Diamond multicrystal group, segment block made of multicrystal group and their manufacturing method

A manufacturing method and diamond technology, applied in the direction of manufacturing tools, metal processing equipment, abrasives, etc., can solve the problems such as the wear resistance and cutting efficiency will not be greatly improved, the manufacturing cost will be increased, and the cutting performance will be poor. Achieve the effect of improving cutting speed and cutting capacity, high cutting efficiency, and more angular edges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

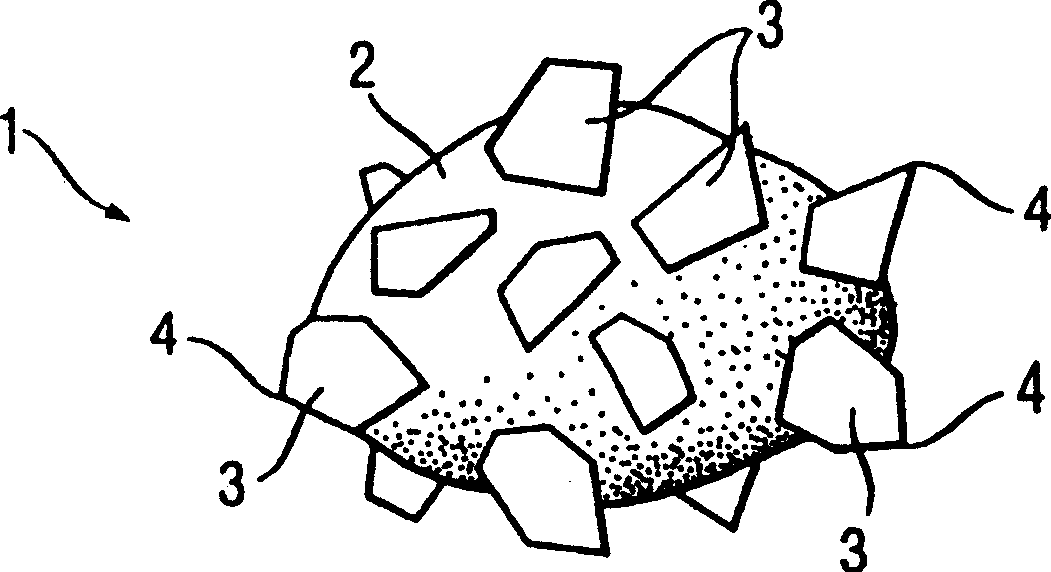

[0029] Embodiment 1: the making of diamond polycrystalline group

[0030] 1) The parent metal powder is selected, and its proportioning is calculated by weight percentage: 3% to 8% of tin, 2% to 20% of molybdenum, 1% to 3% of chromium, 10% to 30% of nickel, and 20% to 60% of cobalt , the balance is copper, a total of 500 grams, for spare;

[0031] 2) The adhesive formula is selected as follows: 100-300 grams of granulator powder of model WS-120, 100-300 grams of acetone, and 350-1200 grams of isopropanol are produced and sold by Nanjing Sishang Technology and Trade Center. Bonding agent; Get the mixed liquid prepared as 140 grams of bonding agent for subsequent use;

[0032] 3) Select 200 grams of diamond particles with a particle size of 250-300 μm, mix the above-mentioned metal powder, adhesive and diamond particles, and stir them evenly;

[0033] 4) then the resulting mixture is granulated by a granulator to make diamond polycrystalline groups;

[0034] 5) Sieve the obta...

Embodiment 2

[0035] Embodiment 2: the making of carcass metal powder group

[0036] 1) Select the carcass metal powder, and its proportioning is by weight percentage: 3% to 8% of tin, 10% to 30% of nickel, 20% to 60% of cobalt, and the balance is copper, and prepare 2200 grams for later use;

[0037] 2) The selected formula is: a solvent adhesive of 100-300 grams of WS-120 granulator powder, 100-300 grams of acetone, and 350-1200 grams of isopropanol produced and sold by Nanjing Sishang Technology and Trade Center; Take the prepared mixed liquid as 330 grams of adhesive for subsequent use;

[0038] 3) Mix the above-mentioned metal powder and binder, and stir it evenly, and obtain matrix metal powder with a particle size of 1.5-1.65 mm through a granulator,

[0039] 4) Sieving the obtained matrix metal powder and drying at 50° C. for 20 minutes to obtain matrix metal powder with a particle size of 1.5-1.65 mm.

Embodiment 3

[0040] Embodiment 3: the making of nodal block

[0041] Φ1600 disc saw; volume concentration 36%; diamond 96.1g / 108 teeth=4.45ct / tooth (1g=5ct)

[0042] The block size is 24mm×9mm×13mm=23.5g / tooth in the working layer

[0043] 1) Get 338g of diamond polycrystalline clusters produced in Example 1 (including 96.1g of diamond, 242g of diamond polycrystalline cluster metal powder)+2200g of matrix metal powder clusters produced in Example 2 and mix evenly, set aside;

[0044] 2) Mix the obtained diamond polycrystalline group containing diamond particles and matrix metal powder evenly, and put them into a mold for sintering under pressure at 700-1100°C;

[0045] 3) Remove the mold after the mold cools down to get figure 2 The finished segment 10 is shown.

[0046] The diamond particles 3 in the segment matrix 0 are distributed in the shape of agglomerates, columns or heaps, the particle size of the diamond particles is 160-850 μm, the particle size of the diamond group or diamon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com