Hardware pipe cutting device

A cutting device and hardware technology, applied in the direction of pipe shearing device, shearing device, attachment device of shearing machine, etc., can solve the problems of high labor cost, hand affecting cutting efficiency, trouble, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

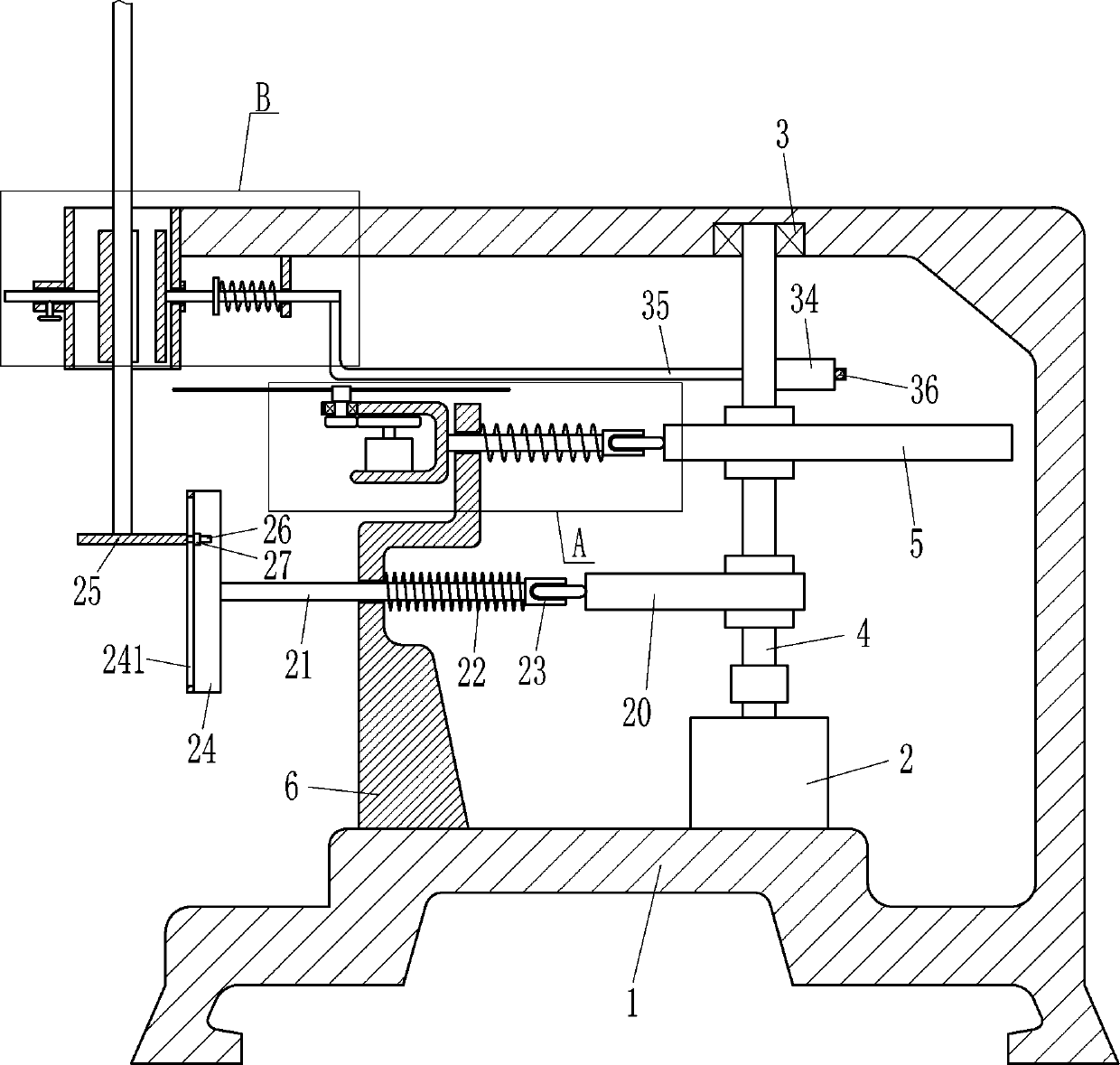

[0017] A hardware pipe cutting device, such as Figure 1-4 As shown, it includes a frame 1, a first motor 2, a first bearing 3, a shaft rod 4, a first cam 5, a first bracket 6, a first slide bar 7, a first roller seat 8, a first spring 9, Second bracket 10, second motor 11, spur gear 12, second bearing 13, shaft gear 14, cutting disc 15, frame 16, first guide sleeve 17, first guide rod 18 and adjustment device 19, inside frame 1 The first motor 2 is provided on the right side of the bottom, and the first bearing 3 is embedded in the top right side of the frame 1. The first bearing 3 is connected with a shaft 4, and the bottom end of the shaft 4 is connected to the first motor through a coupling. The output shaft of 2 is connected, the first cam 5 is provided in the middle of the shaft rod 4, the first bracket 6 is provided on the left side of the inner bottom of the frame 1, the frame 1 is connected with the first bracket 6 by welding, and the first bracket 6 The upper part i...

Embodiment 2

[0019] A hardware pipe cutting device, such as Figure 1-4 As shown, it includes a frame 1, a first motor 2, a first bearing 3, a shaft rod 4, a first cam 5, a first bracket 6, a first slide bar 7, a first roller seat 8, a first spring 9, Second bracket 10, second motor 11, spur gear 12, second bearing 13, shaft gear 14, cutting disc 15, frame 16, first guide sleeve 17, first guide rod 18 and adjustment device 19, inside frame 1 The first motor 2 is provided on the right side of the bottom, and the first bearing 3 is embedded in the top right side of the frame 1. The first bearing 3 is connected with a shaft 4, and the bottom end of the shaft 4 is connected to the first motor through a coupling. The output shaft of 2 is connected, the first cam 5 is provided in the middle of the shaft rod 4, the first bracket 6 is provided on the left side of the inner bottom of the frame 1, and the first sliding rod 7 is provided slidingly on the upper part of the first bracket 6, and the fir...

Embodiment 3

[0022] A hardware pipe cutting device, such as Figure 1-4As shown, it includes a frame 1, a first motor 2, a first bearing 3, a shaft rod 4, a first cam 5, a first bracket 6, a first slide bar 7, a first roller seat 8, a first spring 9, Second bracket 10, second motor 11, spur gear 12, second bearing 13, shaft gear 14, cutting disc 15, frame 16, first guide sleeve 17, first guide rod 18 and adjustment device 19, inside frame 1 The first motor 2 is provided on the right side of the bottom, and the first bearing 3 is embedded in the top right side of the frame 1. The first bearing 3 is connected with a shaft 4, and the bottom end of the shaft 4 is connected to the first motor through a coupling. The output shaft of 2 is connected, the first cam 5 is provided in the middle of the shaft rod 4, the first bracket 6 is provided on the left side of the inner bottom of the frame 1, and the first sliding rod 7 is provided slidingly on the upper part of the first bracket 6, and the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com