Safe type aluminum alloy cutting equipment

A cutting equipment, aluminum alloy technology, applied in metal processing equipment, metal processing, metal processing machinery parts, etc., can solve the problems of difficult aluminum alloy multi-angle cutting, affecting aluminum alloy safe cutting, aluminum alloy sliding or tilting, etc. Achieve the effect of improving safe cutting operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

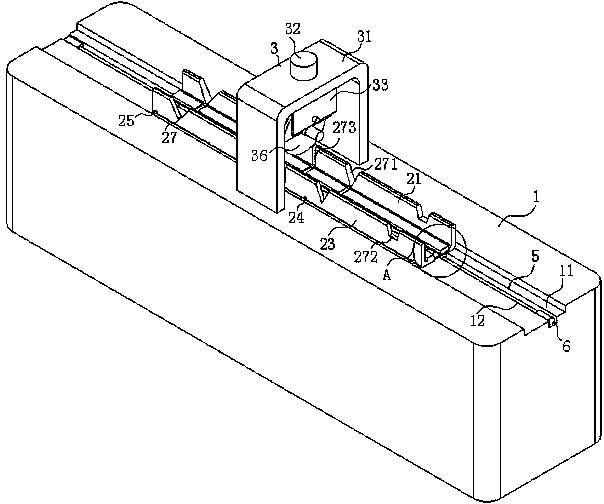

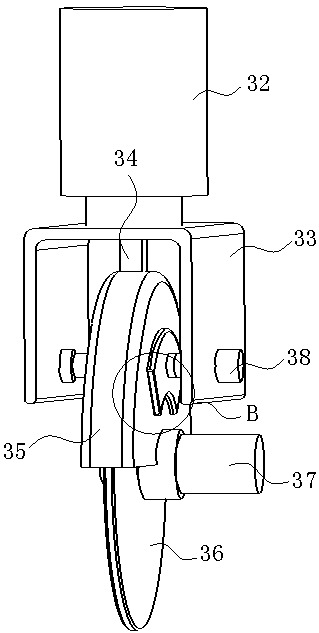

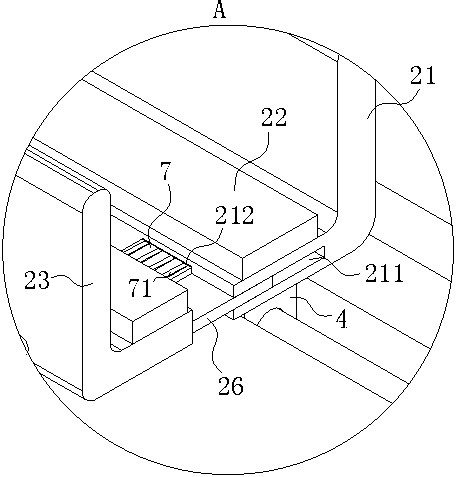

[0029] As an embodiment of the present invention, the bottom end of the guide chute 11 is provided with a limit groove 12; the bottom end of the positioning support plate 21 is provided with a screw rod 5 slider 4, and the screw rod 5 slider 4 is located In the limit groove 12; the screw mandrel 5 slider 4 is connected with the screw mandrel 5 for rotation, and the end of the screw mandrel 5 is connected with the rotating motor 6; the other side wall of the guide chute 11 is provided with a limit guide slot, and a guide cylinder 24 and a guide rod 25 are slidably installed in the limit guide slot; during work, when the fixed and clamped aluminum alloy to be cut needs to be moved to the bottom of the cutting piece 36, the controller controls the rotation of the motor 6 , the rotating motor 6 will drive the screw rod 5 slider 4 to slide in the limit groove 12 through the screw rod 5, and the sliding of the screw rod 5 slider 4 will drive the positioning support plate 21 and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com