Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65results about How to "Affect the cutting effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

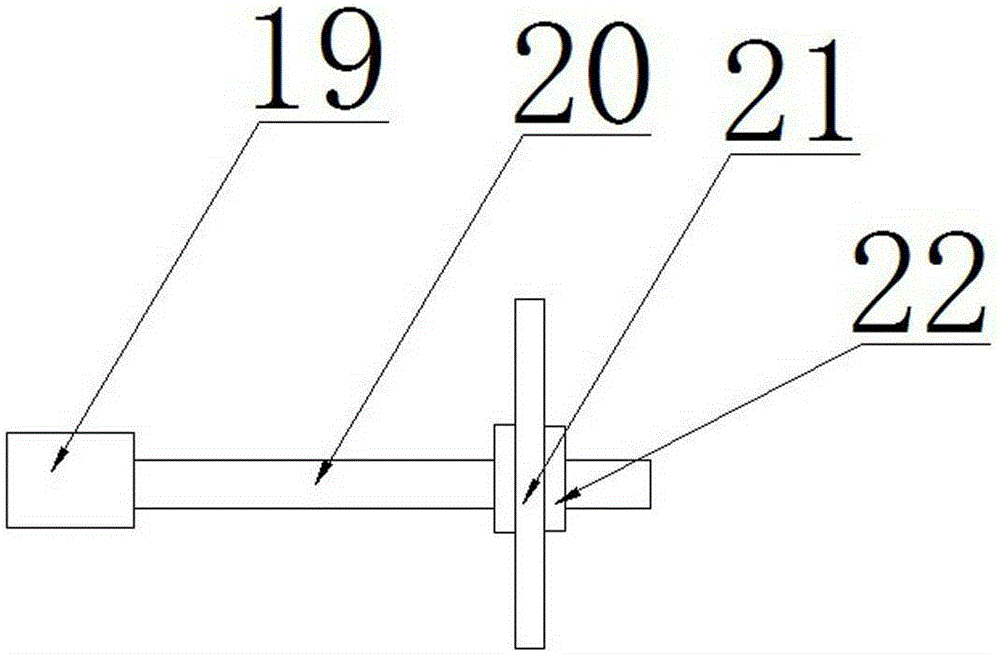

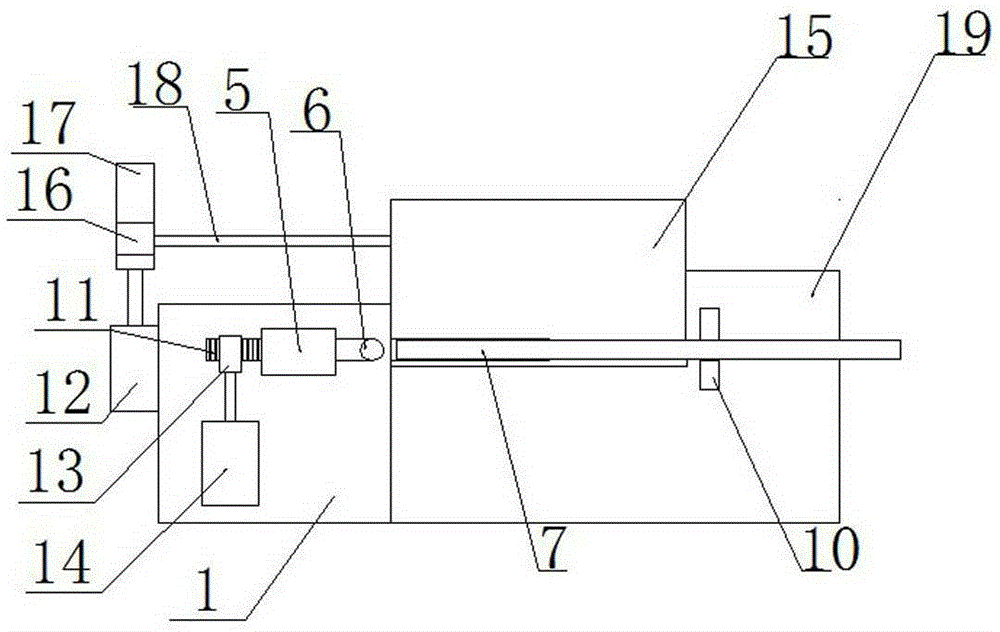

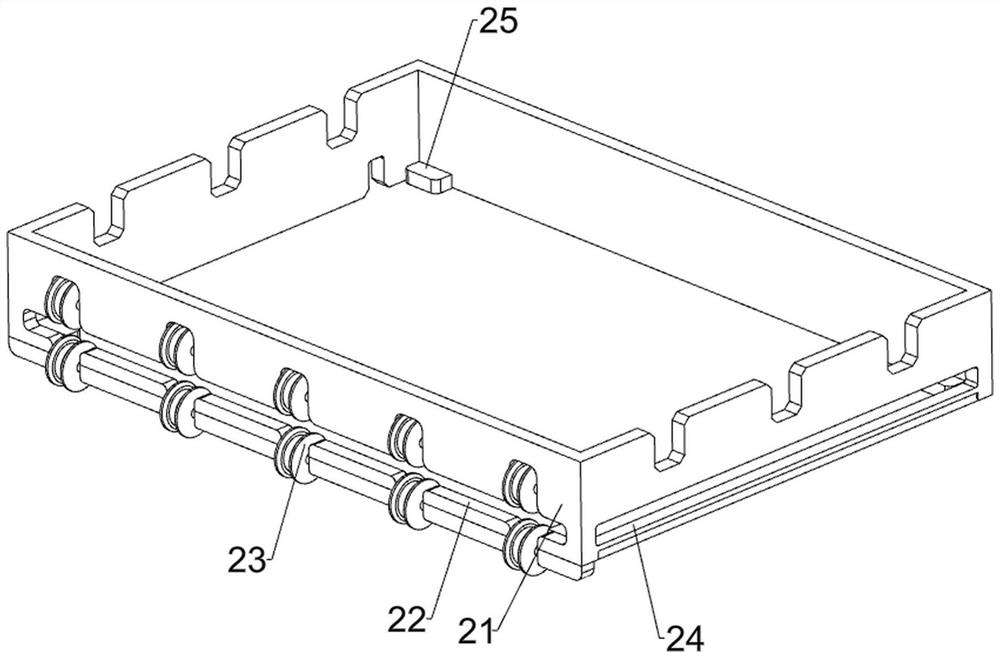

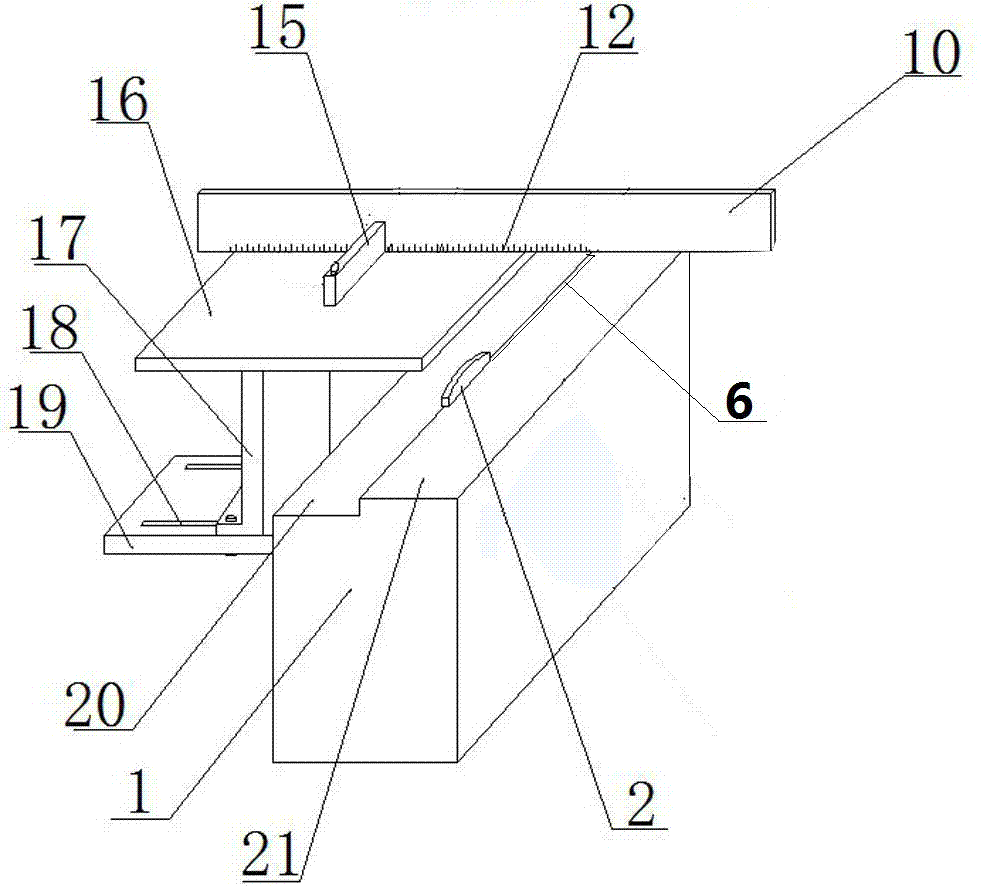

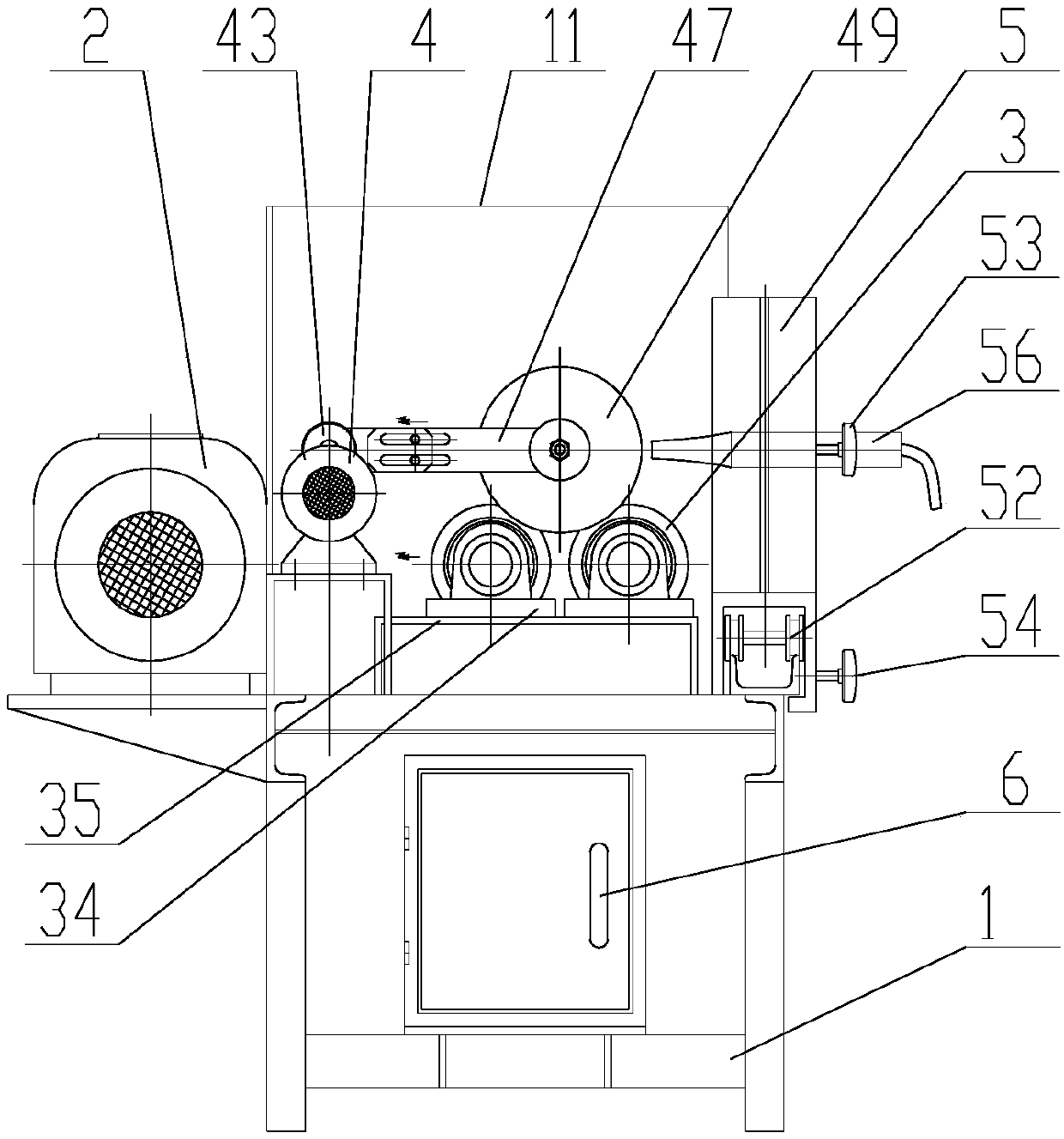

Cutting device for pipe fitting

InactiveCN105499688AReduce wearAffect the cutting effectFeeding apparatusTube shearing machinesPipe fittingProcedural approach

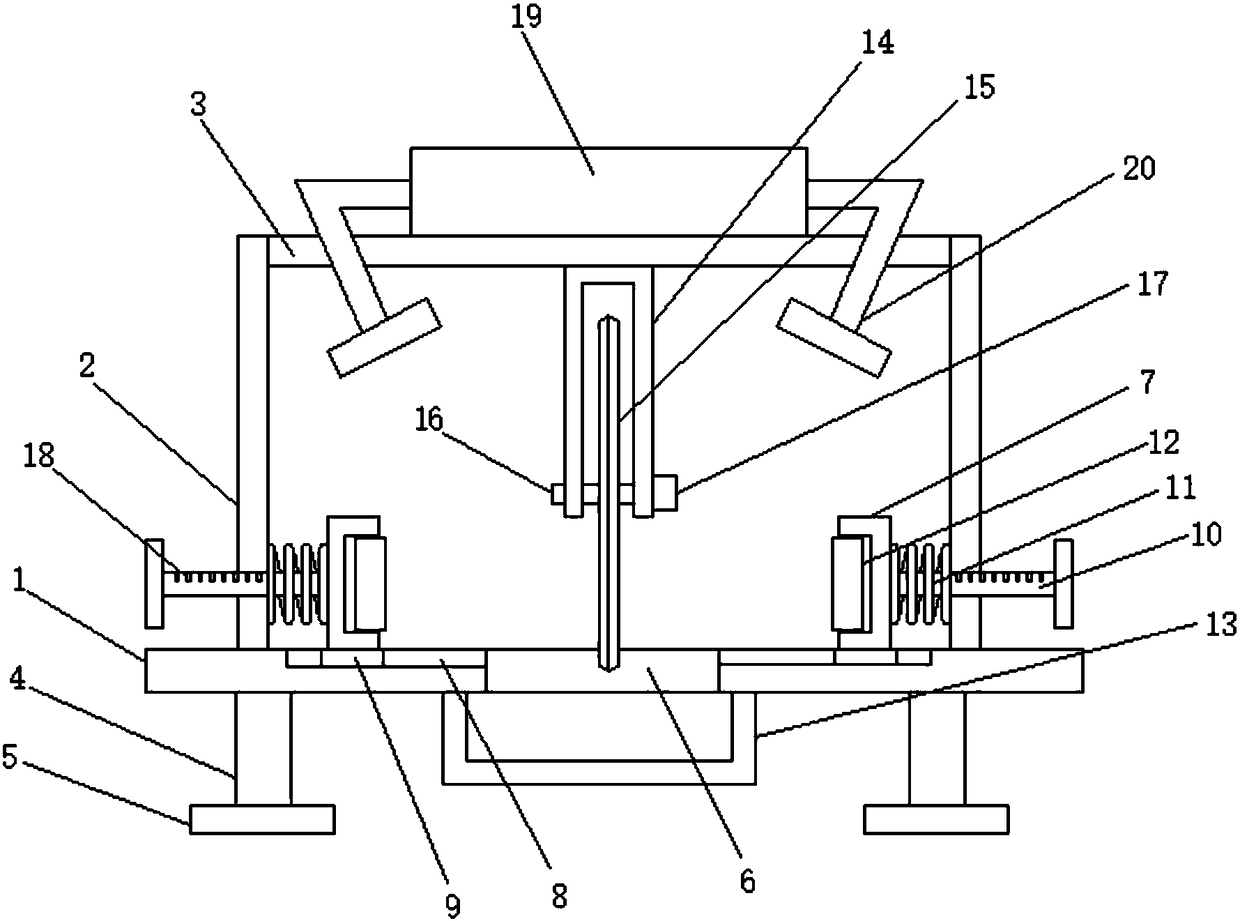

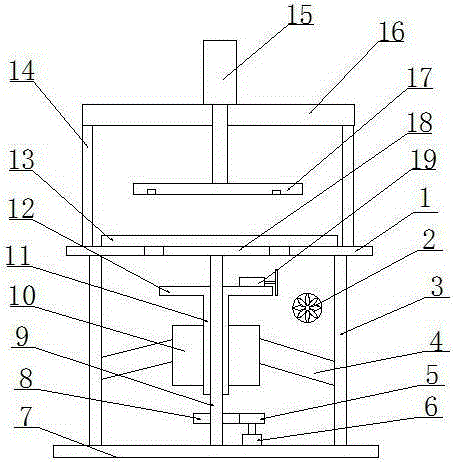

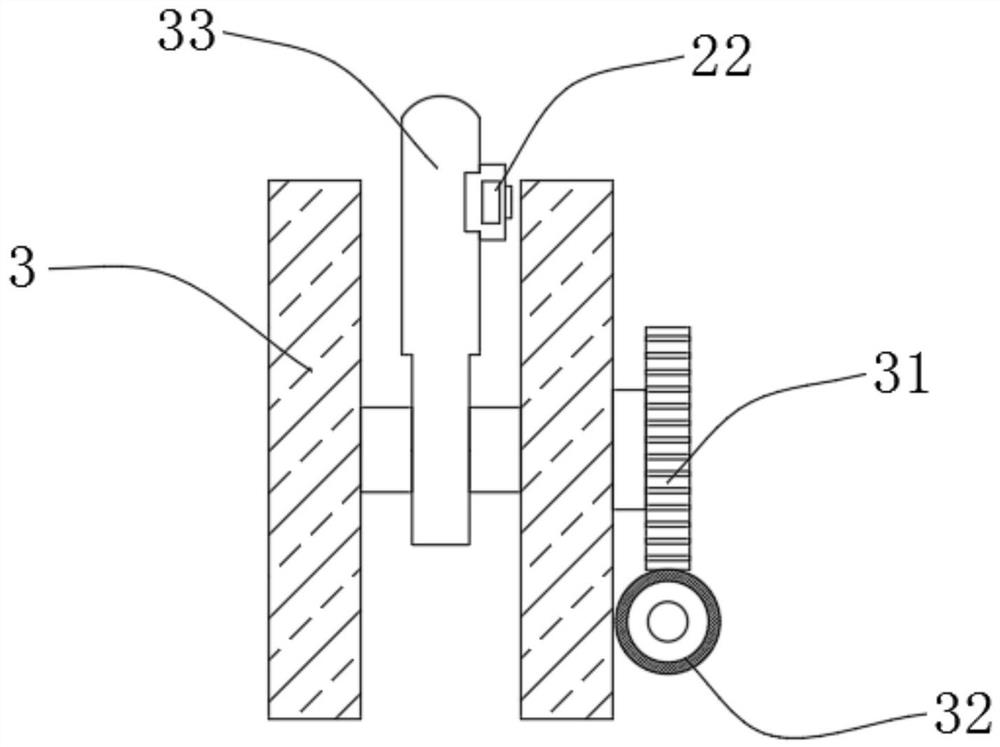

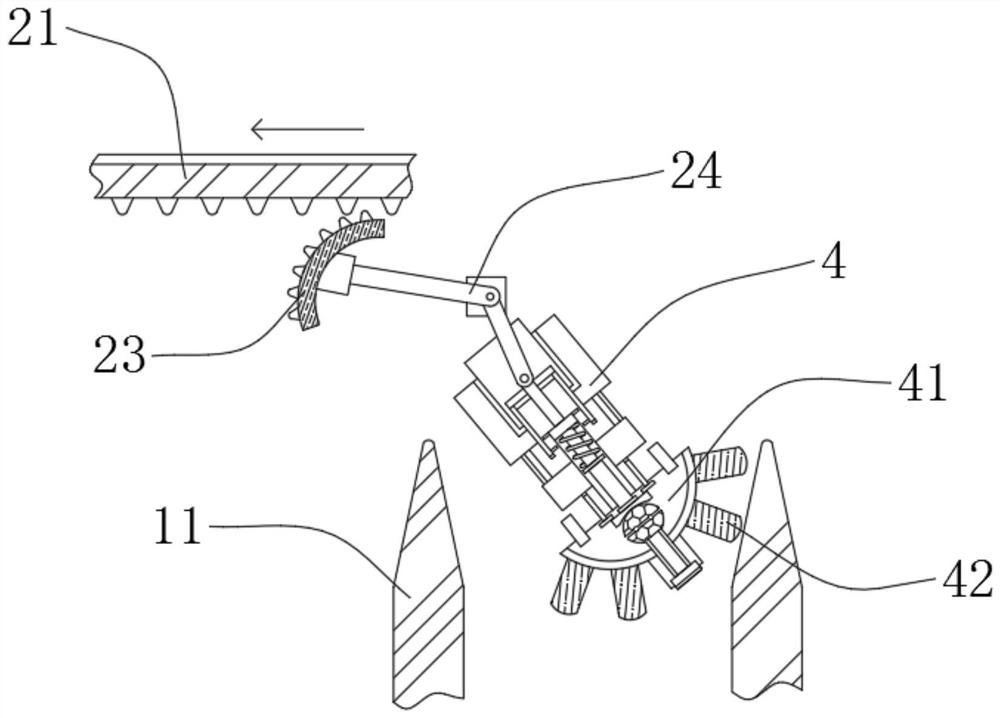

The invention discloses a cutting device for a pipe fitting. The device comprises a cylinder, a first rotating plate, a transmission rod, a second rotating plate, a third rotating plate, a first driving rod, two second driving rods, two third driving rods and two clamping heads, wherein a cutting wheel is mounted on the first rotating plate; when the cylinder drives the first rotating plate to rotate, the cutting wheel can move up and down; when rotating, the first rotating plate sequentially passes through the transmission rod, the second rotating plate, the third rotating plate, the first driving rod, the two second driving rods and the two third driving rods so as to drive the two clamping heads to close or open, and as a result, the pipe fitting to be cut can be clamped or released through the two clamping heads. According to the cutting device for the pipe fitting, a draught fan is arranged, so that the peripheral edges of the cutting wheel can be subjected to cooling and dust removing while cutting the metal pipe fitting by the cutting wheel; when in pipe fitting cutting, the mechanical transmission manner is carried out to drive a clamping mechanism to automatically clamp the pipe fitting, so that the manual control or program control can be saved.

Owner:NINGBO FUSHI AUTOMOBILE COMPONENTS

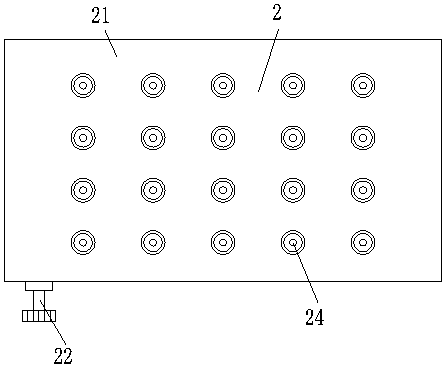

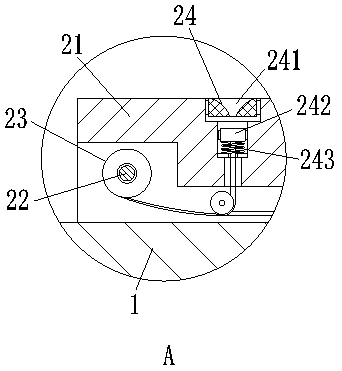

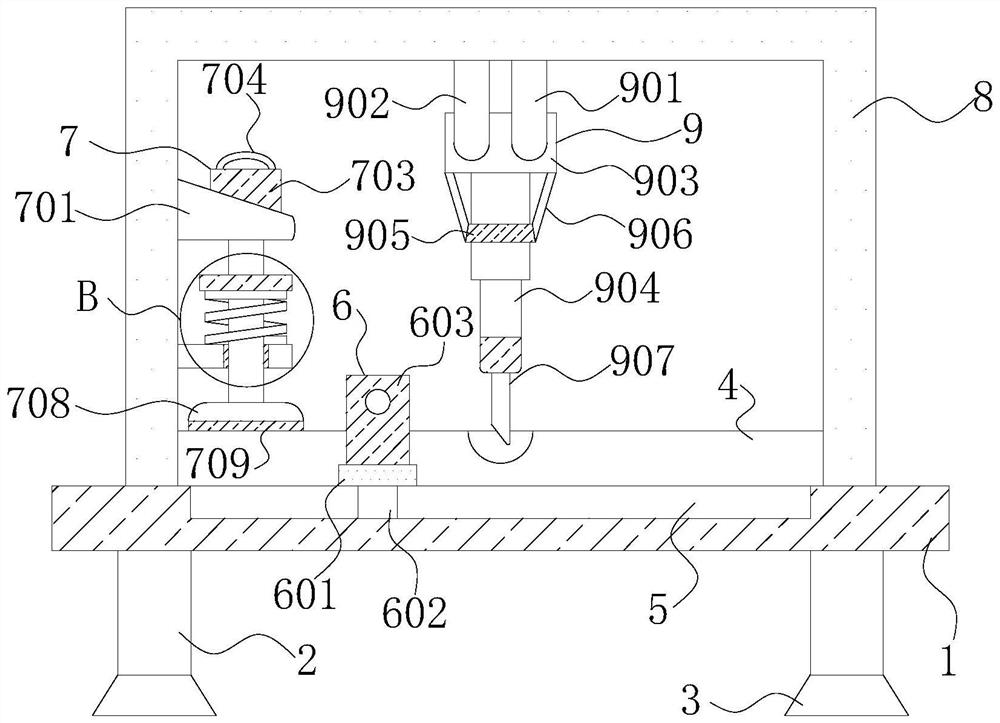

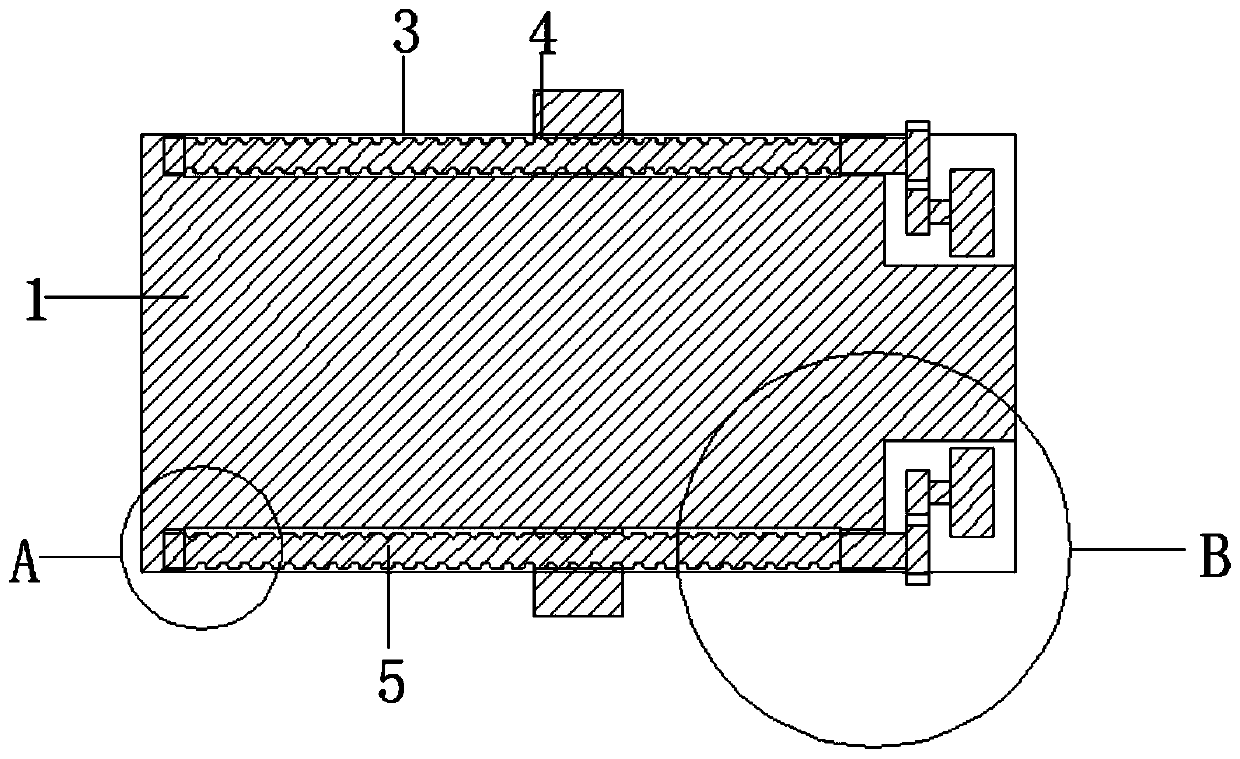

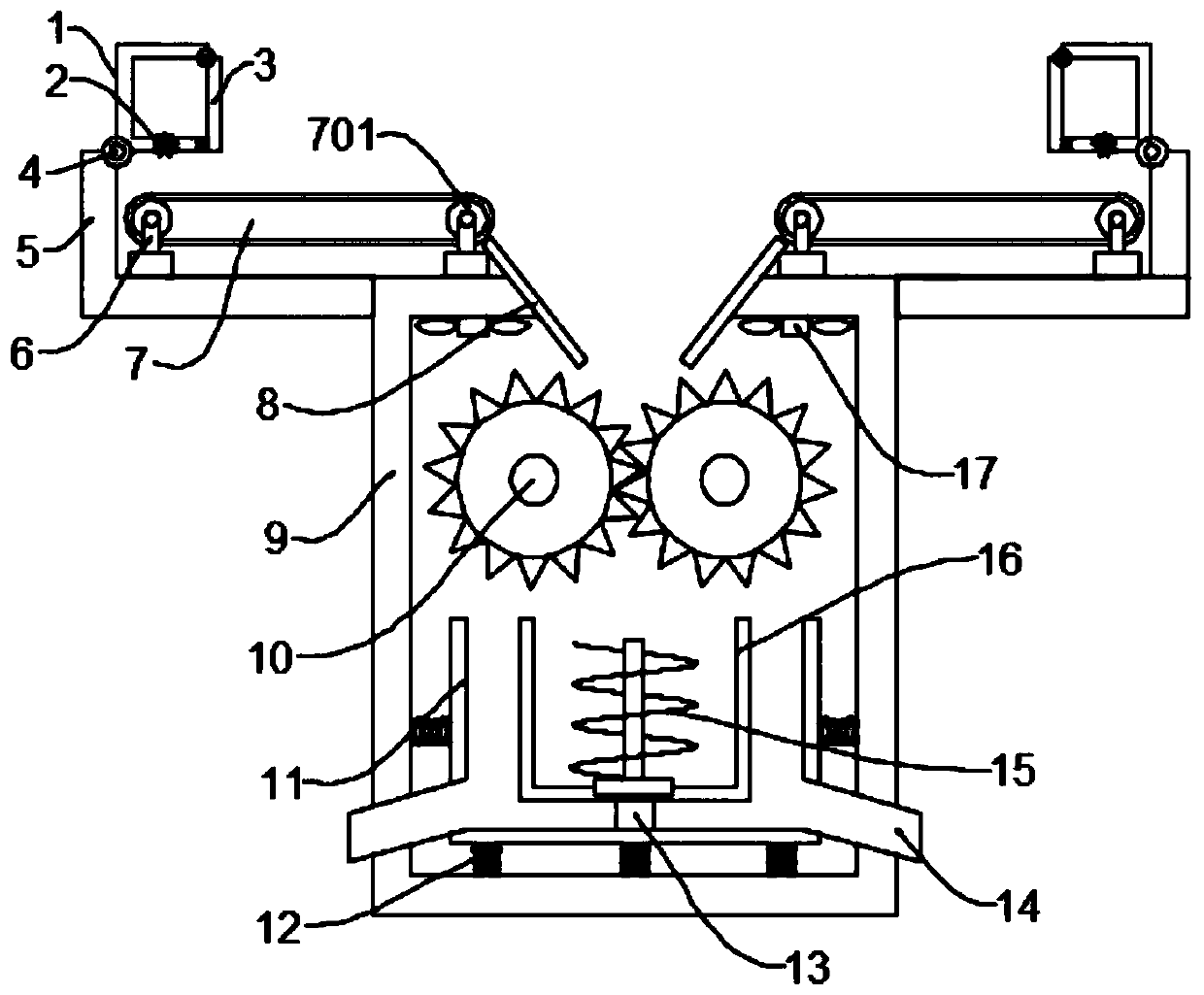

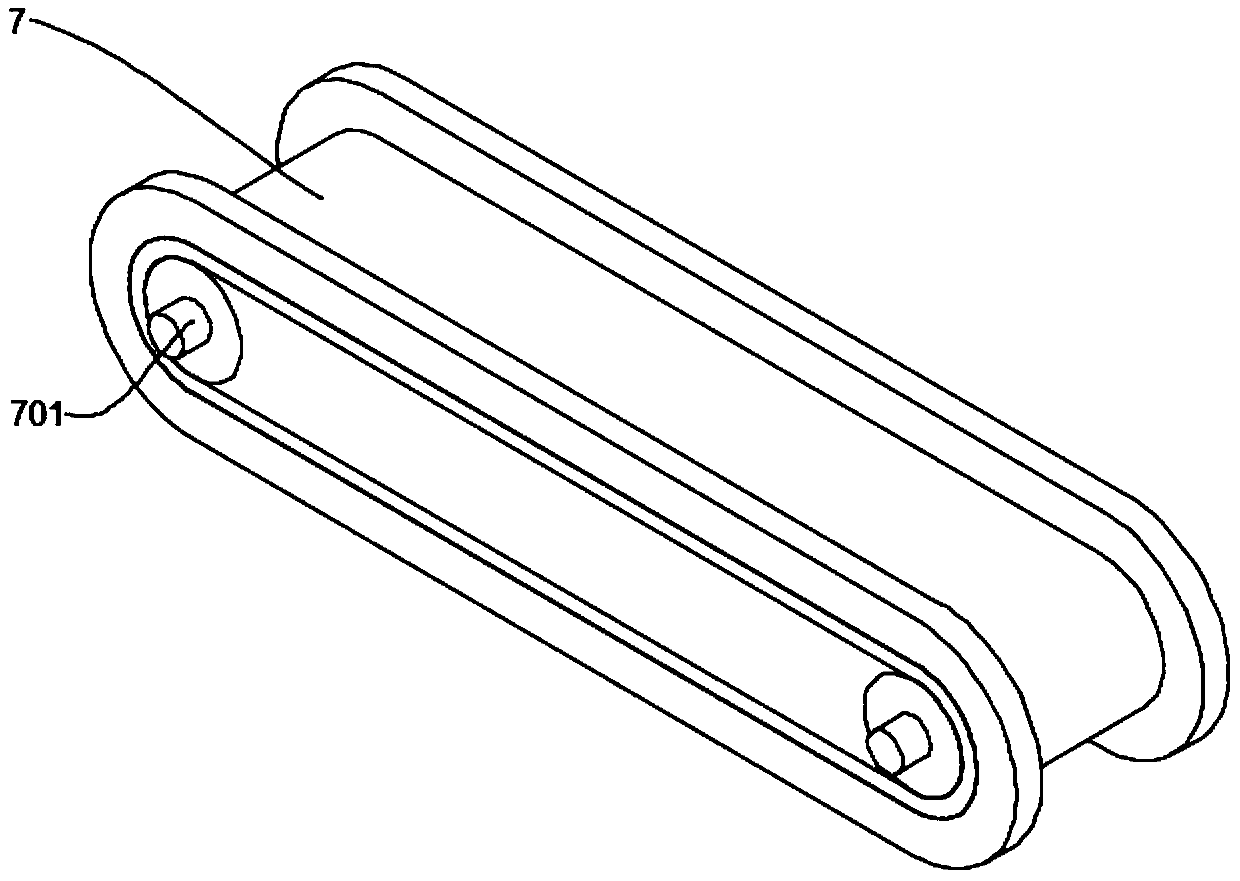

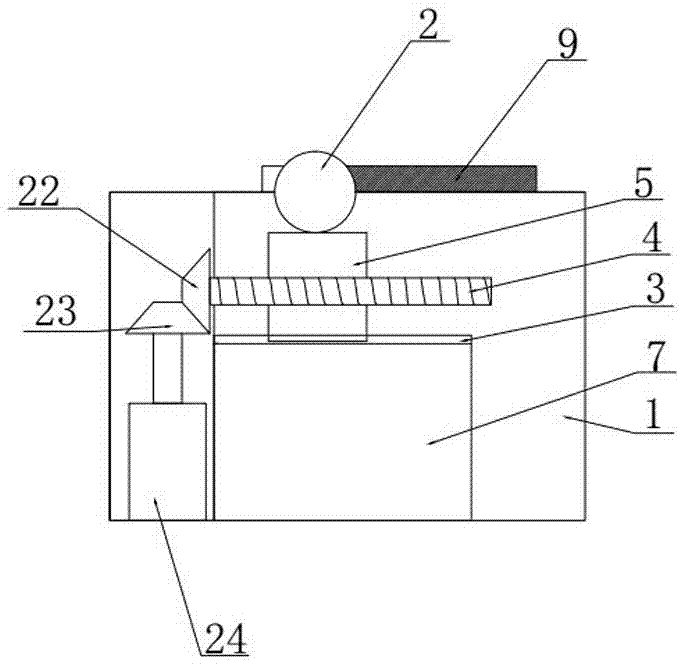

Mobile phone liquid crystal display screen cutting device

ActiveCN110789006AEffective support and fixationAvoid displacementWorking accessoriesStone-like material working toolsLiquid-crystal displayEngineering

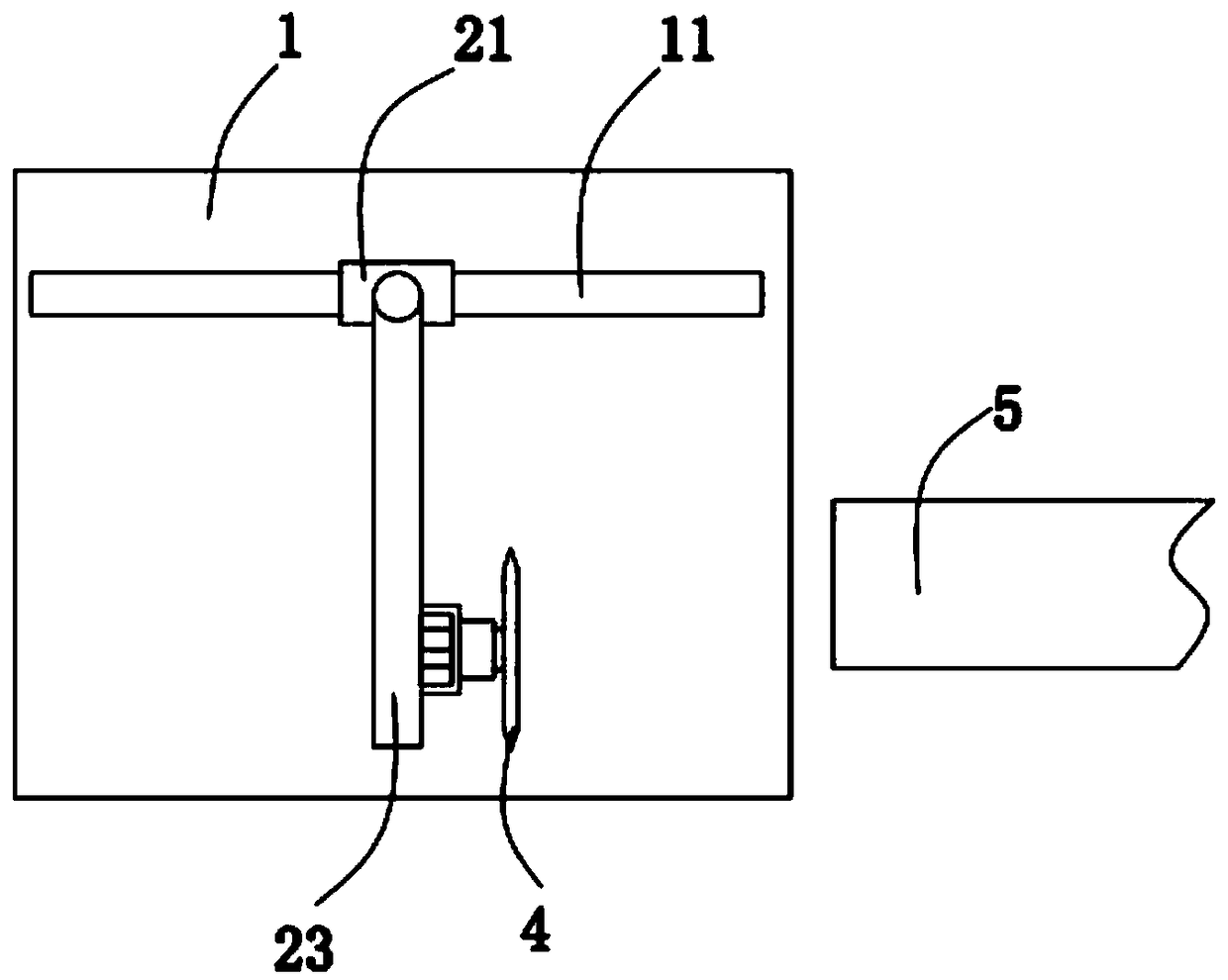

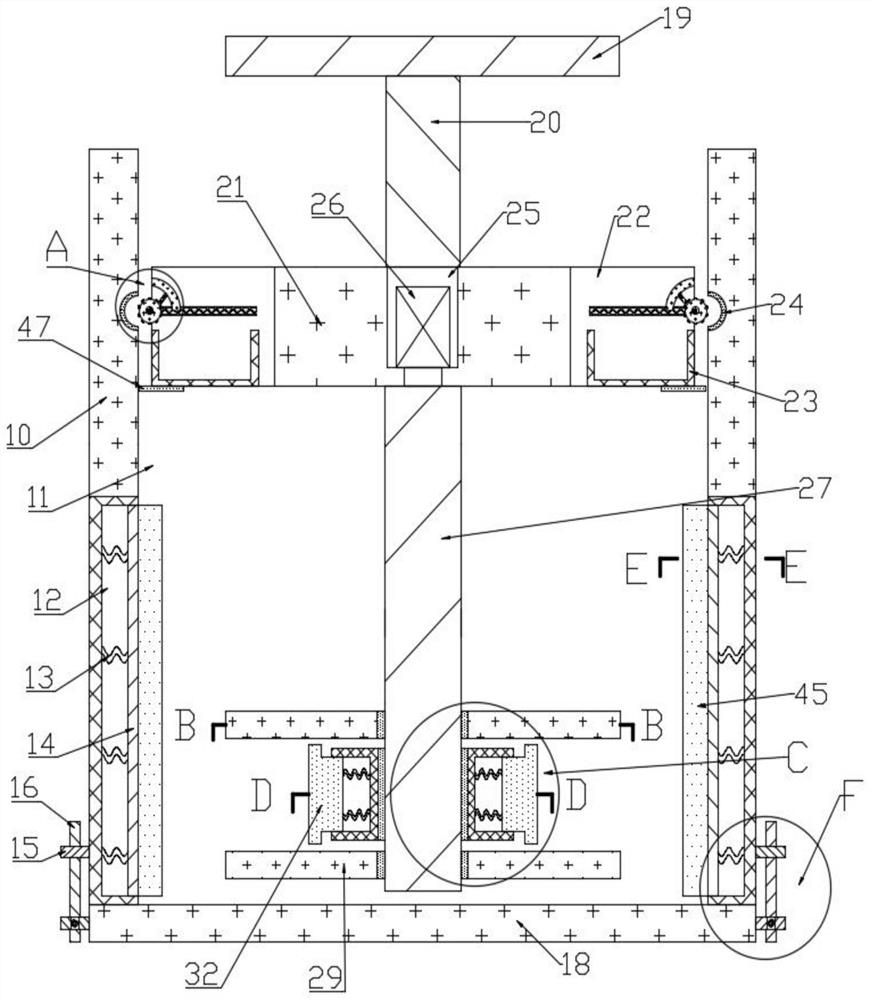

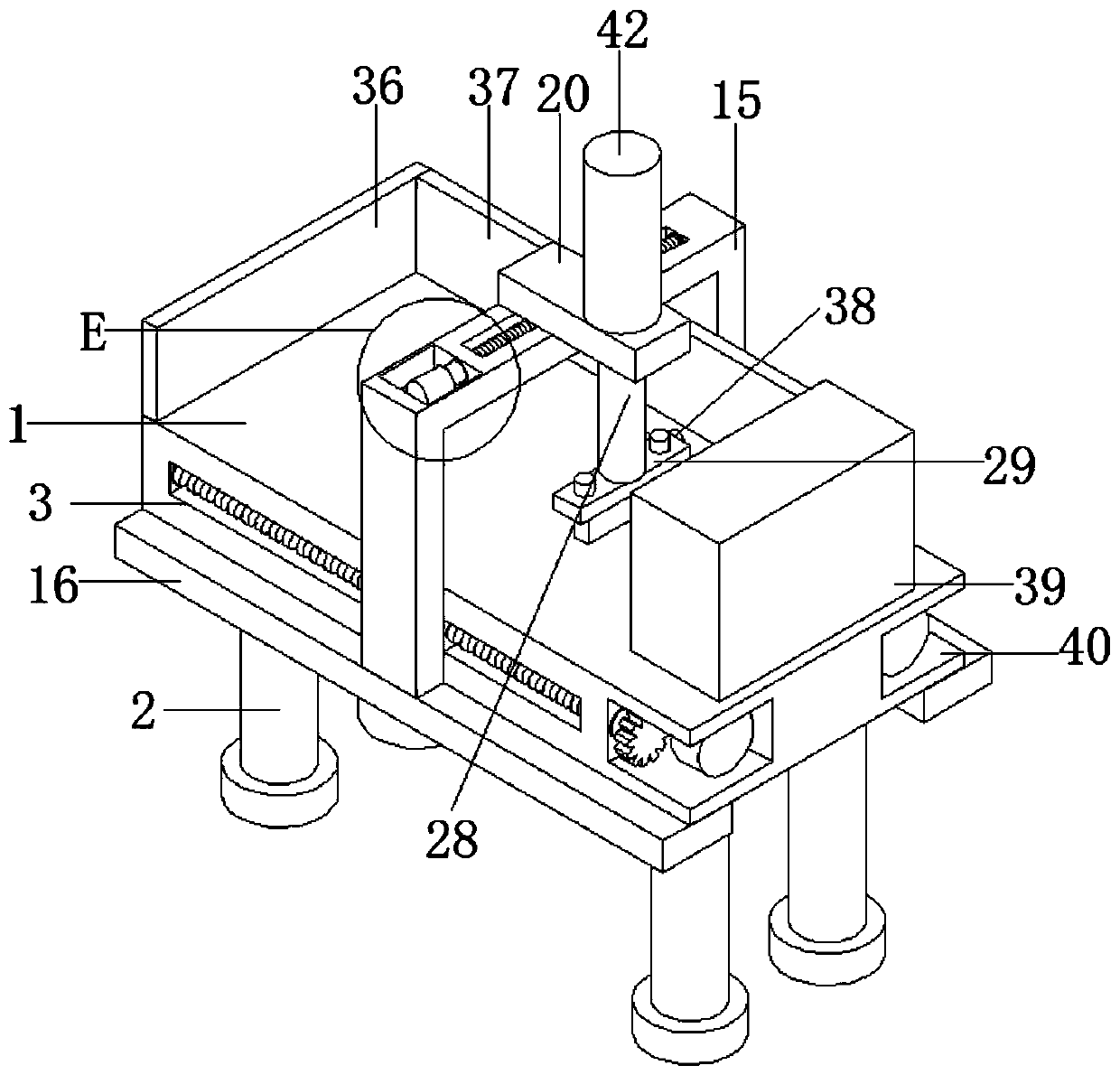

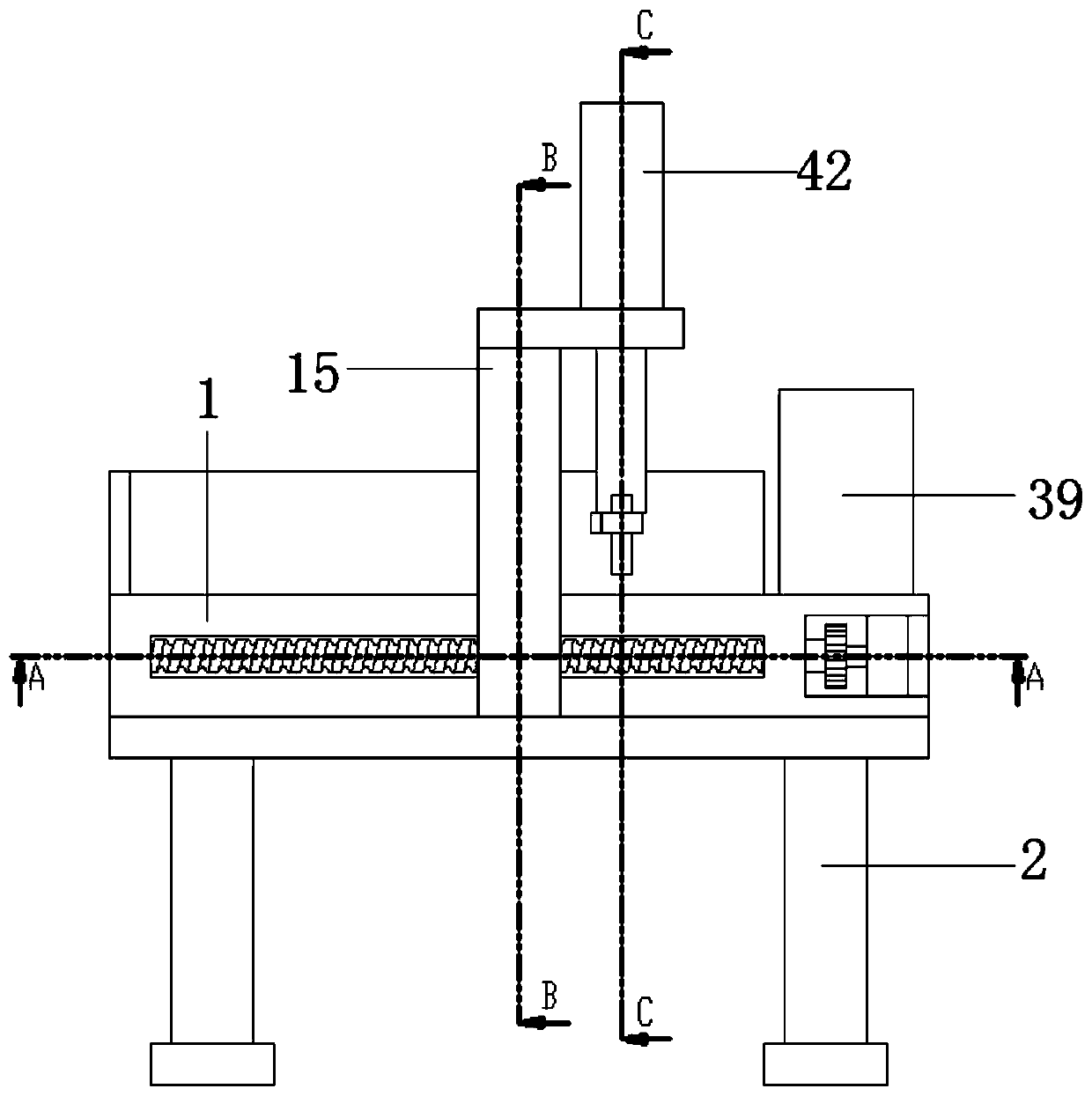

The invention relates to a mobile phone liquid crystal display screen cutting device. The mobile phone liquid crystal display screen cutting device comprises a bottom plate, a bearing frame and a cutting device. The bearing frame is installed in the middle of the upper end of the bottom plate. The cutting device is arranged above the bearing frame and installed on the bottom plate. The mobile phone liquid crystal display screen cutting device can solve the problems that: in the prior art, when a liquid crystal display screen is cut, the pressure adjusting effect between a cutting knife wheel and the liquid crystal display screen is poor, adjustment is inconvenient, the phenomenon that the liquid crystal display screen is broken easily due to the fact that the pressure is too large during cutting is caused, and waste of the liquid crystal display screen is caused easily; and in addition, when the equipment in the prior art cuts the liquid crystal display screen, glass fragments adheringto the surface of the cutting knife wheel cannot be cleaned usually, the phenomenon that the glass fragments are broken easily in the cutting process is caused, the regularity of notches is affected,and subsequent use of the liquid crystal display screen is affected.

Owner:深圳市弗塔信息技术有限公司

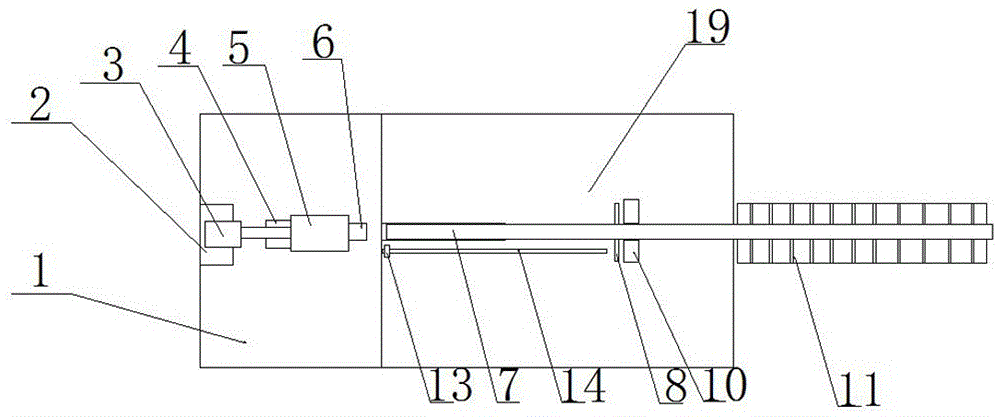

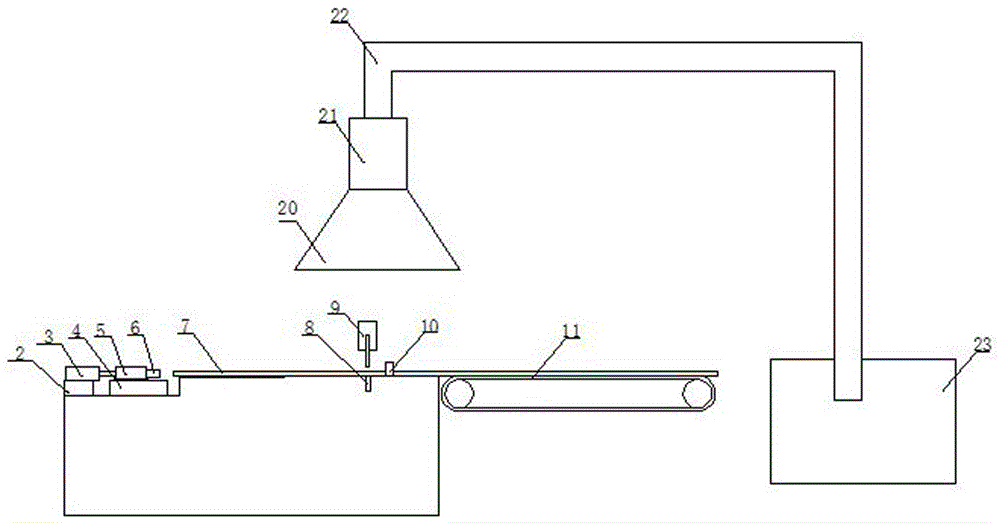

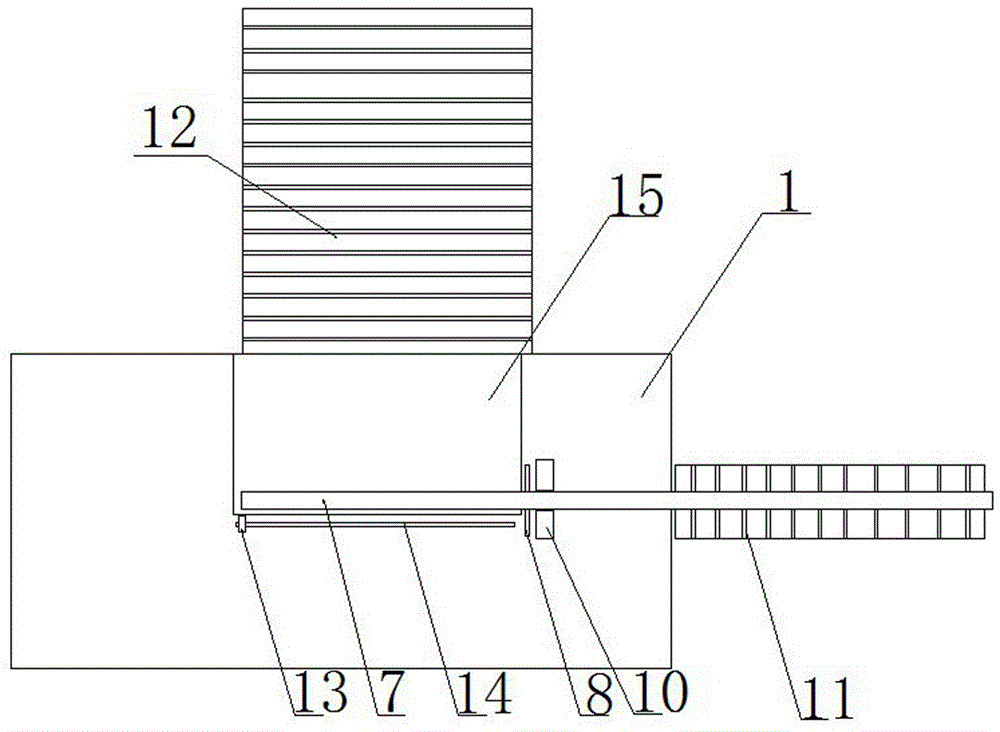

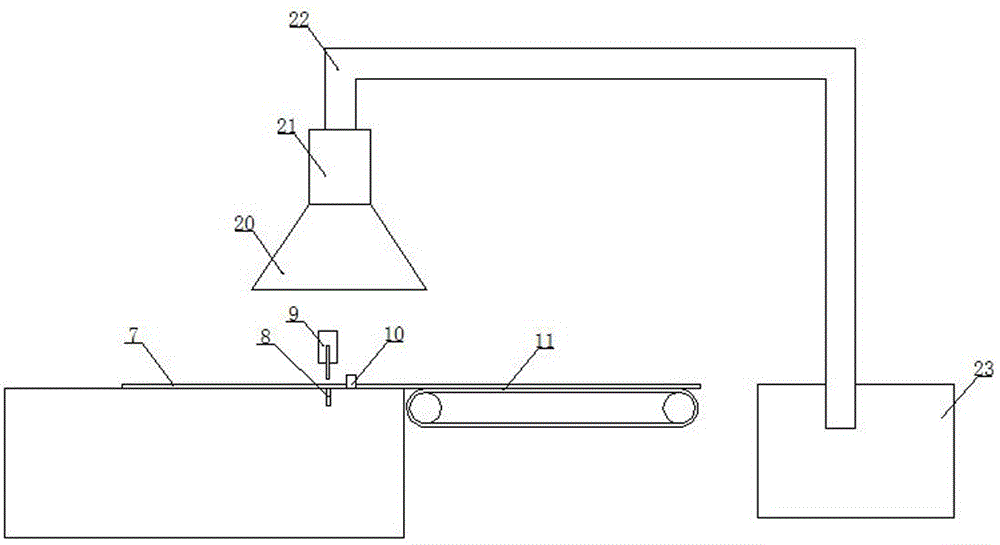

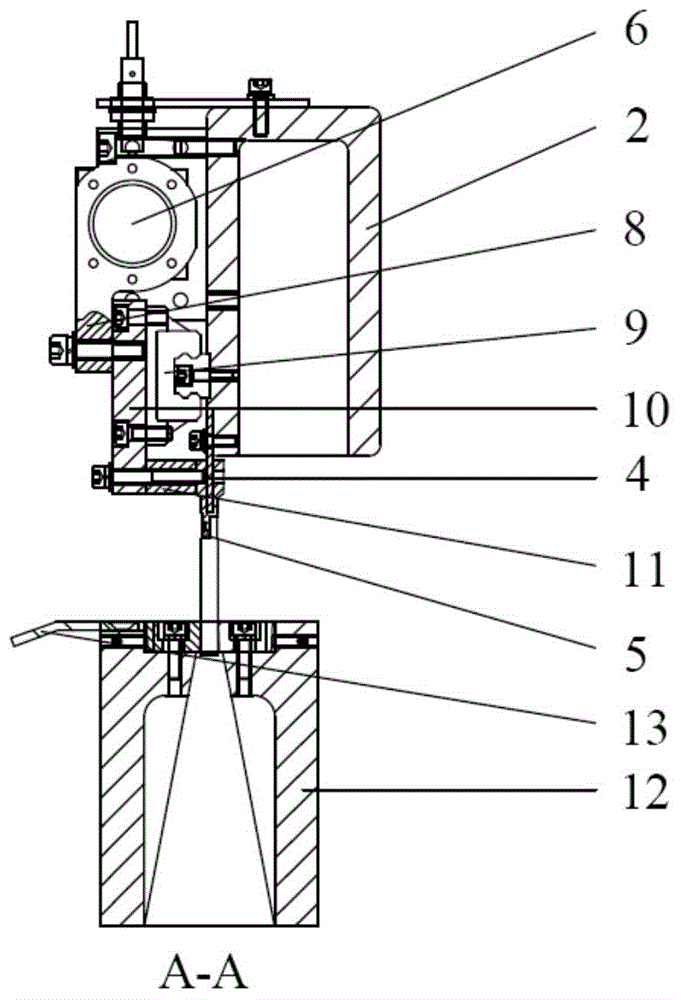

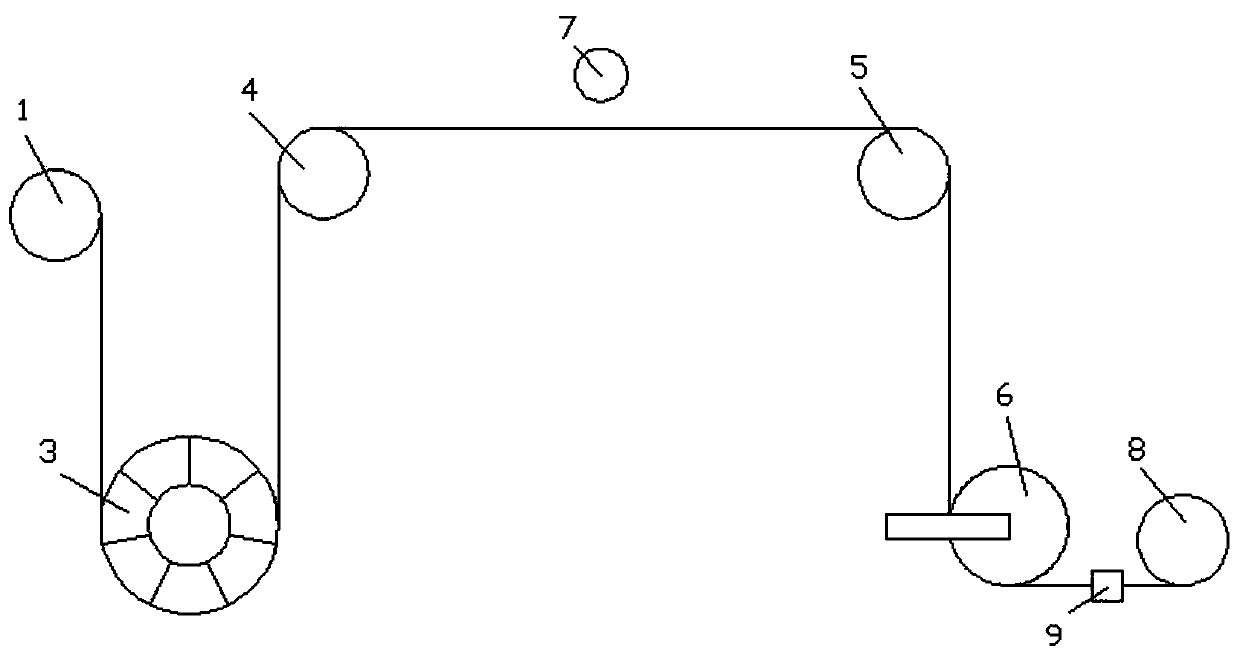

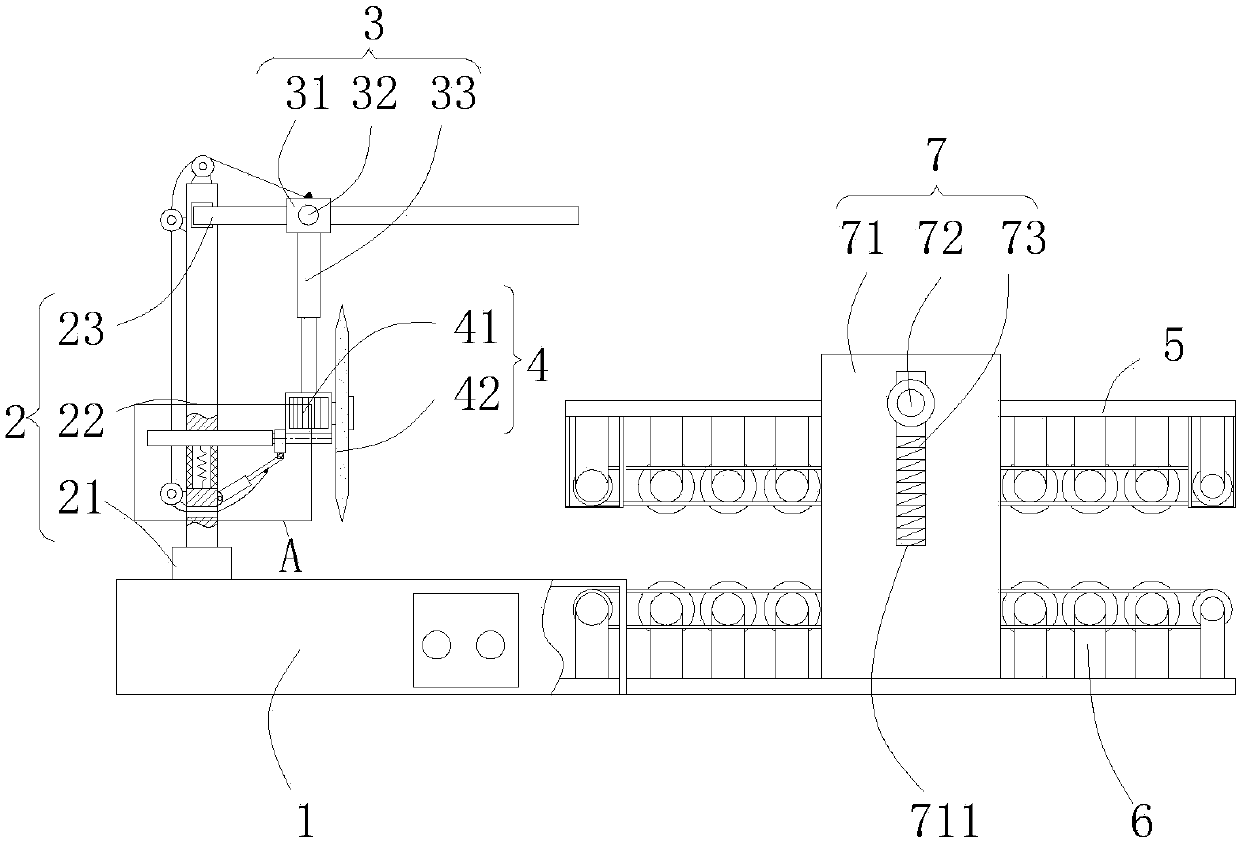

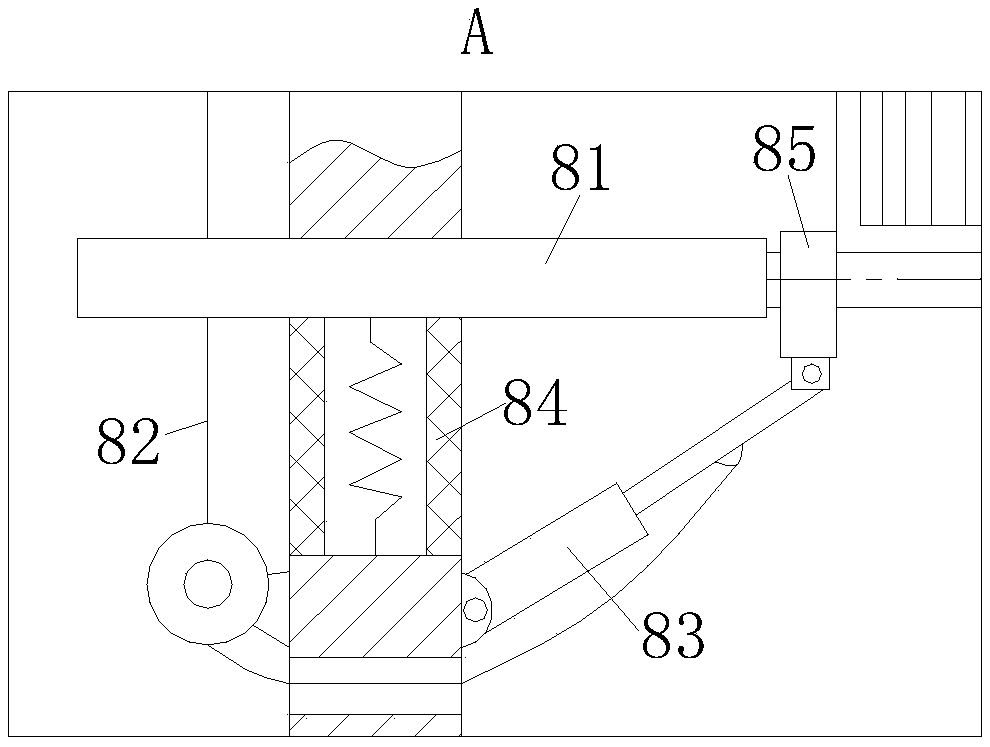

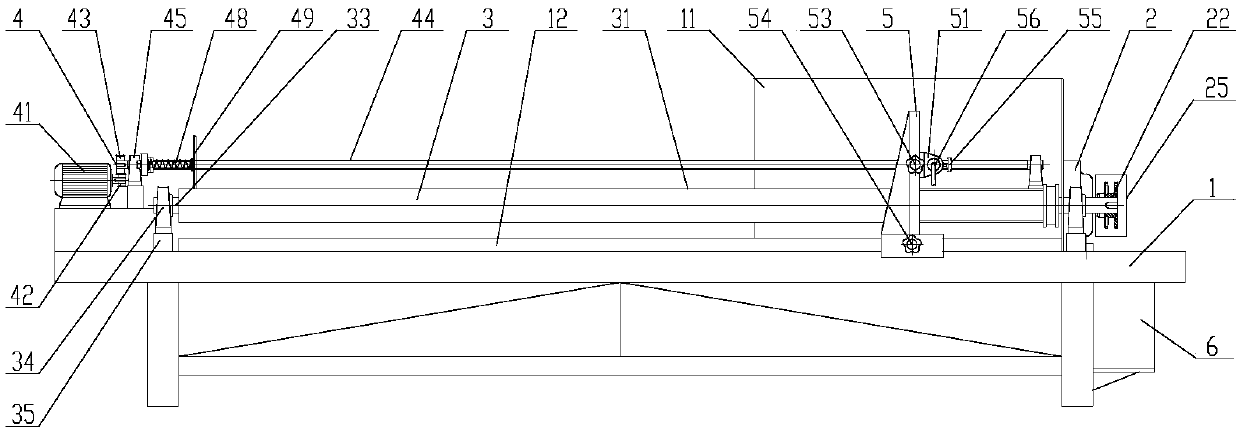

Pipe cutting machine capable of feeding automatically

InactiveCN106217051AEasy piercingImprove work efficiencyEdge grinding machinesMeasurement/indication equipmentsElectric machineryBlock match

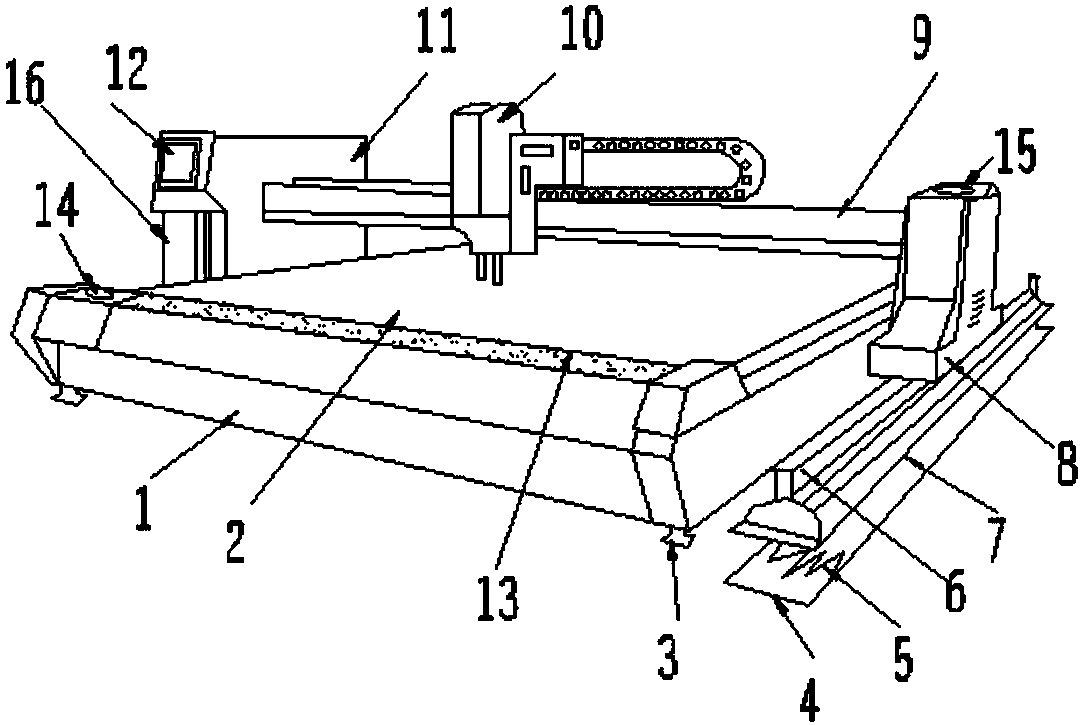

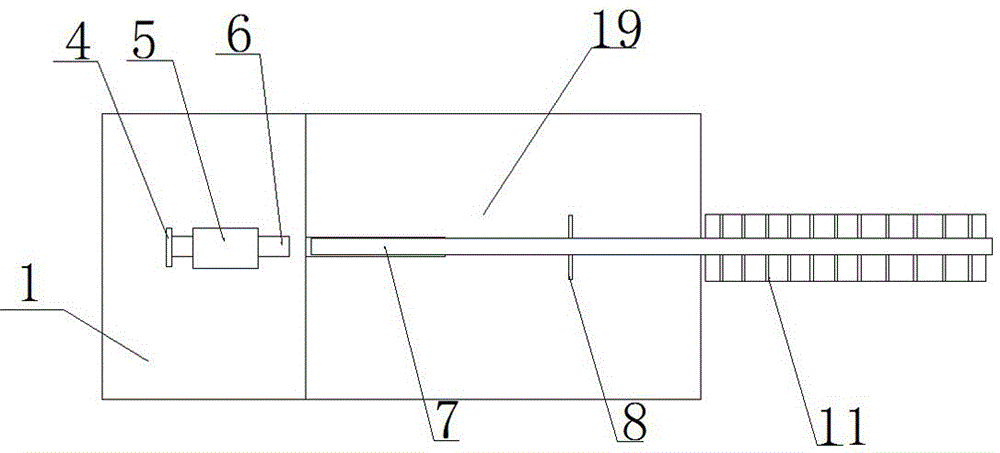

The invention discloses a pipe cutting machine capable of feeding automatically, comprising a machine body working surface, wherein the machine body working surface comprises a machine body edge-grinding surface and a machine body cutting surface higher than the machine body edge-grinding surface; a guide sliding rail is arranged on the machine body edge-grinding surface; a sliding block matched with the guide sliding rail is arranged on the guide sliding rail; a motor is arranged on the sliding block and is connected with a cylinder; grinding materials are arranged on the inner wall of the cylinder; a fixing block is arranged on the machine body edge-grinding surface; a push cylinder is arranged on the fixing block and is connected with the motor; a pair of electromagnet clamping blocks and an infrared sensor are arranged on the machine body cutting surface in a sliding way; a cutting device is arranged on the machine body cutting surface; a calibrated scale is arranged from the knife edge of the cutting device to the moving tail end of the infrared sensor; a feeding conveying belt is arranged on one side of the machine body cutting surface; a controller is arranged in the machine body; and the controller is connected with the motor, the electromagnet clamping blocks, the infrared sensor, the push cylinder and the feeding conveying belt separately. The pipe cutting machine can improve the work efficiency.

Owner:卢道东

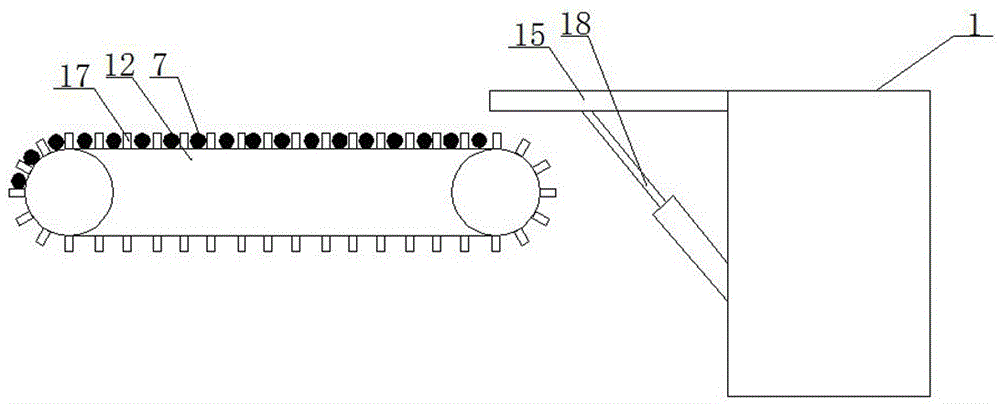

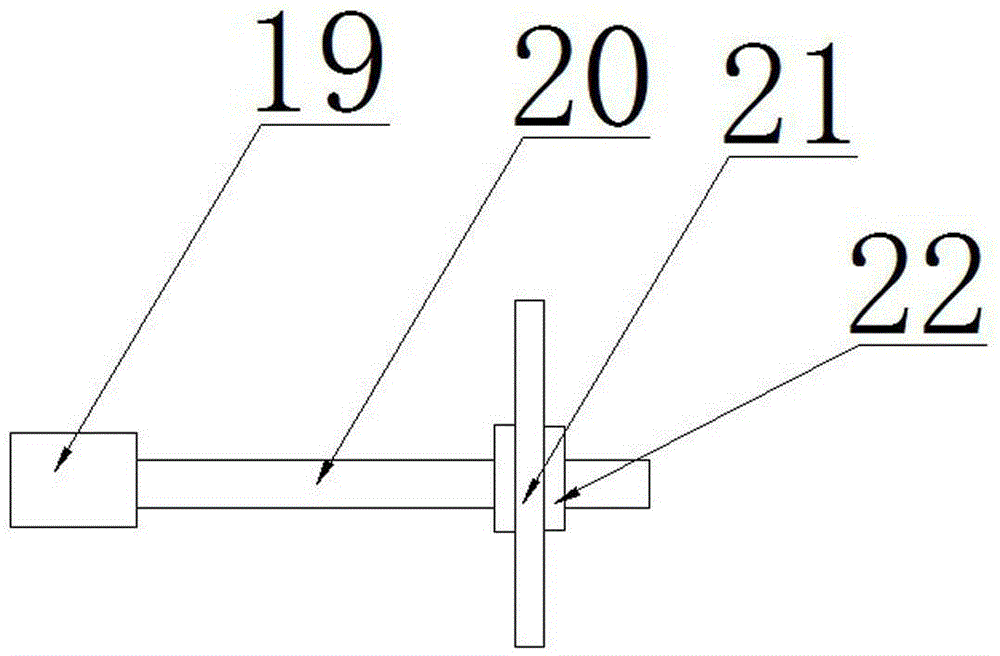

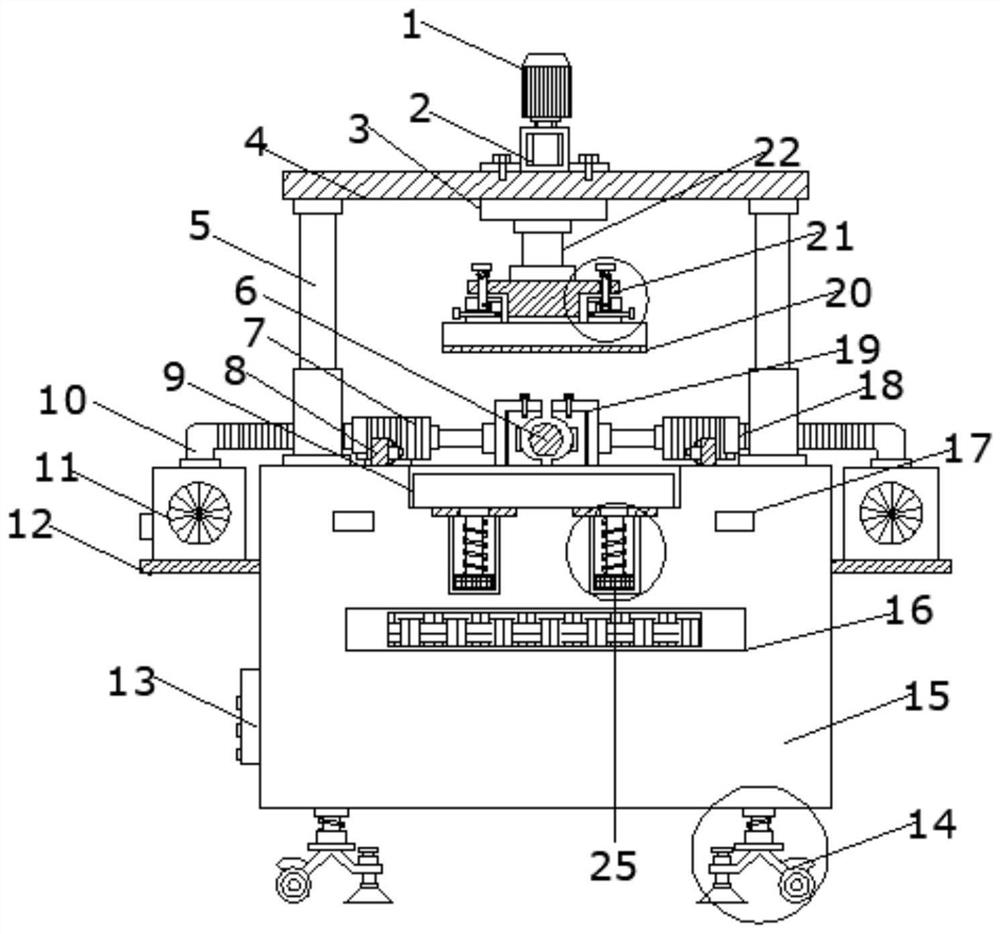

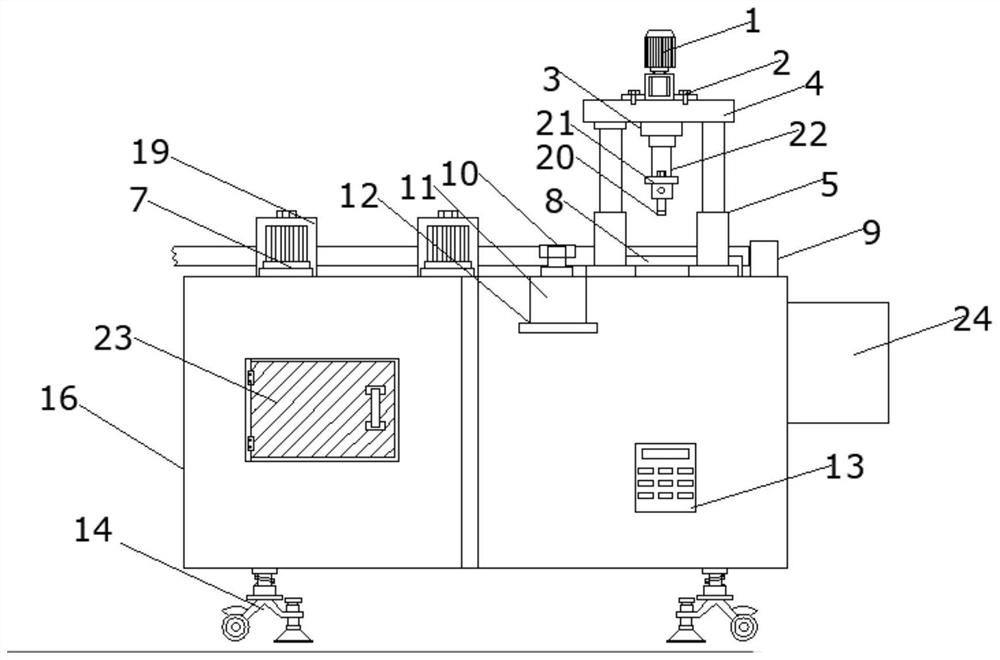

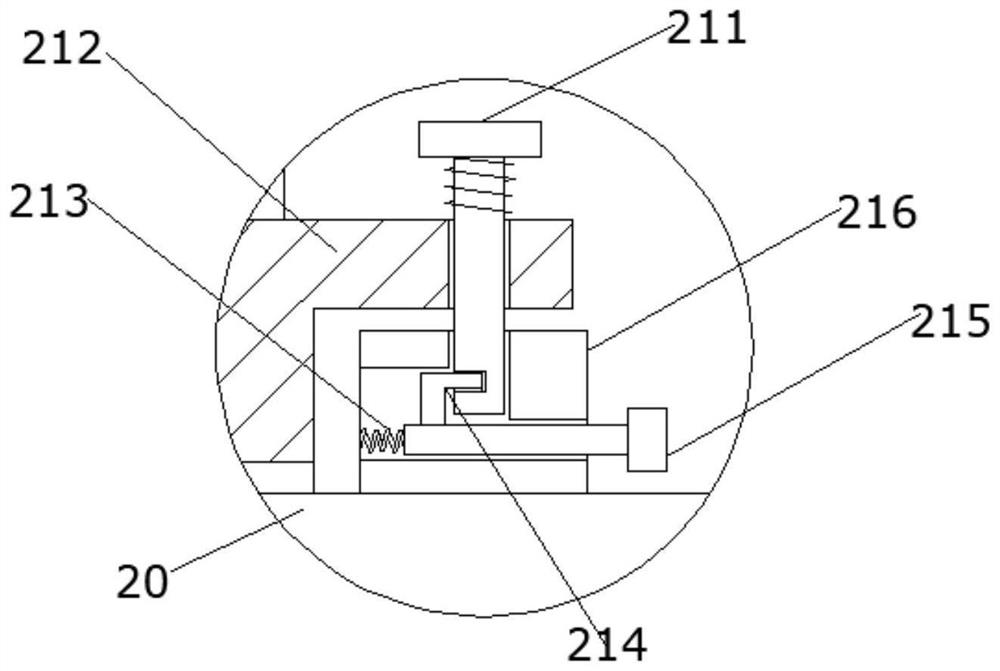

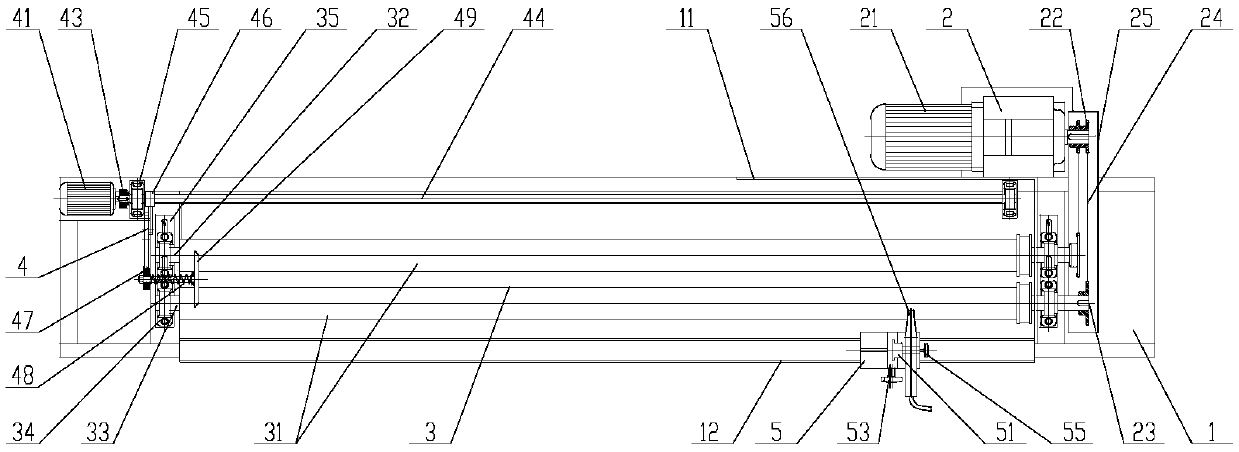

Automatic clamping pipe cutting machine

InactiveCN106216756AImprove work efficiencyReduce manual laborMeasurement/indication equipmentsTube shearing machinesEngineeringMechanical engineering

The invention discloses an automatic clamping pipe cutting machine. The automatic clamping pipe cutting machine comprises a machine body working surface. The machine body working surface is slidably provided with a pair of electromagnet clamping blocks and an infrared sensor. A cutting device is arranged on the machine body working surface. A scale ruler is arranged between a knife edge of the cutting device and the movement tail end of the infrared sensor. The machine body working surface is rotationally provided with a rotating plate flush with the machine body working surface. An air cylinder is arranged between the rotating plate and a machine body, and a discharging conveying belt is arranged on one side of the rotating plate. A plurality of protruding strips are uniformly arranged on the discharging conveying belt. A feeding conveying belt is arranged on one side of the machine body working surface. The machine body is internally provided with a controller. The controller is connected with the electromagnet clamping blocks and the infrared sensor. The automatic clamping pipe cutting machine can improve the working efficiency.

Owner:卢道东

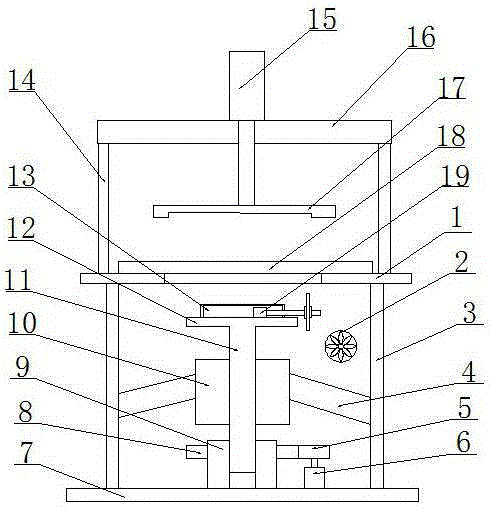

Device for cutting wooden boards with different widths for furniture manufacturing

InactiveCN108127746AGuaranteed to move in a straight lineAffect the cutting effectProfiling/shaping machinesBark-zones/chip/dust/waste removalTransverse axisDrive motor

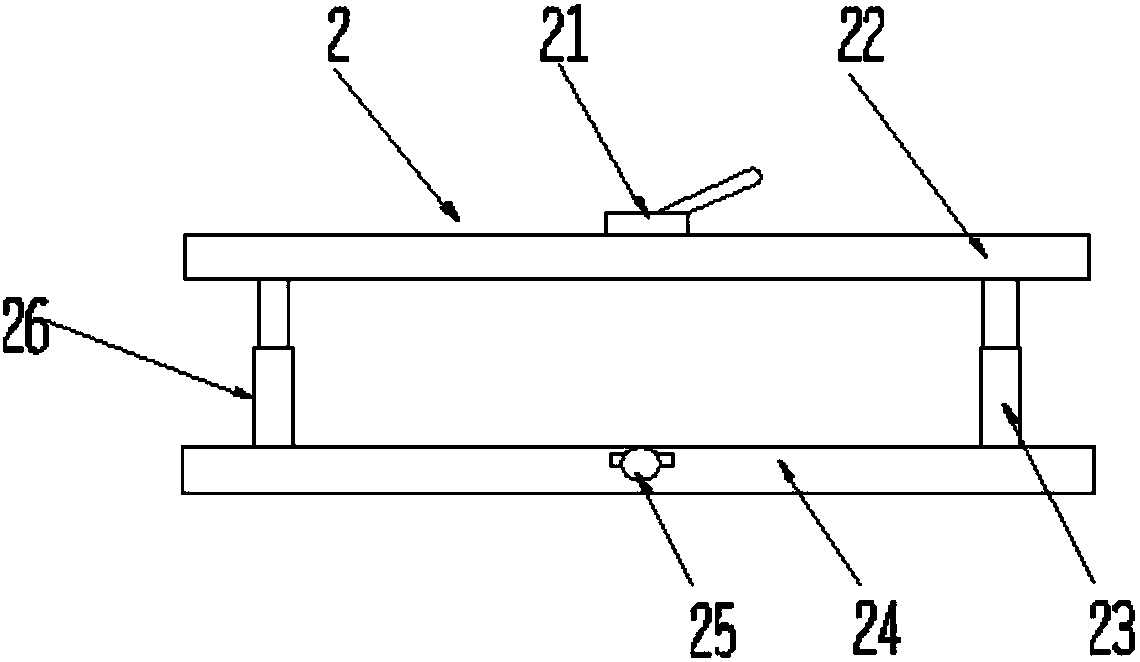

The invention discloses a device for cutting wooden boards with different widths for furniture manufacturing. The device comprises a workbench and two side boards. The two side boards are correspondingly arranged on the two sides of the upper end surface of the workbench. A top board is arranged at the top ends of the side boards. Two symmetrical mounting frames are arranged on the upper end surface of the workbench. A positioning pressure roller is arranged on each mounting frame. Adjusting screw rods are correspondingly arranged on the two side boards. The adjusting screw rods are connectedwith the side boards through threads. One end of each adjusting screw rod abuts against the mounting frame on the same side. One side of each mounting frame is connected with the corresponding side board through a reset spring. A knife holder is arranged in the middle of the lower end surface of the top board. A transverse shaft is arranged at the lower end of the knife holder. One end of the transverse shaft is connected with a driving motor on the knife holder, and a cutting cutter is mounted on the transverse shaft. A vacuum cleaner is arranged on the top board. The device is simple in structure, accurate to position, high in cutting efficiency, capable of being suitable for cutting the wooden boards with the different widths into strips and high in practicability.

Owner:GUANGDONG DEXIN TECH INCUBATOR CO LTD

Automatic cutting equipment for aluminum profile

InactiveCN109014365AWide range of applicationsRealize longitudinal segment cuttingShearing machinesShearing machine accessoriesEngineeringMechanical engineering

The invention belongs to the technical field of aluminum product production and processing, and particularly relates to automatic cutting equipment for aluminum profile. The automatic cutting equipment comprises a base, a first sliding groove, a supporting mechanism, a first sliding seat, a supporting rod, a sliding rod, a displacement mechanism, a second sliding seat, a mounting groove, a through hole, a first limiting knob, a pneumatic rod, a connecting block, a cutting mechanism, a first rotating motor, a cutting blade, a first feeding mechanism, a conveying mechanism, a conveying wheel, afirst gear, a supporting plate, a transmission chain, a driving mechanism, a second gear, a second rotating motor, a third gear, a second feeding mechanism, a limiting mechanism, a limiting plate, asecond sliding groove, a second limiting knob and a spring. According to the automatic cutting equipment, the angle of the cutting blade can be freely adjusted, the cutting requirements of sectional materials of various shapes can be met, and the application range is wide; and the sectional materials can be automatically conveyed forwards through the first feeding mechanism and the second feedingmechanism, so that the cutting is more convenient and accurate, the sectional materials can be limited, and the phenomenon that the sectional materials shake violently and affect the cutting effect isavoided.

Owner:王桂英

Steel plate cutting equipment

InactiveCN108015384ARealize free cuttingEasy to operateGas flame welding apparatusSheet steelSolenoid valve

The invention discloses steel plate cutting equipment. The steel plate cutting equipment comprises a steel plate cutting equipment body, an operation panel, a supporting frame, a base plate, a first spring, a first rail, a supporting base, a first sliding block, a second rail, a cutter device, a second sliding block, a control panel, a measuring device, a sensing device, an alarming device, a mainmachine, a lock catch, a first clamping block, a first electric push rod, a second clamping block, a solenoid valve, a second electric push rod, a sliding wheel groove, a wheel shaft, a microswitch,a contactor, an upper clamping disc, a second spring, a tool bit, a lower clamping disc, a cutting torch clamp, an automatic height adjusting device, a signal line, a direct-current motor, a cable, aHall sensor and a lead screw, and the lower end of the steel plate cutting equipment body is connected with the supporting frame; and the sensing device is arranged on the upper surface of the steel plate cutting equipment body. The steel plate cutting equipment has the beneficial effects that high efficiency is achieved, the intelligent degree is relatively high, safety is achieved, operation isrelatively convenient, the application scope is wide, and the defective percentage is reduced.

Owner:李月彩

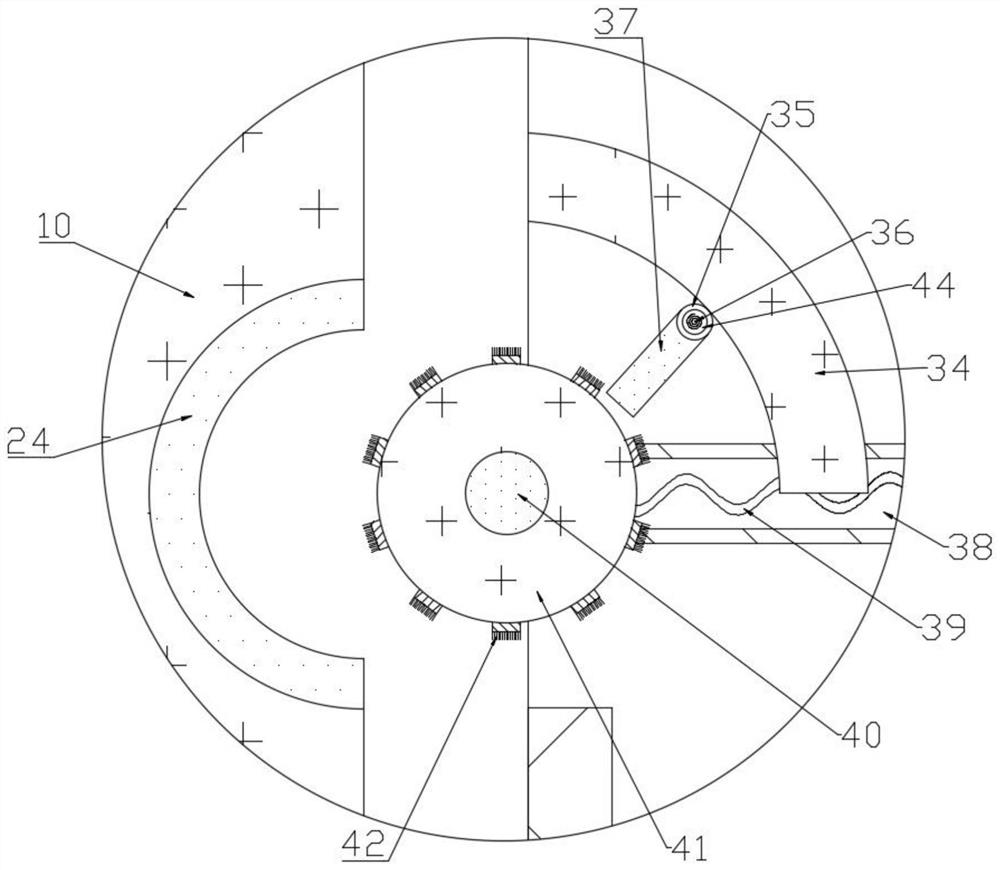

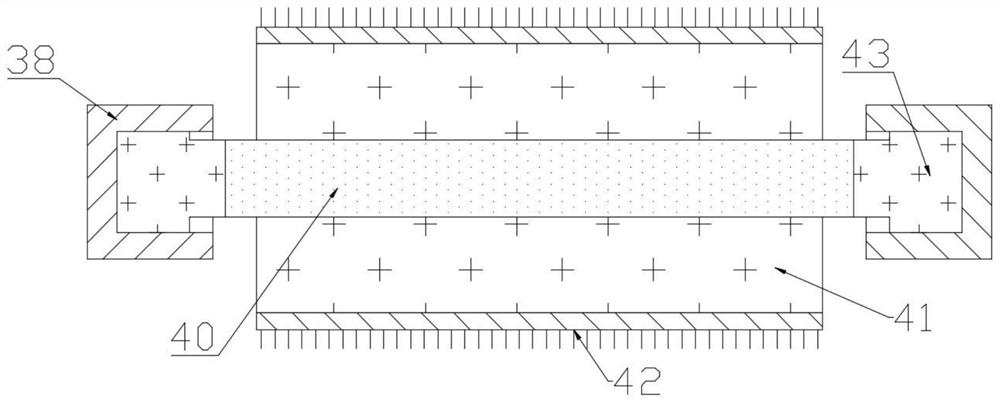

Round sponge cutting machine

InactiveCN105171794AAvoid circular cutsImprove work efficiencyMetal working apparatusMechanical engineering

The invention discloses a round sponge cutting machine which comprises a shell. A workbench is arranged on the shell and provided with a round through groove. A supporting column is arranged in the shell, the lower end of the supporting column is rotatably connected with a bottom plate of the shell, and a supporting plate is arranged at the upper end of the supporting column, flush with the workbench and located in the round through groove in the workbench. A driven gear is arranged on the lower side of the supporting column and provided with a driving gear matched with the driven gear, and the driving gear is provided with a rotating motor. A fixing plate is arranged above the workbench, a cylinder is arranged on the fixing plate, a pressing plate is arranged at the tail end of an output shaft of the cylinder, and an annular groove is formed in the position, where a cutting sheet cuts a sponge, of the pressing plate. By means of the round sponge cutting machine, the work efficiency can be improved.

Owner:CHENGDU DUOLIDUO NEW MATERIAL

Automatic feeding pipe cutter

InactiveCN106141688AEasy piercingImprove work efficiencyOther manufacturing equipments/toolsMaintainance and safety accessoriesConveyor beltAbrasive

The invention discloses an automatic feeding pipe cutting machine, comprising a body working surface; the body working surface includes a body edging surface and a body cutting surface higher than the body edging surface; the body edging surface is provided with a fixed The fixed block is provided with a threaded through hole, a cylinder is installed in the threaded through hole, one end of the cylinder is provided with a rotating handle, and the inner wall of the other end of the cylinder is provided with abrasives; the cutting surface of the body is provided with a cutting device; the body There is a feeding conveyor belt on one side of the cutting surface. This pipe cutter can improve work efficiency.

Owner:卢道东

Meat stuffing cutting device

ActiveCN111938465AGuaranteed cleaning effectAvoid accumulationKitchen equipmentBilateral symmetryFood processing

The invention provides a meat stuffing cutting device, and belongs to the technical field of food processing. The problems that an existing meat stuffing cutting device is not easy to clean, and meatstuffing is prone to being wasted are solved. The meat stuffing cutting device comprises a cylindrical shell, openings are formed in the upper end and the lower end of the shell respectively, a working space is limited in the shell, limiting grooves are formed in the inner walls of the left side and the right side of the shell respectively, and the two limiting grooves are distributed in a bilateral symmetry mode relative to the center line of the shell. A supporting mechanism is detachably connected to an opening in the upper end of the shell, two cleaning mechanisms capable of cleaning residual meat stuffing on the inner wall of the shell are arranged in the supporting mechanism, the two cleaning machines can be distributed in a bilateral symmetry mode relative to the center line of thesupporting mechanism, and the supporting mechanism is further sleeved with a cutting mechanism for mincing meat blocks. The meat stuffing cutting device is more convenient to use and higher in utilization rate.

Owner:杭州岚尔滨智能设备有限公司

Food packaging bag cutting equipment

InactiveCN112223364AAffect the cutting effectAvoid wastingBag making operationsPaper-makingAgricultural engineeringStructural engineering

The invention relates to the technical field of food packaging bags, and discloses food packaging bag cutting equipment which comprises a bottom plate. A fixing frame is fixedly connected to the top of the bottom plate, a base plate is horizontally arranged in the fixing frame, the base plate is fixedly connected with the top of the bottom plate, and a flattening mechanism is arranged above the bottom plate. A fixing mechanism is arranged on the left side of the inner wall of the fixing frame, and a cutting mechanism is arranged on the upper portion of the inner part of the fixing frame. By pulling a pull ring, the pull ring drives a pressing block and a rubber pad to move upwards through an inserting rod, after one end of a food packaging bag is placed at the bottom of the rubber pad, byloosening the pull ring, the food packaging bag can be extruded and fixed under the elastic action of springs, the situation that the cutting effect on the food packaging bag is affected due to movingof the food packaging bag during cutting is effectively avoided, waste of the food packaging bag is avoided, and the cutting quality of the food packaging bag is guaranteed.

Owner:浙江时进包装有限公司

Circular sponge cutting machine with cutting radius adjustable

InactiveCN105171793AImprove work efficiencyAvoid deformationMetal working apparatusCircular surfaceMechanical engineering

The invention discloses a circular sponge cutting machine with the cutting radius adjustable. The circular sponge cutting machine comprises a shell. A workbench is arranged on the shell. A circular through groove is formed in the workbench. A rotating cylinder is arranged inside the shell. The lower end of the rotating cylinder is rotatably connected with a bottom plate of the shell. A driven gear is arranged on the outer circular surface of the rotating cylinder. The driven gear is provided with a driving gear matched with the driven gear. The driving gear is provided with a rotating motor. A rotating rod in thread fit with the rotating cylinder is arranged inside the rotating cylinder. A disc is fixedly connected to the upper end of the rotating rod. A supporting shell and a cutting motor inside the supporting shell are arranged on the disc. A rectangular groove is formed in an output shaft of the cutting motor in the axial direction. A fixing plate is arranged on the workbench. An air cylinder is arranged on the fixing plate. A pressing plate is arranged at the tail end of an output shaft of the air cylinder. A circular groove is formed in the pressing plate. By means of the circular sponge cutting machine with the cutting radius adjustable, the working efficiency can be improved.

Owner:CHENGDU DUOLIDUO NEW MATERIAL

Intelligent cutting method for steel plates

InactiveCN108247173ARealize free cuttingEasy to operateWelding/soldering/cutting articlesMetal working apparatusSheet steelSolenoid valve

The invention discloses an intelligent cutting method for steel plates. An intelligent cutting device comprises a steel plate cutting equipment body, an operation panel, a support, a bottom plate, a first spring, a first rail, a supporting base, a first sliding block, a second rail, a cutter device, a second sliding block, a control panel, a measuring device, an induction device, an alarming device, a main machine, a lock catch, a first clamping block, a first electric pushing rod, a second clamping block, a solenoid valve, a second electric pushing rod, sliding wheel grooves, wheel shafts, amicroswitch, a contact, an upper clamping disc, a second spring, a cutter head, a lower clamping disc, a cutting torch clamp, an automatic height adjusting device, a signal line, a DC motor, an electric cable, a Hall sensor and a lead screw; a lower end of the steel plate cutting equipment body is connected with the support; and the induction device is arranged on an upper surface of the steel plate cutting equipment body. The intelligent cutting method has the beneficial effects of being more high-efficient, higher in intelligent degree, safer, more convenient for operation, wider in application range and lower in defective rate.

Owner:李月彩

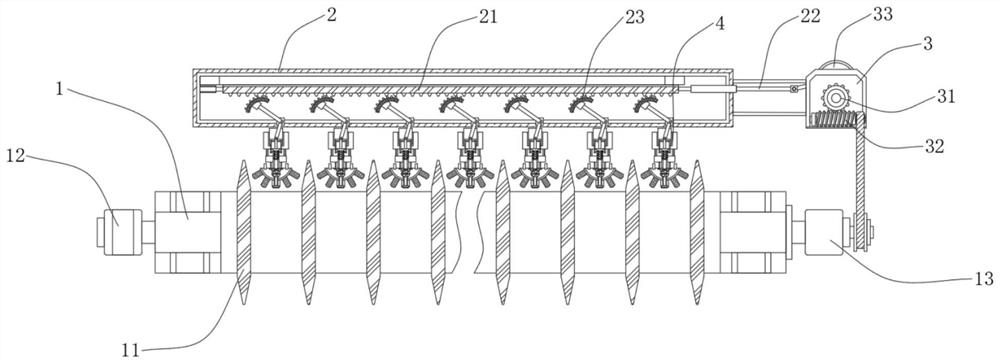

Corrugated paper line imposing and grooving device

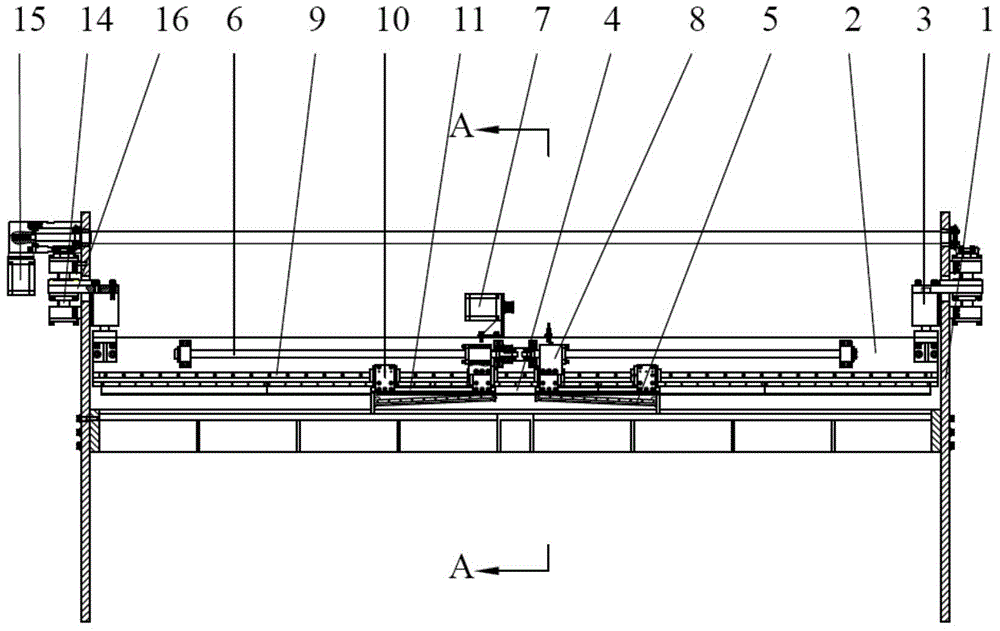

InactiveCN104972691AImprove stabilityAffect the cutting effectBox making operationsPaper-makingElectrical and Electronics engineering

The invention discloses a corrugated paper line imposing and grooving device. The device comprises a stand, a cross beam installed on the stand, a first driving mechanism used for driving the cross beam to move vertically and a line imposing mechanism and a grooving mechanism which are installed on the cross beam respectively, the line imposing mechanism comprises a line imposing knife installed on the cross beam, the grooving mechanism comprises a pair of grooving knives installed on the cross beam and a second driving mechanism used for driving the grooving knives to move horizontally on the cross beam, the line imposing knife and the grooving knives are linked with the cross beam, and two knife edges move in the same plane vertically. By means of the device, the line imposing and grooving can be completed simultaneously, the production efficiency is improved, the device can be applicable to processing the corrugated paper of different specifications, and the labor intensity is reduced.

Owner:江门市金钩包装机械有限公司

Pipe cutting machine with automatic feeding function

InactiveCN106217050AEasy piercingImprove work efficiencyOther manufacturing equipments/toolsMaintainance and safety accessoriesEngineeringBlock match

The invention discloses a pipe cutting machine with the automatic feeding function. The pipe cutting machine comprises a machine body work face, the machine body work face comprises a machine body edge grinding face and a machine body cutting face higher than the machine body edge grinding face, a guide sliding rail is arranged on the machine body edge grinding face, a sliding block matched with the guide sliding rail is arranged on the guide sliding rail, a motor is arranged on the sliding block, the motor is connected with a cylinder, and grinding materials are arranged on the inner wall of the cylinder; a pair of electromagnetic clamping blocks and an infrared sensor are arranged on the machine body cutting face in a sliding manner, a cutting device is arranged on the machine body cutting face, and a dividing ruler is arranged between a knife edge of the cutting device and the moving tail end of the infrared sensor; a feeding conveying belt is arranged on one side of the machine body cutting face; a controller is arranged in the machine body and controls the electromagnetic clamping blocks and the infrared sensor; and according to the pipe cutting machine, work efficiency can be improved.

Owner:卢道东

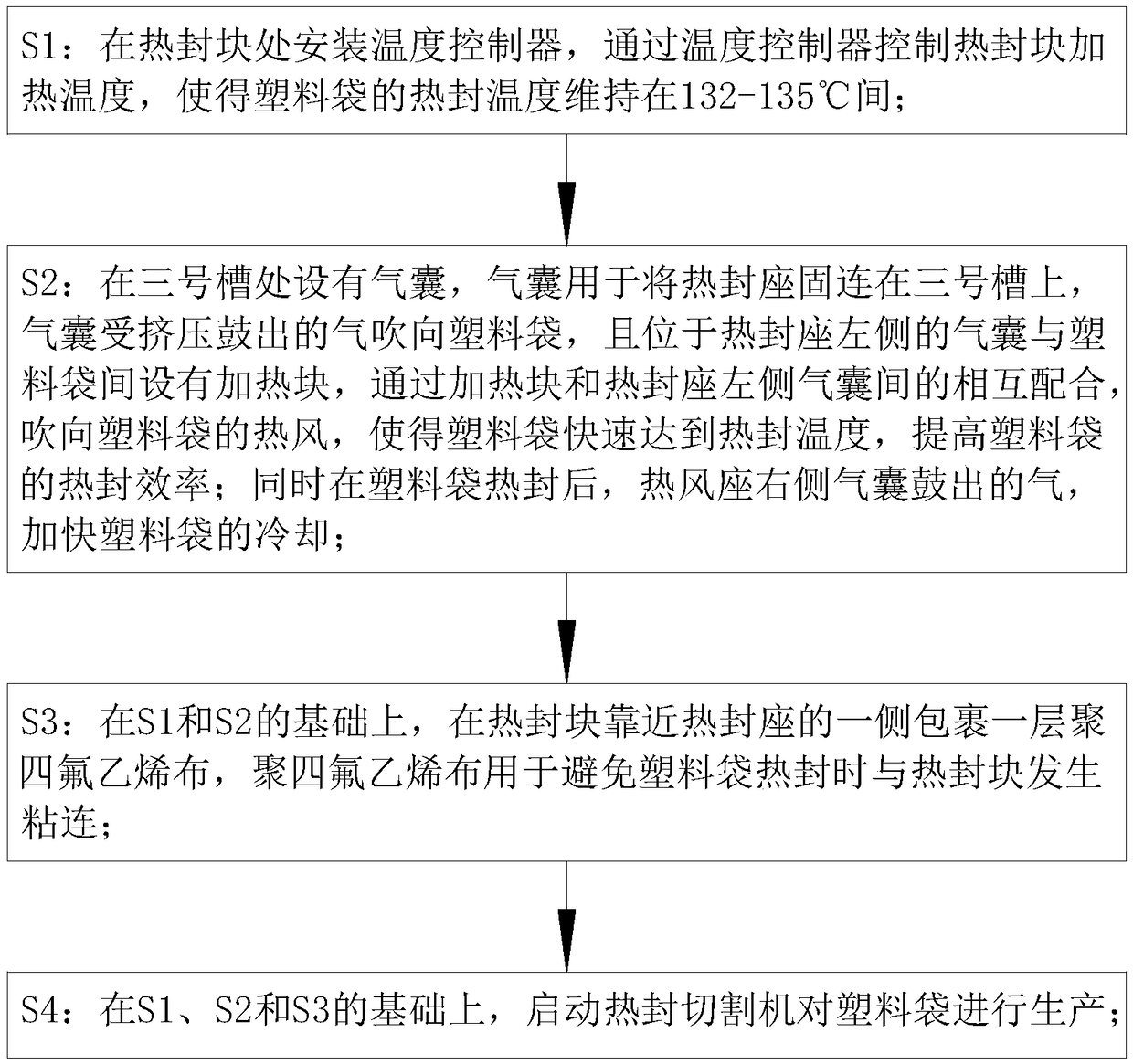

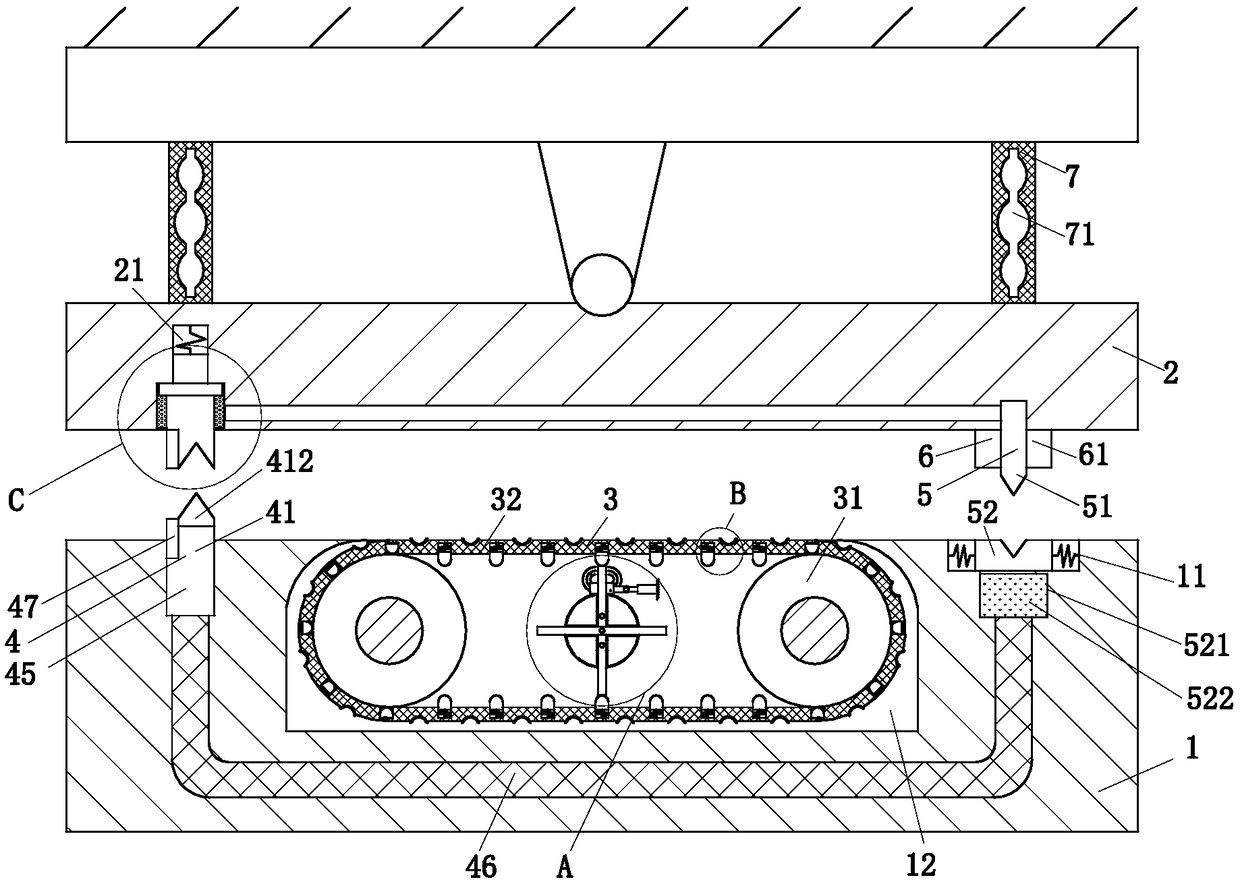

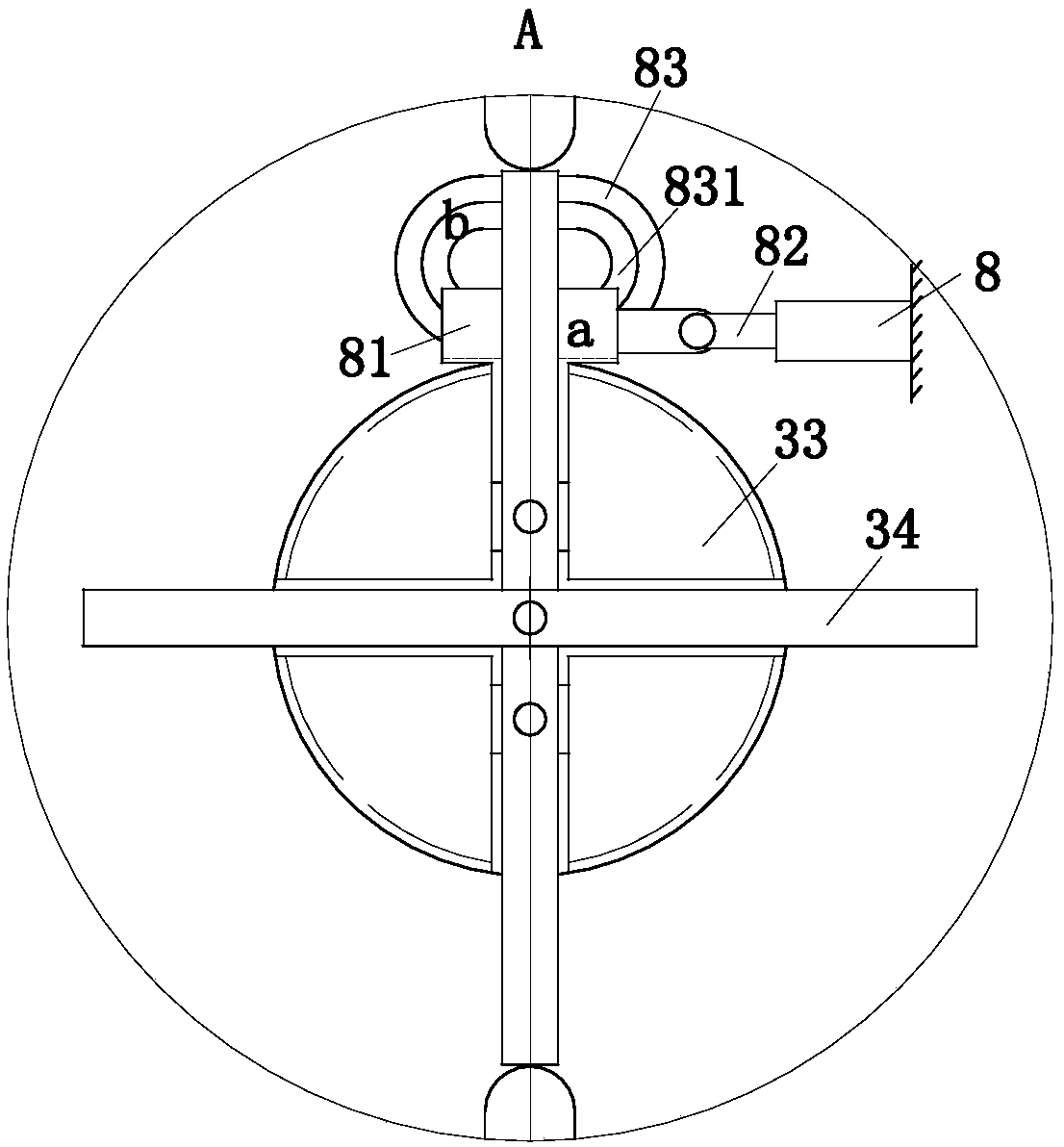

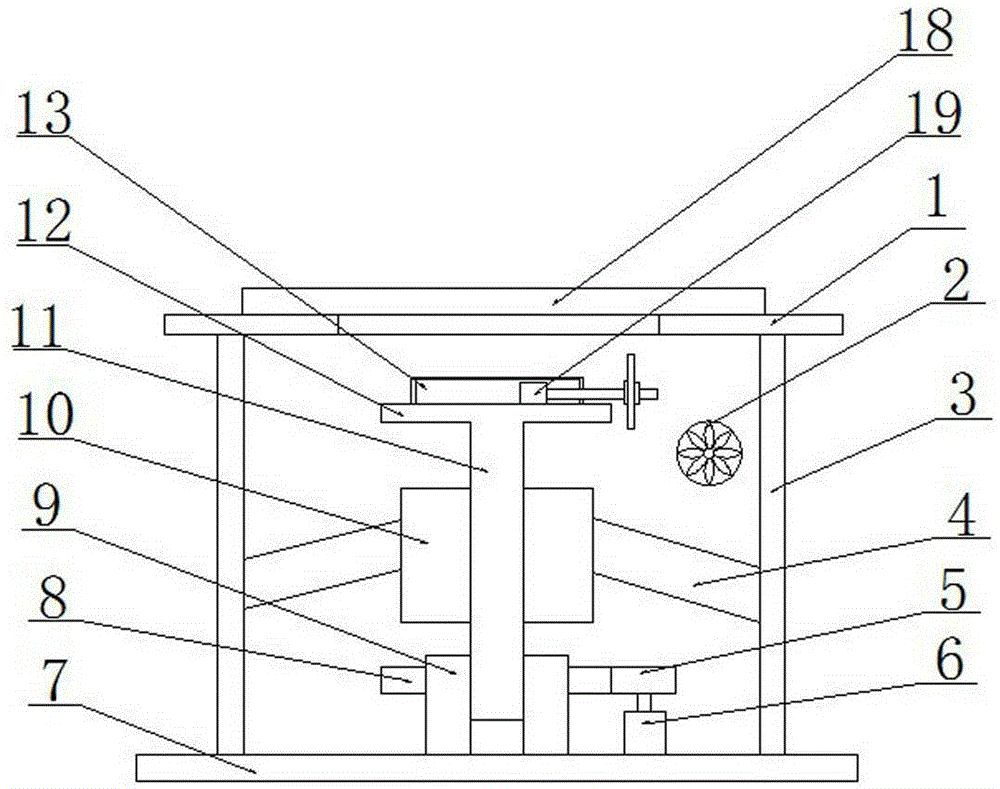

Production technology for plastic bags

PendingCN109177317ARapid coolingIncrease productivityBag making operationsPaper-makingEngineeringPolytetrafluoroethylene

The invention relates to the technical field of plastic bag production, in particular to a production technology for plastic bags. A heat-sealing cutting machine adopted by the production technology comprises a base, a top plate and a top base. The heat-sealing cutting machine further comprises a conveying unit, a cutting unit, a heat-sealing unit, a first driving unit and a controller. Accordingto the production technology for the plastic bags, on the one hand, through cooperation of air bags and a heating block, hot wind is blown to the plastic bags so that heat-sealing temperature of the plastic bags can be reached rapidly; meanwhile, the air bags are utilized to blow air to plastic bags heat-sealed so that the plastic bags heat-sealed can be cooled rapidly, and thus production efficiency of the plastic bags is improved; and on the other hand, a layer of polytetrafluoroethylene fabric is arranged on a heat-sealing block, generation of adhesion of the plastic bags heat-sealed to theheat-sealing block is avoided, and thus the heat-sealing effect of the plastic bags is improved.

Owner:王顺

Sponge cutting machine

InactiveCN105171792AImprove work efficiencyAffect the cutting effectMetal working apparatusEngineeringCircular surface

The invention discloses a sponge cutting machine which comprises a shell. A workbench is arranged on the shell. A circular through groove is formed in the workbench. A rotating cylinder is arranged inside the shell. The lower end of the rotating cylinder is rotatably connected with a bottom plate of the shell. A driven gear is arranged on the outer circular surface of the rotating cylinder. The driven gear is provided with a driving gear matched with the driven gear. The driving gear is provided with a rotating motor. A rotating rod in thread fit with the rotating cylinder is arranged inside the rotating cylinder. A disc is fixedly connected to the upper end of the rotating rod. A supporting shell and a cutting motor inside the supporting shell are arranged on the disc. A rectangular groove is formed in an output shaft of the cutting motor in the axial direction. By means of the sponge cutting machine, the working efficiency can be improved.

Owner:CHENGDU DUOLIDUO NEW MATERIAL

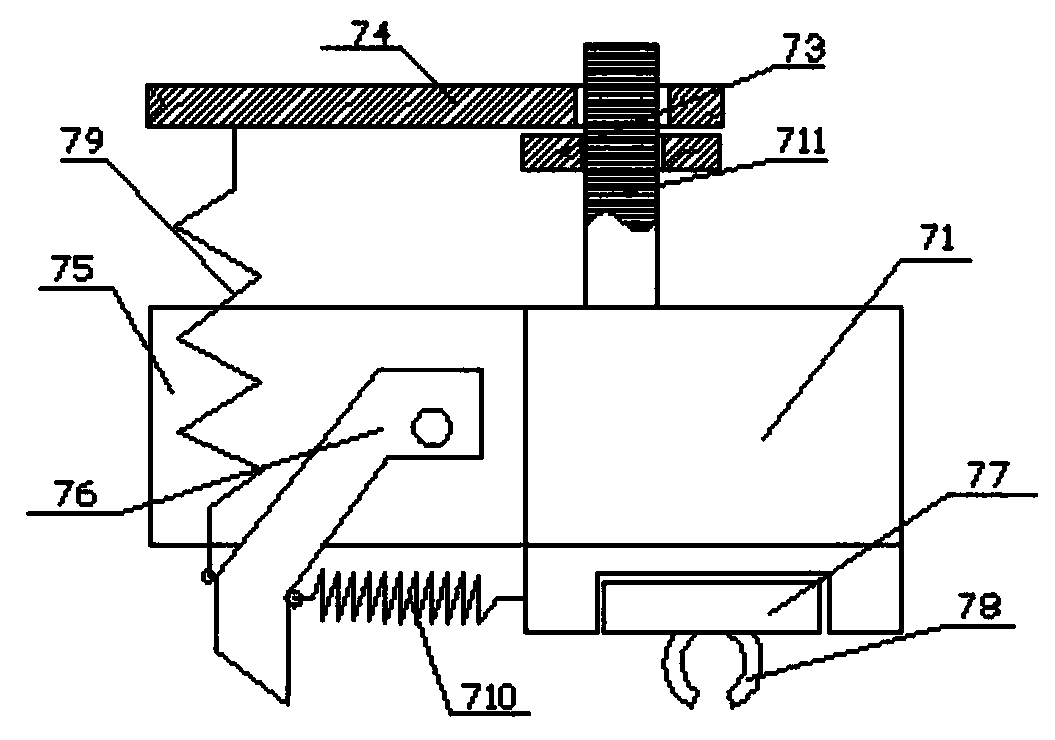

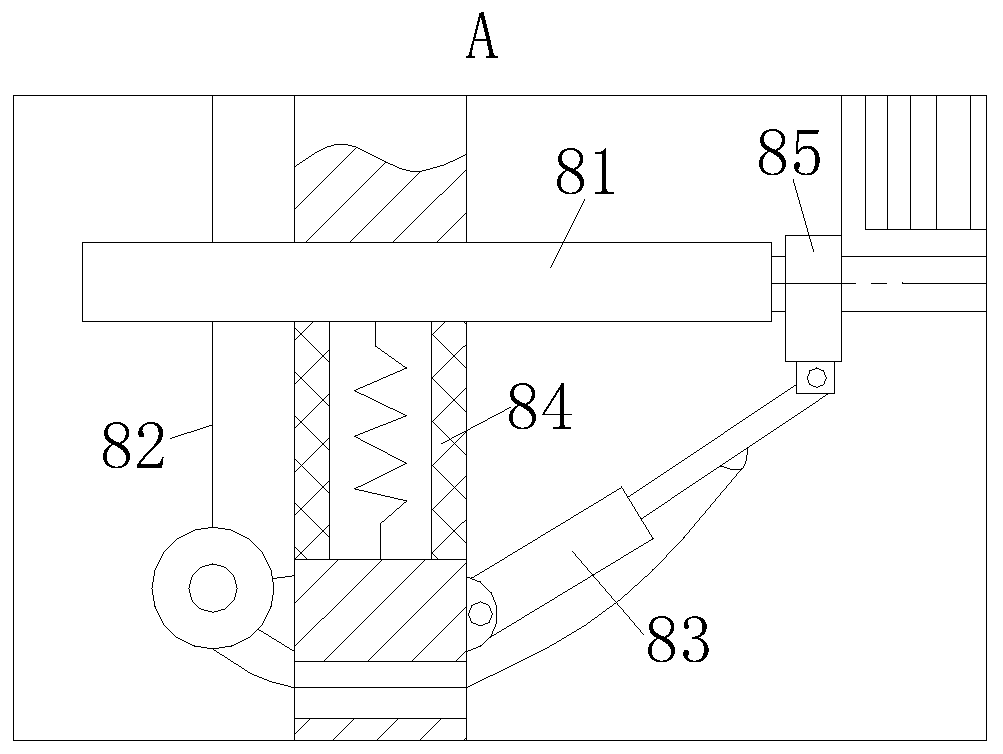

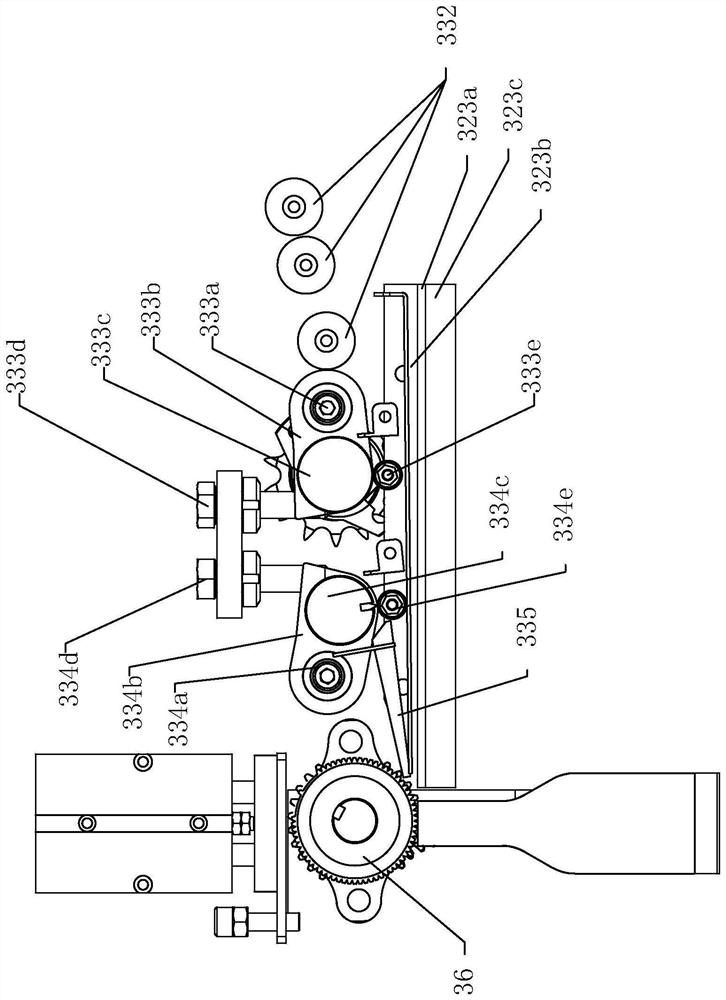

Automatic crimping machine terminal material belt cutting mechanism

InactiveCN112828956ARealize the function of automatic cutting and pushingRealize the limit effectLine/current collector detailsMetal working apparatusStructural engineeringControl room

The invention discloses an automatic crimping machine terminal material belt cutting mechanism. The automatic crimping machine terminal material belt cutting mechanism comprises a damping, moving and fixing integrated mechanism and a waste material pipe, wherein a material belt cutting device body is fixedly arranged at the upper end of the damping, moving and fixing integrated mechanism; a power distribution room is arranged at the outer end of the left side of the material belt cutting device body, and a control chamber is arranged at the outer end of the right side of the material belt cutting device body; electric push rods are fixedly arranged on the upper portions of the two ends of the left side of the material belt cutting device body, and limiting mechanisms are fixedly connected to the front ends of the electric push rods; supporting seats are welded on the outer sides of the upper portions of the two ends of the material belt cutting device body, and dust collectors are fixedly arranged at the upper ends of the supporting seats; dust suction pipes are fixedly connected to the upper ends of the dust collectors; and dust suction covers are arranged at the front ends of the dust suction pipes. According to the automatic crimping machine terminal material belt cutting mechanism, the waste material pipe is automatically cut, and therefore labor force is saved; and meanwhile, the waste material pipe can be limited, therefore the cutting effect is improved, and functionality is greatly improved.

Owner:吉安市联基电子有限公司

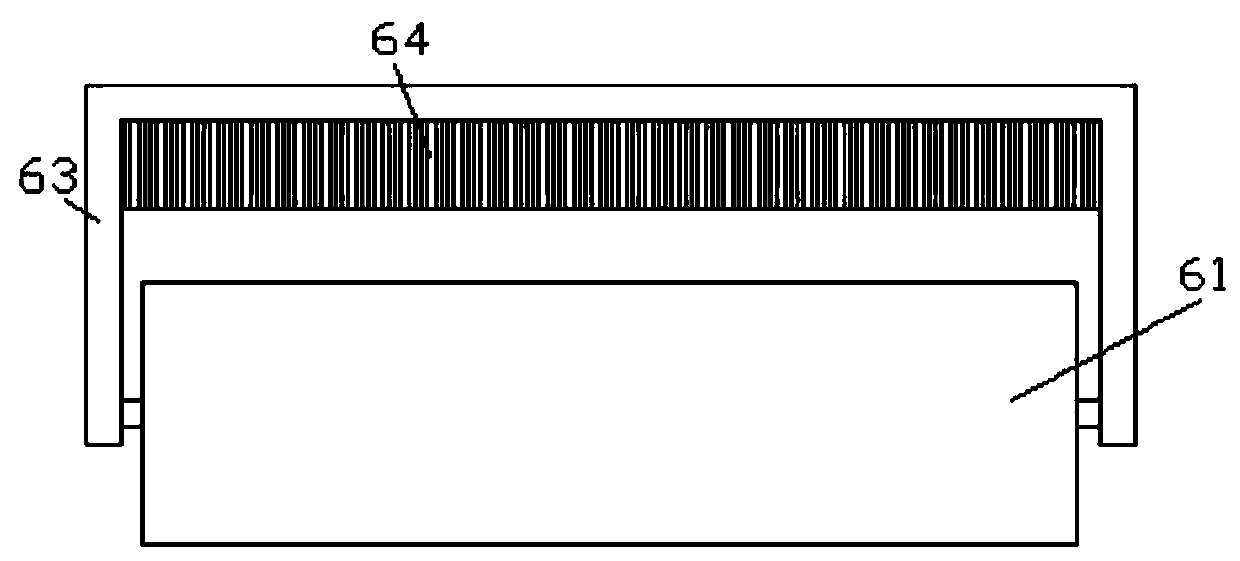

Woven fabric stretching device

InactiveCN111332853AGuaranteed Position AdjustmentGuaranteed angle adjustmentMechanical cleaningPressure cleaningMechanical engineeringWoven fabric

The invention discloses a woven fabric stretching device. The device comprises an unwinding roll, an unfolding roll, a tension roll, a draw off roll, a dedusting rubber roll, a winding roll and a cutting device, wherein the unwinding roll is used for placing woven fabric; the unfolding roll is connected with the unwinding roll through the woven fabric, and the woven fabric is unfolded on the surface of the unfolding roll; the tension roll is connected with the unfolding roll through the woven fabric and used for providing tension force; the draw off roll is connected with the tension roll through the woven fabric and can provide power; the dedusting rubber roll is connected with the draw off roll through the woven fabric and used for deburring the woven fabric; the winding roll is connected with the dedusting rubber roll through the woven fabric and used for accommodating the woven fabric; and the cutting device is used for cutting the woven fabric. According to the woven fabric stretching device, the problem in cleaning of the woven fabric is solved.

Owner:安徽省冠盛纺织科技有限公司

Office paper shredder with self-cleaning function

ActiveCN111992306AWith self-cleaning functionAffect the cutting effectCleaning using toolsCleaning using liquidsFiberReciprocating motion

The invention relates to the technical field of paper shredders, and discloses an office paper shredder with a self-cleaning function. The office paper shredder comprises a shredding shaft, wherein the outer side wall of the shredding shaft is fixedly connected with shredding blades, and one side of the shredding shaft is provided with a fixed seat; and the interior of the fixed seat is slidably connected with a transmission rack, one end of the transmission rack is fixedly connected with a transverse moving rod, and the outer side wall of the transmission rack is engaged with arc-shaped gears. The transverse moving rod drives the transmission rack to reciprocate, the transmission rack drives hinge rods on the arc-shaped gears to swing left and right, then the hinge rods drive semicircularplates on supporting seats to swing left and right, and brushes on the semicircular plates make contact with the shredding blades and rub against the shredding blades, so that paper fibers adhering to the shredding blades are brushed off, the purpose of automatic cleaning is achieved, and then the phenomenon that paper files are not completely cut due to the fact that the cutting effect of the blades is affected when the paper fibers are stacked to a certain degree is effectively avoided.

Owner:梁山兴园商贸有限公司

Electromechanical integration distance-adjusting cutting device

InactiveCN111086054AEasy to operate and controlAffect the cutting effectMetal working apparatusControl systemClassical mechanics

The invention relates to the field of cutting, and particularly relates to an electromechanical integration distance-adjusting cutting device. By arranging an X coordinate adjusting mechanism and an Xcoordinate plate, under the action of a servo motor, a first screw rod is driven to rotate, so that a thread drives a first sliding block to move in a first chute, a gantry plate moves accordingly, and the X coordinate position directly opposite to the cutting mechanism is adjusted and controlled; and by arranging a Y coordinate adjusting mechanism and a Y coordinate plate, a second screw is driven to rotate under the action of a small deceleration servo motor, so that a thread drives a second sliding block to move in a second chute, a mounting plate moves accordingly, the Y coordinate position directly opposite to the cutting mechanism is adjusted and controlled, and the precise position of cutting is determined accordingly. According to the electromechanical integration distance-adjusting cutting device, by arranging a control console with a PLC control system and a display operating system, the control console is used to display the coordinate starting point of the cutting mechanism in real time, and the operation and control of an operator are facilitated; and by arranging a fixing hole, a connecting hole and a fixing rod, the installation and replacement of a cutting knife are facilitated.

Owner:JIAXING NANYANG POLYTECHNIC INST

Aluminium section bar cutting device

ActiveCN109604730ARealize longitudinal segment cuttingAchieve horizontal cuttingLarge fixed membersMetal working apparatusEngineeringMechanical engineering

The invention belongs to the technical field of aluminium section bar producing and processing, and specifically discloses an aluminium section bar cutting device. The aluminium section bar cutting device comprises a base plate, wherein a first slide slot is formed in the surface of the base plate; a supporting module is perpendicularly arranged on the surface of the base plate; the supporting module comprises a first slide block, a fixed column and a slide rod; the first slide rod is in sliding connection to the first slide slot; the first slide slot is of a long-strip-shaped structure; the first slide slot is used for enabling the first slide block to slide front and back on the surface of the base plate; the top surface of the first slide block is perpendicularly equipped with the fixedcolumn; and the first slide block is welded with the fixed column for reinforcing stability of the fixed column. The aluminium section bar cutting device can freely regulate the angle of a cutter disc, meets cutting needs of section bars of various shapes, and is wide in range of application; and a first charge module and a second charge module can automatically convey section bars forwards, so that cutting is more convenient and precise, the section bars can be limited, and the section bars can be prevented from being fiercely shaken to affect the cutting effect.

Owner:佛山市成昌晖五金制品有限公司

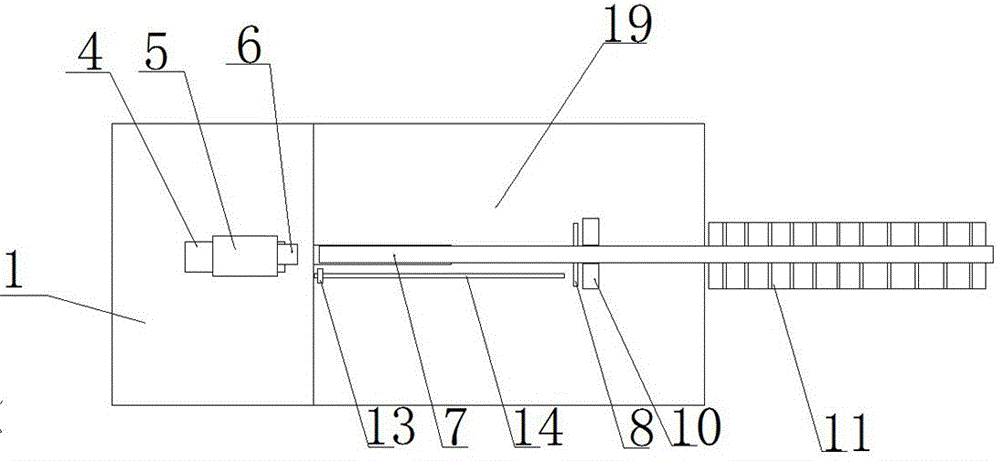

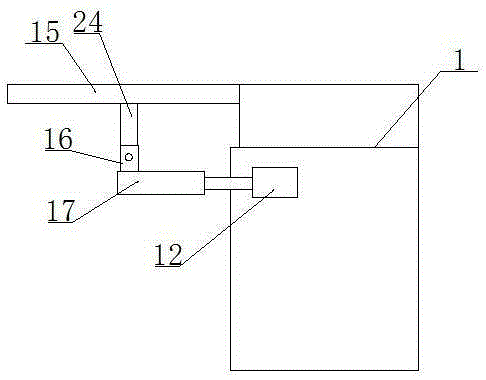

Pipe cutting machine capable of grinding edge while sucking dust

InactiveCN105234793AEasy piercingImprove work efficiencyEdge grinding machinesGrinding drivesDrive shaftEngineering

The invention discloses a pipe cutting machine capable of grinding an edge while sucking dust. The pipe cutting machine comprises a machine body work surface. The machine body work surface comprises a machine body edge grinding surface and a machine body cutting surface higher than the machine body edge grinding surface. A supporting seat is arranged on the machine body edge grinding surface in a sliding mode and provided with a motor. An output shaft of the motor is connected with a sphere body, and abrasive materials are arranged on the outer surface of the sphere body. A fixing seat is arranged on the machine body edge grinding surface and provided with a rotary motor, and an output shaft of the rotary motor is connected with a gear. The gear is provided with a rack matched with the gear, and one end of the rack is connected with the supporting seat. An air cylinder is arranged on the lateral surface of a machine body, and an output shaft of the air cylinder is connected with a strip-shaped tooth. The strip-shaped tooth is provided with a roller tooth engaged with the strip-shaped tooth, and the roller tooth is provided with a transmission shaft driving a rotary plate to overturn. The pipe cutting machine capable of grinding the edge while sucking dust can improve work efficiency.

Owner:卢道东

Aluminum alloy door and window production process

ActiveCN109798047ARealize longitudinal segment cuttingAchieve horizontal cuttingWing framesGlass pane fixingContact positionAluminium alloy

The invention relates to the technical field of door and window processing, in particular to an aluminum alloy door and window production process. The process includes steps: S1, cutting a strip-shaped aluminum sectional material into aluminum strips by a cutting machine; S2, fastening the aluminum strips cut in the S1 by screws and glue to form an aluminum frame, wherein one side is not mounted;S3, mounting glass on the aluminum frame, and mounting the rest of aluminum strips; S4, sealing glass and aluminum alloy contact positions in S3 by glue. The aluminum alloy door and window productionprocess has advantages that the angle of a cutter disc can be freely adjusted to meet cutting requirements of sectional materials in various shapes, so that a wide application range is realized; by afirst feeding module and a second feeding module, the sectional material can be conveyed forward automatically, and accordingly convenience and accuracy in cutting are achieved, and influences on cutting effects due to violet shaking of the sectional material are avoided by limiting of the sectional material.

Owner:湖北联投新材料开发有限公司

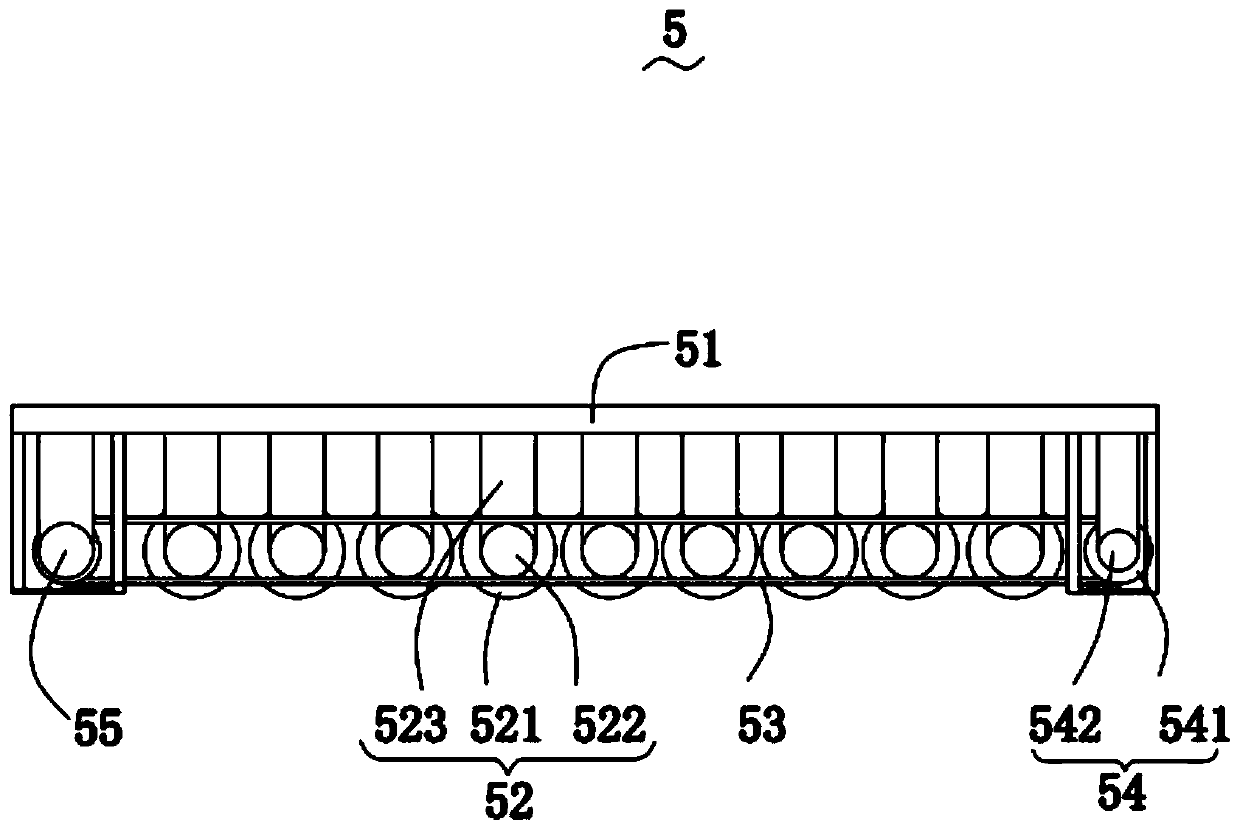

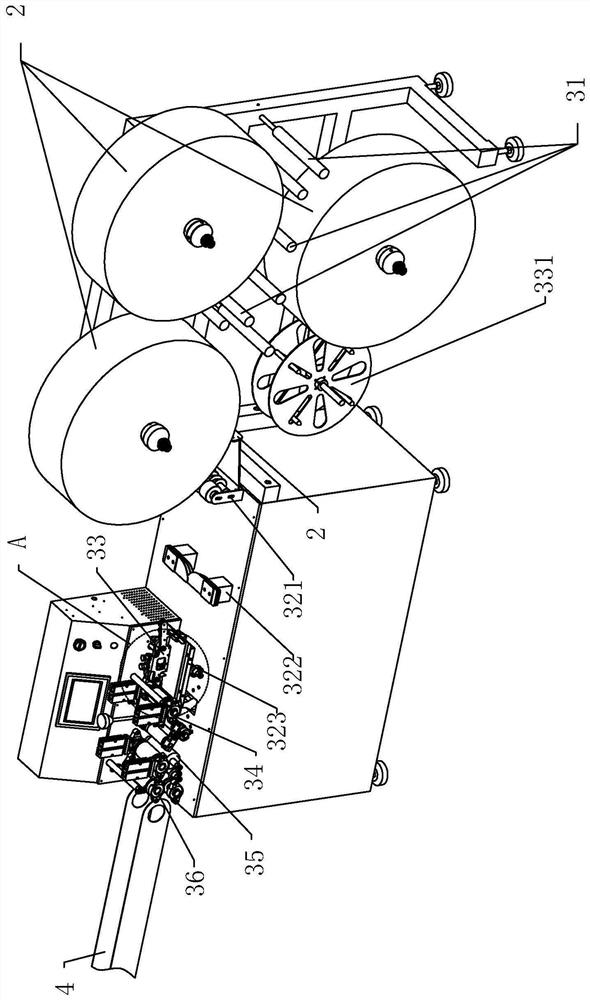

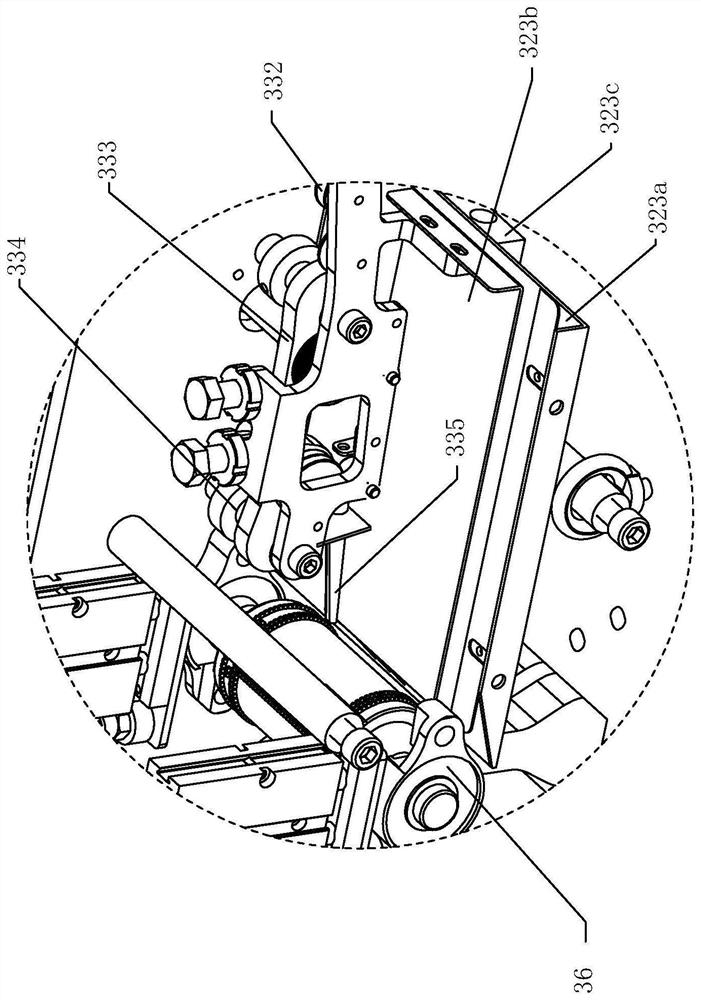

Mask forming machine

ActiveCN112223770APrecise positioningHigh conveying precisionSevering textilesHeating/cooling textile fabricsMolding machineStructural engineering

The invention relates to mask production equipment, in particular to a mask forming machine which comprises a rack, a non-woven fabric unwinding device, a forming device and an output device. The non-woven fabric unwinding device, the forming device and the output device are arranged on the rack; the forming device comprises a first guide assembly, a folding assembly, a nose bridge strip adding assembly, a composite roller assembly, a second guide assembly and a slitting assembly; the folding assembly comprises an indentation roller, a folding frame and a shaping mechanism; the nose bridge strip adding assembly comprises a nose bridge strip unwinding roller, a nose bridge strip guide roller assembly, a nose bridge strip conveying assembly, a nose bridge strip cutter assembly and a nose bridge strip guide pipe; the length of the nose bridge strip guide pipe is smaller than the length of a cut nose bridge strip; the composite roller assembly comprises a composite roller, a welding head and an ultrasonic generator; and the slitting assembly comprises an upper slitting roller and a bottom slitting roller. Non-woven fabric and the nose bridge strip can be conveyed to the forming deviceat the same time, so that the production efficiency is improved.

Owner:泉州外星人智能科技有限公司

Cutting and crushing device for junked tires

PendingCN110843156AAccelerate tire shredding rate and screening rateImprove crushing recovery efficiencyPlastic recyclingMechanical material recoveryStructural engineeringMechanical engineering

The invention provides a cutting and crushing device for junked tires, and belongs to the technical field of tires. The cutting and crushing device comprises feeding chambers and a crushing chamber. The inner bottom of each feeding chamber is connected with a cutting machine. The upper portion of the right side of the outer portion of each feeding chamber is movably connected with a moving plate.A supporting plate is fixedly arranged on the outer portion of each feeding chamber. The upper portion of each supporting plate is fixedly connected with a conveying belt. The two ends of the inner side of each conveying belt are movably connected with electromotors. The outer portion of the bottom of each electromotor is fixedly connected with a base. According to the device, the feeding chambersare sealed through the moving plates, and the situation that tires overflow when cut in the feeding chambers, and the tire cutting effect is influenced is avoided; crushing wheels are cooled throughfans, meanwhile, tire residues clamped on crushing teeth of the crushing wheels are blown down, and the situation that the crushing effect is influenced by residues is avoided; the tires are further crushed through crushing rods, the crushed tires fall into a storage barrel through leaking holes in the bottom and the side face of a crushing barrel, the crushing barrel is driven by a rotating discto rotate, and the tire crushing rate and screening rate are improved; and the crushing and recovery efficiency of the device is improved.

Owner:江西维美亚轮胎有限公司

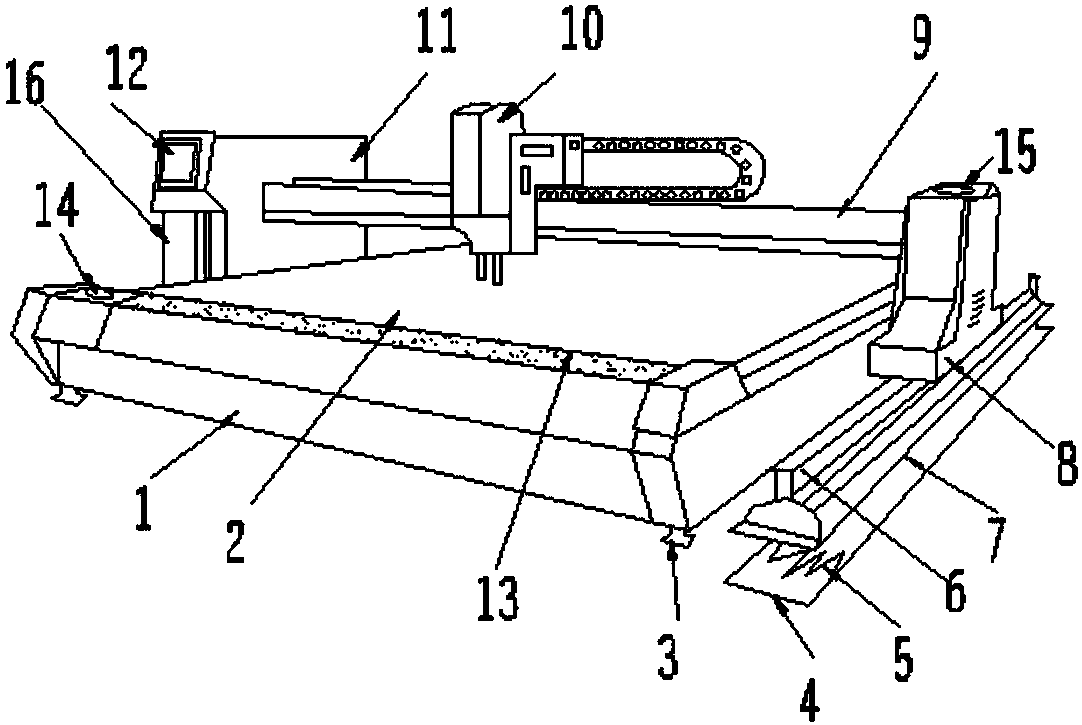

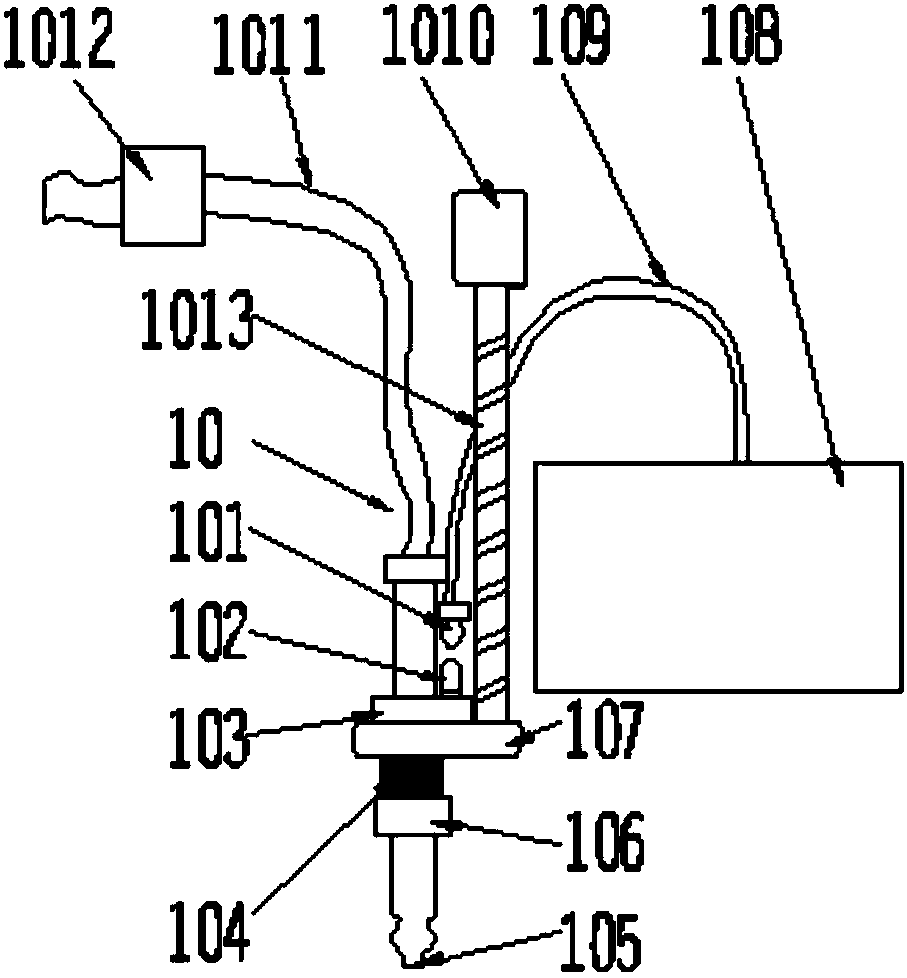

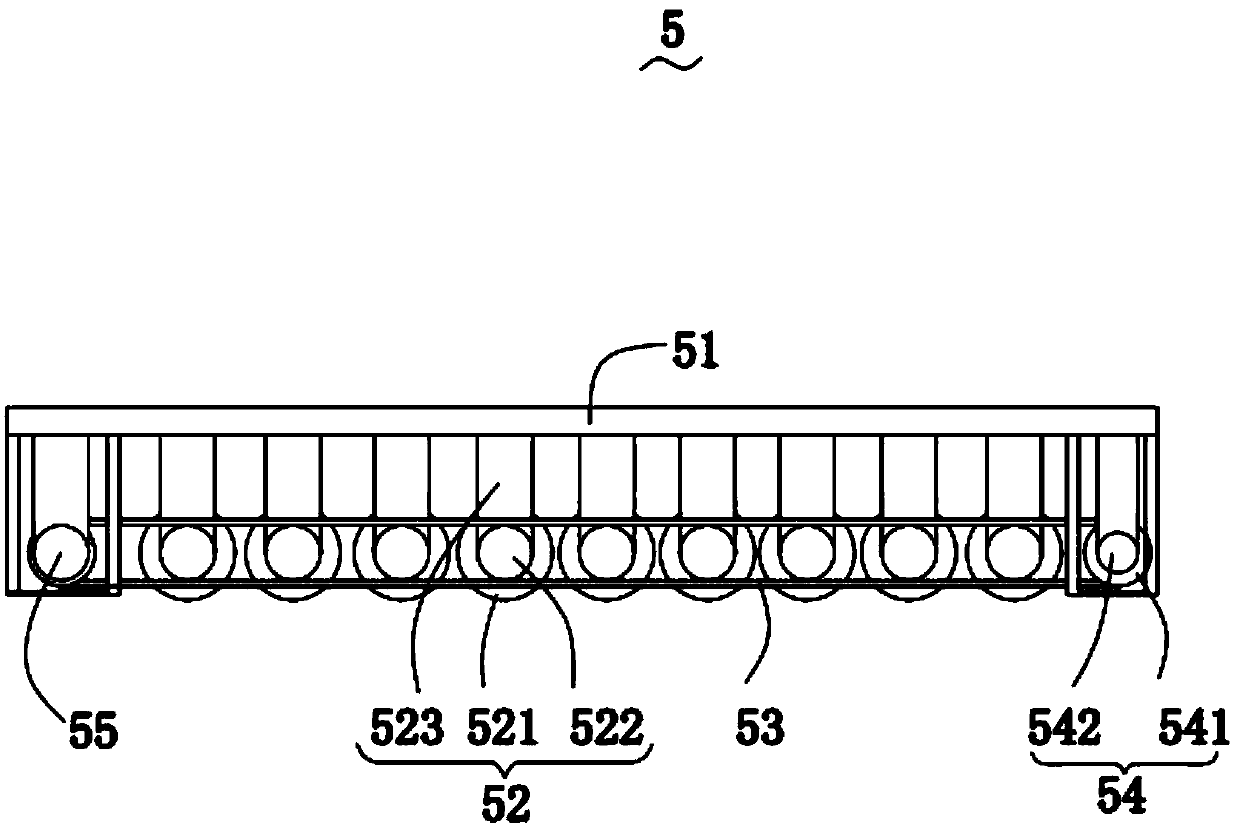

Novel plate laser cutting machine

ActiveCN112975175ACutting effectEasy to collectWelding/cutting auxillary devicesAuxillary welding devicesLaser cuttingMechanical engineering

The invention relates to a cutting machine, in particular to a novel plate laser cutting machine. The novel plate laser cutting machine aims to achieve the technical effects that automatic moving cutting is achieved, and plates are convenient to fix and take for use. The novel plate laser cutting machine comprises a rack; a feeding assembly which is mounted on the rack; a cutting assembly which is mounted on the feeding assembly; and a pushing assembly which is mounted between the feeding assembly and the cutting assembly. According to the novel plate laser cutting machine, the pushing assembly is arranged, so that cut plates can be pushed out of a discharging opening, and then workers can conveniently take out the cut plates; and a supporting assembly is arranged, so that the situation that cutting of the plates is affected due to midway falling of the plates during cutting can be effectively prevented.

Owner:赣州市恒邦金属制品有限公司

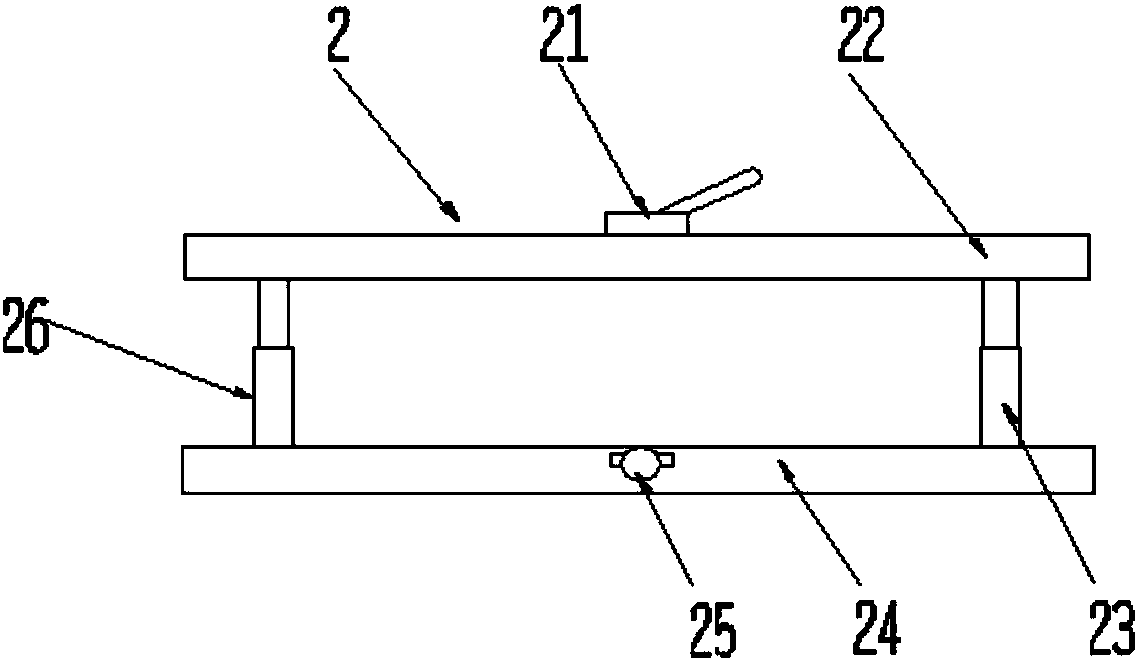

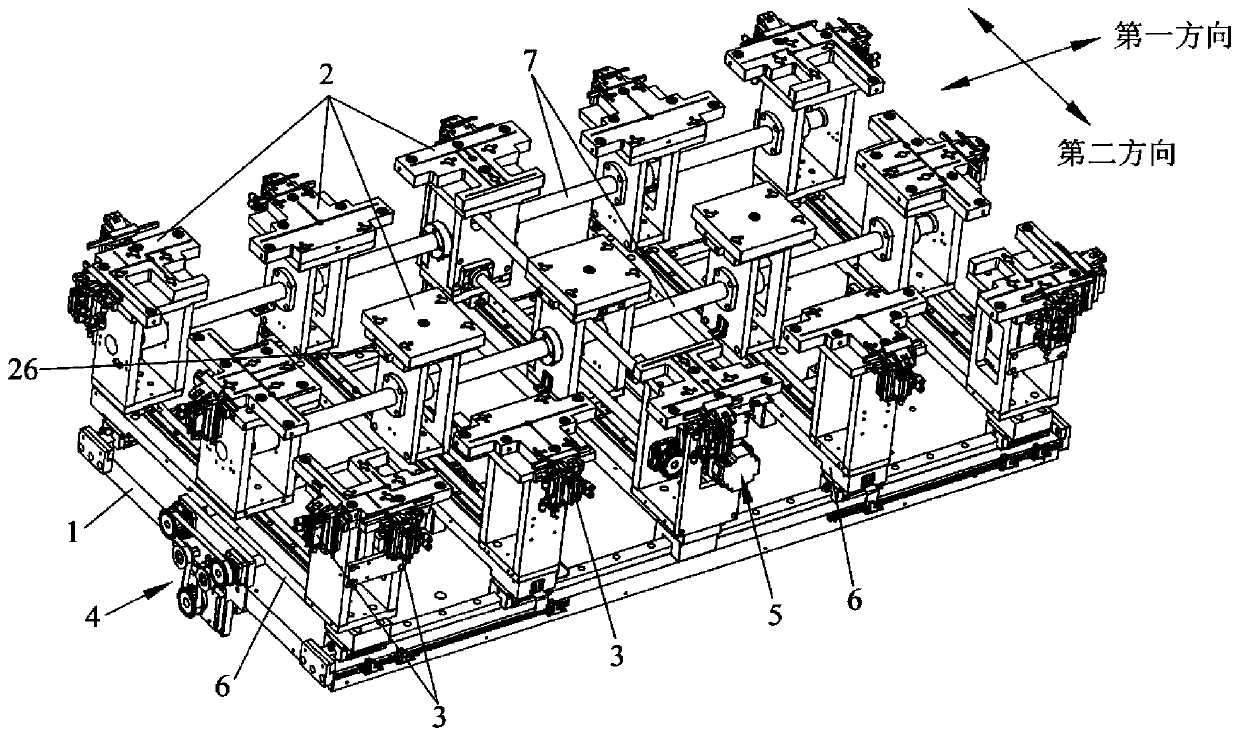

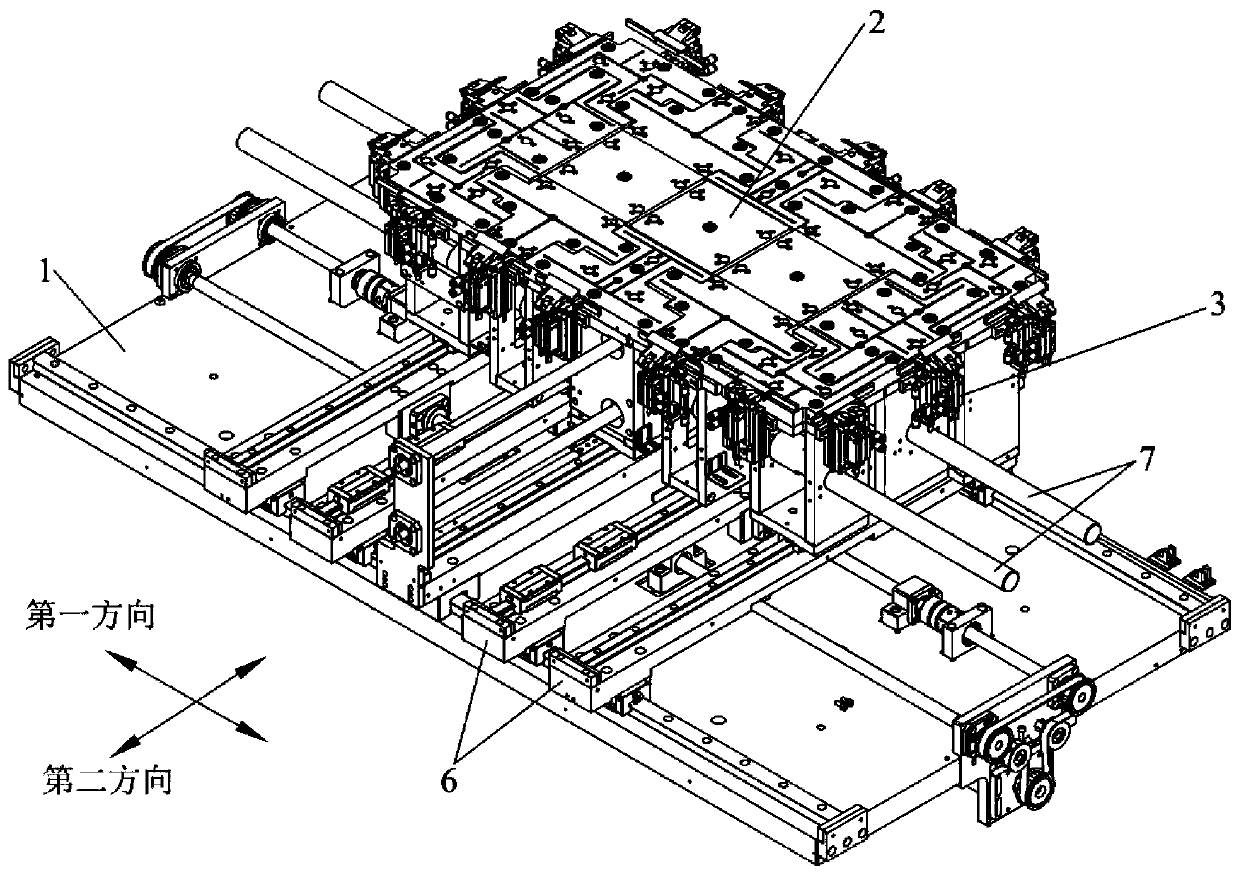

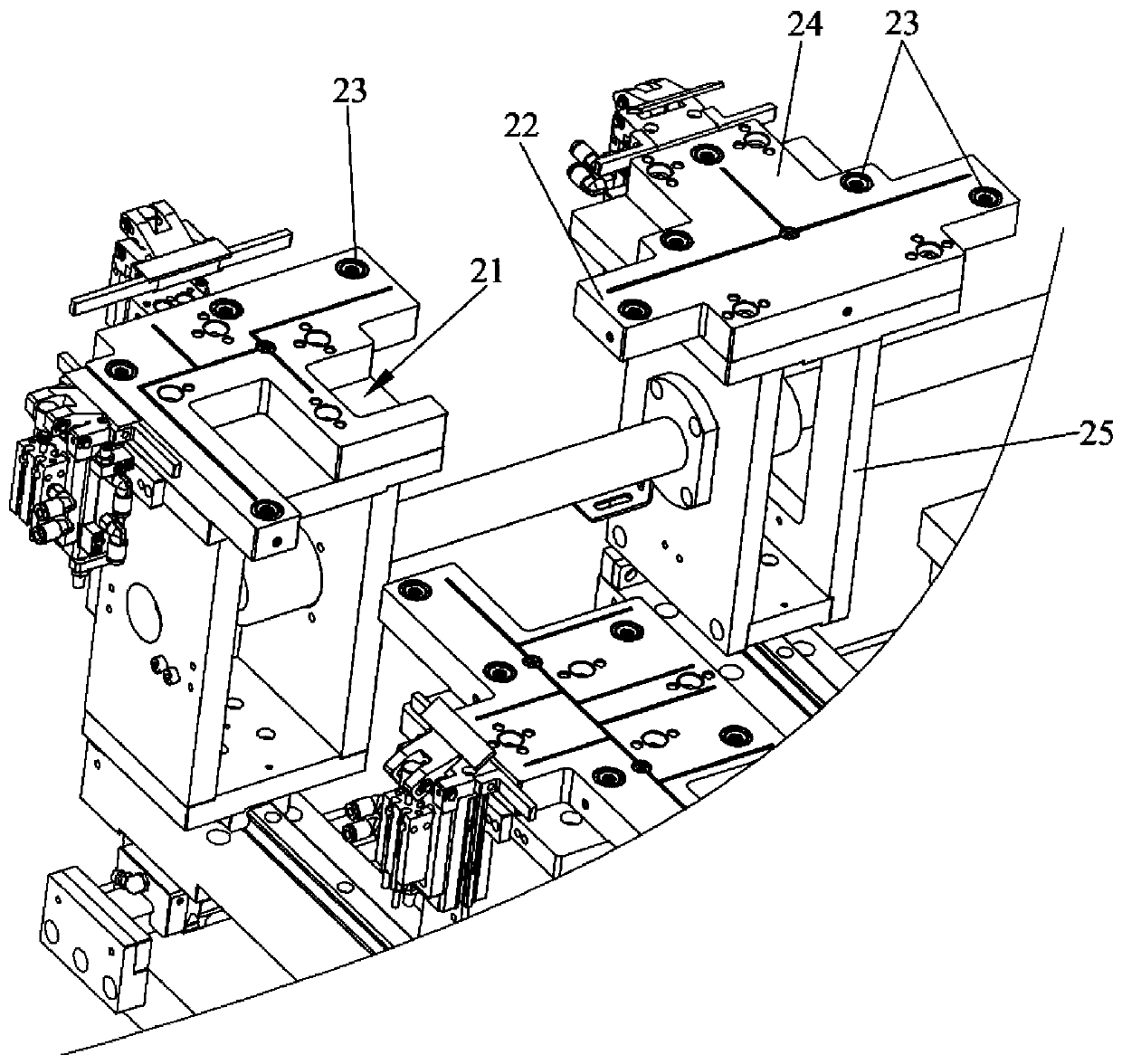

Cutting platform and cutting device

ActiveCN110789004AAvoid cutsAvoid affecting the cutting effectWorking accessoriesStone-like material working toolsStructural engineeringMechanical engineering

The invention relates to the technical field of cutting devices, and discloses a cutting platform and a cutting device. The cutting platform comprises a base and carrying tables. The carrying tables are arranged on the base in rectangular arrays to form a bearing plane. The bearing plane is used for bearing a workpiece. The carrying tables can get close to each other or away from each other so asto adjust the size of the bearing plane. According to the cutting platform, the size of the bearing plane composed of the carrying tables can be adjusted according to the size of the workpiece, when the workpiece is placed on the bearing plane, the edge of the workpiece can be located outside the edge of the bearing plane, the distance between the edge of the workpiece and the edge of the bearingplane cannot be too long, and therefore it is easily avoided that cutting damage happens to the cutting tables when the distance between the edge of the workpiece and the edge of the bearing plane istoo short or the workpiece is prone to drooping and the cutting effect is influenced when the distance between the edge of the workpiece and the edge of the bearing plane is too long.

Owner:苏州科韵激光科技有限公司

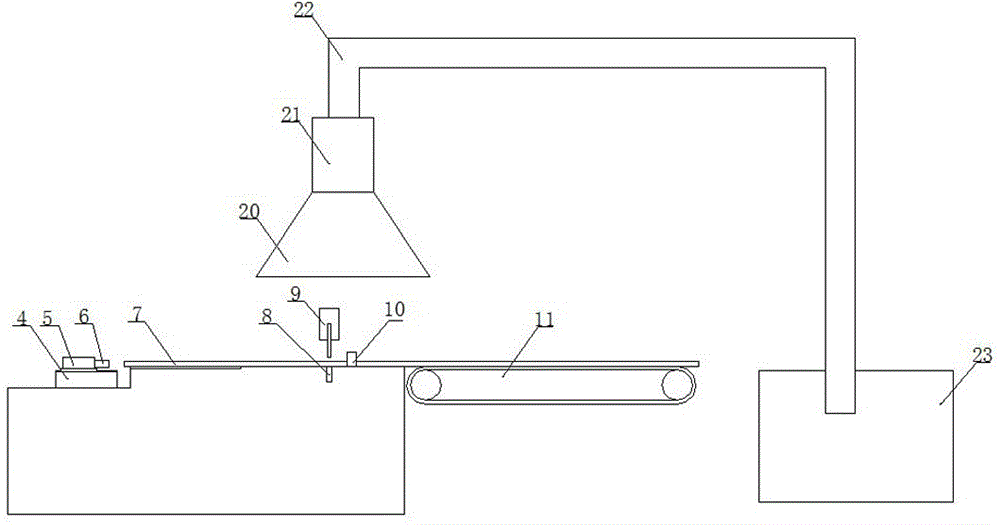

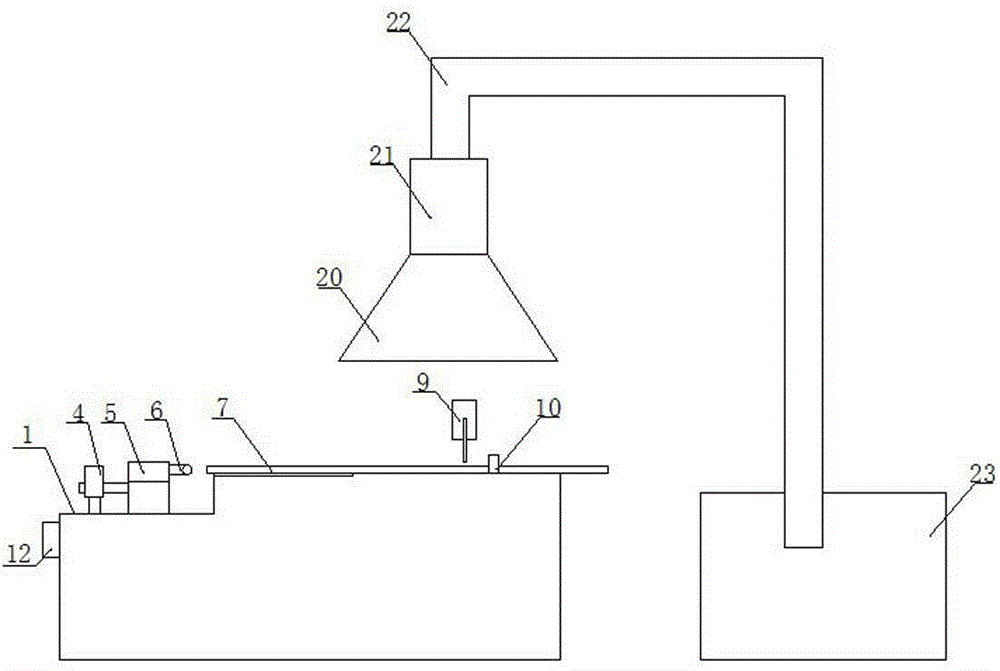

Board cutting machine with movable saw cutter

InactiveCN107282991AAvoid offsetImprove cutting efficiencyMetal sawing devicesMaintainance and safety accessoriesEngineeringMechanical engineering

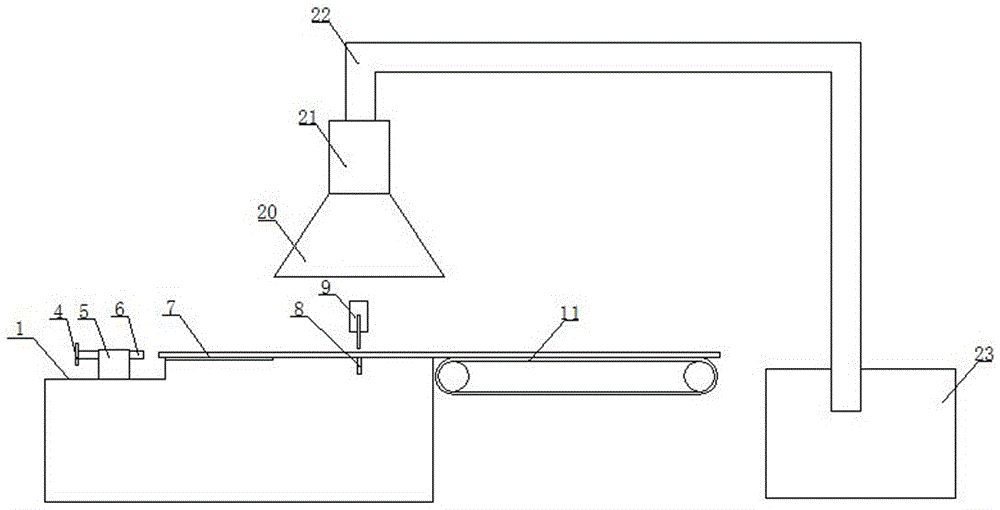

The invention relates to the technical field of cutting machines, in particular to a board cutting machine with a movable saw blade, which includes a machine body, on which a fixed platform is arranged, on which a metering plate, a fixed plate, and a movable supporting device are arranged. It is equipped with a movable saw blade and equipped with a knife groove. At the same time, a fan and a suction cover are arranged above the working surface of the machine body. The joint action of each link can effectively ensure the cutting accuracy and cutting efficiency, and reduce the occurrence of defective products.

Owner:XINDU MAJIAZHEN XINYUE MACHINERY FACTORY

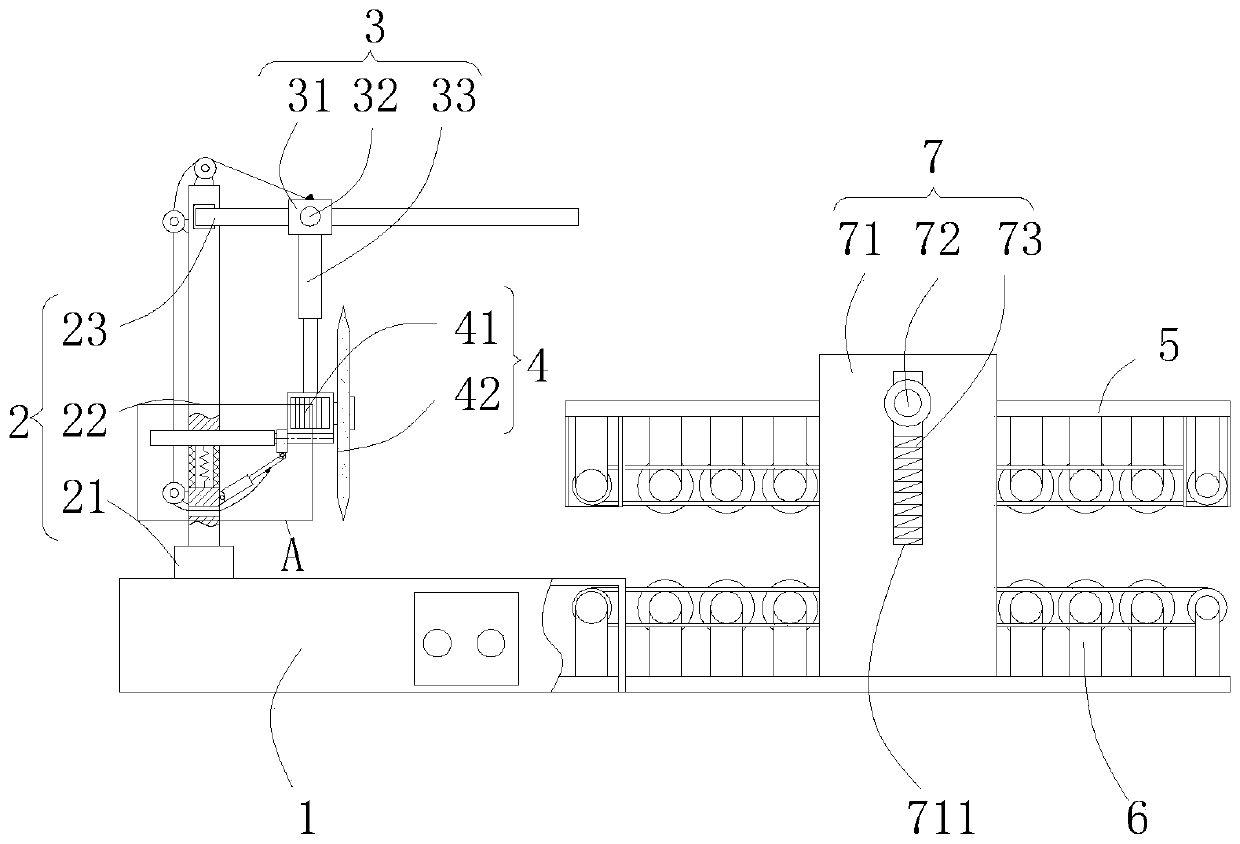

Circular pipe automatic cutting machine

PendingCN109571114AImprove cutting effectCause damageLarge fixed membersPositioning apparatusEngineeringUltimate tensile strength

The invention discloses a circular pipe automatic cutting machine which comprises a rack, a workpiece bearing mechanism arranged on the rack, a host transmission system arranged at one end of the workpiece bearing mechanism, an automatic pipe inlet system arranged at the other end of the workpiece bearing mechanism and a knife holder control device arranged on the workpiece bearing mechanism; oneend of the workpiece bearing mechanism is further provided with an electric cabinet; the electric cabinet is arranged below the host transmission system; and the host transmission system can drive theworkpiece bearing mechanism to rotate. The circular pipe automatic cutting machine is reasonable in structure layout, simple in mounting and operation and convenient and practical in processing, realizes cutting automatic pipe inlet, weakens the operation intensity, reduces the cutting period time, improves the efficiency, reduces material waste and ensures the quality of a part due to accurate size of the cut part and thus achieves the purpose of efficient, accurate and safe cutting processing.

Owner:浙江益森久城环保设备有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com