Dried bean curd surface cutting machine

A technology of dried tofu and cutting machine, which is applied in cheese substitutes, metal processing, dairy products, etc., and can solve the problem of uneven dried tofu and small pieces of dried tofu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

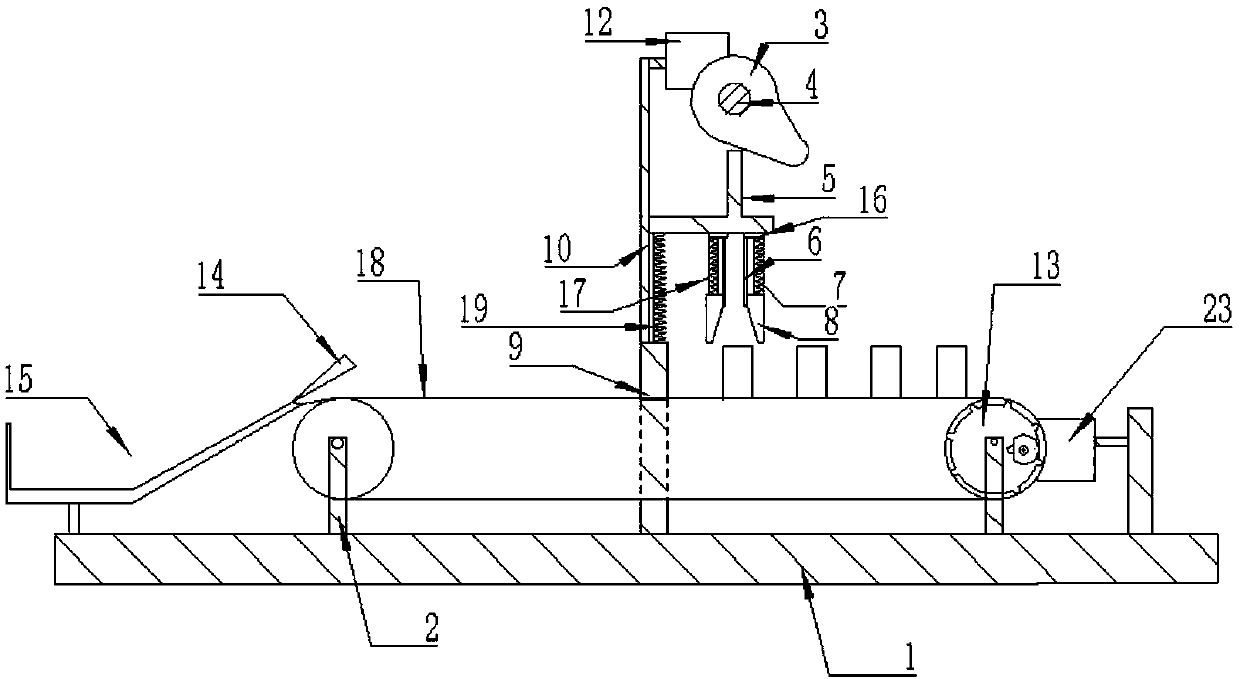

[0026] The orientation words such as "left, right" described in this embodiment only correspond to figure 1 and figure 2 , a dried tofu surface cutting machine, such as figure 1 As shown, including the base 1, the support rod 2 and the stand 9, the support rod 2 and the stand 9 are all fixedly welded on the base 1, the left side of the stand 9 top is equipped with a vertical slide rail 10, and the end of the transmission member 5 The upper part is slidably connected on the vertical slide rail 10, and the transmission part 5 is in the shape of an inverted "T". The other end is welded on the stand 9, the top of the stand 9 is placed with a first motor 12 for power transmission, the cam 3 is connected to the transmission shaft of the first motor 12 on the stand 9 in rotation, and the transmission member 5 is positioned above the transmission member 5. The cam 3 cooperates to realize the linear movement of the transmission member 5 relative to the stand 9.

[0027] Two compres...

Embodiment 2

[0036] A kind of dried bean curd surface cutting machine, compared with embodiment 1, the difference of this embodiment is: (1) as image 3 As shown, the cam 3 mechanism that drives the transmission part 5 to move downward in the embodiment 1 is replaced with a telescopic cylinder 20, and the power becomes an air compressor 24. The telescopic cylinder 20 is installed on the stand 7 through the air compressor, and the transmission part 5 directly links to each other with the piston rod 21 in the telescopic cylinder 20.

[0037] (2) The cutting knife 6 and the spring on the transmission part 5 are connected with the transmission part 5 through the rectangular block 16, and the rectangular block 16 is slidingly connected with the transmission part 5, and a locking mechanism is installed on the sliding track.

[0038] Other steps are roughly the same as in Embodiment 1, except that when the dried tofu moves to the bottom of the cutting knife 6 along with the conveyor belt 18, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com