Adhesive tape cutting mechanism and method thereof

A tape cutting and cutting mechanism technology, which is applied in the direction of electrical components, manufacturing wiring harnesses, circuits, etc., can solve the problems of continuous tape cutting, blade wear, and cutting difficulties, so as to improve production efficiency and avoid wear problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further elaborated and illustrated below in conjunction with the accompanying drawings and specific embodiments. The technical features of the various implementations in the present invention can be combined accordingly on the premise that there is no conflict with each other.

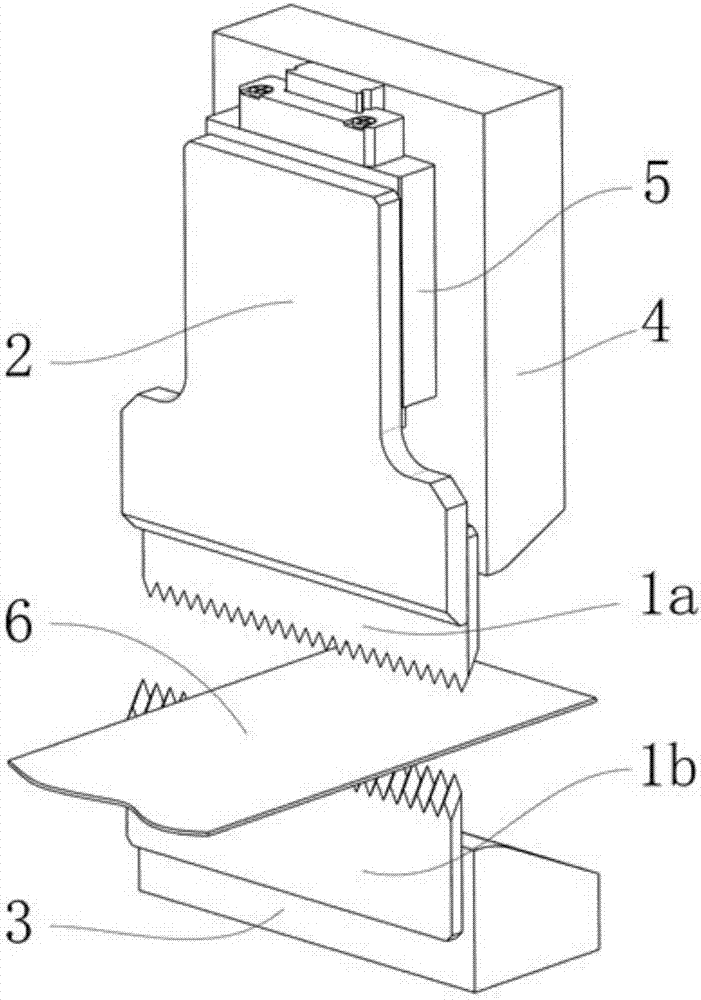

[0028] like figure 1 As shown, the tape cutting mechanism of this embodiment includes an upper blade 1a, a lower blade 1b, a blade support plate 2, a lower blade fixing seat 3, an upper blade fixing seat 4, a precision linear guide rail 5, and an adhesive tape 6.

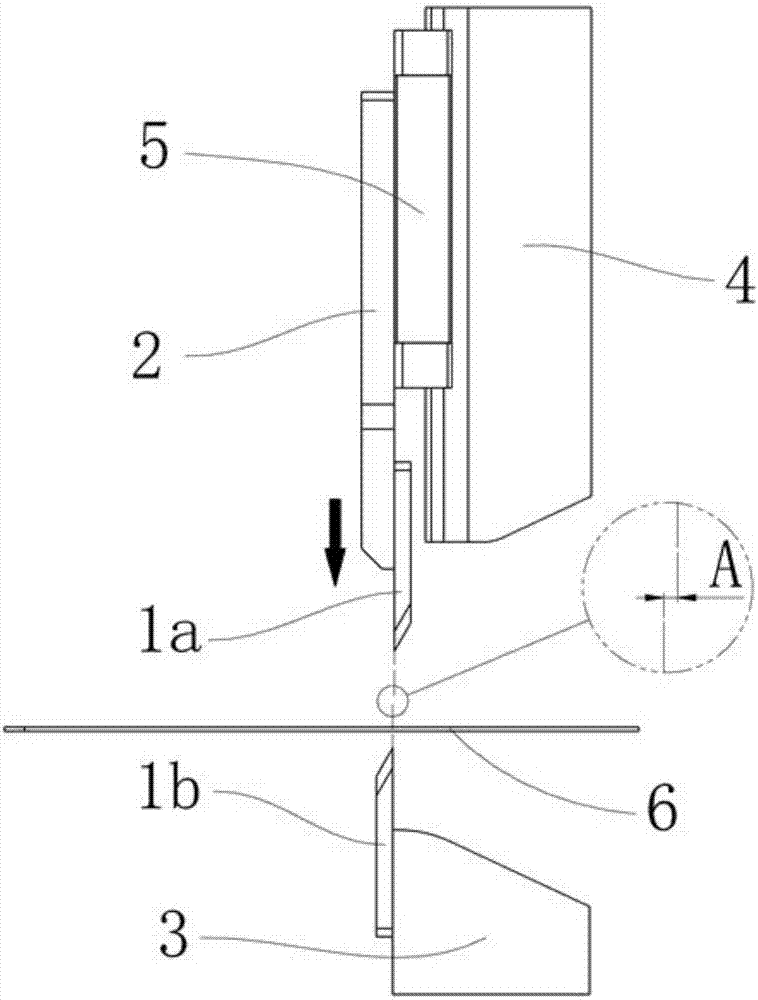

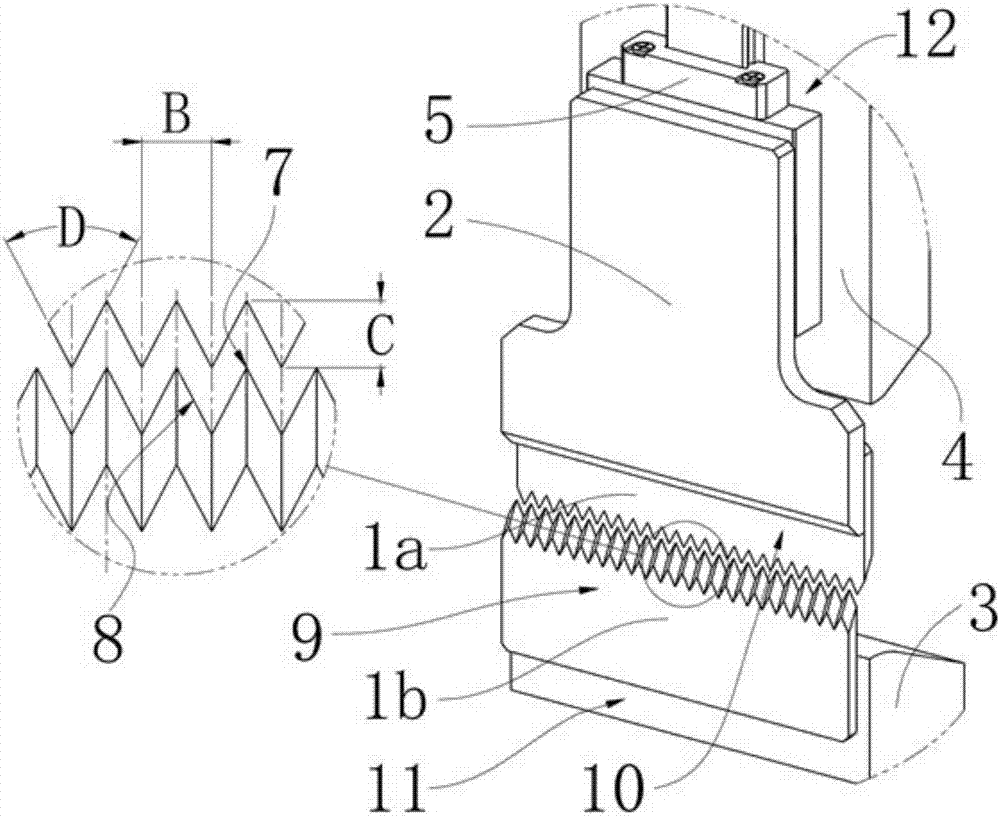

[0029] Both the cutting edge portions of the upper blade 1a and the lower blade 1b are serrated. like figure 2 , image 3The lower blade 1 b shown is fixed on the lower blade fixing seat 3 , and the non-cutting surface 10 of the blade is in close contact with the blade mounting surface 11 on the lower blade fixing seat 3 during installation. The upper blade 1a is installed on the guide rail fixing su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com