Electromechanical integration distance-adjusting cutting device

A cutting device and distance adjustment technology, applied in metal processing and other directions, can solve the problems of inconvenient cutting position, inability to precisely locate the cutting position, etc., and achieve the effect of easy operation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

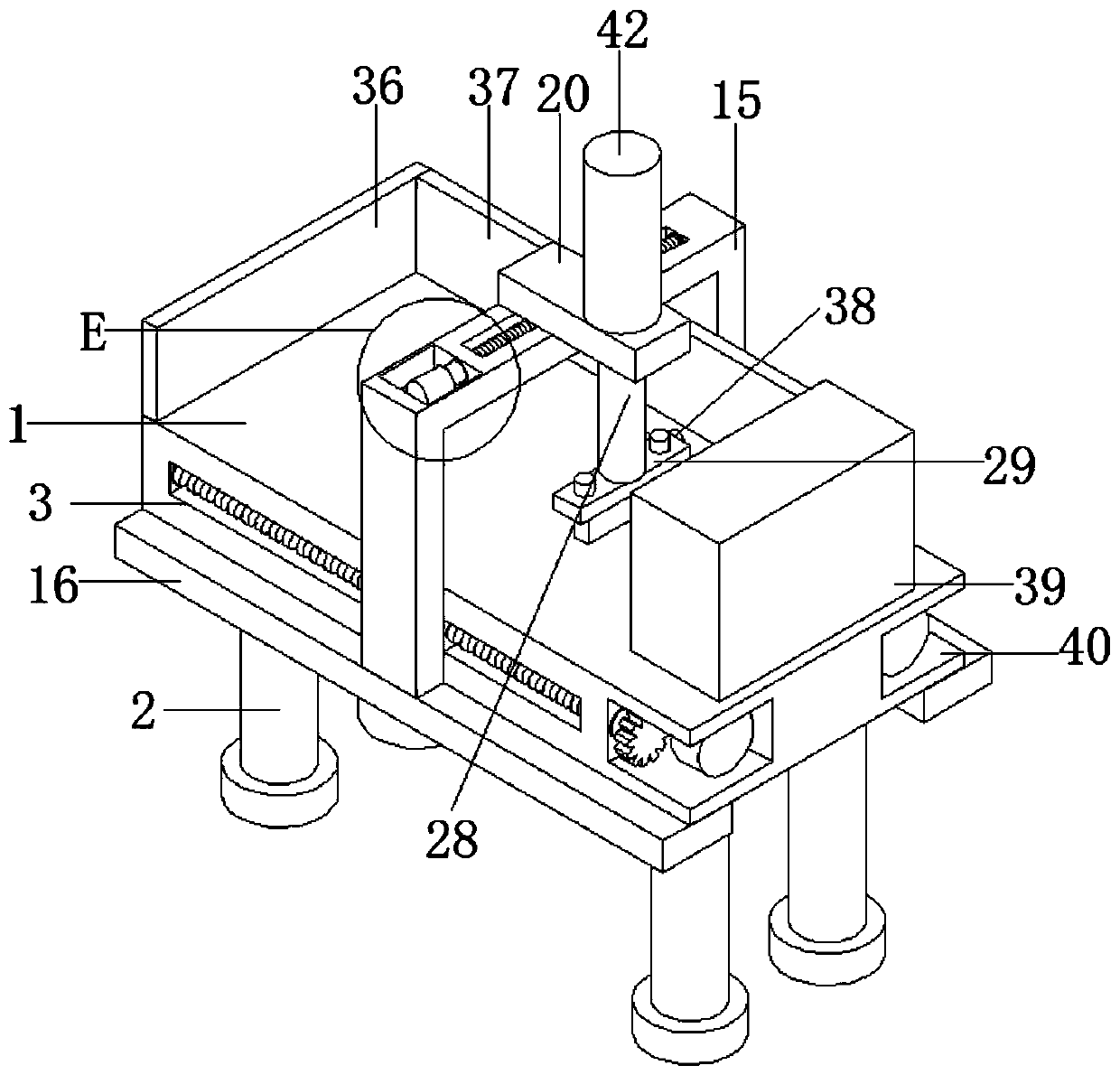

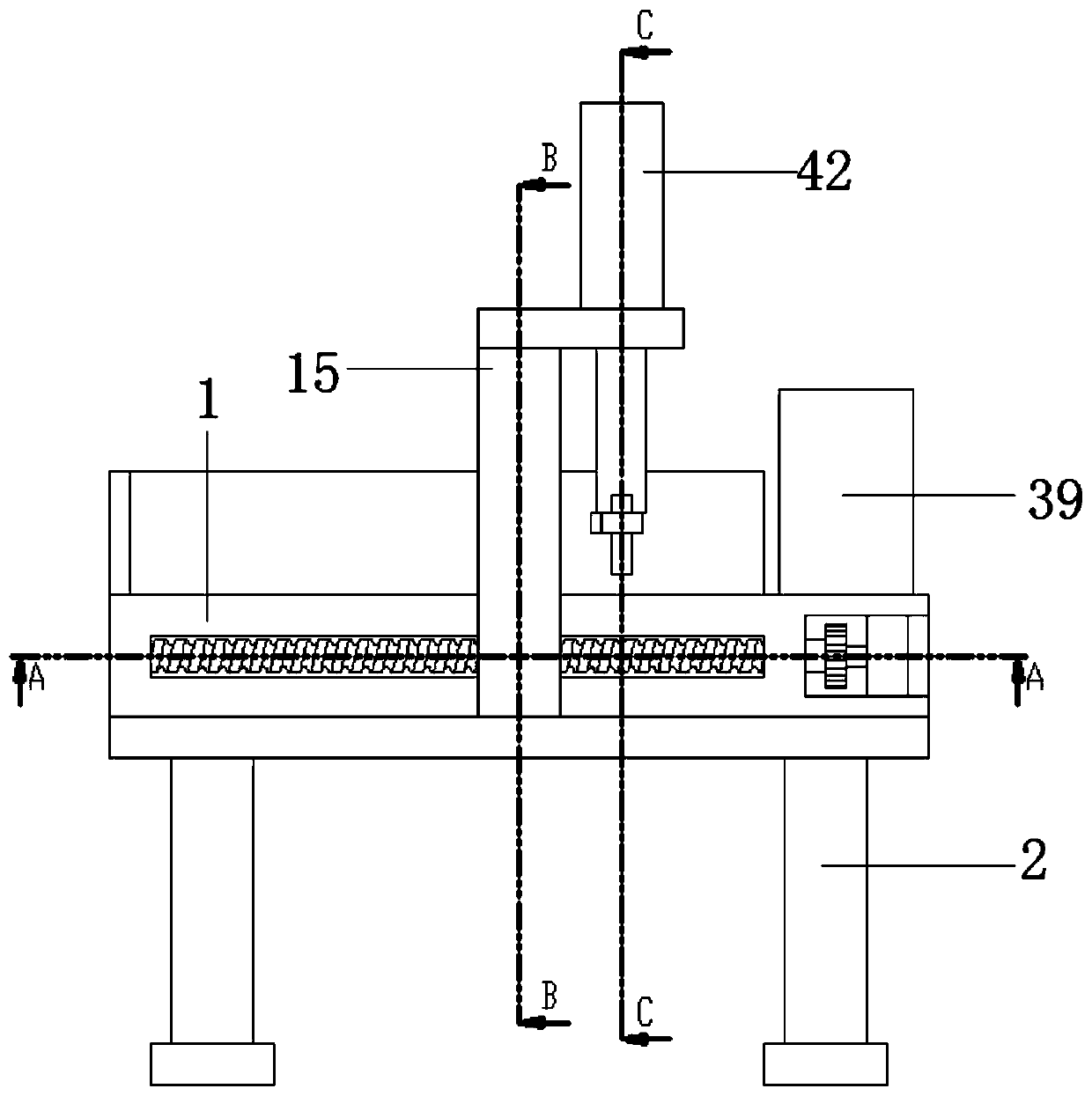

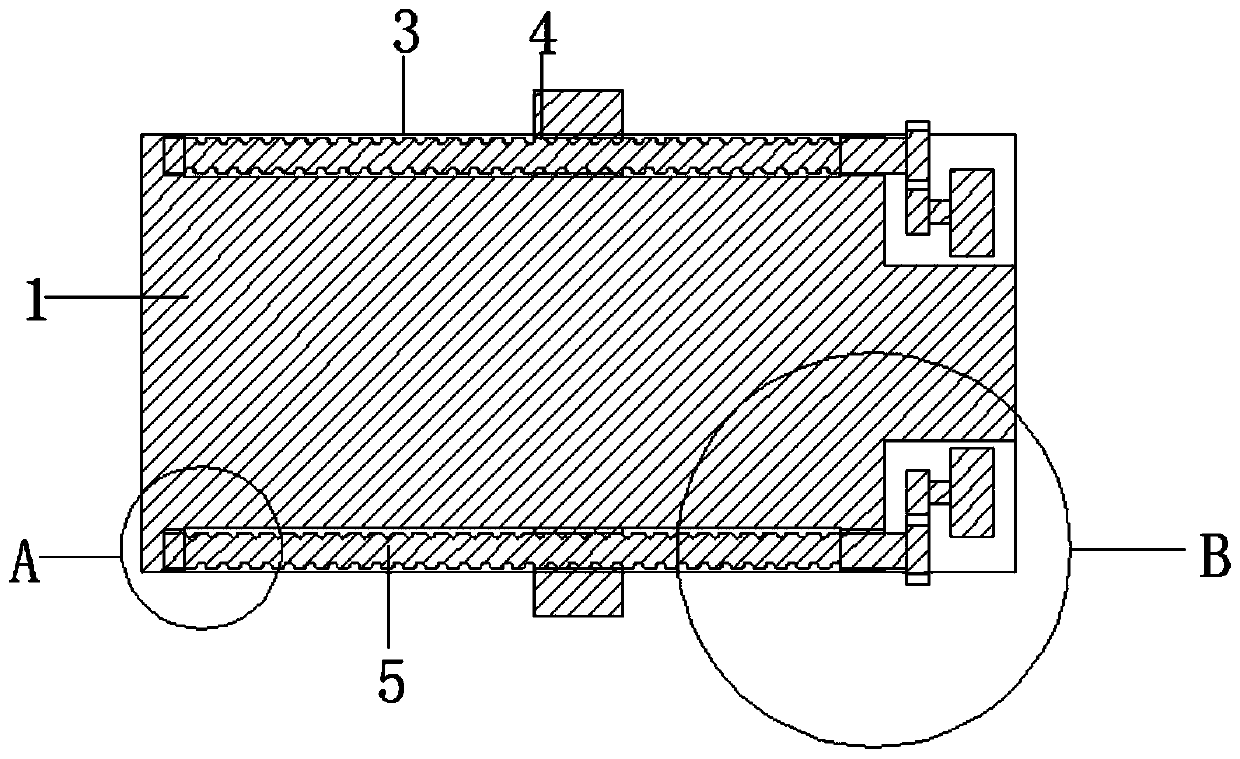

[0034] Such as Figure 1-10 As shown, a mechatronic distance-adjustable cutting device includes a worktable 1, a Y coordinate plate 36 and an X coordinate plate 37 are respectively fixed on the left edge and rear edge of the top end of the workbench 1, and the bottom end of the workbench 1 is fixed There are four sets of support legs 2, which are symmetrically arranged at the four corners of the bottom of the worktable 1 at equal intervals. The bottom of the support legs 2 is fixed with an anti-skid plate, and the front and rear sides of the workbench 1 are symmetrically provided with first chute 3. The length of the first chute 3 is greater than half of the length of the workbench 1 and the left end of the first chute 3 is close to the front left edge of the workbench 1, the right end of the first chute 3 exceeds the center of the front side of the workbench 1, and the workbench 1 There are two groups of first installation grooves 40 symmetrically opened on the right side, th...

Embodiment 2

[0037] Embodiment 2 is a further improvement on Embodiment 1.

[0038] Such as figure 1 , Figure 4 , Figure 5 , Figure 7 , Figure 8 and Figure 11 As shown, the front and rear edges of the bottom end of the workbench plate 1 are symmetrically fixedly welded with a support plate 16, the bottom end of the gantry plate 15 is in contact with the support plate 16, and the rear side of the support plate 16 is fixedly welded to the surface wall of the support leg 2; The length is equal to the length of the first chute 3, the length of the first connecting bearing 7, the depth of the first hidden groove 6 and the length of the first connecting rod 8 are the same, the depth of the first through groove 9 is the same as the length of the first rotating bearing 10 Same, the length of the first rotating rod 11 is slightly greater than the depth of the first through groove 9; The length of the second screw rod 19 is equal to the length of the second chute 17, the length of the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com