A cutting device used in aluminum processing and production

A cutting device and aluminum technology, applied in feeding devices, metal processing, metal processing equipment and other directions, can solve the problems of low waste recycling rate, inconvenient use and operation, easy bending and deformation of aluminum materials, etc. The effect of improving work efficiency and improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

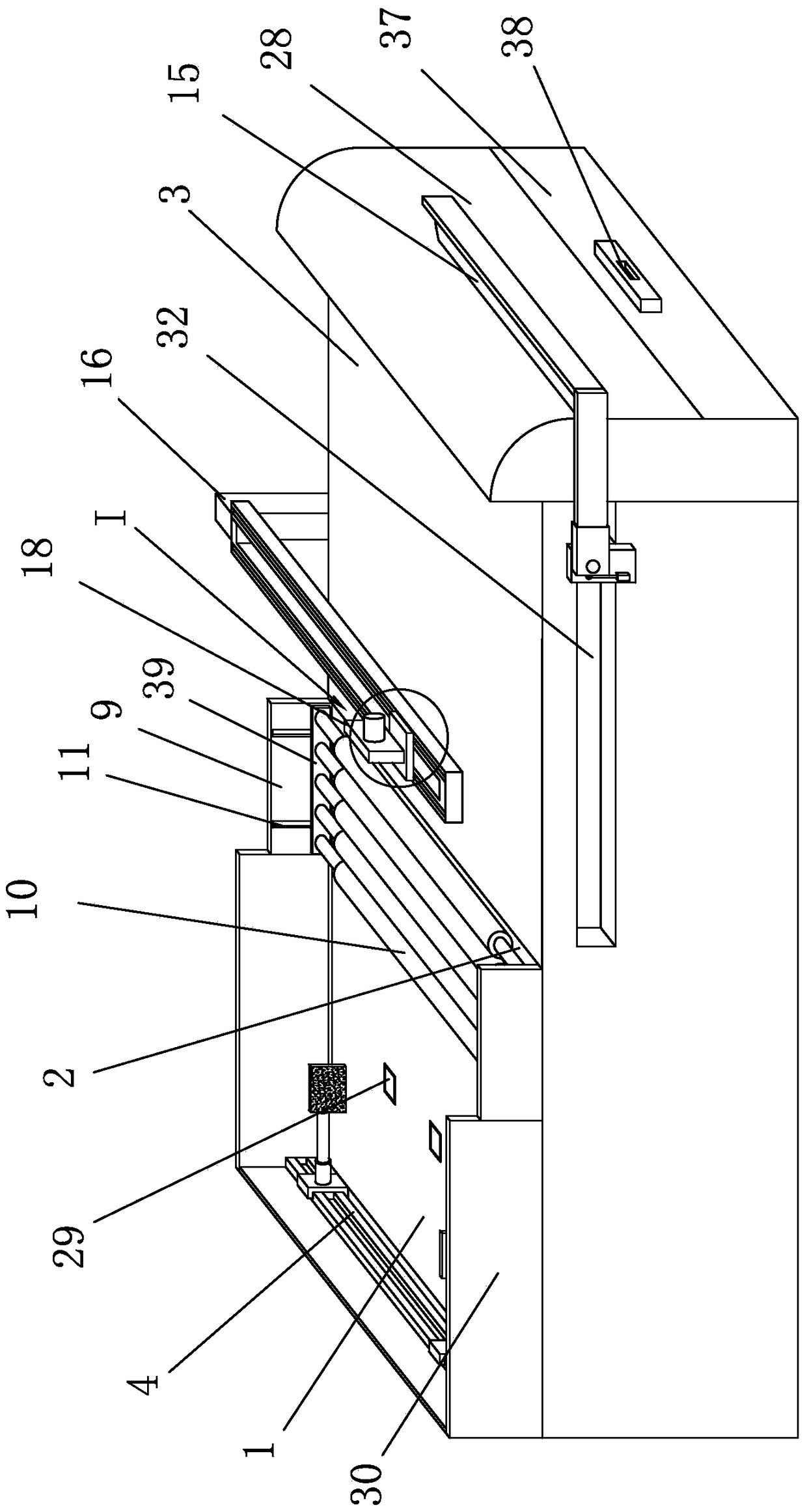

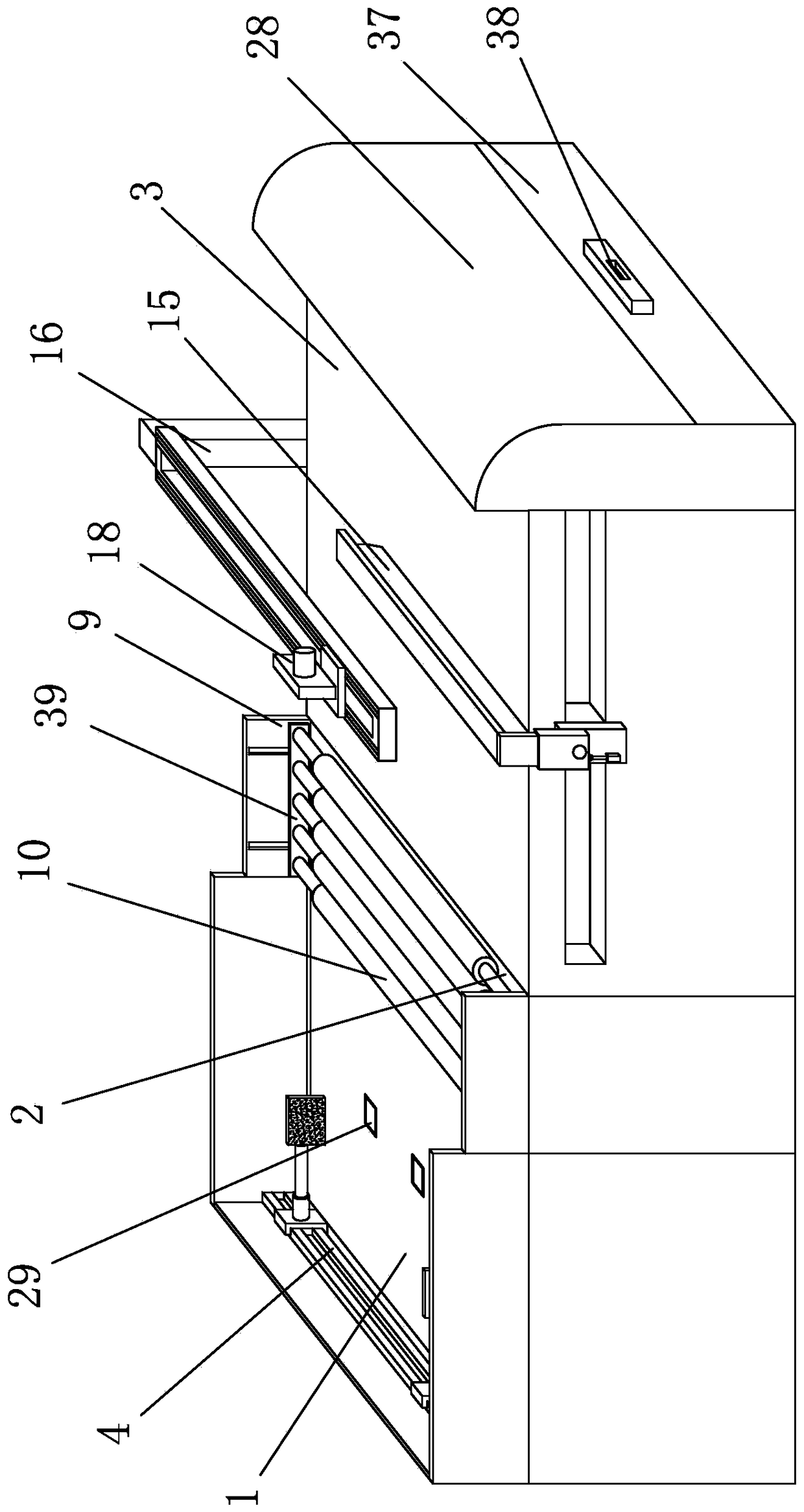

[0033] Such as Figure 1 to Figure 7 As shown, it is a cutting device applied to the processing and production of aluminum materials according to the present invention, which includes a discharge platform 1, a pressing platform 2 and a cutting platform 3, the heights of the discharging platform 1, the pressing platform 2 and the cutting platform 3 are equal, and the cutting platform The height of 3 is less than the height of waste collection box 28. The design of the height of discharge platform 1, pressing platform 2 and cutting platform 3 can facilitate the transmission of aluminum materials and prevent the interruption of aluminum transmission due to height difference. Waste collection box 28 The high design can facilitate the waste generated after cutting to enter the waste collection box 28, preventing it from splashing outside the waste collection box 28, and the design is more reasonable and scientific.

[0034] The discharge table 1 is provided with a baffle plate 30, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com