Automatic feeding pipe cutter

A technology of automatic feeding and pipe cutting machine, which is applied in the direction of metal processing machinery parts, other manufacturing equipment/tools, maintenance and safety accessories, etc. It can solve the problems of wasting manpower and reducing work efficiency, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

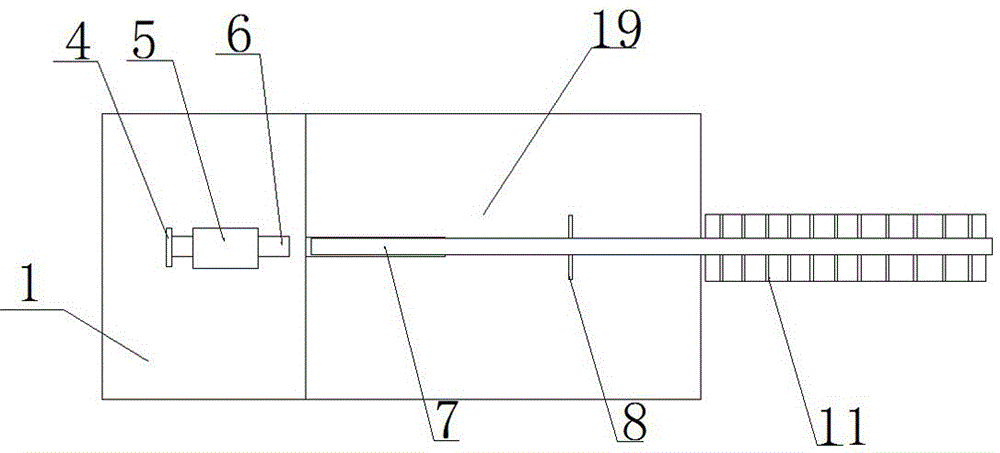

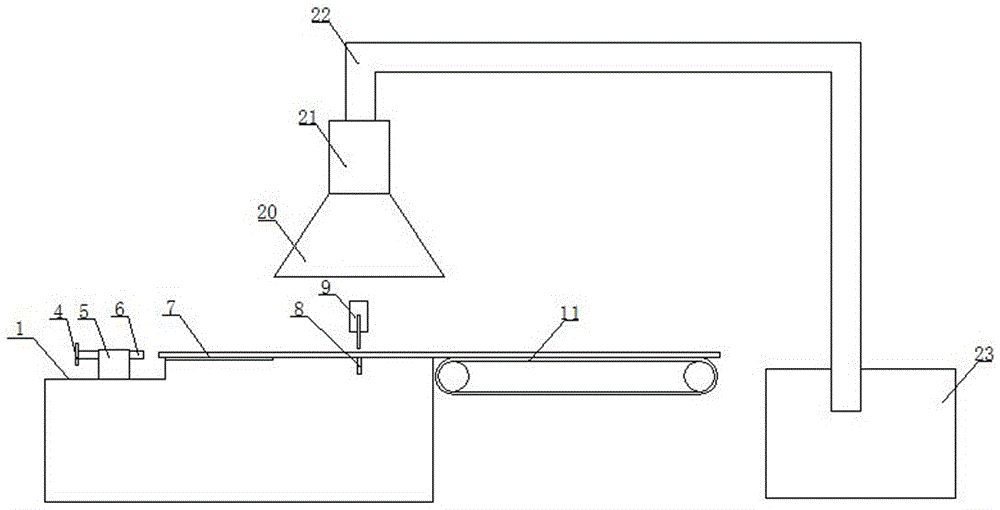

[0014] Figure 1-2 Shown is an automatic feeding pipe cutting machine provided by the present invention, including: body edging surface 1, rotating handle 4, fixed block 5, cylinder 6, steel pipe 7, cutting groove 8, cutting device 9, feeding Conveyor belt 11 and body cutting surface 19. The working surface of the body includes a body edging surface 1 and a body cutting surface 19 higher than the body edging surface 1; the body edging surface 1 is provided with a fixed block 5, and the fixed block 5 is provided with a threaded through hole through which the thread passes. A cylinder 6 is installed in the hole, and one end of the cylinder 6 is provided with a rotating handle 4, and the inner wall of the other end of the cylinder 6 is provided with abrasive materials; the cutting surface 19 of the body is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com