A Method for Cutting Two-Phase Composite Materials Using Ultrafast Laser

A composite material, ultra-fast laser technology, applied in laser welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve the problems of uneven laser cutting surface, discontinuous structure, easy falling off of non-metallic particles, etc. Small heat-affected zone, good method stability, continuous effect of cutting microstructures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

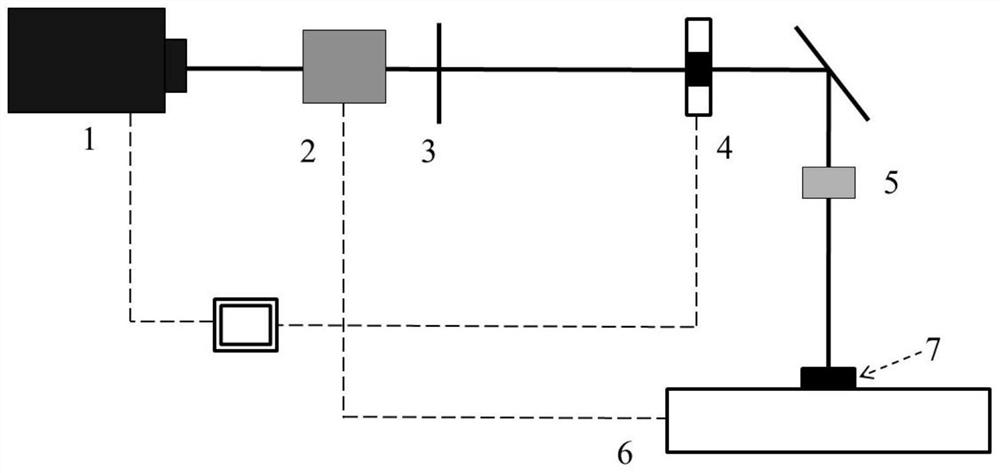

[0025] Use as figure 1 The laser cutting system shown specifically includes an ultrafast laser 1, an optical parametric amplifier 2, an energy attenuator 3, an optical shutter 4, a focusing lens 5, a moving platform 6, and a two-phase composite material 7 to be processed;

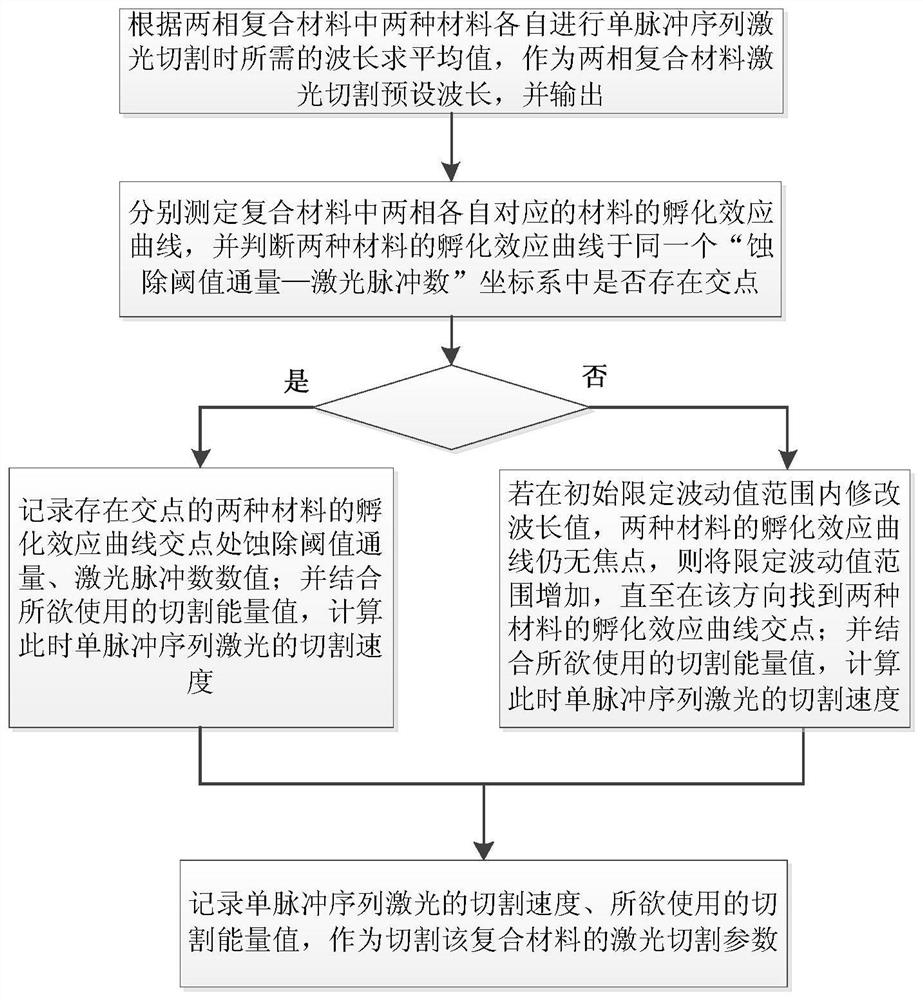

[0026] A method for cutting two-phase composite materials using ultrafast laser, the specific steps are as follows figure 2 As shown,

[0027] Step 1: Turn on the laser, adjust the position and posture of the internal components of the laser cutting system, and calculate the average value according to the wavelength required for single-pulse laser cutting of the two materials in the two-phase composite material, as the two-phase composite material laser cutting Preset wavelength

[0028] Step 2: Ensure that the optical path of the single pulse sequence laser output in the test is turned on, and can pass through the energy attenuator, light control optical shutter, and lens in sequence until the composite materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com