Novel plate laser cutting machine

A laser cutting machine, a new type of sheet metal technology, applied in laser welding equipment, welding/cutting auxiliary equipment, auxiliary welding equipment, etc., can solve the problems of trouble to take out the sheet, offset cutting position, waste of physical strength, etc., to achieve the effect of convenient collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

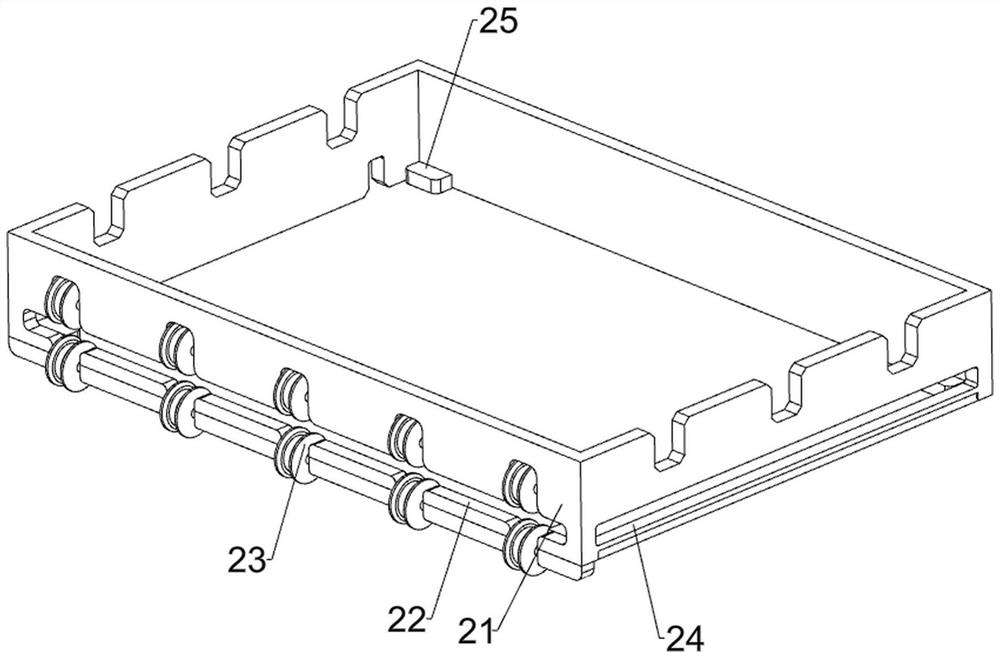

[0029] A new type of plate laser cutting machine, such as Figure 1-5 As shown, it includes a frame 1, a feeding assembly 2, a cutting assembly 3 and a pushing assembly 4, the frame 1 is provided with a feeding assembly 2, the feeding assembly 2 is provided with a cutting assembly 3, and the frame 1 is provided with a Push material assembly 4 is arranged.

[0030] When it is necessary to laser cut the plate, put the plate into the feeding component 2, then start the cutting component 3, and the cutting component 3 will perform laser cutting on the plate. After the cutting is completed, control the cutting component 3 to operate in reverse, and then drive The material assembly 4 is operated, so that the cut boards will be pushed out, which is convenient for the staff to take out the cut boards. After pushing out, the pusher assembly 4 will automatically reset, and then repeat the above process. When all the boards are completely cut, Close the cutting assembly 3 and get final ...

Embodiment 2

[0038] On the basis of Example 1, such as figure 1 , Figure 6 , Figure 7 and Figure 8 As shown, a support assembly 5 is also included, and the support assembly 5 includes an L-shaped slide plate 51, a support plate 52, a vertical plate 53 and a special-shaped plate 54, and the rear side of the placement frame 21 is slidably provided with an L-shaped slide plate 51, and the L-shaped slide plate The front side of 51 is connected with support plate 52 , and the lower side of support plate 52 is provided with riser 53 , is connected with special-shaped plate 54 between riser 53 and connecting plate 42 .

[0039] When the board is placed on the placement block 25, the board will be dragged by the support plate 52, which can effectively prevent the board from falling halfway when cutting the board, thereby affecting the cutting of the board. The support plate 52 and the L-shaped slide plate 51 move to the right, so that the plate is not easy to fall when it is pushed out.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com