Integrated feeding and discharging cutting device for metal material machining

A metal material and cutting device technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve problems such as improving the safety of workers, splashing sparks and debris, and affecting the normal work of workers, etc. The effect of reducing security risks, increasing stability, and being easy to handle

Inactive Publication Date: 2022-06-21

HANGZHOU GONGCHENG AUTOMATION EQUIP

View PDF12 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Among them, steel is the basic structural material, known as the "skeleton of industry". Due to the advancement of science and technology, the wide application of various new chemical materials and new non-metallic materials, the substitutes for steel continue to increase, and the demand for steel is relatively large. decline, but so far, the dominant position of steel in the composition of industrial raw materials is still difficult to replace

[0003] According to the metal material cutting device mentioned in CN216264806U and CN113664285A when in use, for the convenience of loading and unloading of metal materials, the cutting device is mostly set in the open air. When the cutting device cuts the metal material, it is easy to produce sparks and debris. The open-air setting of the device can easily lead to sparks and debris splashing, which affects the normal work of the staff, increases the safety hazards of the staff, and reduces the work efficiency of metal material cutting. In order to solve the above problems, we have made improvements , an integrated loading and unloading cutting device for metal material processing is proposed

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

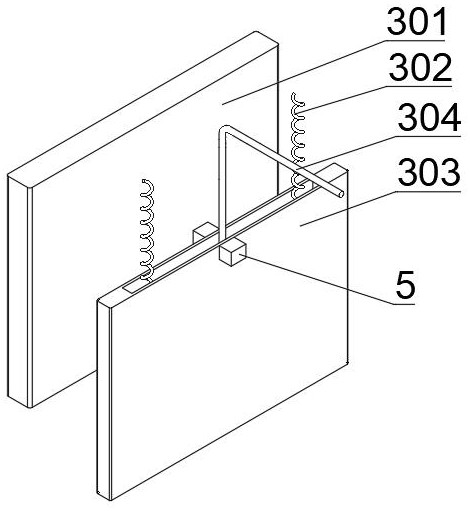

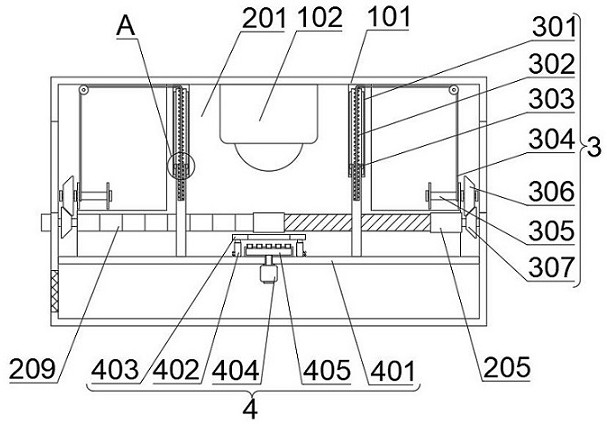

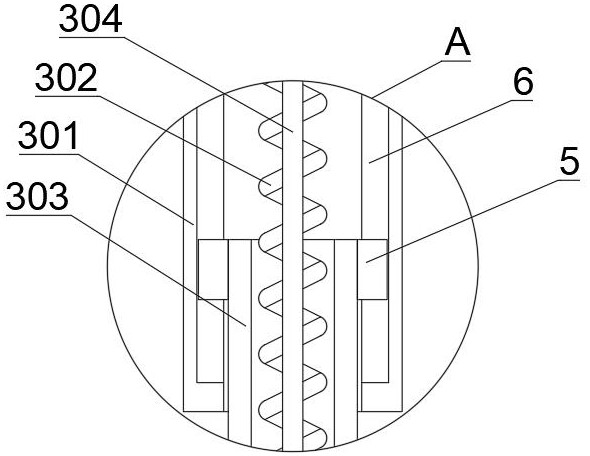

The invention discloses an integrated feeding and discharging cutting device for metal material machining, and relates to the technical field of metal material machining equipment. The device comprises a cutting module, the cutting module comprises a box body, cutting equipment is arranged in the middle of the inner top wall of the box body, a shielding mechanism is arranged in the box body, the shielding mechanism comprises first mounting plates, and reset springs are arranged on the inner top walls of the two first mounting plates; a first shielding plate is arranged at the lower ends of every two reset springs, when the feeding mechanism conveys metal materials, the winding roller can be driven to rotate to unwind the connecting rope, the first shielding plates can be driven to move in the first mounting plate through the elastic force of the reset springs, the shielding plates seal the cutting area in the box body, and the cutting efficiency is improved. When the cutting equipment cuts a metal material, sparks and chippings generated during cutting of the metal material can be prevented from splashing, and therefore potential safety hazards of workers are reduced.

Description

technical field [0001] The invention relates to the technical field of metal material processing equipment, in particular to an integrated loading and unloading cutting device for metal material processing. Background technique [0002] Metal materials refer to materials with luster, ductility, easy conduction, heat transfer and other properties. They are generally divided into ferrous metals and non-ferrous metals. Ferrous metals include iron, chromium, manganese, etc. Among them, steel is the basic structural material, known as the "skeleton of industry". Due to the advancement of science and technology, the wide application of various new chemical materials and new non-metallic materials, the substitutes for steel continue to increase, and the demand for steel is relatively large. However, so far, the dominant position of steel in the composition of industrial raw materials is still difficult to replace. [0003] According to the metal material cutting device mentioned i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23Q11/08B23Q11/00

CPCB23Q11/08B23Q11/0046

Inventor 黄建伟

Owner HANGZHOU GONGCHENG AUTOMATION EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com