Novel automatic intelligent food slicing machine

A slicing machine and food technology, applied in metal processing and other directions, can solve the problems of lower grade, high labor intensity, lower yield rate, etc., and achieve the effect of improving slicing quality and efficiency, improving qualification rate and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

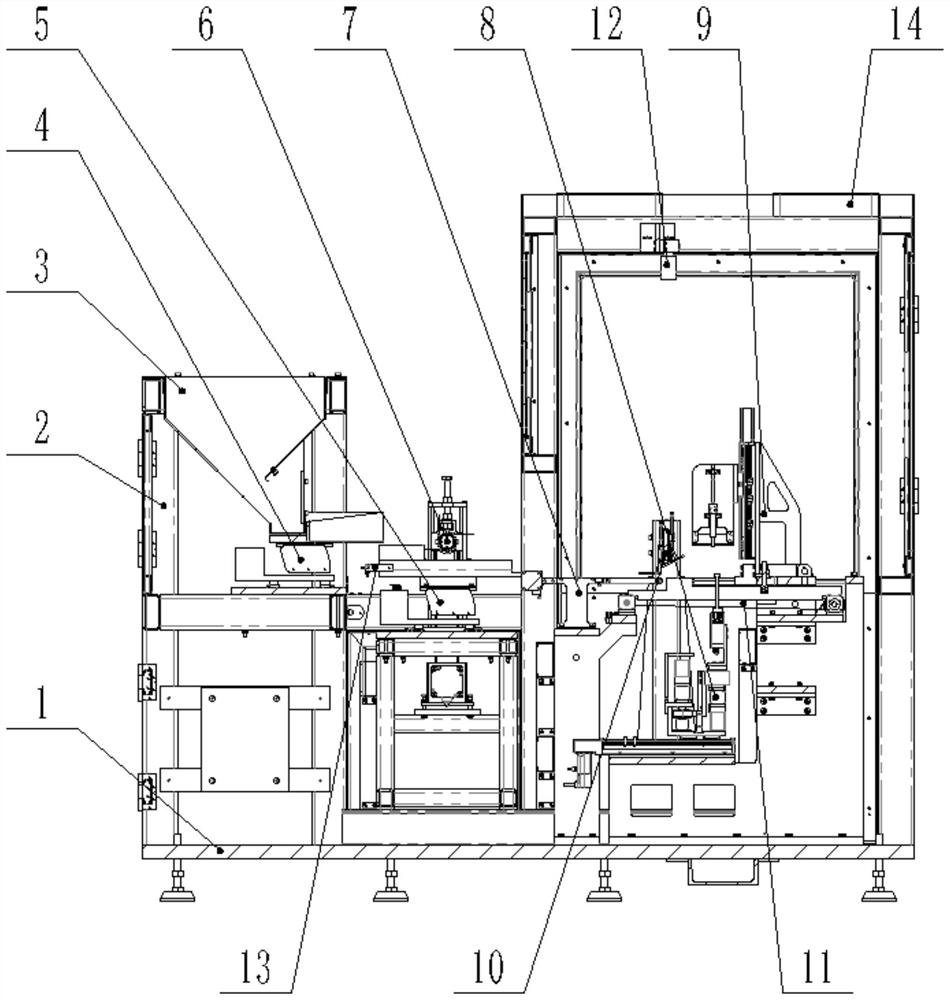

[0038] See Figure 1 to Figure 13 , a novel automatic intelligent food slicing machine of the present embodiment, comprising a base 1, a frame 2 disposed on the base and at least one feeding unit disposed on the frame, each of the The feeding unit includes a storage bin mechanism 3, a primary feeding mechanism 4, a secondary feeding mechanism 5, and an anti-overlapping mechanism 6. The food slicer also includes a frame and each feeding unit Corresponding feeding mechanism 7, clamping translation rotation mechanism 8, slicing mechanism 9, posture adjustment and feeding mechanism 10, discharge belt conveyor 11, the food to be cut in the described storage bin, such as betel nut, is fed through the first stage in turn. Mechanism, secondary feeding mechanism, and anti-superposition structure feed into the feeding mechanism, adjust the posture and then adjust the position through the clamping translation and rotation mechanism, and slice it by the slicing mechanism, and the sliced ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com