An aluminum profile cutting device

A cutting device and technology for aluminum profiles, which are applied to large fixed members, metal processing equipment, metal processing machinery parts, etc., can solve the problems of difficult operation, troublesome, single cutting angle, etc., and achieve the effect of wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the techniques of the present invention, the creation characteristics, the purpose and efficacy are readily understood, and the present invention is further illustrated in connection with the specific embodiments.

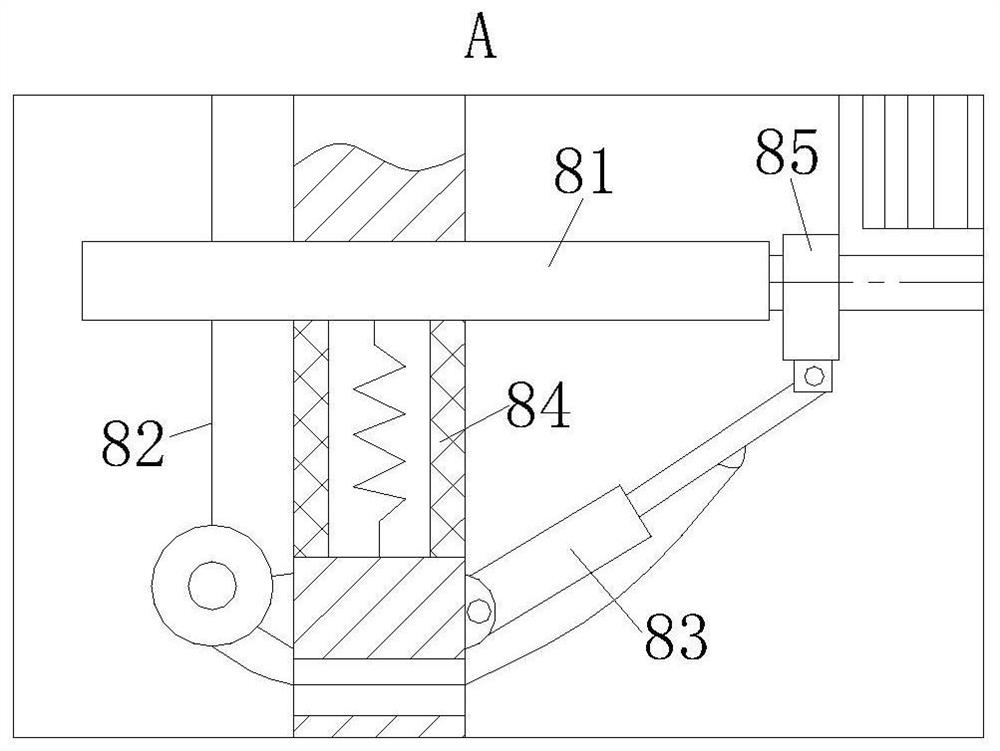

[0025] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5FIG An aluminum cutting apparatus according to the present invention, comprises a substrate 1; the surface of the substrate 1 is opened first slot 11, and perpendicular to the surface of the substrate 1 is provided with a support module 2; the support module 2 includes a first slider 21, the slider 23 and the fixed pillars 22, 21 and the first slider 11 connected to the first sliding chute; the first chute structure 11 is elongated, the a chute 11 for the first slider 21 slides in the front and rear surface of the substrate 1; the first slide is provided with a vertical top surface 21 of the mounting post 22, first slider 21 and the weld 22 between the mounting post for reinforcing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com