A ceramic-metal composite bond grinding wheel and its preparation method

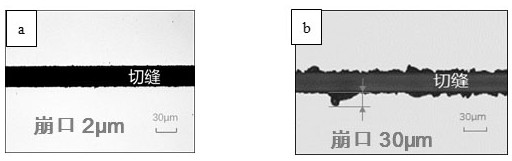

A composite bond and ceramic bond technology, applied in metal processing equipment, manufacturing tools, grinding/polishing equipment, etc., can solve the problems of difficult to mix evenly, uneven phase distribution of abrasive layer, easy to produce agglomeration, etc. The effect of improving microstructure consistency, improving mixing uniformity, and improving cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

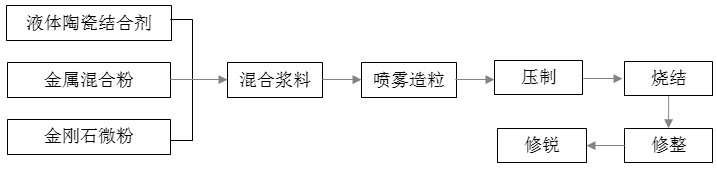

[0027] Such as figure 1 As shown, a method for preparing a ceramic metal composite binding agent grinding wheel comprising the steps of:

[0028] 1) Preparation of Liquid ceramic binders: Acquisition of equivalent Al (NO 3 ) 3 , H 3 BO 3 LINO 3 Nano 3 Soluble in water, slowly add 50% SiO 2 Sol, resulting in a liquid ceramic binding agent;

[0029] The raw material is based on oxide molar percentage, and the ratio of the raw materials in liquid ceramic binders is: Al 2 O 3 17%, B 2 O 3 15%, Li 2 O 5%, NA 2 O 15%, SIO 2 48%, the solid content of liquid ceramic binding agent is 50%;

[0030] 2) Preparation of ceramic metal composite binding agent: Diamond fine powder, metal mixed powder is added to the liquid ceramic binder and continuously stir mix and mix, obtain a mixed slurry;

[0031] The mass percentage of each component in the mixed slurry is: 12% diamond fine powder, 78% metal mixed powder, and 10% of the liquid ceramic binding agent. Metal mixed powder consists of the follo...

Embodiment 2

[0035] A method of preparing a ceramic metal composite binding agent grinding wheel comprising the steps of:

[0036] 1) Preparation of Liquid ceramic binders: Acquisition of equivalent Al (NO 3 ) 3 , H 3 BO 3 LINO 3 Nano 3 Soluble in water, then add 30% SiO 2 Sol, resulting in a liquid ceramic binding agent;

[0037] The raw material is based on oxide molar percentage, and the ratio of the raw materials in liquid ceramic binders is: Al 2 O 3 17%, B 2 O 3 20%, Li 2 O 8%, NA 2 O 18%, SIO 2 37%, the solid content of liquid ceramic binding agent was 40%;

[0038] 3) Preparation of ceramic metal composite binding agent: Diamond fine powder, metal mixed powder is added to the liquid ceramic binder and is continuously stirred and mixed, and mixed slurry;

[0039] The mass percentage of each component in the mixed slurry is: 15% diamond fine powder, 73% metal mixed powder, and a liquid ceramic binding agent 12%. Metal mixed powder consists of the following mass percentage of feedstock: S...

Embodiment 3

[0043] A method of preparing a ceramic metal composite binding agent grinding wheel comprising the steps of:

[0044] 1) Preparation of Liquid ceramic binders: Acquisition of equivalent Al (NO 3 ) 3 , H 3 BO 3 LINO 3 Nano 3 Soluble in water, slowly add 40% SiO 2 Sol, resulting in a liquid ceramic binding agent;

[0045] The raw material is based on oxide molar percentage, and the ratio of the raw materials in liquid ceramic binders is: Al 2 O 3 15%, B 2 O 3 17%, Li 2 O 7%, NA 2 O 17%, SIO 2 44%, the solid content of liquid ceramic binders is 45%;

[0046] 2) Preparation of ceramic metal composite binding agent: Diamond fine powder, metal mixed powder is added to the liquid ceramic binder and continuously stir mix and mix, obtain a mixed slurry;

[0047] The mass percentage of each component in the mixed slurry is: 10% diamond micro powder, 85% metal mixed powder, 5% of the liquid ceramic binding agent. Metal mixed powder consists of the following mass percentage of raw materials: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com