Aluminium section bar cutting device

A cutting device and technology for aluminum profiles, applied in the direction of large fixed members, metal processing machinery parts, metal processing, etc., can solve the problems of difficult operation, troublesome, single cutting angle, etc., and achieve the effect of wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

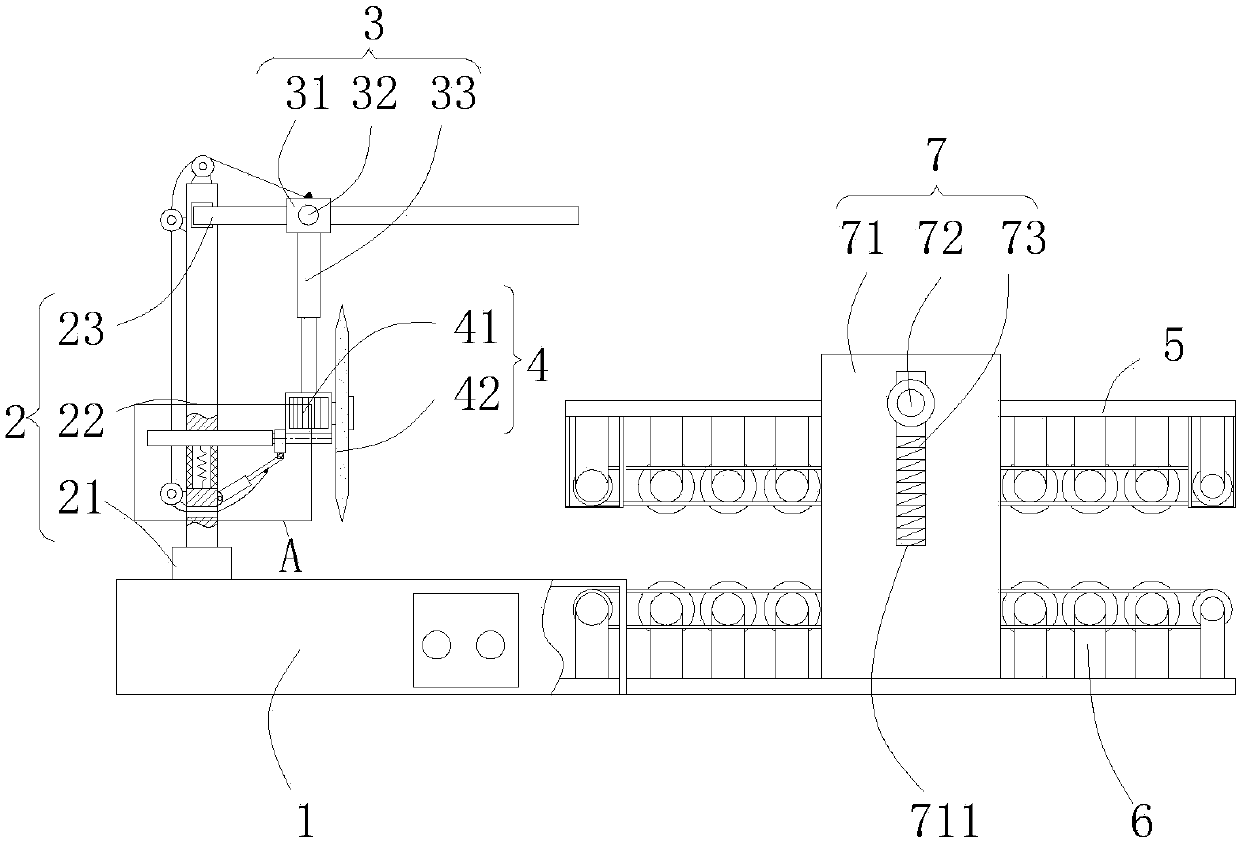

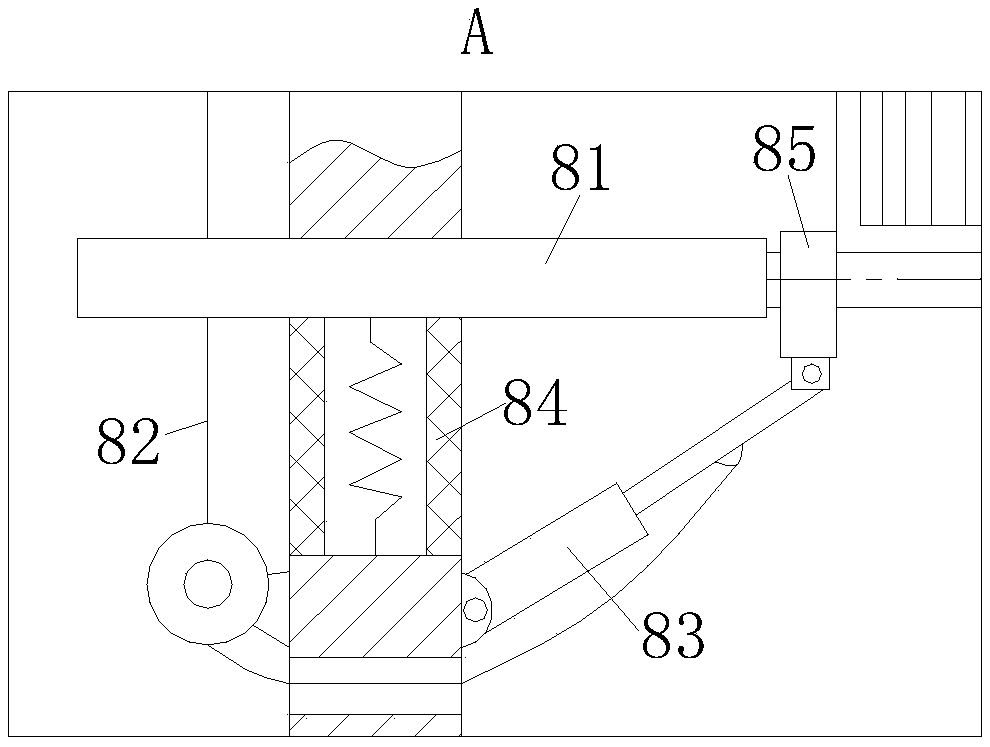

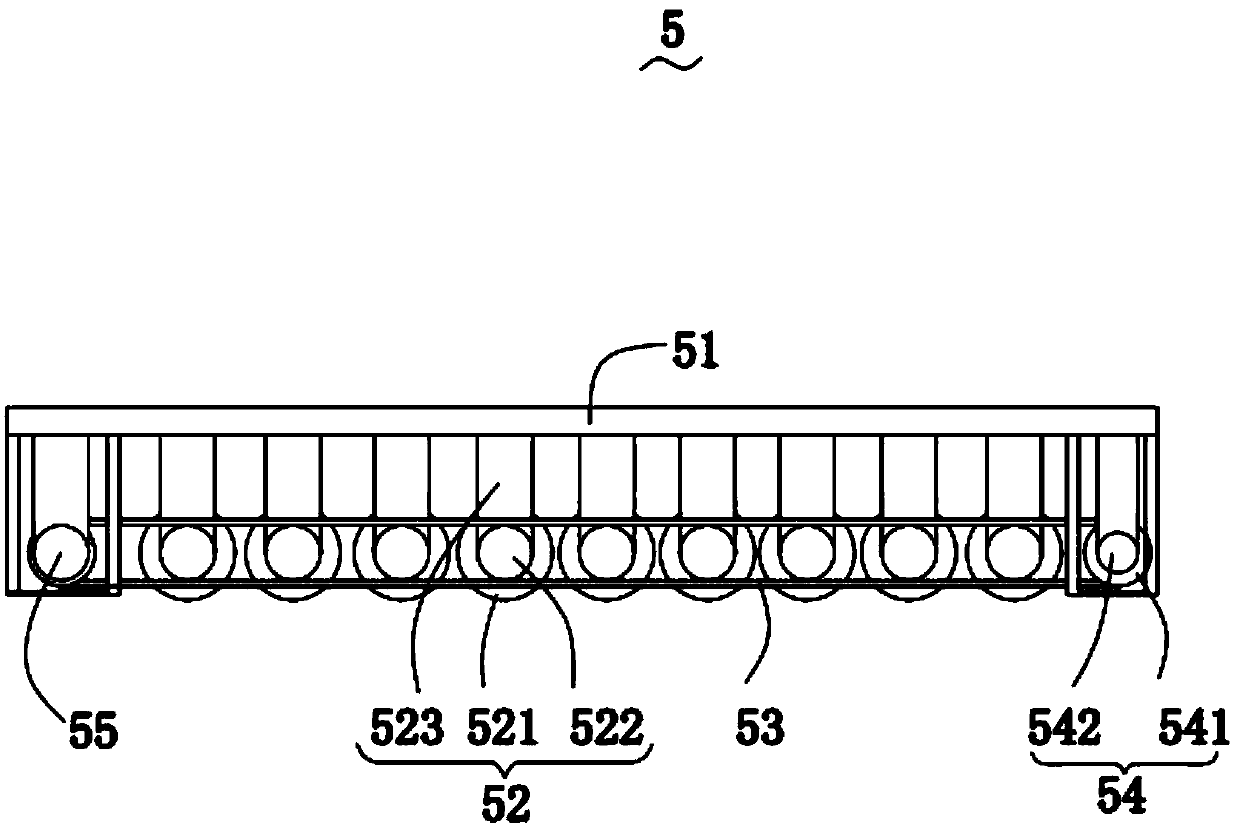

[0025] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5As shown, an aluminum profile cutting device according to the present invention includes a base plate 1; a first chute 11 is opened on the surface of the base plate 1, and a support module 2 is vertically provided on the surface of the base plate 1; the support The module 2 includes a first slider 21, a fixed column 22 and a slider 23, and the first slider 21 is slidably connected with the first chute 11; the first chute 11 is a long strip structure, and the first chute 11 A chute 11 is used for the first slider 21 to slide back and forth on the surface of the substrate 1; the top surface of the first slider 21 is vertically provided with the fixed column 22, and the first sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com