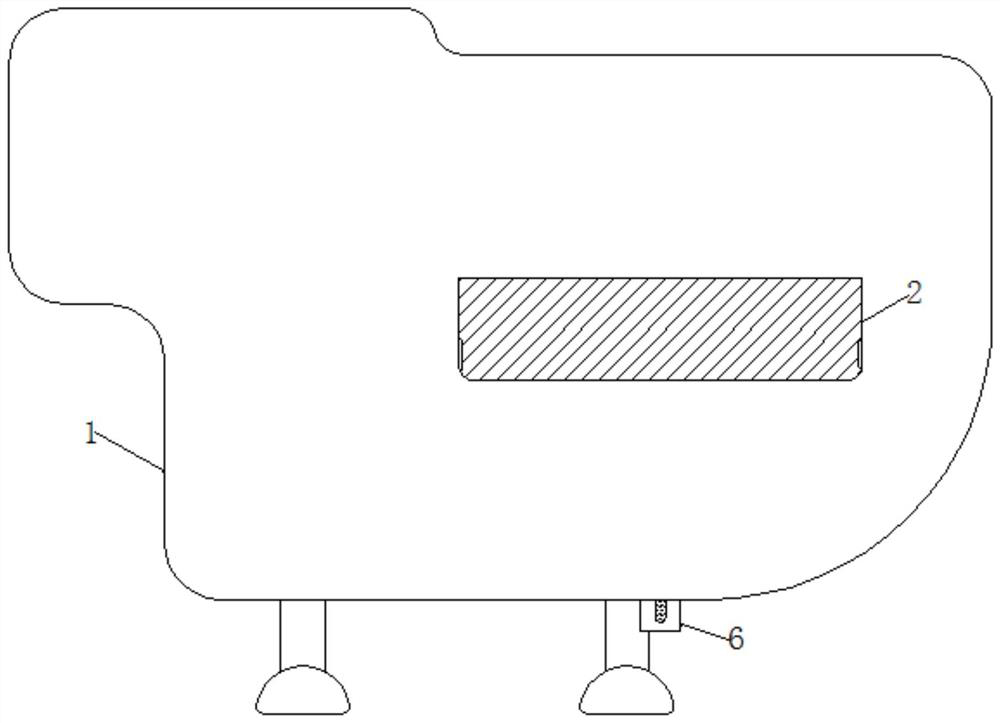

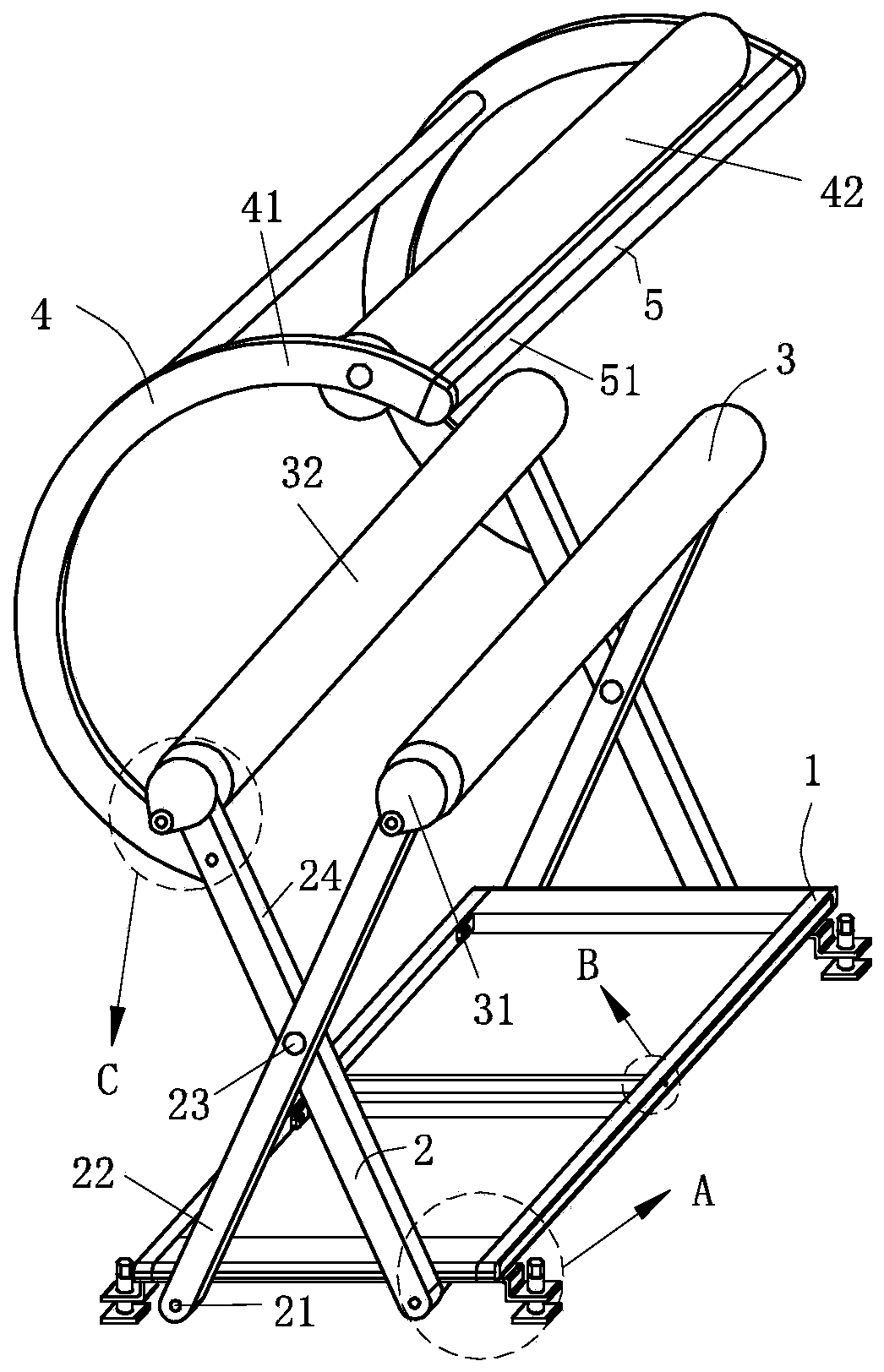

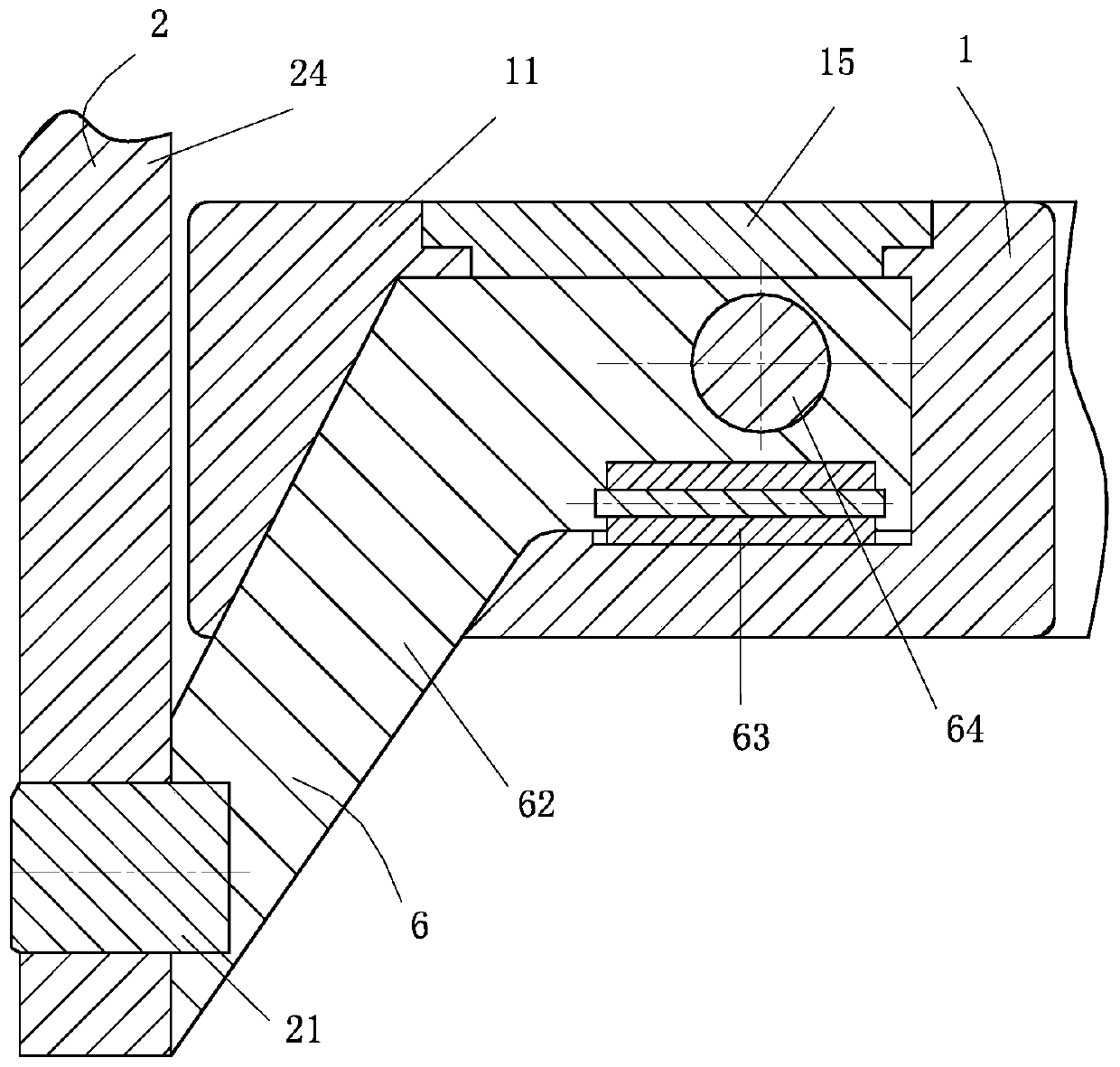

Vacuum adsorption device of battery pole piece

InactiveCN101774087ANo warpingNo situationLaser beam welding apparatusPlanar substrateElectrical battery

The invention provides a vacuum adsorption device of a battery pole piece, which is suitable for laser cutting operation and has simple structure and strong practicality. The device comprises a sealed cavity which is provided with vents communicated with a vacuum generator; the key point is that the top surface of the cavity is a plane substrate provided with plural adsorption through holes; the substrate is provide with an indent clearance groove along the cutting line of the battery pole piece; the cavity and the vacuum generator form a vacuumizing device; under the vacuumizing action of the vacuum generator, the battery pole piece can be tightly adsorbed on the substrate without lifting and bending or collapsing; the substrate is provided with the indent clearance groove along the cutting line of the battery pole piece, thus avoiding the uneven substrate as the substrate is cut and scratched when laser light beams cut the substrate during laser cutting, ensuring the cutting quality of subsequent battery pole pieces, and prolonging the service life of the substrate. The device has simple and reasonable structure, favorable adsorption effect and better popularization and application values.

Owner:CHERY AUTOMOBILE CO LTD

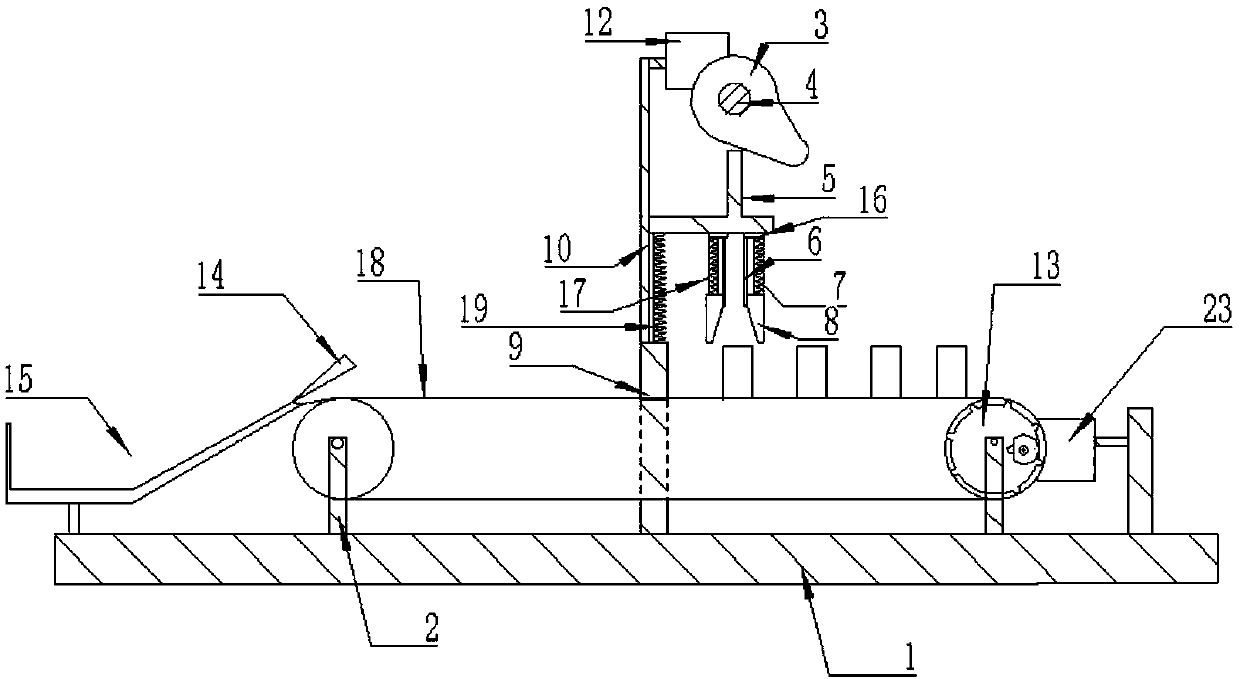

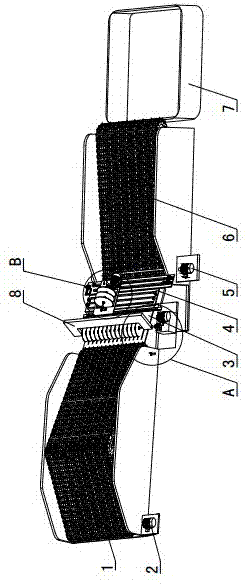

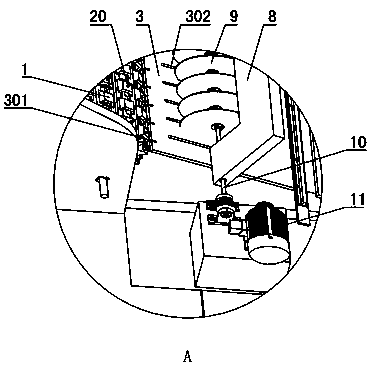

Automatic heat-shrinkable tubing threading and roasting machine

ActiveCN109435225AReduce laborEasy to control the lengthLine/current collector detailsMetal working apparatusEngineeringAutomation

The invention discloses an automatic heat-shrinkable tubing threading and roasting machine and belongs to the technical field of wire rod processing. The automatic heat-shrinkable tubing threading androasting machine comprises a worktable, a wire rod feeding mechanism, a heat-shrinkable tubing feeding mechanism, a packaged cutting mechanism and a heat-shrinkable tubing limiting mechanism. A bushing rack is arranged on the top of the worktable, two conduit grooves are formed in the top of the bushing rack, a limiting ring is arranged in each conduit groove, and the packaged cutting mechanism comprises a left cutting assembly and a packaged cutting assembly. The automatic heat-shrinkable tubing threading and roasting machine has the beneficial effects that the automatic heat-shrinkable tubing threading and roasting machine is high in degree of automation, can achieve the feeding operation of the wire rod and the heat-shrinkable tubing; the to-be-cut wire rod and the eat-shrinkable tubing sleeved o the wire rod can be pre-limited through the eat-shrinkable tubing limiting mechanism; the packaged right end of the wire rod can be cut in a proper position by the packaged cutting mechanism, so that a user can control the length of the eat-shrinkable tubing with high precision.

Owner:山东金博防腐材料有限公司

Dried bean curd surface cutting machine

ActiveCN109605437AAvoid uneven cuttingEasy to fixCheese manufactureMetal working apparatusEngineeringCam

The invention belongs to the field of dried bean curd processing and particularly discloses a dried bean curd surface cutting machine used for cutting off the two opposite surfaces of each dried beancurd. The dried bean curd surface cutting machine comprises a base, a vertical frame, supporting rods, a conveying unit, a cutting unit and a collecting unit, the vertical frame and the supporting rods are fixed to the base, the conveying unit comprises a conveying belt and a first intermittent conveying mechanism for driving the conveying belt to move, the conveying belt and the first intermittent conveying mechanism are both mounted on the supporting rods, the cutting unit comprises a cam, a transmission part, two cutting knives, a first elastic reset part, guiding modules and two second elastic reset parts, the two cutting knives are both mounted on the transmission part, each guiding module is mounted on the outer side of the corresponding cutting knife, and a horn-shaped clamping opening is defined between the two guiding modules. After the dried bean curd surface cutting machine is adopted, through the horn-shaped clamping opening, the cutting thickness of dried bean curds can beaccurately controlled when the surfaces of the dried bean curds are cut by the cutting machine, and the dried bean curds are collected more advantageously after cutting.

Owner:湖南省志平食品有限公司

Preparation method of monodirectional preimpregnation narrowband for automatic filament placement

A convenient preparation method of a monodirectional preimpregnation narrowband for automatic filament placement belongs to the composite material laying and forming field, and mainly comprises the following steps: width prepreg uncoiling, back lining paper rewinding, prepreg slitting, preimpregnation narrowband coating, and spiral rewinding of a coated preimpregnation narrowband. The preimpregnation narrowband for automatic filament placement can be prepared by the method, and is continuous in length, constant in width, and good in unwinding.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

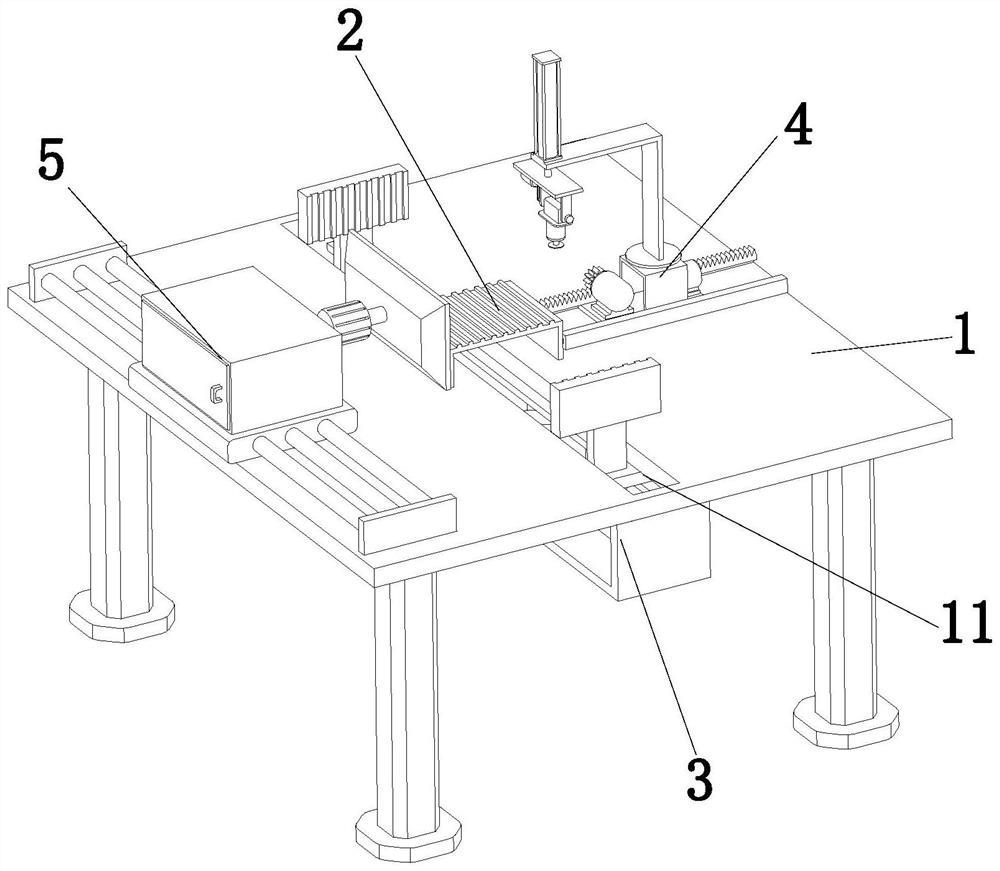

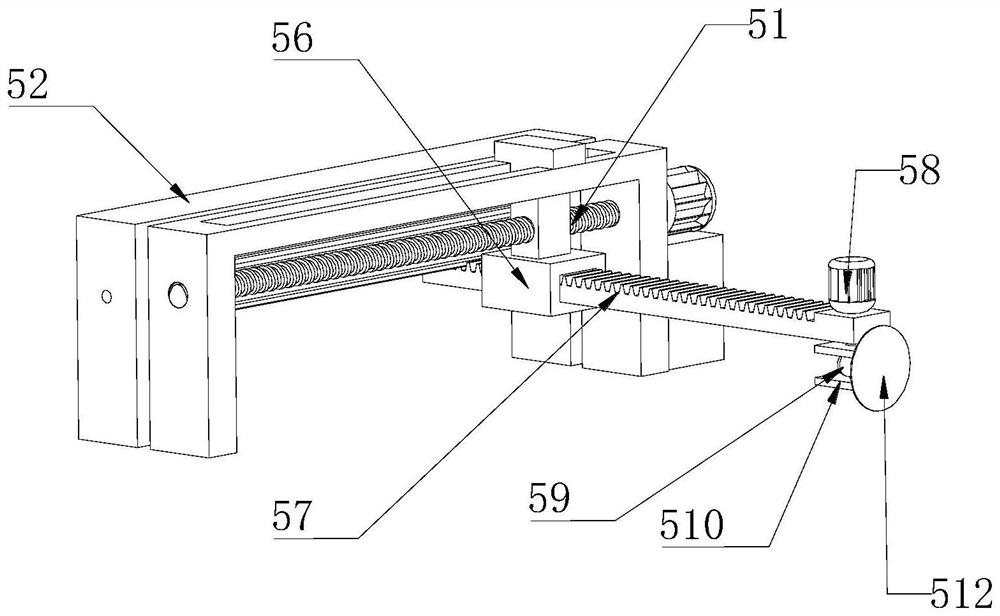

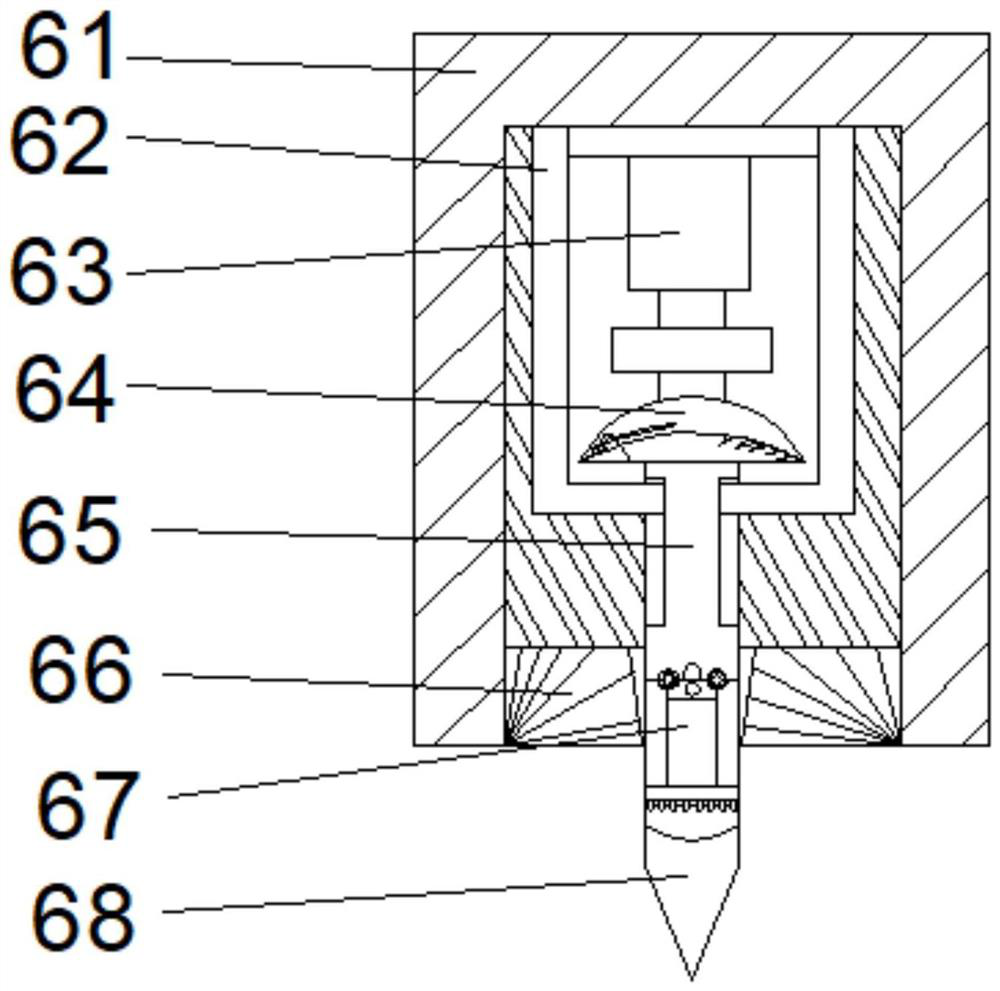

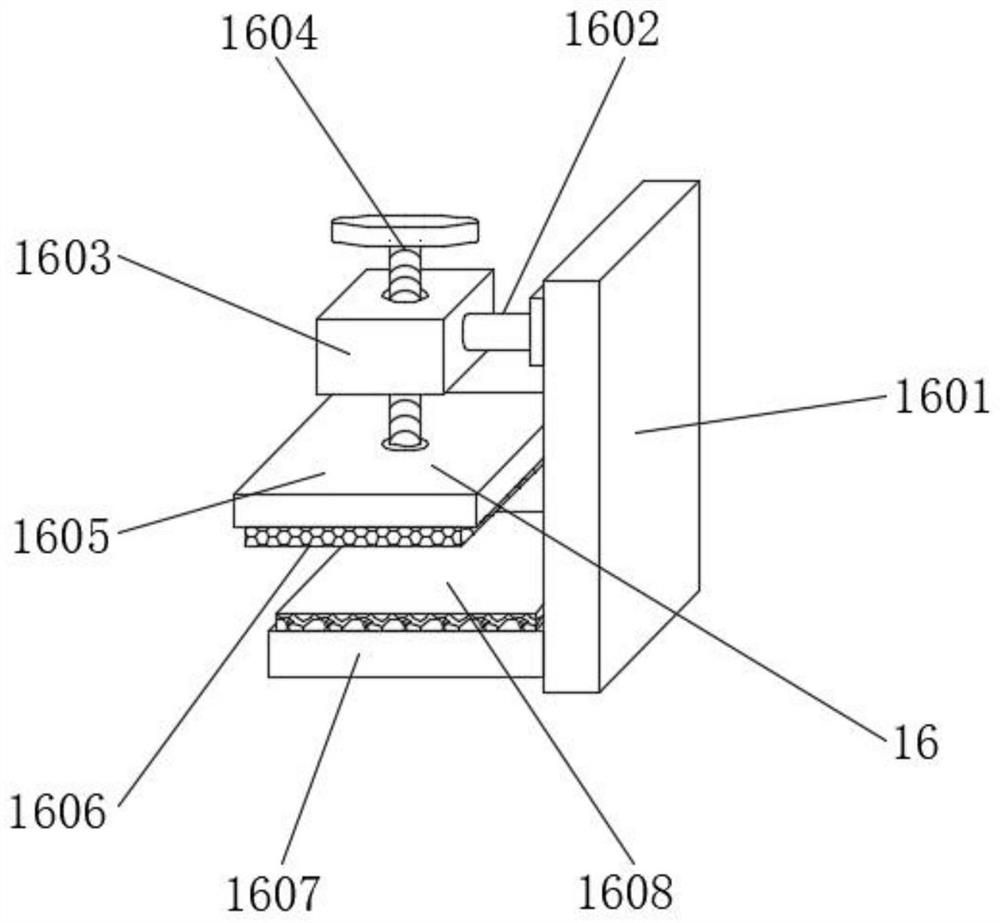

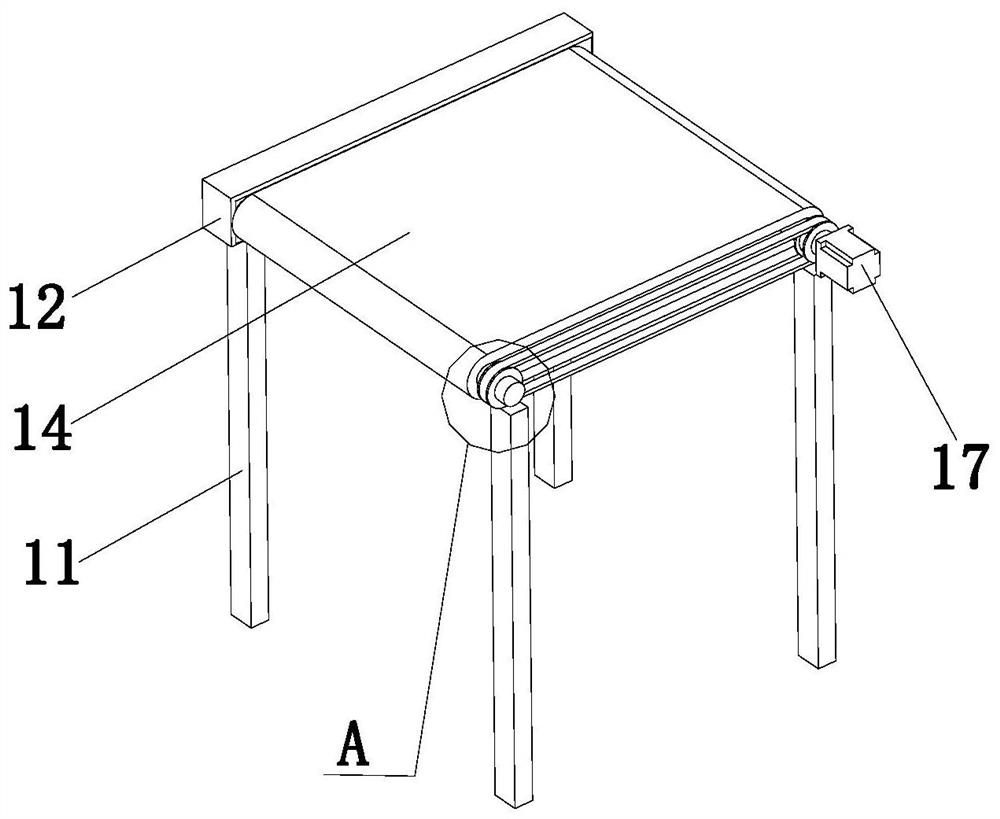

Die-casting part cutting device

InactiveCN111644706AAffect cutting qualityImprove work efficiencyPositioning apparatusMaintainance and safety accessoriesMetal machiningIndustrial engineering

The invention discloses a die-casting part cutting device and relates to the technical field of metal machining. The die-casting part cutting device comprises a cutting table, a carrying platform, a clamping mechanism, a cutting mechanism and a scrap removing mechanism. The middle position of the cutting table is provided with a fixing slot. The carrying platform is fixedly arranged in the middleposition of the cutting table. The clamping mechanism is fixedly arranged on the lower portion of the fixing slot of the cutting table. The cutting mechanism is fixedly arranged on one side of the upper surface of the cutting table. The working end of the cutting mechanism is located on the carrying platform. The scrap removing mechanism is located on the other side of the cutting table. The working end of the scrap removing mechanism is aligned with the carrying platform. The die-casting part cutting device completes automatic cutting operation of die-casting parts and scrap removing operation in the cutting process through cooperation of all the mechanisms on the cutting table and has high practicality.

Owner:WUHU SUNVOUR DIE CASTING

Toughened glass cutting device applicable to solar energy

InactiveCN107188402AReasonable deliveryImprove cutting effectGlass severing apparatusEngineeringToughened glass

The invention provides a toughened glass cutting device applicable to solar energy, and belongs to the technical field of solar energy. The toughened glass cutting device applicable to the solar energy comprises a cutting machine frame and an operation platform, wherein the operation platform is arranged on a machine frame; a conveying roller group structure capable of ascending and descending is arranged on the operation platform; a connecting frame is arranged on the machine frame; a cutting assembly and an adsorption fixing assembly are arranged on the connecting frame; one side of the machine frame is provided with a collecting structure used for putting cut toughened glass; the conveying roller group structurally comprises a square ascending and descending frame; a plurality of rotating rollers in parallel arrangement are arranged in the ascending and descending frame; the ascending and descending frame is arranged on the operation platform in a sleeving way; the lower end of the ascending and descending frame is provided with a pushing air cylinder used for pushing the ascending and descending frame to vertically ascend and descend; the pushing air cylinder is fixed on the machine frame; the adsorption fixing assembly comprises a second ascending and descending air cylinder and a vacuum suction disc. A combination between the conveying roller group structure capable of ascending and descending and the operation platform is utilized, so that the conveyance and the fixing and cutting of the toughened glass are more reasonable; the cutting effect of the toughened glass is effectively improved.

Owner:HAINING JIANENG SOLAR ENERGY IND

Rubber block cutting device for rubber tube production

The invention discloses a rubber block cutting device for rubber tube production. The device comprises a cutting bottom plate, four sets of standing columns are arranged above the cutting bottom plate, the tops of the four sets of the standing columns are provided with top plates,the sides of the upper portions of the top platesare fixed to dust suction fans through screws, the bottoms of the topplatesare fixed to electric guiding rails by the screws, the electric guiding railsare provided with sliding blocks, the bottoms of the sliding blocksare fixed to telescopic air cylinders by the screws, telescopic rods of the telescopic air cylinders are fixed to mounting plates by the screws, two sides of a cutting disk are symmetrically provided with connecting rods, the ends of the connecting rodsare fixedly welded to the mounting plates, the ends, away from the mounting plate, of the connecting rodsare connected with mounting frames, and the vertical sections of the mounting framesare of n-shaped structures. The device has reasonable structure and novel design, flattens a rubber block in the process of cutting the rubber block, effectively improves the cutting quality of the rubber block, quickly sucks out the cutting powder, and effectively improves the cutting environment.

Owner:刘薇

Decorative ceramic tile cutting and positioning device

ActiveCN113547650AReduce labor intensityIncrease cutting rateWorking accessoriesVibration suppression adjustmentsCeramic tilesEngineering

Owner:阿郎装饰股份有限公司

Dustproof cutting device for plate processing

InactiveCN113172711AImprove cutting efficiencyAffect cutting qualityProfiling/shaping machinesBark-zones/chip/dust/waste removalWood machiningEngineering

The invention discloses a dustproof cutting device for plate processing, and belongs to the technical field of wood processing. The dustproof cutting device comprises a workbench, a first fixing assembly, a second fixing assembly and a cutting assembly, wherein the first fixing assembly is arranged on the workbench, a lifting assembly and a pushing assembly are distributed in front of and behind a processing area, two clamping ends are distributed on the left side and the right side of the processing area, the cutting assembly is arranged above the workbench, and the cutting assembly is provided with a cutting end and a driving structure for enabling the cutting end to move. According to the dustproof cutting device, a plate is placed into the processing area of the workbench from the front of the workbench, then the two clamping ends of the second fixing assembly synchronously move from the two sides of the operation site, then the cutting assembly cuts the front side and the rear side of the plate, the two clamping ends of the second fixing assembly are loosened, the left side and the right side of the plate are cut, the plate does not need to be repeatedly moved in the process, the processing time is saved, and the processing efficiency is improved.

Owner:闻掌根

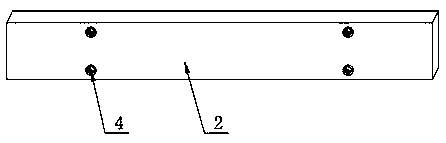

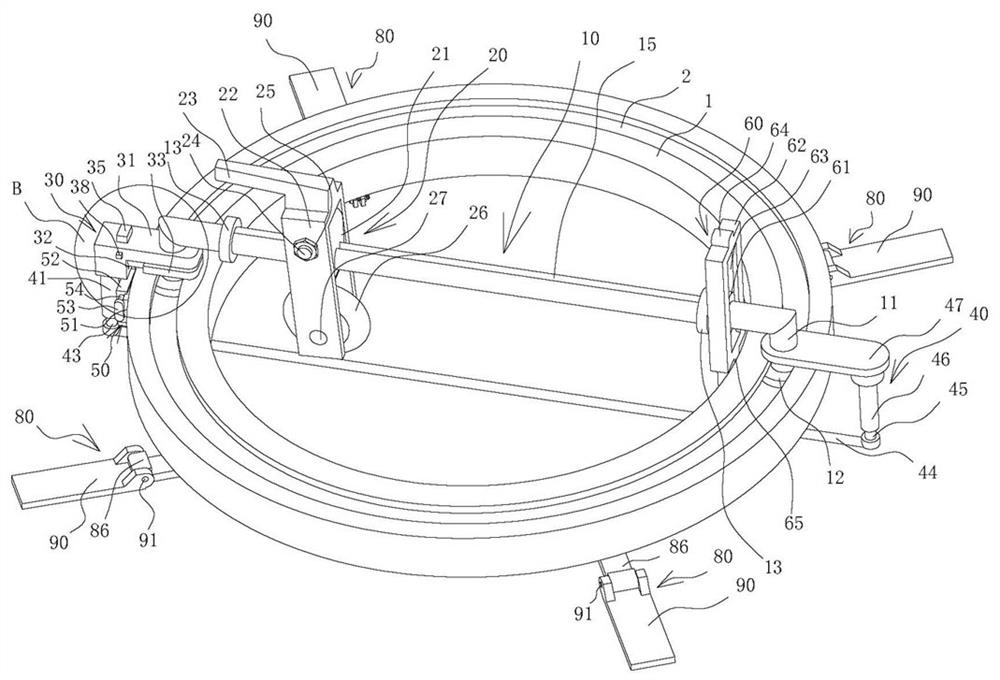

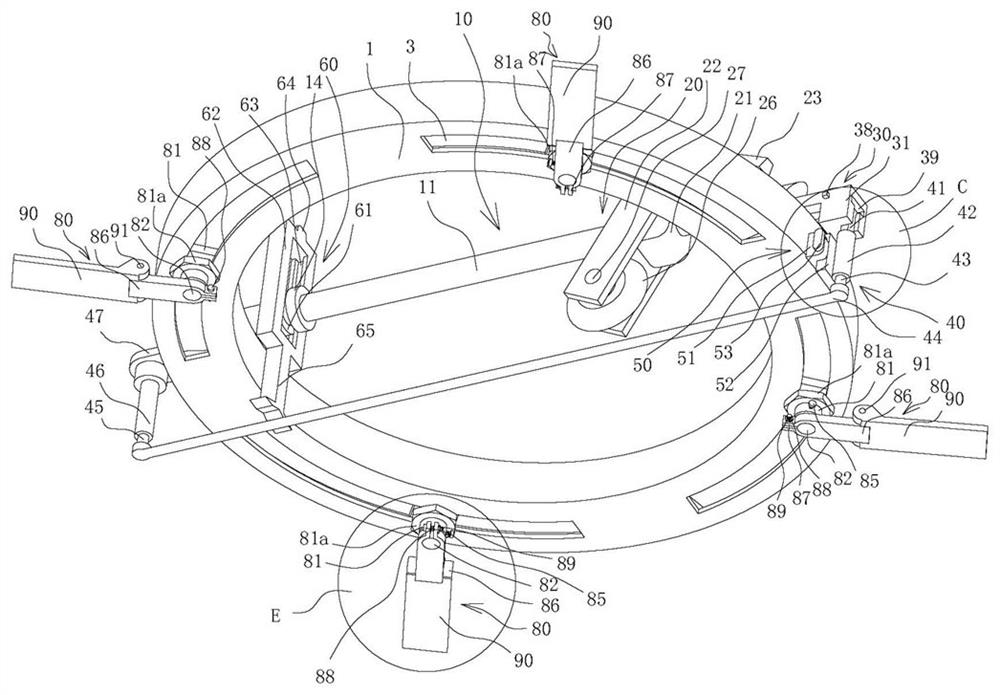

Manual ceramic tile cutting machine

ActiveCN110900854AEffective positioningEasy to useWorking accessoriesStone-like material working toolsStructural engineeringLever pressing

The invention discloses a manual ceramic tile cutting machine. The structure comprises a rack. A first sliding groove is arranged in one end of the rack. A plurality of uniformly distributed second sliding grooves are arranged in the other end of the rack. A guide mechanism is arranged in the first sliding groove. A cutting mechanism is arranged on the guide mechanism. A fixing mechanism is arranged at one end of the guide mechanism. The other end of the guide mechanism is provided with a pressing rod mechanism for promoting ceramic tile breakage, the other end of the fixing mechanism is provided with an auxiliary mechanism for assisting the pressing rod mechanism to break ceramic tiles. The other end of the auxiliary mechanism is connected with the guide mechanism. One end of the rack isprovided with a vertical mechanism for assisting ceramic tile positioning. A support mechanism capable of fixing a relative position between the ceramic tiles and the rack is arranged in the second sliding groove. The cutting machine has advantages that position fixing between irregular ceramic tiles and the cutting machine can be easily completed; a cutting angle can be adjusted; an application range is widened; and production efficiency is improved.

Owner:泰安如仁智能科技有限公司

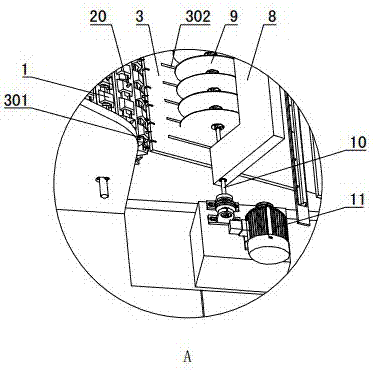

An improved automatic bamboo shoot slicer

ActiveCN110103270BLimit left and right positionAffect cutting qualityCleaning using toolsMetal working apparatusAgricultural engineeringStructural engineering

The invention discloses an improved automatic bamboo shoot slicing machine, which includes a frame and a belt transmission mechanism arranged on the upper surface of the frame. One end of the frame for feeding is provided with a side baffle for limiting the bamboo shoots. The frame is provided with a baffle fine-tuning mechanism for the side baffles. A bamboo shoot soft pressing mechanism and a blade swing mechanism for cutting bamboo shoots are installed in the middle of the frame. The bamboo shoot soft pressing mechanism is located between the blade swing mechanism and the side baffles. , and the bamboo shoot soft pressing mechanism is provided with a flat pressing mechanism on the side near the feed end to prevent the bamboo shoots from stacking. The invention can not only limit the bamboo shoots to ensure the regularity when feeding the bamboo shoots, but also ensure the stability when cutting the bamboo shoots, which greatly ensures the better appearance of the bamboo shoots after cutting. At the same time, the invention as a whole can The high degree of disassembly greatly facilitates disassembly and assembly operations, especially the difficulty of replacing the cutter, which saves time and labor costs for enterprises.

Owner:成都精钟满机械设备制造有限公司

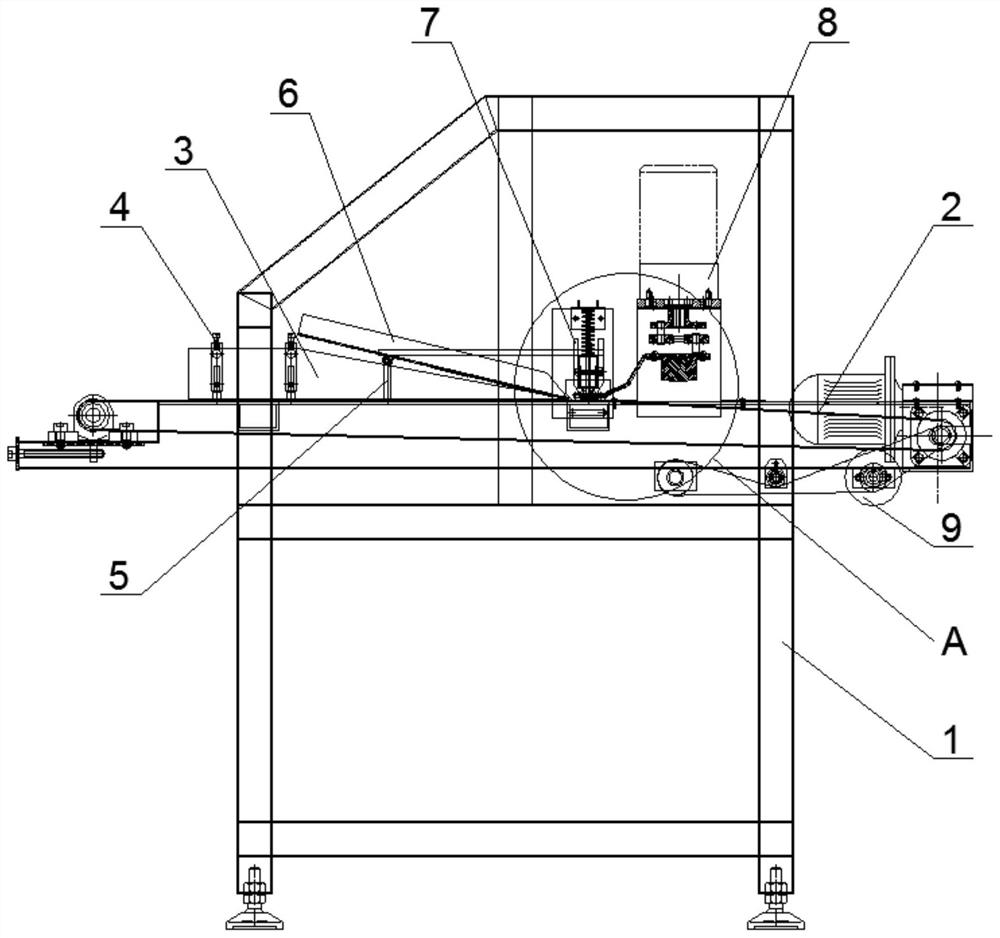

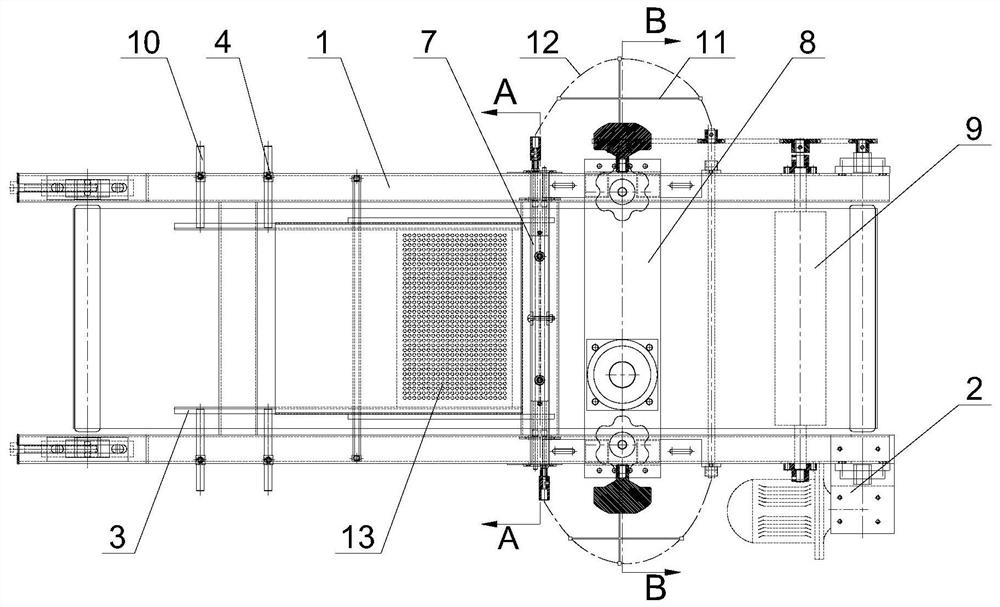

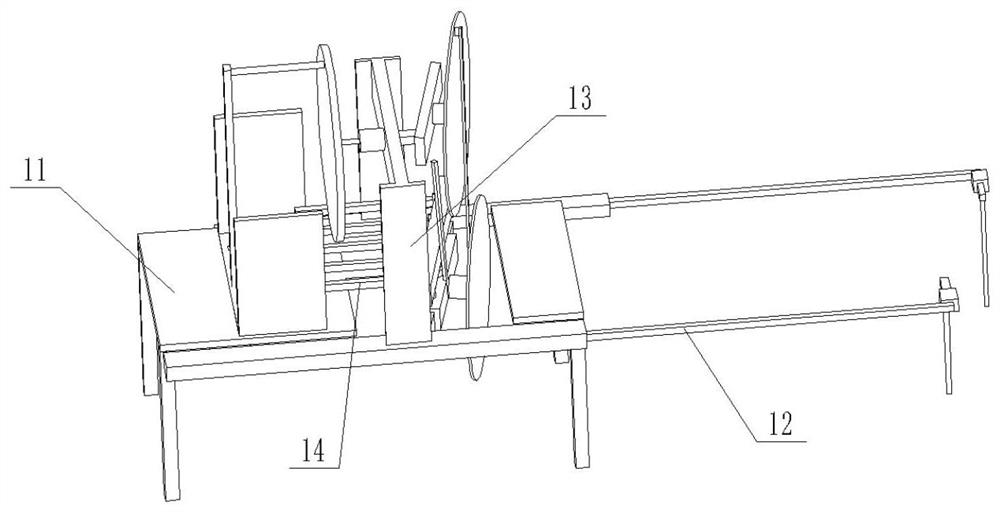

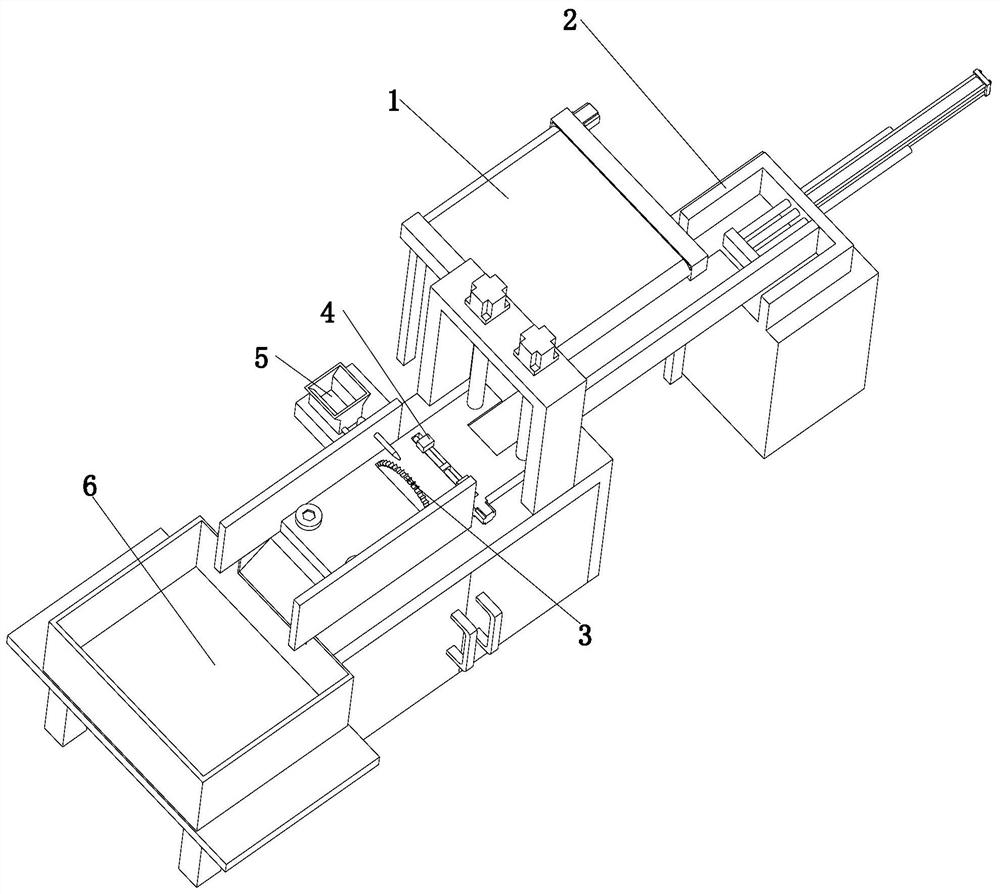

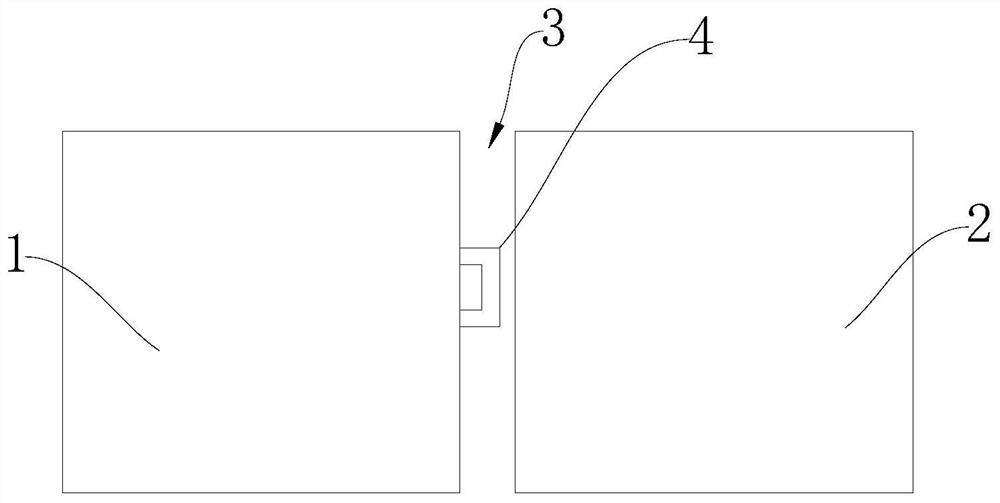

Combined type automatic cutting machine for cow leather

InactiveCN106868230AAvoid random movementPrecise control of cutting sizeLeather clicking/perforating/clickingMechanical engineering

The invention discloses a combined type automatic cutting machine for cow leather, and belongs to the technical field of cutting equipment for the cow leather. The cutting machine is characterized by comprising a cow leather conveying mechanism, a transverse cutting mechanism and a longitudinal cutting mechanism; a cutting platform (3) is arranged below the transverse cutting mechanism and the longitudinal cutting mechanism; the transverse cutting mechanism and the longitudinal cutting mechanism are sequentially arranged in the cow leather conveying direction; the horizontal cutting mechanism is coordinated with the cutting platform (3) to cut the cow leather into strips; the longitudinal cutting mechanism is coordinated with the cutting platform (3) to cut the cow leather into blocks; and the cow leather conveying mechanism conveys the cow leather to the cutting platform (3) and conveys the cut blocky cow leather away. According to the combined type automatic cutting machine for the cow leather, the problem that cow leather moves randomly in the cutting process due to the fact that the cow leather is soft can be avoided, the cutting size of the cow leather can be conveniently and accurately controlled, the size of the cut cow leather can be ensured to be stable, the subsequent processing technology can be simplified, and the product quality can be improved.

Owner:SHANDONG UNIV OF TECH

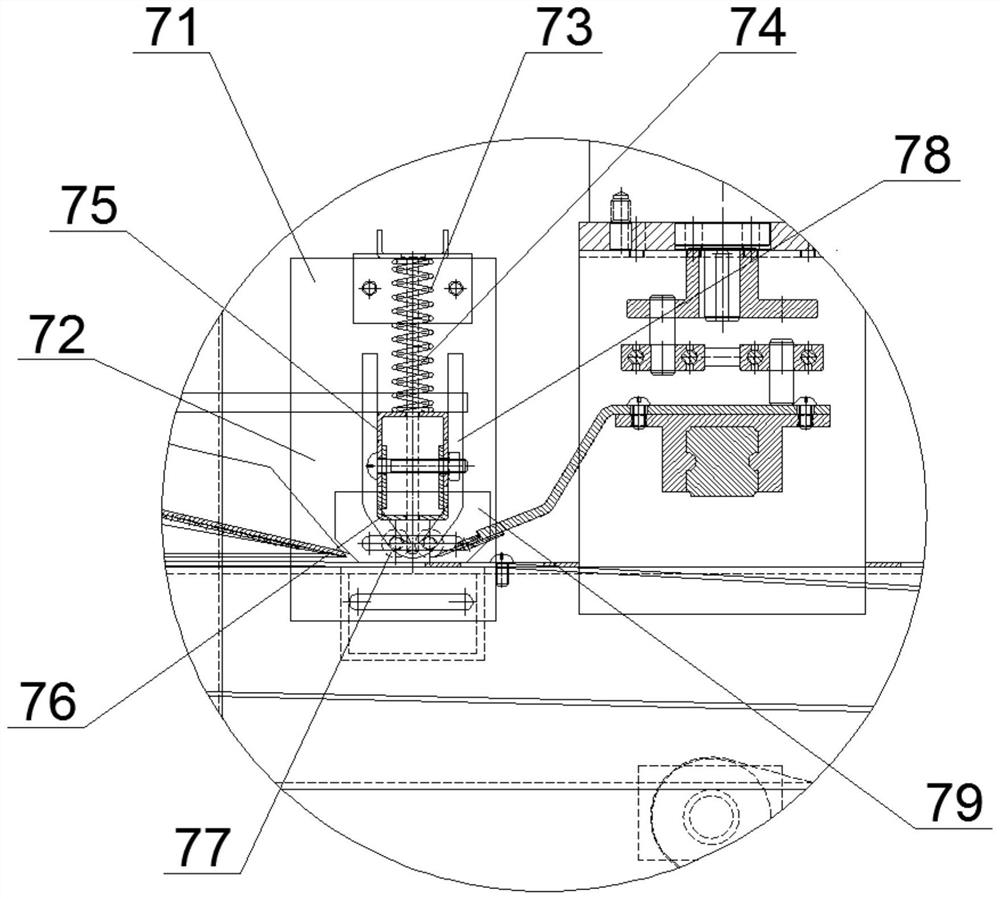

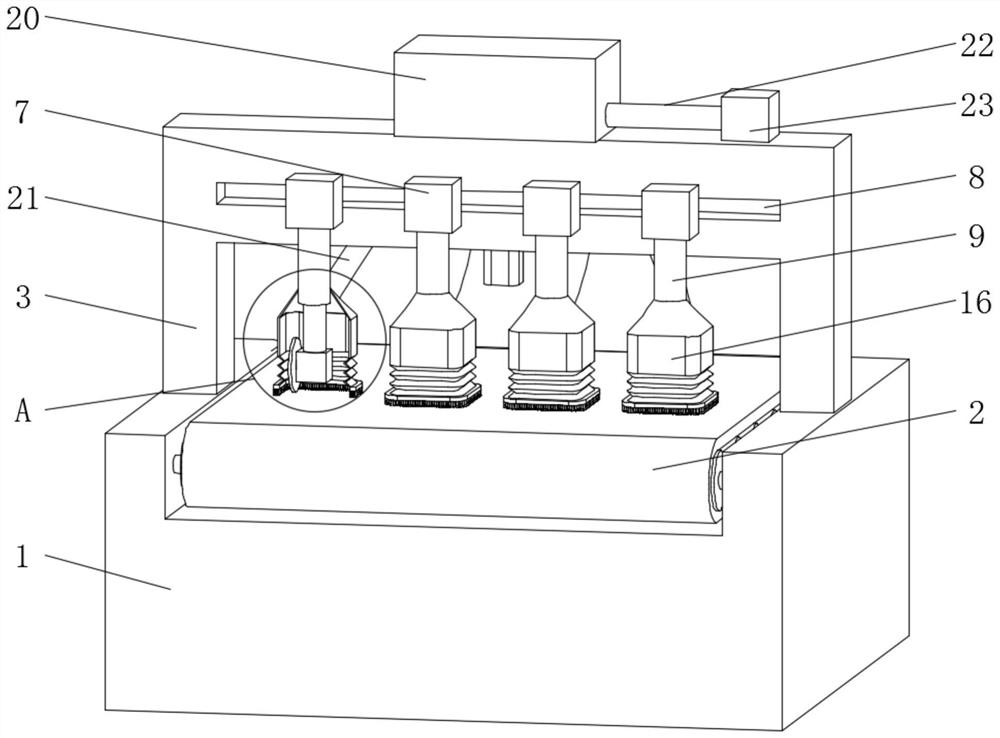

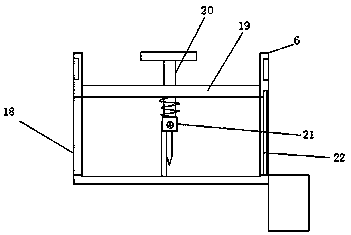

Automatic passing and baking heat-shrinking casing machine

ActiveCN111674032AReduce laborEasy to control the lengthLine/current collector detailsMetal working apparatusWire rodEngineering

The invention discloses an automatic passing and baking heat-shrinking casing machine, and belongs to the technical field of wire rod processing. The automatic passing and baking heat-shrinking casingmachine comprises a worktable, a wire rod feeding mechanism, a heat-shrinking casing feeding mechanism, a set cutting mechanism and a heat-shrinking casing limiting mechanism. A casing frame is arranged at the top of the worktable, two guide pipe grooves are formed in the top of the casing frame, each of guide pipe groove is internally provided with a limit ring, and the set cutting mechanism comprises a left end cutting assembly and a set cutting assembly. The automatic passing and baking heat-shrinking casing machine has the beneficial effects that the automation degree is high, the feed operation of wire rods and heat-shrinking casings can be realized, the wire rods to be cut and the heat-shrinking casings sleeving the wire rods can be pre-limited through the heat-shrinking casing limiting mechanism, the right end of a wire set can be cut in an appropriate position through the set cutting mechanism, so that workers control the length of the heat-shrinking castings with high precision.

Owner:苏州宇盛电子有限公司

Pipe cutting machine with feeding and unloading mechanisms

InactiveCN109015837AImprove cutting efficiencyAffect cutting qualityMetal working apparatusCouplingElectric machinery

The invention discloses a pipe cutting machine with feeding and unloading mechanisms. The pipe cutting machine comprises a U-shaped frame; a second roller is mounted on the right side of a groove of the U-shaped frame through a mounting frame; a first roller is mounted on the right side of the upper surface of the U-shaped frame through a mounting frame; an input shaft of the first roller and an output shaft of a stepper motor are connected through a coupling; the stepper motor is fixed on the upper surface of the U-shaped frame; a second electromagnetic brake is mounted on the left side of the groove of the U-shaped frame; the lower end of the left side surface of the U-shaped frame and the lower end of an L-shaped frame are fixedly connected; a first electromagnetic brake is mounted at the upper end of the L-shaped frame; pipe bodies are clamped by the first electromagnetic brake and the second electromagnetic brake, so that the influence on the cutting quality of the pipe bodies byshaking of the pipe bodies is prevented; the stepper motor drives the first roller to rotate so as to drive the pipe bodies to move to the left side by a certain distance; and cut short pipe bodies are ejected out from the first electromagnetic brake by the pipe bodies, so that the automatic feeding and unloading of the pipe bodies are realized, and the cutting efficiency of the cutting machine isimproved.

Owner:JIANGSU YANGGUANG NOVAL FENCE SCI & TECH CO LTD

Multi-angle metal pipe fitting cutting device

InactiveCN113319360AImprove cutting efficiencyShorten the timeTube shearing machinesShearing machine accessoriesEngineeringStructural engineering

The invention discloses a multi-angle metal pipe fitting cutting device, and belongs to the field of metal cutting. The multi-angle metal pipe fitting cutting device comprises a cutting device, a feeding device, a supporting plate and a power device. The power device is fixedly connected to the side face of the feeding device. The cutting device is fixedly connected to the upper end of the supporting plate and the upper end of the feeding device, and a gap is reserved between the supporting plate and the feeding device. According to the multi-angle metal pipe fitting cutting device, a plurality of pipe fittings with inclined sections can be cut at the same time, the cutting efficiency is improved, and time is saved; the pipe fittings with the inclined sections can be continuously cut through a cutter I and a cutter II, the working efficiency is guaranteed, and meanwhile the situation that the inclination angle of the cutters is changed due to the fact that a worker moves the cutters, and the machining quality is affected can be avoided; and the machining requirement that the tangent planes of the pipe fittings are planes or inclined planes can be met through adjustment, the occupied area of the equipment can be saved, and then factory building funds are saved.

Owner:曹松禄

Rubber and plastic product cutting device

The invention discloses a rubber and plastic product cutting device. The device comprises a base; an operation table is fixedly connected with the top of the base; a control table is fixedly connectedwith the right side of the front face of the operation table; sliding grooves are formed in the middles of the outer walls of the two sides of the operation table; movable frames are arranged on theinner walls of the two sides of each sliding groove; a cutting device is arranged at the position, located at the left side of the upper portion of the operation table, of the tops of the movable frames; and a protection device is fixedly connected with the top of the front face of the operation table. According to the rubber and plastic product cutting device, the cutting device, the protection device and the operation table are arranged, when the cutting device conducts cutting on the operation table, the forming of a trace space between a side plate and a tool is realized, and the tool ascends and descends to be scraped through the side plate, so that materials adhering to the tool in the cutting process can be cleaned conveniently, the cutting quality of the cutter is prevented from being affected by scraps, the friction force is further improved, and therefore the materials are cut off and cannot deviate.

Owner:高虎

Environment-friendly flame-retardant ship stone-plastic floor and method and device thereof

ActiveCN113291414AAvoid the problem of halogen elementsEnvironmental upgradeSynthetic resin layered productsLaminationTextile printerMarine engineering

The invention discloses an environment-friendly flame-retardant ship stone-plastic floor and method and device thereof. The environment-friendly flame-retardant ship stone-plastic floor comprises a hard PP / PE base material layer, a back coating balance layer is arranged at the lower end of the hard PP / PE base material layer, a PP / PE printing layer is arranged at the upper end of the hard PP / PE base material layer, and a UV coating is arranged at the upper end of the PP / PE printing layer. In the environment-friendly flame-retardant ship stone-plastic floor, PE resin is adopted to modify PP resin through a compatilizer to form a blending material, calcium carbonate filler with the optimal cost performance is adopted to develop a Non-PVC stone-plastic floor base layer, then a PP / PE printing layer added with a flame retardant is hot-pressed on a base material, the surface of a hot-pressed plate is coated with a protective layer of 0.10-0.30 [mu] m in a curtain coating mode, and finally slitting, slotting and packaging are performed. As the main component elements of the product are C and H, the smoke density and toxicity of gas after combustion are far lower than those of a traditional PVC stone plastic floor.

Owner:福建思嘉新材料科技有限公司

High-efficiency Chinese herb cutting device

InactiveCN108555990AImprove work efficiencyAffect cutting qualityMetal working apparatusEngineeringChinese herbology

The invention relates to a high-efficiency Chinese herb cutting device. The high-efficiency Chinese herb cutting device comprises a cutting table, which is provided with, sequentially from left to right, a feeding tank and a cutting tank; four corners of the bottom of the cutting table are symmetrically provided with cuboid support rods, and the bottom ends of the cuboid support rods are fixedly provided with moving wheels through connecting blocks. By means of a cutting mechanism, the high-efficiency Chinese herb cutting device is high in working efficiency and high in automation degree; by means of a herb pressing plate, the high-efficiency Chinese herb cutting device can clamp and fix herbs to be cut to avoid influence on cutting quality due to sliding the herbs during cutting; by meansof a herb pushing plate and a herb limiting plate, the high-efficiency Chinese herb cutting device can effectively control size uniformity of the herbs to be cut; by means of a small cutting module,the high-efficiency Chinese herb cutting device is applicable to cutting both large and small batches of herbs; by means of the moving wheels and a sliding type support pallet, the high-efficiency Chinese herb cutting device is convenient to use and capable of being effectively collected after usage to save space occupied, thereby being applicable to generalization.

Owner:徐见

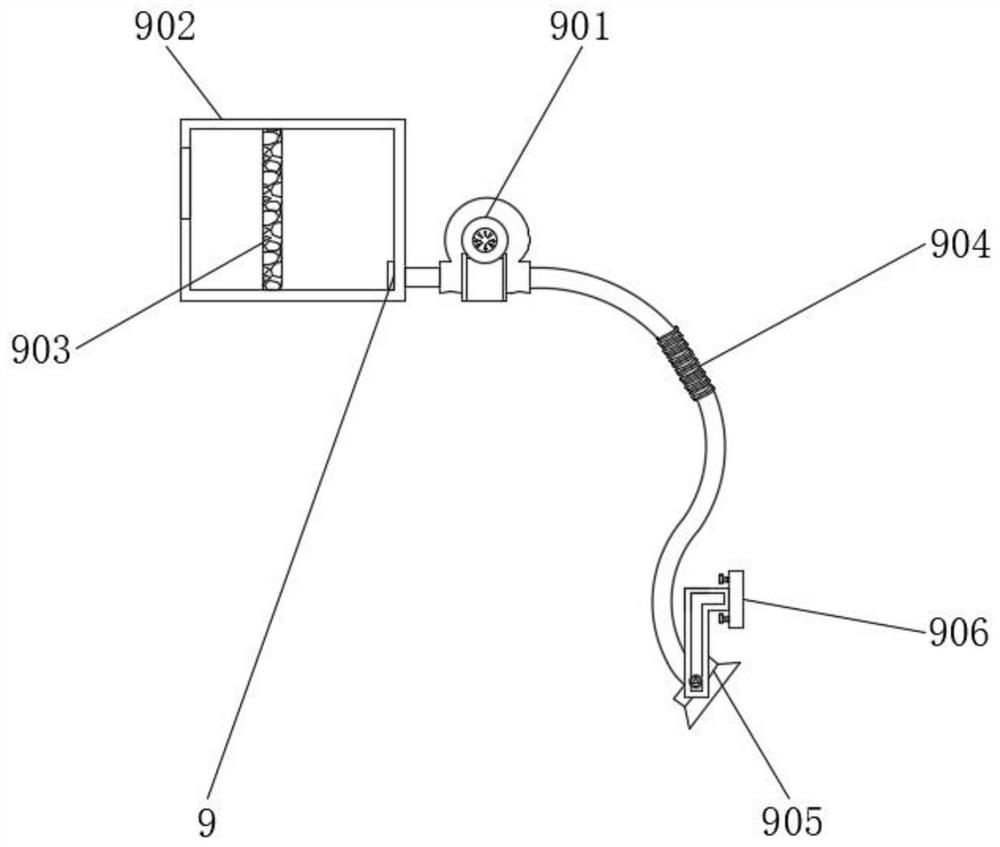

Intelligent optical fiber laser cutting machine with high safety

PendingCN113787263AAvoid indentationAvoid health effectsLaser beam welding apparatusEngineeringStructural engineering

The invention discloses an intelligent optical fiber laser cutting machine with high safety. The intelligent optical fiber laser cutting machine comprises a base, a cavity is formed in the base, electric push rods are fixedly mounted on the two sides of the inner wall of the cavity, a sliding block is fixedly connected to one side of the cavity, a connecting rod is welded to the upper end of the sliding block, and the connecting rod penetrates through the base to be welded with a movable seat; and the movable seat is slidably connected with the base through a sliding block, side plates are welded to the two sides of the upper end of the base, a transverse plate is welded to the upper ends of the side plates, a purification mechanism is arranged at the upper end of the transverse plate, and supporting legs are welded to the two sides of the lower end of the base. Under the action of an exhaust fan, a gas collection tank, a gas purification plate, a telescopic hose, an air suction cover and a mounting frame, some poisonous and harmful gas or smoke dust generated during cutting can be absorbed and purified through the gas purification plate, the influence on the health of the respiratory tract of an operator is avoided, and the safety performance of the optical fiber laser cutting machine is greatly improved.

Owner:JIANGSU HUYUN LASER EQUIP CO LTD

Hydraulic swing type plate shearing machine

PendingCN114769698AAvoid manual operationImprove parallelismShearing machinesShearing machine accessoriesStructural engineeringManual handling

The invention belongs to the technical field of plate shearing machines, and particularly relates to a hydraulic swing type plate shearing machine. Comprising a rack, a base and a cutting unit, the machine frame is fixedly connected to the upper surface of the machine base, and the cutting unit is arranged in the machine frame above the machine base. The device further comprises a correcting assembly. The correcting assembly is arranged on the upper surface of the left side of the base. The correcting assembly is used for correcting the angle of a plate placed on the machine base. A fixing assembly; the fixing assembly is used for fixing and clamping the corrected plate; according to the plate shearing machine, the correcting assembly and the fixing assembly are arranged for automatically correcting the position of a plate to be machined and clamping and fixing the plate to be machined, manual operation is avoided, the parallelism between the plate and the cutter is improved, the forming quality of the cut plate is improved, meanwhile, the operation time is shortened, and the working efficiency of the plate shearing machine is improved.

Owner:吴章萍

A Combined Cowhide Automatic Cutting Machine

InactiveCN106868230BAvoid random movementPrecise control of cutting sizeLeather clicking/perforating/clickingMetal working apparatusEngineeringMechanical engineering

The invention discloses a combined type automatic cutting machine for cow leather, and belongs to the technical field of cutting equipment for the cow leather. The cutting machine is characterized by comprising a cow leather conveying mechanism, a transverse cutting mechanism and a longitudinal cutting mechanism; a cutting platform (3) is arranged below the transverse cutting mechanism and the longitudinal cutting mechanism; the transverse cutting mechanism and the longitudinal cutting mechanism are sequentially arranged in the cow leather conveying direction; the horizontal cutting mechanism is coordinated with the cutting platform (3) to cut the cow leather into strips; the longitudinal cutting mechanism is coordinated with the cutting platform (3) to cut the cow leather into blocks; and the cow leather conveying mechanism conveys the cow leather to the cutting platform (3) and conveys the cut blocky cow leather away. According to the combined type automatic cutting machine for the cow leather, the problem that cow leather moves randomly in the cutting process due to the fact that the cow leather is soft can be avoided, the cutting size of the cow leather can be conveniently and accurately controlled, the size of the cut cow leather can be ensured to be stable, the subsequent processing technology can be simplified, and the product quality can be improved.

Owner:SHANDONG UNIV OF TECH

Cutting device for electric tricycle part machining

InactiveCN109434176AEasy to shrinkAffect cutting qualityShearing machinesLarge fixed membersElectric machineryScrap

The invention discloses a cutting device for electric tricycle part machining, and relates to the field of electric tricycle part machining. The cutting device comprises a fixing base, a supporting base is connected to the bottom of the fixing base, fixing bolts are connected to the portions, close to the upper portion of the supporting base, of the two outer side walls of the fixing base, and threaded holes are symmetrically formed in the exterior of the end, corresponding to the fixing bolts, of the interior of the supporting base; the two sides of the bottom of the fixing base are each provided with a wheel; and a clamping screw is installed at the top end of the fixing base, a fixing rod is connected to the side, far away from the clamping screw, of the top end of the fixing base, a motor is installed at the top end of the fixing rod, and a belt protecting shell is connected to one side of the motor. According to the cutting device for electric tricycle part machining, when the cutting device works, the condition that the wheels waggle to influence the cutting quality is avoided, the cutting stability is improved, the condition that cutting scraps splash to influence an operatecan be prevented in the cutting process, and then the safety performance of the cutting device is improved.

Owner:LUYUAN ELECTRIC VEHICLE JIANGSU CO LTD

An aluminum alloy profile cutting and fixing device

ActiveCN112091323BQuality impactAvoid offsetMetal sawing devicesMetal sawing accessoriesEngineeringStructural engineering

The invention relates to the technical field of aluminum alloy profiles, and discloses a cutting and fixing device for aluminum alloy profiles, including a conveying part, a boosting part, a cutting part, a fixing part, a cooling part and a bearing part, and the conveying part is arranged between the boosting part and the supporting part. In the middle of the cutting part, the boosting part is arranged on one side of the conveying part, the cutting part is arranged on the other side of the conveying part, and the cutting part and the boosting part correspond to each other, and the fixing part is arranged on the cutting part. The top of the component, the cooling component is set on the top of the cutting component, and the cooling component is located on the side of the fixed component, and the bearing component is set on the side of the cutting component, which can be used according to the needs of the operator for the aluminum alloy profile The cutting angle can be adjusted to make the operation easier and more convenient.

Owner:贵州惠航科技有限责任公司

Chip metal wire, manufacturing method thereof and wafer

PendingCN113363240AUniform compositionAffect cutting qualitySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsHemt circuitsEngineering physics

The invention provides a chip metal wire, a manufacturing method thereof and a wafer, and belongs to the field of chips. The chip metal wire comprises a first metal wire, wherein the first metal wire vertically crosses a scribing groove between two adjacent chips, two connecting ends of the first metal wire are located in the same chip, and the connecting ends are used for connecting a test circuit module in the chip. According to the chip metal wire provided by the invention, the chip metal wire vertically crosses the scribing groove between the two adjacent chips, so that the material composition in the scribing groove is kept uniform, the pressures on the two surfaces of the saw blade in the scribing groove are consistent, the cutting quality cannot be influenced by the cutting deflection of the saw blade, and meanwhile, the first metal wire is ensured to be cut by the saw blade.

Owner:BEIJING SMARTCHIP MICROELECTRONICS TECH COMPANY +3

A manual tile cutter

ActiveCN110900854BEffective positioningEasy to useWorking accessoriesStone-like material working toolsStructural engineeringMachine

The invention discloses a manual ceramic tile cutting machine, which comprises a frame, one end of the frame is provided with a first chute, the other end of the frame is provided with a plurality of evenly distributed second chute, the first chute is provided with a guide Mechanism, the guiding mechanism is provided with a cutting mechanism, one end of the guiding mechanism is provided with a fixing mechanism, the other end of the guiding mechanism is provided with a pressure rod mechanism to promote the breaking of the tiles, and the other end of the fixing mechanism is provided with an auxiliary pressure rod mechanism to promote the ceramic tiles. The other end of the mechanism is connected with the guide mechanism. One end of the frame is provided with a vertical mechanism to help the tiles to be positioned. The second chute is provided with a support mechanism capable of fixing the relative position between the tiles and the frame. The beneficial effects of the present invention: the present invention can The position fixing between the irregular tiles and the invention can be easily completed, and the cutting angle can be adjusted, which improves the scope of application of the invention and improves the production efficiency.

Owner:泰安如仁智能科技有限公司

Plastic film cutting-off machine

The invention discloses a plastic film cutting-off machine. The plastic film cutting-off machine is characterized by comprising a frame, a cutting-off device and a rotary drum, wherein the cutting-off device is arranged on the frame; the rotary drum is used for the placement of a plastic film; the cutting-off device comprises a cutter; one end of the cutter is fixedly arranged on a support; the other end of the cutter is fixedly arranged on a main shaft; the main shaft is connected with a gas push oil cylinder; the support is fixedly arranged on the frame; and the rotary drum is sheathed on a rotary shaft of a stepping motor. The plastic film cutting-off machine has the advantages of rational structure, good controllability and high automation degree.

Owner:NANTONG JUFA PLASTIC PROD

An automatic threading and drying heat shrinkable sleeve machine

ActiveCN109435225BReduce laborEasy to control the lengthLine/current collector detailsMetal working apparatusHeat-shrinkable sleeveWire rod

The invention discloses an automatic threading and drying heat-shrinkable sleeve machine, which belongs to the technical field of wire material processing and includes a workbench, a wire material feeding mechanism, a heat-shrinkable sleeve feeding mechanism, a suit cutting mechanism and a heat-shrinkable sleeve limit mechanism , the top of the workbench is provided with a casing frame, the top of the casing frame is provided with two conduit grooves, each of the conduit grooves is provided with a limit ring, and the set cutting mechanism includes a left end cutting assembly and set cutting components. The beneficial effect of the present invention is that the degree of automation is high, the feeding operation of the wire rod and the heat-shrinkable sleeve can be realized, and the wire rod to be cut and the heat-shrinkable sleeve put on the wire rod can be controlled by the heat-shrinkable sleeve limit mechanism. The position is limited in advance, and the right end of the wire set can be cut at a suitable position through the set cutting mechanism, so that the worker can control the length of the heat shrinkable sleeve with high precision.

Owner:DONGYING LANTIAN PLASTIC CO LTD

An automatic fixing and linear cutting wood trimming equipment for construction

The invention relates to the field of construction technology, and discloses an automatic fixing and linear cutting wood trimming equipment for construction, which includes a housing, the surface of the housing is provided with a placement opening, and the rotating rod rotates to make the moving rod move intermittently left and right , to provide a power source for the subsequent fixing operation and cutting operation, increase the linkage between the structures, and make the operation more convenient. The connecting rod moves to the right to make the rotary rod rotate, causing the clamping rods to move closer to each other and then farther away, automatically fixing the wooden board. The stability of the wood board is guaranteed, avoiding the deviation of the wood board during subsequent cutting, which affects the cutting quality of the wood board, and after the cutting is completed, the fixation is automatically released to facilitate the next round of cutting operations. The moving rod pushes the moving board to move left and right, causing The knife wheel cuts the wood board in a one-way straight line, so that the cut of the wood board is kept horizontal, the cutting quality of the wood board is guaranteed, and the hands are freed to avoid long-term manual cutting, which will cause a burden on the arm.

Owner:济南鲁北园区开发建设有限公司

Conveying and guiding structure for PE pipeline production and processing

ActiveCN111497202AImprove efficiencyQuality improvementHollow article cleaningTubular articlesMolding machineStructural engineering

The invention relates to the field of PE pipeline production and processing devices, in particular to a conveying and guiding structure for PE pipeline production and processing. The conveying and guiding structure comprises a supporting structure, transmission structures, guiding structures, limiting structures, a cleaning structure and driving structures; the limiting structures used for limiting and depressurizing a pipeline are arranged on the transmission structures, then the limiting structures are matched with the guiding structures to limit and guide a PE hollow-wall pipeline from three directions, so that the stability in the pipeline conveying process is greatly improved, the situation that the precision of forming of the pipeline by a forming machine is affected by excessive shaking amplitude of the pipeline is effectively prevented, and the guiding quality of the pipeline is improved; and the cleaning structure used for cleaning sweeps on the pipeline is arranged on the endparts of the limiting structures, the cleaning structure and the two guiding structures are located on three edges of a triangular prism, so that the cleaning structure is in touch with the pipeline,the sweeps on the pipeline are removed, pipeline shaking caused by the sweeps being in touch with the guiding structures is effectively prevented, and thus the forming efficiency and the cutting quality of the pipeline are greatly improved.

Owner:SHANDONG ZHONGLU PIPE IND

Rotary knife device capable of automatically compensating

PendingCN110154118AAutomatic clearance compensationAffect cutting qualityMetal working apparatusRotary engineEngineering

The invention relates to the field of cutting blades, in particular to a rotary knife device capable of automatically compensating. The rotary knife comprises a blade, a knife flywheel, a mounting base and a bearing base, wherein the mounting base and the knife flywheel are fixedly arranged; the mounting base and the bearing base are connected to a rotary shaft through bearings; the bearing base and the mounting base define a cavity; at least two thrust parts are arranged in the cavity for pushing the bearing base; and the bearing base drives the rotary shaft to move in a direction away from the mounting base, so that the blade is pushed to perform automatic compensation on the knife flywheel, and therefore, problems such as poor cutting quality and part damages caused by gaps generated byblade cutting abrasion are solved.

Owner:CHONGQING CHANGZHENG HEAVY IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com