Plate cutting device

A cutting device and board technology, applied in wood processing equipment, special forming/shaping machines, manufacturing tools, etc., can solve the problems of requiring a lot of manpower, being easily injured, and low processing efficiency, so as to ensure personal safety, convenient operation, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

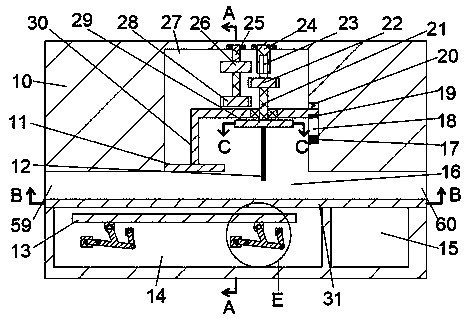

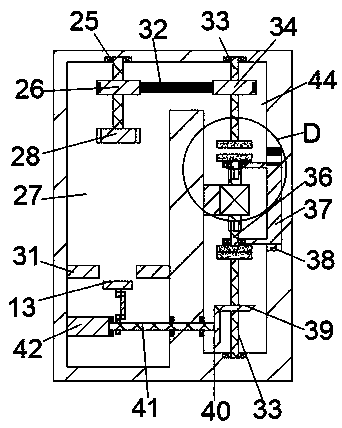

[0018] Combine below Figure 1-6 The present invention is described in detail, and for convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0019] A plate cutting device of the device of the present invention includes a cutting machine 10, a cutting chamber 27 is arranged in the cutting machine 10, and the lower side of the cutting chamber 27 is communicated with left and right sides through a feed port 59 and a discharge port 60. A sliding cavity 16 communicating with the outside world, the lower side of the sliding cavity 16 is connected with a transmission cavity 14, and the transmission cavity 14 is provided with a transmission plate 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com