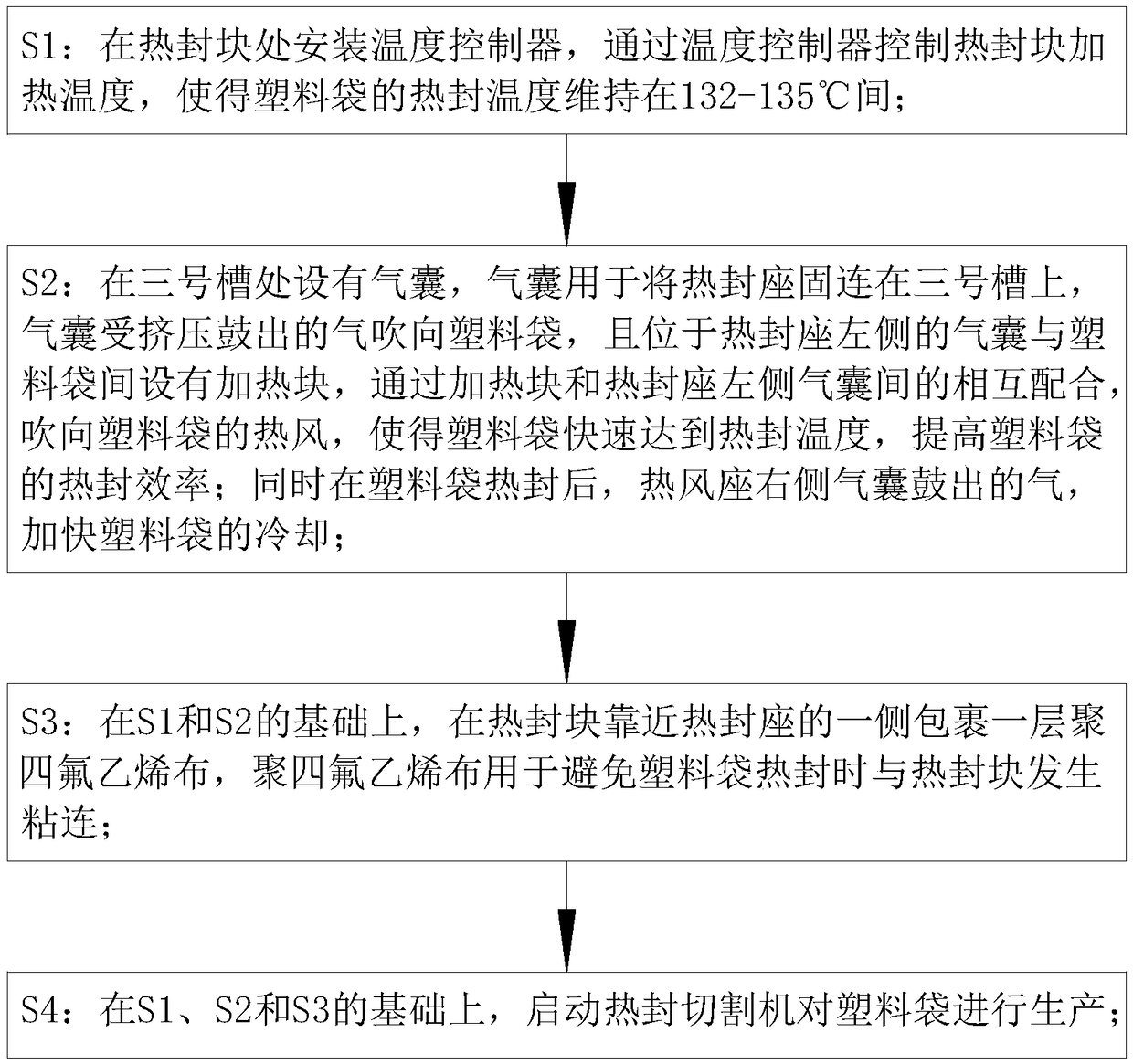

Production technology for plastic bags

A production process and plastic bag technology, applied in the field of plastic bag production, can solve the problems of heat-sealing plastic bag heat-sealing parts sticking, plastic bag heat-sealing efficiency is low, etc., to improve service life, improve heat-sealing cutting efficiency, improve heat The effect of sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

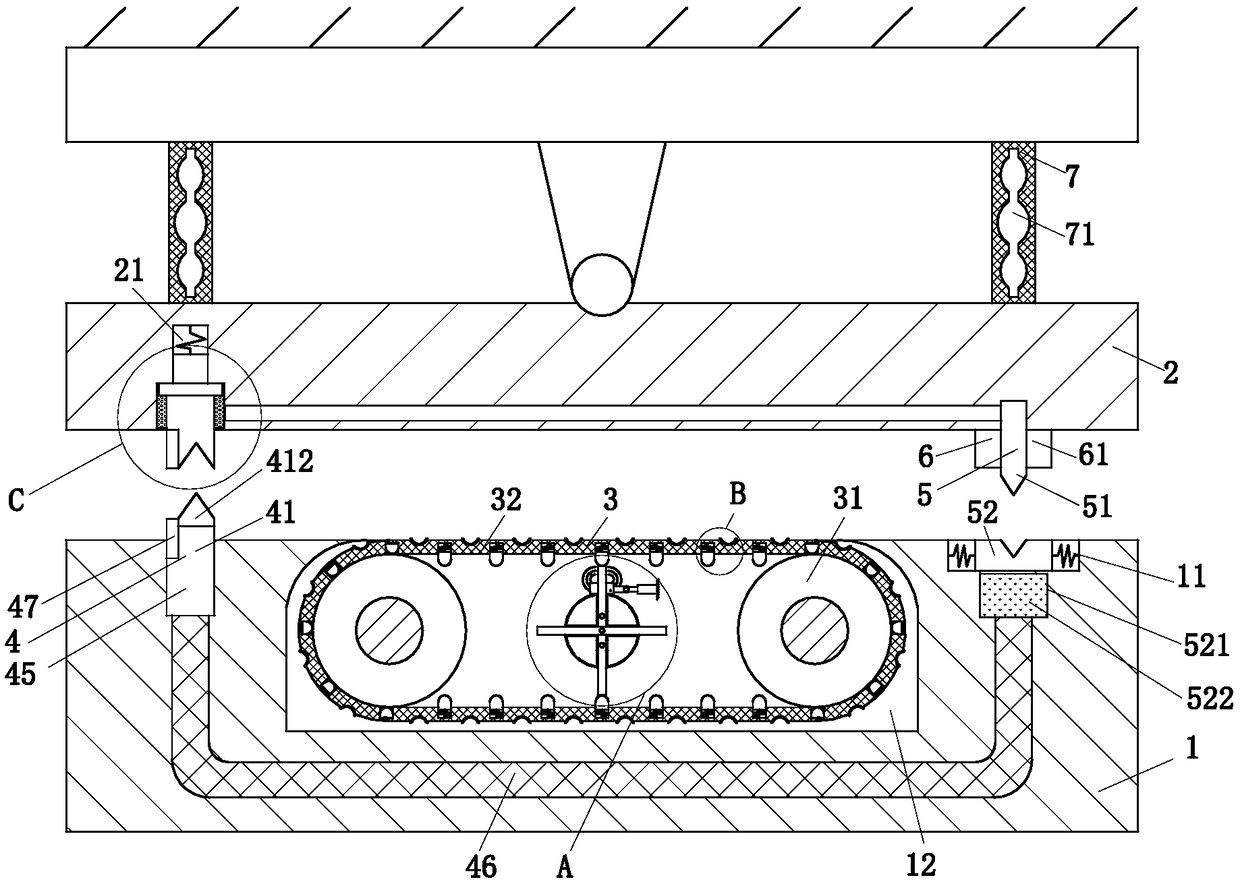

[0041] As an embodiment of the present invention, the No. 1 driving unit 6 is an electromagnet 61, and the electromagnet 61 is fixedly connected to the outer ring of the heat sealing block 51; the heat sealing seat 52 is made of magnetic material, and the electromagnetic When the iron 61 is energized, a suction force is generated between the electromagnet 61 and the heat-sealing block 51 . In the present invention, the No. 1 drive unit 6 is set as an electromagnet 61, and the heat sealing seat 52 is made of magnetic material, and the right side of the top plate 2 moves downward through the suction force between the electromagnet 61 and the heat sealing seat 52, thereby reducing additional power. source, thereby improving the practicability of the heat sealing cutting machine.

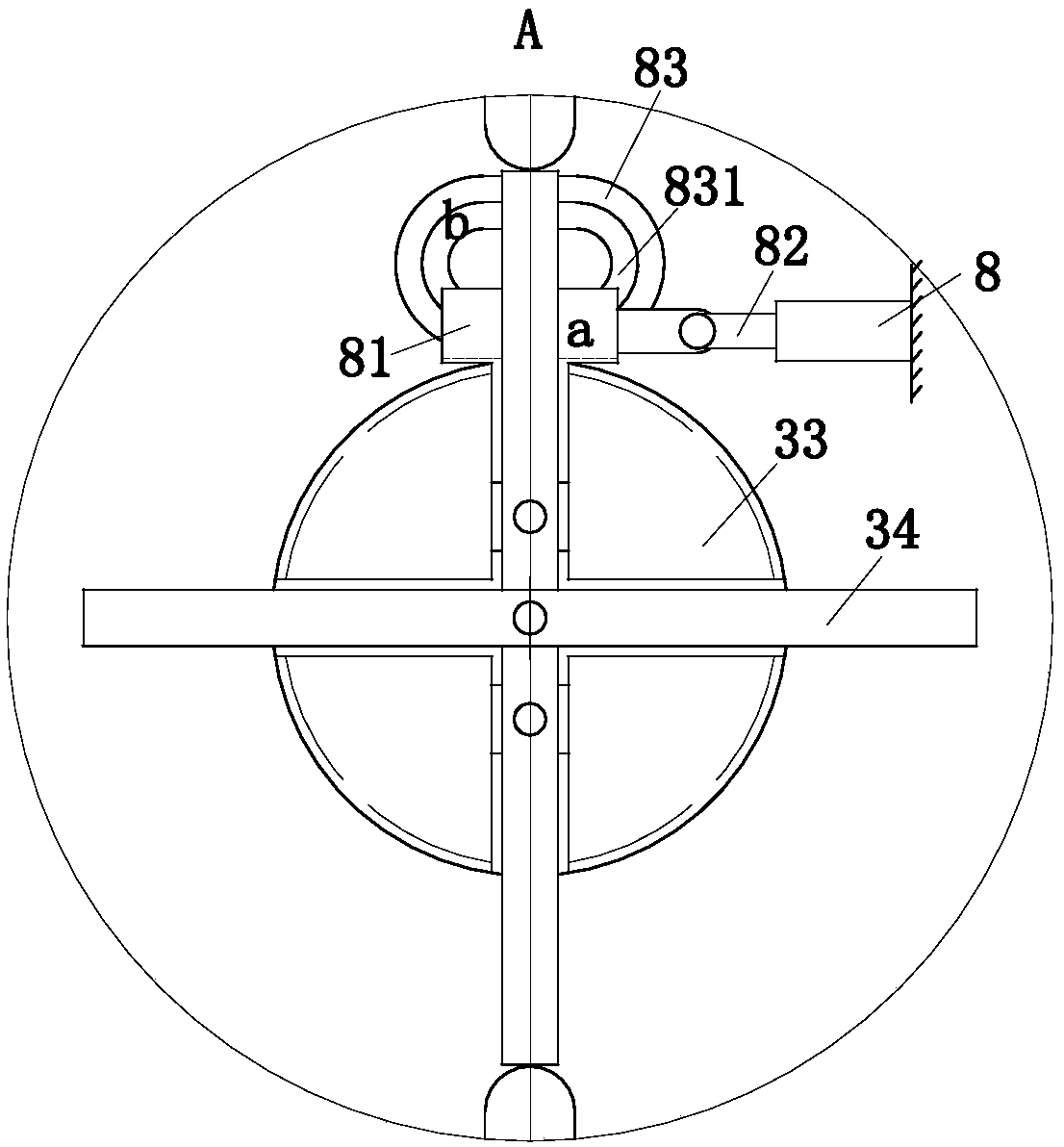

[0042]As an embodiment of the present invention, the No. 2 drive unit 8 includes a rack 81, a cylinder 82 and an annular plate 83; the annular plate 83 is fixedly connected to the base 1, and the annula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com